Introduction

In a world where safety and reliability are paramount, understanding explosion proof technology is more crucial than ever. But what is explosion proof? At its core, it refers to equipment designed to contain explosions or prevent them from occurring in hazardous environments. This technology is not just a buzzword; it represents a vital aspect of industrial safety that protects lives and property.

Understanding Explosion Proof Technology

When we ask, What is meant by explosion proof?, we're delving into the intricacies of how certain materials and designs can withstand explosive forces. Explosion proof equipment typically features robust enclosures made from specialized materials that can endure high pressure and temperature conditions. Additionally, these products are engineered with specific design principles aimed at preventing ignition sources from igniting flammable gases or dust present in the environment.

Importance of Explosion Proof Equipment

The importance of explosion proof equipment cannot be overstated; these devices are essential for ensuring safety in industries where volatile substances are commonplace. What is explosion resistant? Essentially, it's about creating barriers that protect against potential hazards while maintaining operational efficiency. The requirements for explosion proof systems often include rigorous testing and adherence to strict industry standards, ensuring that businesses can operate without fear of catastrophic incidents.

Industries That Rely on Explosion Proof Solutions

Several industries heavily rely on explosion proof solutions to safeguard their operations, including oil and gas, chemical processing, mining, and construction. In these sectors, the presence of flammable materials necessitates the use of specialized equipment designed to meet stringent safety standards. By understanding what material is explosion proof—such as aluminum or stainless steel—companies can make informed decisions about their safety protocols while minimizing risk exposure.

What Is Explosion Proof?

When we delve into the world of explosion proof technology, it’s essential to clarify what is explosion proof. Essentially, explosion proof refers to equipment designed to contain any explosion that might occur within its housing, preventing ignition from escaping into the surrounding environment. This critical safety feature is paramount in industries where flammable gases, vapors, or dust are present.

Definition and Key Features

So, what is meant by explosion proof? At its core, explosion-proof equipment is built to withstand and contain explosions without compromising safety. Key features include robust enclosures made from materials such as steel or aluminum that can handle significant pressure and temperature changes without failing. Additionally, these devices often have specialized seals and gaskets that prevent the ingress of hazardous materials while maintaining operational integrity.

What is explosion resistant? While similar in intent, “explosion resistant” implies a design that minimizes damage but may not fully contain an explosion like true explosion-proof gear does. The requirements for explosion proof equipment vary by industry but generally include rigorous testing against specific standards set by organizations like the National Electrical Code (NEC) or Underwriters Laboratories (UL).

Historical Context and Development

The journey of understanding what is explosion proof began in earnest during the Industrial Revolution when industries started utilizing flammable materials on a grand scale. Early incidents prompted the development of safer equipment designs to mitigate risks associated with explosions in factories and mines. Over time, advancements in material science led to more effective solutions for containing potential blasts.

As technology progressed, regulations around what constitutes an acceptable level of safety evolved as well—leading us to today’s stringent requirements for certification and compliance in various sectors. The development of standardized testing methods ensured that manufacturers could reliably produce equipment meeting these rigorous safety benchmarks.

Common Misconceptions

Despite its importance, there are several common misconceptions about what is explosion proof that can lead to confusion among users and decision-makers alike. One prevalent myth is that all devices labeled as explosion-proof are invulnerable; however, even the best-designed products have limits based on their specifications and intended use environments.

Another misunderstanding revolves around materials used in construction; many people wonder what material is explosion proof? While metals like steel are common choices due to their strength and durability, other materials can also be utilized effectively depending on specific application needs.

Lastly, some may think that once a product meets initial requirements for being classified as explosion-proof, it remains so indefinitely—this isn’t true! Regular maintenance and adherence to updated safety standards are crucial components of ensuring ongoing compliance with evolving industry regulations.

How Does Explosion Proof Equipment Work?

To truly grasp what is explosion proof, it's essential to understand how this specialized equipment operates in hazardous environments. Explosion proof equipment is designed not only to withstand explosions but also to prevent ignition sources from causing an explosion in the first place. This involves a combination of innovative enclosure designs, strict control of potential ignition sources, and adherence to rigorous testing and certification standards.

Explosion Proof Enclosure Design

The design of explosion proof enclosures is at the heart of what is meant by explosion proof technology. These enclosures are crafted from materials that can endure high pressures and temperatures, effectively containing any internal explosions without allowing flames or hot gases to escape into the surrounding environment. Common materials used for these enclosures include heavy-duty metals like aluminum or stainless steel, which provide the necessary strength and durability.

