Introduction

In industries where flammable gases, vapors, or dust are present, adhering to explosion proof standards is not just a regulatory requirement; it's a matter of safety. These standards define the criteria for equipment and enclosures designed to prevent explosions from occurring in hazardous environments. Understanding what is the explosion-proof standard and how it applies can significantly impact operational safety and compliance.

Overview of Explosion Proof Standards

Explosion proof standards encompass a range of regulations and guidelines that ensure equipment can operate safely in potentially explosive atmospheres. These standards serve as benchmarks for manufacturers and users alike, detailing specifications that products must meet to be deemed safe for use in volatile settings. By knowing what are the standards for explosion-proof enclosures, businesses can better safeguard their operations against catastrophic incidents.

Importance of Compliance in Industry

Compliance with explosion proof standards is paramount in industries such as oil and gas, chemical manufacturing, and pharmaceuticals where the risk of explosions is prevalent. Non-compliance can lead not only to severe financial penalties but also to devastating accidents that could harm employees or damage facilities. Therefore, understanding what is the code for explosion-proof is crucial for companies aiming to maintain a safe working environment while adhering to legal obligations.

Future Trends in Safety Standards

As technology evolves, so too do the safety standards governing explosive environments; future trends indicate an increased focus on innovation and adaptability within these regulations. The rise of smart technologies means that new solutions will need to align with existing codes while ensuring enhanced protection against potential hazards. Additionally, questions like Does ATEX mean explosion-proof? will continue shaping discussions around global compliance as international markets converge on unified safety protocols.

What is the Explosion-Proof Standard?

When we talk about explosion-proof standards, we're diving into a world where safety takes precedence, especially in industries dealing with flammable materials. These standards are designed to prevent explosions in environments where hazardous substances might be present. Essentially, they set the bar for equipment and practices that ensure a safe working environment.

Definition and Purpose of the Standard

The explosion-proof standard refers to a set of guidelines and specifications aimed at safeguarding both people and property from potential explosions caused by ignitable gases or dust. The primary purpose of these standards is to create equipment that can contain any explosive force generated within it while preventing external ignition sources from penetrating its enclosure. By adhering to these standards, industries can significantly reduce the risk of catastrophic incidents.

Historical Context and Development

The journey toward establishing robust explosion-proof standards began in the early 20th century when industrial accidents highlighted the dire need for improved safety measures. Over time, various organizations recognized the importance of creating standardized protocols to address these hazards effectively. Today, what we refer to as explosion-proof standards have evolved through continuous research and feedback from real-world applications across multiple industries.

Key Organizations Involved

Several key organizations play pivotal roles in developing and enforcing explosion-proof standards globally. Among them are the National Fire Protection Association (NFPA), which provides codes related to fire safety, including those pertinent to explosive environments, and Underwriters Laboratories (UL), known for their rigorous testing protocols for electrical equipment. Additionally, international bodies like IECEx contribute by harmonizing global practices surrounding what is considered an explosion-proof standard.

What Are the Standards for Explosion-Proof Enclosures?

When discussing explosion-proof standards, one crucial aspect is understanding the various types of enclosures designed to mitigate risks in hazardous environments. These enclosures are engineered to contain any potential explosions that may occur within them, preventing the ignition of flammable gases or dust in the surrounding atmosphere. The standards for explosion-proof enclosures ensure that these protective designs are not only effective but also compliant with regulatory codes.

