Introduction

When understanding the basics of flammable gases, it's important to know which gases are flammable and why. Flammable gases such as hydrogen, methane, and propane can ignite and burn in the presence of oxygen. These gases pose significant risks due to their potential for explosion and fire, making implementing safety measures when handling them crucial.

Understanding the Basics of Flammable Gases

Flammable gases encompass a wide range of substances, including natural gas, butane, and ethylene. Due to their flammability, they are classified as Class 2.1 under the United Nations' Hazardous Materials System. Gasoline is one of the most common flammable liquids used in various industries and is classified as a Class 3 flammable liquid due to its highly volatile nature.

Risks and Safety Measures Associated with Flammable Gases

The high flammability of these gases makes them prone to ignition at low concentrations in the air, posing a significant risk of fire or explosion. It's essential to implement proper storage, handling, and ventilation measures when dealing with these substances to mitigate these risks effectively.

The Importance of Identifying Flammable Gases

Identifying flammable gases is crucial for maintaining a safe workplace environment. Properly recognizing these gases and understanding their properties can significantly reduce the risk of accidents and incidents. To mitigate these risks effectively, proper storage, handling, and ventilation measures must be implemented when dealing with these substancesmanyNationsTo effectively identify flammable gases, consider the following steps:

- Familiarize yourself with common flammable gases: Understand the characteristics and hazards of gases such as hydrogen, methane, propane, and acetylene.

- Implement gas detection systems: Utilize equipment to monitor gas levels and alert personnel in case of leaks or accumulations.

- Conduct regular inspections: Check for potential gas leaks, damaged equipment, and inadequate ventilation.

- Provide employee training: Educate workers about flammable gas hazards, emergency procedures, and the importance of following safety protocols.

Following these guidelines and prioritizing safety can create a safer workplace for everyone.

Flammable Gases: What You Need to Know

When identifying common flammable gases, it's important to recognize that methane, propane, and butane are highly flammable and pose significant risks if not handled properly. These gases are commonly used in various industrial processes and can be found in household items such as lighters and camping stoves.

Understanding the properties and characteristics of flammable gases is crucial for ensuring safety. Flammable gases are typically colorless, odorless, and highly volatile. They have a low flash point and can ignite easily when exposed to a spark or flame. Due to their potential for combustion, it's essential to handle these gases with extreme caution.

The science behind flammability lies in the chemical composition of these gases. Flammability is determined by combustible elements within the gas molecules, which react with oxygen in the air to produce heat and light. This process, known as combustion, makes these gases so dangerous when not properly controlled.

Safe Handling and Storage of Flammable Gases

Best Practices for Handling Flammable Gases

When handling flammable gases, it's crucial always to wear proper protective gear, including gloves and goggles, to minimize the risk of exposure. Additionally, ensure that all equipment used is designed for use with flammable materials and regularly maintained to prevent leaks or malfunctions. Lastly, flammable gases should always be handled in well-ventilated areas to avoid the build-up of potentially dangerous concentrations.

In addition to wearing protective gear and ensuring equipment is designed for flammable materials, it's important always to have a fire extinguisher nearby when handling flammable gases. This provides an extra layer of safety in case of accidental ignition, allowing for quick and effective response to potential fires. Furthermore, regular training on proper handling and emergency procedures should be provided to all personnel working with flammable gases, ensuring everyone is prepared to respond effectively in an emergency.