Moreover, these enclosures are often sealed tightly to prevent dust or moisture ingress—factors that can compromise safety in explosive atmospheres. The engineering behind these designs ensures that even if an internal explosion occurs, the structure will remain intact, thereby protecting personnel and sensitive equipment nearby. Understanding what is explosion resistant helps clarify why such robust design features are critical for industries where explosive hazards are prevalent.

How Ignition Sources are Controlled

Controlling ignition sources is another fundamental aspect of how does explosion proof equipment work. This involves implementing various safety measures that mitigate potential risks associated with sparks or heat generated by electrical components or machinery. For example, using intrinsically safe devices ensures that electrical energy remains below levels capable of igniting flammable substances.

Additionally, proper grounding techniques and thermal management systems help reduce the risk of overheating components within these enclosures. By understanding what material is explosion proof—such as non-sparking metals—it becomes clear how manufacturers prioritize safety in their designs while still delivering functionality required by various industries.

Testing and Certification Standards

The requirements for explosion proof equipment extend beyond just design; they must also pass rigorous testing and certification processes to ensure compliance with industry standards. Organizations such as Underwriters Laboratories (UL) and ATEX (the European Union's directive on explosive atmospheres) set forth specific criteria that all explosion proof products must meet before being deemed safe for use in hazardous locations.

Testing often includes subjecting equipment to simulated explosive conditions to verify its integrity under extreme circumstances. This process not only confirms what is meant by explosion proof but also reassures users about the reliability of their safety solutions when working in potentially dangerous environments. Ultimately, understanding these standards empowers businesses to make informed decisions regarding their safety protocols while ensuring compliance with legal regulations.

Industries That Use Explosion Proof Products

Explosion proof products are crucial in various industries where flammable materials and hazardous environments are commonplace. Understanding what is explosion proof technology can help organizations ensure safety and compliance with industry regulations. The demand for these specialized solutions is evident across sectors like oil and gas, chemical processing, mining, and construction.

Oil and Gas Sector Applications

In the oil and gas industry, where volatile substances are handled daily, the question of what is meant by explosion proof becomes paramount. Equipment such as pumps, motors, and lighting must meet strict standards to prevent ignition in potentially explosive atmospheres. The materials used in explosion proof equipment must be robust enough to withstand harsh conditions while providing reliable performance—this leads us to ask: what material is explosion proof?

The requirements for explosion proof equipment in this sector include rigorous testing against potential ignition sources like sparks or heat. For example, enclosures are designed to contain any internal explosions without allowing flames or gases to escape into the surrounding environment. As a result, companies invest heavily in understanding what is explosion resistant technology to protect their workers and assets.

Chemical Processing Facilities

Chemical processing facilities often deal with a wide range of hazardous materials that can easily ignite if not properly contained. Here again, understanding what is explosion proof becomes essential for maintaining safety standards within these environments. Equipment used in this sector must not only be built from appropriate materials but also be designed according to stringent safety protocols.

To meet the requirements for explosion proof certifications, equipment undergoes extensive testing that evaluates its ability to withstand explosions without compromising safety. This includes assessing how well ignition sources are controlled within the machinery itself—an area where knowledge about what is meant by explosion proof can significantly impact operational efficiency and worker safety. As such, manufacturers focus on developing advanced technologies that offer both protection and reliability.

Mining and Construction Safety

Mining operations present unique challenges when it comes to ensuring safe working conditions; thus, the role of explosion proof products cannot be overstated here either. In environments filled with dust particles or flammable gases like methane, knowing what is explosion resistant can save lives while maintaining productivity levels on-site. Equipment such as lights, communication devices, and machinery must adhere to strict guidelines regarding their design and functionality.

When evaluating mining equipment specifically designed for explosive atmospheres, one must consider not only compliance with regulations but also the quality of materials used—again raising questions about what material is explosion proof? These factors ultimately determine whether equipment will perform safely under extreme conditions while minimizing risks associated with explosions or fires caused by ignition sources present during operations.

Investing in high-quality explosion-proof solutions ensures that personnel remain safe while also protecting valuable resources from potential damage due to accidents or unforeseen circumstances related directly back down into those core principles surrounding understanding requirements for effective implementation across various industries today!

The Role of Jinrong in Explosion Proof Manufacturing

When it comes to understanding what is explosion proof, Jinrong stands out as a key player in the industry. Founded with a commitment to safety and innovation, Jinrong has carved out a niche in the explosion proof equipment market. Their mission is clear: provide reliable solutions that meet stringent safety standards while addressing the diverse needs of various industries.