Types of Explosion-Proof Enclosures

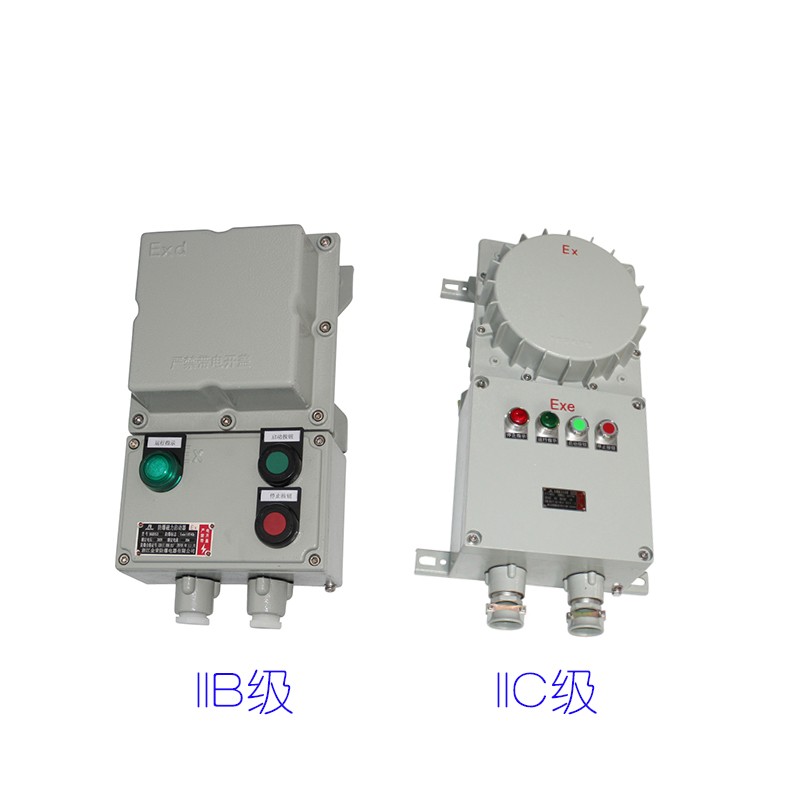

There are several types of explosion-proof enclosures, each tailored for specific applications and environments. These include flameproof enclosures, which can withstand internal explosions and prevent flames from escaping; increased safety enclosures, which minimize risk by using components that reduce the likelihood of ignition; and intrinsically safe enclosures that limit energy levels to prevent sparks. Understanding these variations is crucial when determining what is the explosion-proof standard suitable for a given application.

Moreover, each type serves a unique purpose based on environmental conditions and operational requirements. For instance, flameproof enclosures are often used in oil refineries where volatile substances abound, while intrinsically safe designs may be found in laboratories handling sensitive materials. By adhering to established standards for these enclosure types, industries can ensure safety and compliance with relevant regulations.

Material Specifications and Testing

Material specifications play a vital role in ensuring that explosion-proof standards are met effectively. The materials used in constructing these enclosures must be robust enough to withstand high pressures and temperatures generated during an explosion while being resistant to corrosion from harsh industrial environments. Common materials include aluminum alloys and stainless steel, both known for their strength-to-weight ratio and durability.

Importance of Certified Designs

The importance of certified designs cannot be overstated when discussing what is the code for explosion-proof equipment. Certification guarantees that an enclosure has undergone extensive testing by recognized organizations against stringent industry standards like those set forth by ANSI or NFPA guidelines. This certification process not only validates product safety but also enhances credibility among clients who prioritize compliance with local regulations.

Furthermore, relying on certified designs minimizes liability risks associated with workplace accidents due to equipment failure or non-compliance with explosion proof standards. In addition to protecting personnel and assets, certified products often lead to lower insurance premiums as they demonstrate adherence to best practices in safety management systems across various sectors. As industries continue evolving towards more stringent safety measures globally—including directives like ATEX—staying informed about these certifications will become increasingly necessary.

What is the Code for Explosion-Proof?

Overview of Relevant Codes

The codes governing explosion-proof standards vary by region but generally align on key principles aimed at minimizing risks associated with explosive materials. These codes cover everything from electrical installations to mechanical systems in industries like oil and gas, chemicals, and mining. They are essential not just for compliance but also for fostering a culture of safety that protects lives and property.

In many cases, these codes are developed by industry organizations that focus on best practices in hazardous locations. Compliance with these standards ensures that equipment can withstand specific conditions without becoming an ignition source. Understanding what is the code for explosion-proof applications is vital for anyone involved in industries where such risks exist.