Proper Storage and Ventilation Requirements

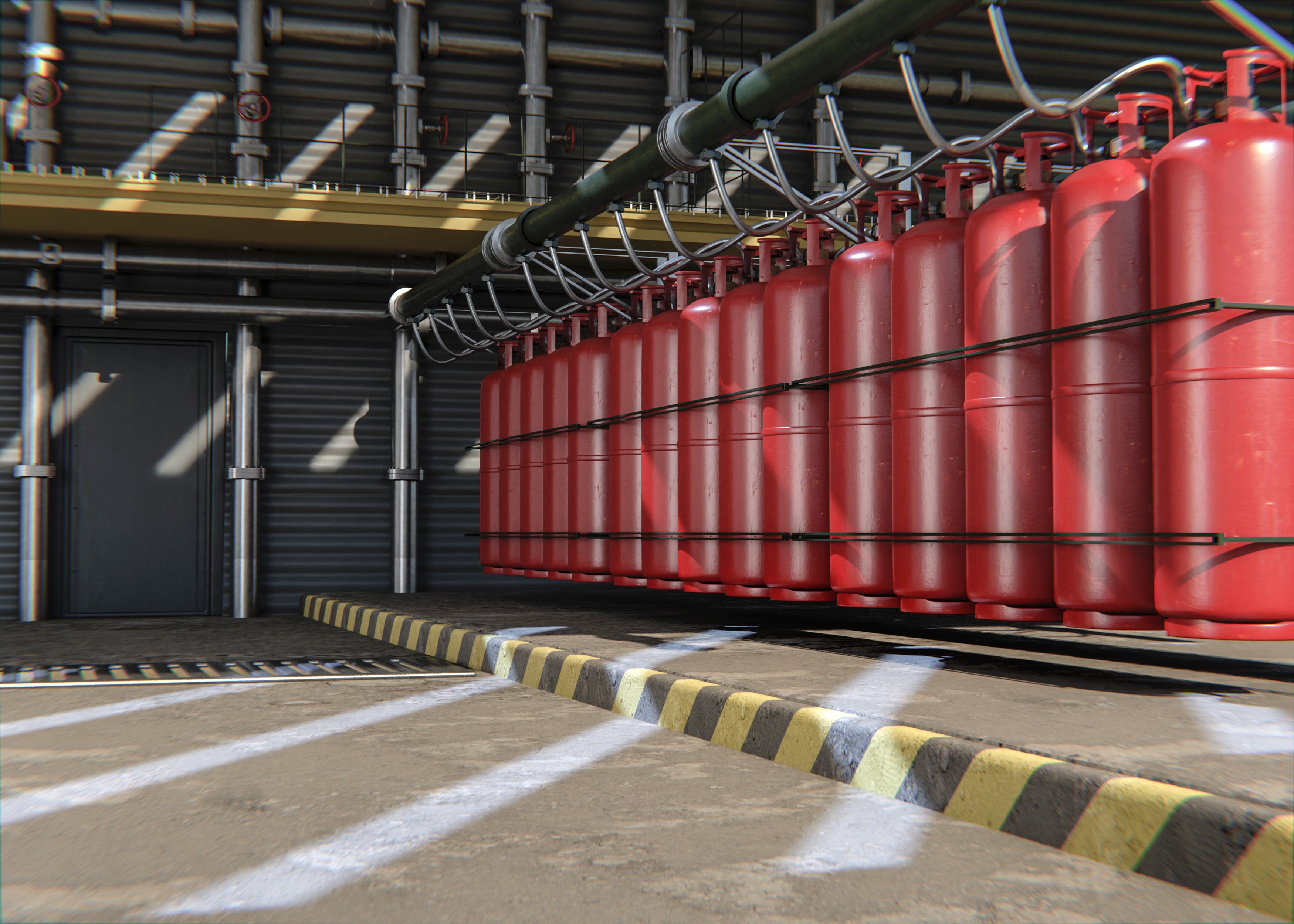

Proper storage of flammable gases is crucial for preventing accidents. To ensure safety, follow these guidelines:

- Store gases in designated, well-ventilated areas away from ignition sources like flames or electrical equipment.

- Use only containers designed for flammable materials and keep them tightly sealed.

- Regularly inspect storage areas and containers for damage or leaks. Replace damaged containers immediately.

- Clearly mark storage areas with warning signs to alert personnel and visitors.

By adhering to these safety measures, you can significantly reduce the risk of fire or explosion caused by flammable gases.

Safety Equipment and Precautions

In addition to using personal protective equipment, safety measures such as fire extinguishers, emergency eyewash stations, and showers should be in place in case of accidental exposure or ignition. All personnel working with flammable gases should be provided with regular training on the safe handling of flammable gases, emphasizing the importance of following established safety protocols at all times.