Background of Jinrong

Jinrong's journey began with a vision to enhance workplace safety in hazardous environments. With years of experience under their belt, they have become synonymous with quality and reliability in explosion proof manufacturing. But what is meant by explosion proof? It refers to equipment designed to contain any explosions that may occur within its enclosure, preventing ignition sources from escaping and causing catastrophic incidents.

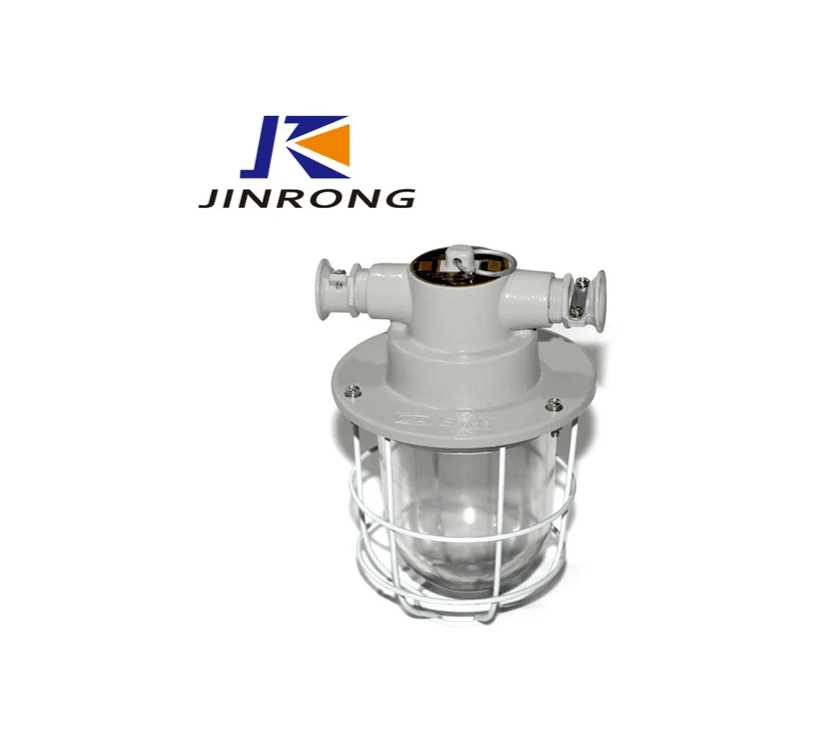

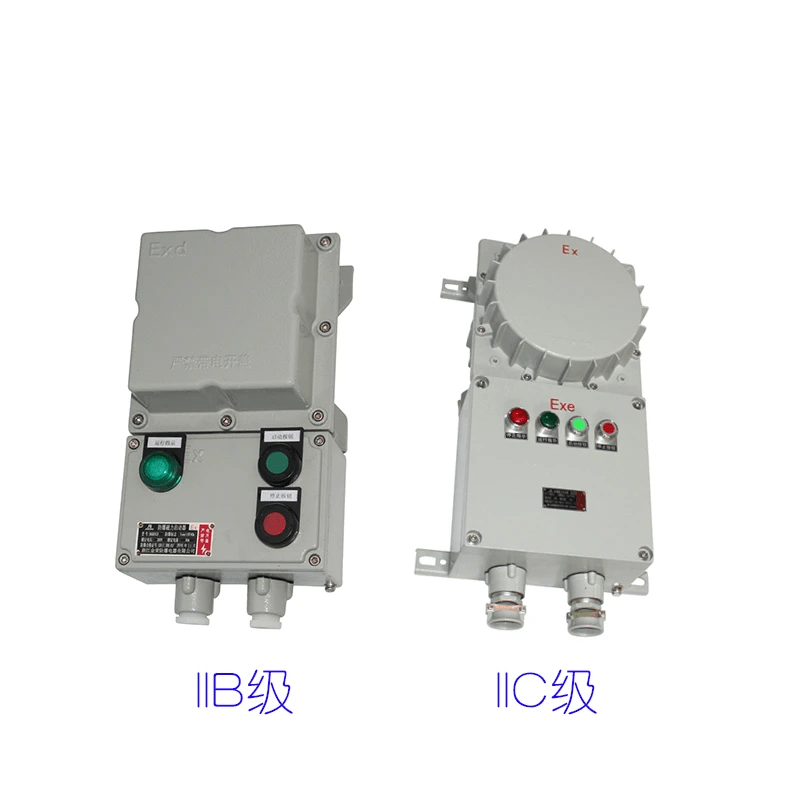

Product Line Overview

Jinrong offers an extensive range of products tailored for different applications where safety is paramount. Their lineup includes explosion proof lighting fixtures, control panels, and various enclosures made from materials specifically engineered for durability and resistance to harsh conditions. So, what material is explosion proof? Typically, materials like aluminum or stainless steel are used due to their strength and ability to withstand extreme pressure without compromising safety.