ANSI and NFPA Standards

Two prominent organizations that set critical benchmarks for explosion-proof standards are ANSI (American National Standards Institute) and NFPA (National Fire Protection Association). ANSI provides a framework for various safety-related standards while NFPA focuses specifically on fire prevention strategies, including those related to explosive environments. Together, they create a robust system of guidelines that support safe operations across multiple sectors.

For instance, NFPA 70 outlines the National Electrical Code (NEC), which includes provisions specifically addressing equipment intended for use in hazardous locations. Similarly, ANSI/ISA 12.00 series provides detailed specifications regarding instrumentation used in potentially explosive atmospheres. When exploring what are the standards for explosion-proof enclosures or systems, it’s essential to reference both ANSI and NFPA guidelines.

Role of Local Regulations

While national standards provide a solid foundation, local regulations often add another layer of specificity tailored to regional needs or industry practices. Local authorities may adopt national codes or modify them based on unique environmental conditions or historical incidents within their jurisdiction. This means that understanding local regulations is just as important as knowing broader national standards when it comes to complying with explosion-proof requirements.

Local regulations often dictate installation procedures, maintenance schedules, and even training requirements for personnel working with explosion-proof systems or enclosures. Therefore, businesses must stay informed about any changes at both national and local levels to ensure ongoing compliance with what is the code for explosion-proof applications in their area. Keeping abreast of these updates not only helps avoid penalties but also enhances overall workplace safety.

Does ATEX Mean Explosion-Proof?

Explanation of ATEX Directive

The ATEX directive delineates the requirements for equipment and protective systems designed to be used in potentially explosive environments. Essentially, it aims to reduce the risk of explosions by ensuring that products meet specific explosion-proof standards before they can be marketed within the EU. Compliance with these standards not only protects workers but also helps companies avoid hefty fines associated with non-compliance.

To achieve ATEX certification, products must undergo rigorous testing and evaluation to ensure they can withstand explosive conditions without igniting surrounding materials. This includes assessments of design integrity and material specifications—essentially answering the question: what are the standards for explosion-proof enclosures? The directive also emphasizes ongoing compliance monitoring, which reinforces its importance across various industries.

Comparison with Other Standards

While ATEX is pivotal in Europe, other regions have their own sets of explosion-proof standards that serve similar purposes but may differ significantly in specifics. For instance, North America primarily follows NEC (National Electrical Code) and NFPA (National Fire Protection Association) guidelines when it comes to what is the code for explosion-proof applications. In contrast to ATEX's comprehensive approach, these codes often focus more on electrical installations and equipment classifications.

One notable difference lies in how different regions classify hazardous locations; while ATEX uses a zone system based on frequency and duration of exposure to explosive atmospheres, North American codes employ a division system that categorizes areas based on potential hazards. Understanding these differences is vital for global manufacturers who need to navigate multiple regulatory landscapes while ensuring compliance with applicable explosion proof standards.

Applicability in Various Regions

The applicability of the ATEX directive extends beyond European borders but varies widely depending on local regulations and industry practices around the globe. In regions outside Europe—like Asia-Pacific or Latin America—companies may encounter different interpretations of what constitutes compliance with explosion-proof standards. This variation can lead to confusion regarding whether products certified under one standard are acceptable under another.

For example, while an enclosure designed according to ATEX specifications might be deemed safe within EU countries, manufacturers intending to export their products must also consider local codes such as IECEx or UL certifications relevant to their target markets. As global trade continues evolving alongside advancements in safety technology, staying informed about various regulations becomes imperative for businesses aiming at international expansion while adhering strictly to what is the code for explosion-proof applications.

The Role of Jinrong in Explosion-Proof Manufacturing

In the realm of explosion-proof manufacturing, Jinrong stands out as a beacon of innovation and reliability. With a commitment to adhering to strict explosion proof standards, Jinrong has carved a niche for itself in providing top-notch solutions that meet the rigorous demands of various industries. Their vision is clear: to enhance safety and efficiency through superior design and engineering that aligns with what is the explosion-proof standard?