Testing and Detection of Flammable Gases

Methods for Testing Flammability

Using the right testing methods is crucial when determining what gas is flammableMarkAdhering to these safety measuresThe most common method is the Lower Explosive Limit (LEL) test, which identifies the lowest gas concentration that can ignite in air. Another method is the Flash Point test, which measures the temperature at which a gas can ignite. Gas chromatography is also used to analyze flammable gas composition and detect impurities.

In addition to these testing methods, it's important to have reliable detectors and monitoring systems in place to continuously assess the presence of flammable gases. These systems can provide real-time data on gas concentrations, allowing immediate action to be taken if dangerous levels are detected. Furthermore, regular maintenance and calibration of these systems are essential to ensure their accuracy and effectiveness in identifying potential fire hazards. By investing in high-quality detector and monitoring systems, businesses can mitigate the risk of explosive gas-related incidents and create a safer working environment for their employees.

Importance of Detector and Monitoring Systems

Detector and monitoring systems are essential safeguards in industrial and commercial environments. These systems provide early warning alerts to prevent catastrophic incidents by continuously scrutinizing air quality for flammable gases.

These systems offer several key benefits:

- Enhanced safety: Early detection of flammable gases protects workers and assets from potential hazards.

- Regulatory compliance: Adherence to safety regulations is ensured through consistent monitoring.

- Preventative maintenance: Identification of potential leaks helps maintain equipment integrity and minimizes downtime.

- Cost reduction: Early detection of issues prevents costly equipment damage and disruptions to operations.

Implementing detector and monitoring systems is crucial for creating a secure and efficient workplace.

Compliance with Safety Regulations

Compliance with safety regulations regarding flammable gases is paramount to preventing accidents and protecting lives. Organizations must adhere to guidelines set by regulatory bodies such as OSHA and NFPA to ensure safe handling, storage, and usage of flammable gases. Maintaining compliance involves regular inspections, maintenance of detection systems, employee training on safety protocols, and proper documentation.

Applications and Industries at Risk

Flammable gases are commonly found in various industries, including chemical manufacturing, oil and gas refining, and pharmaceutical production. These industries require strict safety measures to prevent accidents and protect workers and the environment.

Industries Requiring Flammable Gas Safety Measures

Chemical manufacturing plants often produce flammable gases such as hydrogen, methane, and propane. Oil and gas refineries handle volatile substances like butane and ethylene, which pose significant flammability risks. Pharmaceutical companies also utilize flammable gases in their research and development activities, making safety protocols crucial for employee well-being.

Chemical manufacturing plants are not the only ones facing the challenges of handling flammable gases. The electronics industry also relies on flammable gases such as silane and phosphine for semiconductor production, creating potential fire and explosion hazards. Additionally, the food and beverage industry uses flammable gases like carbon dioxide for carbonation processes, requiring careful safety measures to prevent accidents and ensure employee protection. These diverse industries all share the need for stringent safety protocols to mitigate the risks associated with handling flammable gases.

Case Studies of Flammable Gas Incidents

One notable incident involved a chemical plant explosion caused by a highly flammable hydrogen gas leak. The resulting fire caused extensive damage to the facility and surrounding areas. Another case involved a refinery explosion caused by the ignition of hydrocarbon vapors, which resulted in serious injuries to workers. These incidents highlight the importance of stringent safety measures when dealing with flammable gases.

The chemical plant explosion caused by a leak of highly flammable hydrogen gas is a stark reminder of the potential dangers of handling such volatile substances. The resulting fire caused extensive damage to the facility and posed a significant risk to the surrounding areas, highlighting the need for robust safety protocols and emergency response plans. Similarly, the refinery explosion that resulted from the ignition of hydrocarbon vapors underscores the critical importance of thorough risk assessments and proactive measures to prevent such incidents from occurring in industrial settings.

Importance of Risk Assessment

Conducting thorough risk assessments is essential for identifying hazards associated with flammable gases in industrial settings. Understanding the properties and behaviors of different types of flammable gases allows for implementing targeted safety measures to mitigate risks effectively. Regular risk assessments also help update safety protocols based on evolving industry standards.