Certifications and Standards Compliance

To ensure that their products are truly explosion resistant, Jinrong adheres strictly to international testing and certification standards. These requirements for explosion proof equipment include compliance with regulations set forth by organizations such as ATEX and IECEx, which guarantee that products can safely operate in explosive atmospheres. By consistently meeting these certifications, Jinrong reinforces its reputation as a trusted manufacturer committed to providing safe solutions for industries like oil and gas or chemical processing.

Choosing the Right Explosion Proof Equipment

Selecting the right explosion proof equipment is crucial for ensuring safety and compliance in hazardous environments. Understanding what is explosion proof and what is meant by explosion proof can guide you in making informed decisions. With various factors to consider, including material specifications and design features, it’s essential to choose equipment that meets stringent safety standards.

Factors to Consider in Selection

When choosing explosion proof equipment, several factors come into play. First, you should assess the specific environment where the equipment will be used; different industries have varying requirements for what is explosion resistant. Additionally, consider the materials used in construction—what material is explosion proof? Common choices include metals like aluminum or stainless steel that can withstand pressure without compromising integrity.

Another critical factor involves understanding what are the requirements for explosion proof certification in your industry. This includes knowing the classification of hazardous locations and ensuring that your selected equipment complies with relevant safety standards such as ATEX or NEC guidelines. Ultimately, a well-informed selection process not only enhances safety but also ensures regulatory compliance.

Importance of Quality and Compliance

Quality assurance in explosion proof technology cannot be overstated; it directly impacts operational safety and efficiency. When asking what is explosion proof?, one must remember that quality materials and rigorous testing are essential to prevent catastrophic failures during an incident. Equipment that lacks proper certification may not perform as expected when faced with ignition sources, leading to dangerous situations.

Compliance with established standards also plays a vital role in maintaining workplace safety. Regulatory bodies set forth guidelines outlining what is meant by explosion proof, which manufacturers must adhere to during production processes. Choosing high-quality products from reputable manufacturers ensures you receive reliable solutions designed specifically for hazardous environments.

Future Trends in Explosion Proof Technology

As industries evolve, so do technologies associated with explosion protection—a trend driven by innovation and regulatory changes alike. The future of what is explosion resistant may involve advanced materials that provide better durability while being lighter and more cost-effective than traditional options. Emerging technologies like IoT (Internet of Things) integration promise enhanced monitoring capabilities for early detection of potential hazards.

Moreover, sustainability is becoming increasingly important; manufacturers are exploring eco-friendly materials without compromising on safety features—an exciting development for those wondering about what material is explosion proof today versus tomorrow! As we look ahead, staying informed about these trends will help businesses choose cutting-edge solutions while maintaining compliance with evolving regulations.

Conclusion

In wrapping up our discussion on explosion-proof technology, it’s essential to clarify what is explosion proof and its significance in various industries. At its core, explosion proof refers to equipment designed to contain any explosions that might occur within its enclosure, preventing ignition of surrounding flammable materials. This leads us to the question: what is meant by explosion proof? It means that certain products are built with robust materials and designs tailored to withstand extreme conditions, ensuring safety in hazardous environments.

Recap on What Is Explosion Proof

So, what is explosion resistant? Essentially, it’s about creating barriers between potential ignition sources and flammable substances. The materials used in this technology are often metals or specially treated compounds that can endure high pressures and temperatures without compromising structural integrity. Understanding the requirements for explosion proof equipment is crucial for industries where safety is paramount; these include strict adherence to testing standards and certifications.

The Crucial Role of Safety Equipment

Safety equipment plays a pivotal role in protecting workers and facilities from catastrophic events caused by explosions. In sectors like oil and gas or chemical processing, the stakes are incredibly high; thus, knowing what material is explosion proof can make a significant difference in operational safety. These products not only prevent accidents but also foster a culture of responsibility and care for employee welfare, emphasizing that safety should never be an afterthought.

Your Next Steps in Explosion Proof Solutions

As you consider your next moves regarding explosion-proof solutions, start by assessing your specific needs based on the environment you operate in. Evaluate what is meant by explosion proof in your context—whether you require specialized enclosures or other protective measures—and ensure compliance with all relevant standards. Don’t forget to explore innovative options available today; future trends point toward more advanced materials and technologies that will redefine how we approach safety in hazardous areas.