History and Vision of Jinrong

Jinrong's journey began over two decades ago, rooted in a passion for safety and excellence in industrial applications. From humble beginnings, the company has evolved into a leader in explosion-proof technology, driven by its mission to ensure compliance with what are the standards for explosion-proof enclosures? Their vision extends beyond mere production; it encompasses a dedication to fostering safer work environments worldwide.

The company’s history is marked by strategic partnerships and innovations that have shaped its trajectory. By continuously investing in research and development, Jinrong aims to stay ahead of trends while remaining committed to meeting global codes for explosion-proof equipment. This forward-thinking approach ensures they not only meet current regulations but also anticipate future needs within an ever-evolving industry landscape.

Product Range and Certifications

Jinrong offers an extensive product range designed specifically for environments where safety is paramount. Their offerings include various types of enclosures that comply with established explosion proof standards, ensuring reliability across different applications. Each product undergoes rigorous testing to confirm it meets or exceeds what is the code for explosion-proof requirements set by relevant authorities.

Certifications are crucial in this sector, and Jinrong takes them seriously—each product proudly displays its certifications from recognized organizations such as ANSI and NFPA. This not only reassures clients about compliance but also reinforces Jinrong's commitment to quality assurance throughout their manufacturing processes. By adhering strictly to these standards, they help clients navigate complex regulatory landscapes effortlessly.

In addition to robust physical products, Jinrong also provides tailored solutions that cater specifically to client needs—demonstrating their understanding of diverse operational challenges faced across industries requiring explosion-proof solutions.

Collaboration with Distributors

Collaboration lies at the heart of Jinrong’s strategy for expanding its reach within the global market for explosion-proof equipment. By partnering with distributors who share their dedication towards maintaining high safety standards, they ensure that clients receive both quality products and expert support regarding what are the standards for explosion-proof enclosures? Such partnerships help streamline distribution while enhancing customer service capabilities across regions.

These collaborations enable distributors not only access innovative products but also gain valuable insights into compliance requirements related to local regulations on explosive atmospheres—essential knowledge when considering does ATEX mean explosion-proof? Through training sessions and ongoing support initiatives from Jinrong, distributors become well-equipped ambassadors who can effectively communicate product benefits while ensuring adherence to all applicable codes.

Ultimately, these strategic alliances foster an environment where safety becomes paramount—a shared goal among all stakeholders involved in delivering reliable solutions compliant with stringent industry norms like those set forth by ATEX directives.

Conclusion

In wrapping up our exploration of explosion proof standards, it’s clear that these regulations are not just technicalities but essential guidelines that safeguard lives and property in hazardous environments. As industries evolve, so too will the standards governing explosion-proof safety measures, ensuring that compliance remains a top priority for manufacturers and operators alike. The future is bright for explosion-proof standards as innovation continues to drive improvements in safety technology.

The Future of Explosion Proof Standards

The future of explosion proof standards looks promising as advancements in technology pave the way for more efficient and effective solutions. With the ongoing development of new materials and designs, we can expect to see even stricter regulations aimed at enhancing safety in industries prone to explosive hazards. Moreover, global harmonization of these standards may become a reality, allowing for a more unified approach to what is the explosion-proof standard across different regions.

Best Practices for Compliance

Regular audits and assessments can help identify compliance gaps while fostering a culture of safety awareness among employees. Additionally, staying updated on what is the code for explosion-proof installations will empower businesses to meet or exceed current regulations effectively.

Importance of Ongoing Education and Training

Education plays an integral role in maintaining compliance with evolving explosion proof standards; therefore, ongoing training programs are crucial for all personnel involved with hazardous materials or environments. By understanding does ATEX mean explosion-proof and how it relates to other international standards, employees can better appreciate the importance of adhering to these guidelines. Investing in education not only enhances workplace safety but also cultivates a knowledgeable workforce capable of navigating complex regulatory landscapes.