Furthermore, conducting regular risk assessments for flammable gases in industrial settings is crucial for maintaining compliance with safety regulations and standards. By staying updated on industry best practices, companies can ensure that their safety protocols align with the latest requirements, reducing the likelihood of accidents or regulatory violations. This proactive approach also demonstrates a commitment to prioritizing the well-being of employees and the surrounding environment, fostering a positive reputation within the industry.

Understanding the applications and industries at risk when handling flammable gases is crucial for ensuring workplace safety and preventing accidents that could have severe consequences for both people and the environment.

Choosing the Right Equipment and Suppliers

When selecting reliable suppliers for flammable gas handling equipment, it's essential to consider their track record, certifications, and customer reviews. Look for suppliers with a proven history of providing high-quality, compliant equipment that meets industry standards and regulations. Ensure the supplier offers comprehensive support and training to maximize safety and efficiency in handling flammable gases.

Selecting Reliable Suppliers for Flammable Gas Handling Equipment

Choosing a supplier with expertise in manufacturing flammable gas-handling equipment is crucial for ensuring the safety of your operations. Look for suppliers specializing in ex-proof manufacturing, which involves designing and producing equipment designed to prevent the ignition of flammable gases in hazardous environments. By partnering with an experienced supplier like Jinrong, you can have confidence in the reliability and effectiveness of your flammable gas-handling equipment.

Factors to Consider When Choosing Flammable Gas Safety Products

Selecting the right flammable gas safety products is crucial for protecting your workplace. To make an informed decision, consider the following factors:

- Product Performance: Look for durable, accurate, and user-friendly products that can detect a wide range of flammable gases, even at low concentrations.

- Compatibility: Choose products that align with your industry requirements and safety protocols.

- Support and Resources: Prioritize products with comprehensive user manuals, training materials, and ongoing technical support.

- Manufacturer Reputation: Select a reputable manufacturer with a proven track record of producing high-quality, certified safety products.

By carefully evaluating these factors, you can confidently invest in flammable gas safety products that meet your needs and prioritize the safety of your workforce.

Jinrong: Your Partner in Ex-Proof Manufacturing Expertise

Jinrong specializes in ex-proof manufacturing expertise, offering a wide range of high-quality flammable gas handling equipment and safety products designed to meet the stringent requirements of various industries. Focusing on innovation and compliance with international standards, Jinrong provides tailored solutions to help businesses manage the risks associated with flammable gases while maintaining operational efficiency.

In addition to providing top-notch flammable gas handling equipment and safety products, Jinrong offers comprehensive training and support services to ensure businesses are well-equipped to handle potential risks. Our team of experts is dedicated to assisting clients in understanding the best practices for handling flammable gases and implementing effective safety protocols. By partnering with Jinrong, businesses can have peace of mind knowing they have a reliable ally in managing their ex-proof manufacturing needs.

Protect Yourself and Your Environment from Flammable Gases

Knowledge is key to protecting yourself and your environment from flammable gases. Understanding what gases are flammable and which are flammable gases can help you take the necessary precautions to stay safe. Remember that even the most flammable gas, like gasoline, can be handled safely with the right education and equipment.

The Ongoing Importance of Flammable Gas Education

Flammable gas education is crucial for everyone, whether you work in an industry that deals with flammable gases or not. Knowing why gasoline is flammable and what class it belongs to can prevent accidents in everyday life. The ongoing importance of flammable gas education cannot be overstated, as it helps protect individuals and communities from potential dangers.

Partnering with Jinrong for Expert Safety Solutions

Partnering with a reliable supplier like Jinrong is crucial for expert safety solutions for handling flammable gases. Their expertise in ex-proof manufacturing ensures that you have access to top-quality equipment and products designed to keep you safe. Whether you need proper storage solutions or detection systems, Jinrong has you covered every step.

In addition to their ex-proof manufacturing expertise, Jinrong offers comprehensive training and support for their safety solutions. Their team of professionals can provide on-site training for your staff, ensuring everyone knows how to use and maintain the equipment properly. With Jinrong as your partner, you can have peace of mind knowing that you are receiving top-quality products and the knowledge and skills to use them effectively.