Introduction

What is an Ex D Terminal Box?

An Ex D terminal box is a type of electrical enclosure that provides a safe housing for electrical connections in potentially explosive environments. The Ex designation indicates compliance with international standards for explosion-proof equipment, while the D signifies that it can withstand internal explosions without allowing flames or hot gases to escape. These boxes are commonly used in industries such as oil and gas, chemicals, and mining where flammable gases or dust may be present.

Importance of Compatibility in Ex Equipment

Compatibility among different types of Ex equipment is vital to prevent dangerous situations that could arise from improper installations or mismatched components. Using an incompatible junction box can lead to failures that compromise safety and put lives at risk. Therefore, understanding the relationship between various electrical enclosures and their specific applications ensures that all components work harmoniously together.

Overview of Electrical Box Enclosures

Electrical box enclosures serve as protective housings for wiring connections, safeguarding them from environmental factors like moisture, dust, and physical damage. Within the realm of electrical enclosures, there are various types designed for specific applications; however, not all are suitable for hazardous areas like those requiring an Ex D terminal box. Choosing the right electrical box enclosure involves considering factors such as material durability, size requirements, and environmental conditions to ensure optimal performance and safety.

The Fundamentals of Ex D Terminal Boxes

These enclosures are specifically designed to protect electrical equipment from explosive atmospheres, ensuring that operations can proceed without a hitch. Understanding their definition and purpose is crucial for anyone working with ex equipment.

Definition and Purpose

An ex d terminal box is an explosion-proof junction box engineered to contain any internal explosions, preventing flames or hot gases from escaping into the surrounding area. This containment is essential in environments where flammable gases or dust may be present, making these boxes indispensable for safety. The primary purpose of an electrical box enclosure like this is to safeguard both personnel and equipment by minimizing the risk of ignition.

Common Applications in Hazardous Areas

Ex d terminal boxes are commonly found in a variety of hazardous locations such as oil refineries, chemical processing plants, and mining operations. In these settings, the potential for explosive atmospheres makes it imperative to use robust electrical enclosures that meet stringent safety standards. By utilizing an ex d terminal box, companies can ensure compliance with regulations while protecting their valuable assets.

Types of Ex D Terminal Boxes

There are several types of ex d terminal boxes available on the market, each tailored for specific applications and environments. Some models feature different sizes and capacities to accommodate various junction box electrical needs, while others may be constructed from materials designed to withstand extreme conditions. Understanding these variations helps organizations select the right electrical box enclosure that meets both safety requirements and operational demands.

Ensuring Compatibility with Ex Equipment

Factors Affecting Compatibility

Several factors affect the compatibility of an Ex D terminal box with other Ex equipment. First and foremost is the classification of the hazardous area where the electrical box enclosure will be installed; different zones have varying requirements for explosion protection. Additionally, temperature ratings, ingress protection levels, and material properties of both the junction box electrical and connected devices must align to ensure safety and functionality.

Another critical factor is the electrical specifications such as voltage rating and current capacity; mismatched ratings can lead to failures or even dangerous incidents. The environmental conditions—like humidity, dust levels, or exposure to corrosive substances—also play a significant role in determining which electrical enclosures are suitable for a given application. Finally, manufacturers’ recommendations should always be consulted to ensure that all components work harmoniously together.

Key Standards and Certifications

To guarantee compatibility among various Ex equipment, adherence to key standards and certifications is essential. Organizations such as IECEx (International Electrotechnical Commission Explosive) and ATEX (Atmosphères Explosibles) set rigorous guidelines for designing and testing electrical enclosures used in explosive atmospheres. Compliance with these standards ensures that your chosen ex d terminal box has undergone thorough testing for performance under hazardous conditions.

Certifications also provide assurance that products have been evaluated by independent bodies for safety features like flameproofing or increased safety measures. This not only aids in compliance but also enhances customer confidence in product reliability when selecting junction boxes or other related components. Remember: choosing certified products means investing in peace of mind.

Role of Electrical Junction Boxes

Electrical junction boxes serve as crucial links between various pieces of Ex equipment within hazardous areas. These junction box electrical units facilitate safe connections among cables while providing necessary protection against environmental hazards like dust or moisture intrusion. When properly installed, they contribute significantly to maintaining system integrity by preventing short circuits or potential explosions due to improper wiring configurations.

Moreover, selecting an appropriate junction box can enhance overall system efficiency by allowing easier maintenance access without compromising safety standards dictated by regulations governing ex d terminal boxes. This translates into lower downtime during routine checks or repairs—an essential consideration for industries operating under strict safety protocols! Ultimately, understanding their role helps engineers make informed decisions about which electrical enclosures will best suit their specific needs.

Selecting the Right Electrical Box Enclosure

Choosing the right electrical box enclosure is crucial for ensuring safety and reliability, especially when dealing with Ex D terminal boxes in hazardous environments. The enclosure must not only protect the internal components but also comply with various standards to ensure compatibility with Ex equipment. With a plethora of options available, understanding the key selection criteria can help you make an informed decision.

Material Considerations

Common materials for junction box electrical applications include stainless steel, aluminum, and fiberglass, each offering different levels of durability and corrosion resistance. For instance, stainless steel is ideal for harsh environments due to its strength and resistance to chemicals, while fiberglass provides excellent insulation properties and is lightweight.

Additionally, consider how these materials perform under extreme temperatures or exposure to various chemicals commonly found in hazardous areas. The choice of material can also impact installation ease—some materials are easier to work with than others when it comes to modifications or repairs on-site. Ultimately, selecting the right material will enhance the longevity and reliability of your Ex D terminal box.

Size and Capacity Requirements

Next up in our selection process is size and capacity—because no one wants a cramped junction box! It’s essential that your electrical enclosures provide ample space for all wiring connections without compromising safety or functionality. When determining size requirements for your Ex equipment setup, consider not just current needs but also potential future expansions.

Overcrowded junction boxes can lead to overheating or even failure of components over time; hence it's wise to err on the side of caution by choosing a slightly larger electrical box enclosure than initially needed. Additionally, ensure that there’s enough room for proper cable management within the enclosure—good organization helps prevent accidental disconnections during maintenance checks!

Climate and Environment Factors

The environment where your Ex D terminal box will be installed plays a pivotal role in your selection process as well. Factors such as humidity levels, temperature fluctuations, dust exposure, or even potential water ingress must be taken into account when choosing an electrical enclosure type. For instance, if your application involves outdoor installations subjected to rain or snow, look for enclosures rated with higher IP (Ingress Protection) ratings.

Moreover, consider how local climate conditions might affect the longevity of different materials used in manufacturing these enclosures; some may degrade faster under specific environmental stresses than others do! By carefully assessing climate factors alongside other selection criteria like size and material considerations mentioned earlier—you’ll ensure that your chosen junction box meets all operational demands effectively.

The Role of Jinrong in Ex Equipment Manufacturing

Company History and Overview

Founded over two decades ago, Jinrong has established itself as a leader in the field of Ex equipment manufacturing. The company began with a vision to provide reliable solutions for industries operating in potentially explosive atmospheres. Today, Jinrong's extensive experience and technological advancements have positioned them at the forefront of the electrical box enclosure market.

Jinrong’s journey is marked by continuous improvement and adaptation to changing industry needs. From humble beginnings, they have expanded their product range while maintaining a keen focus on safety standards relevant to junction boxes and other electrical enclosures. Their dedication has earned them trust among clients across various sectors that require robust Ex d terminal boxes.

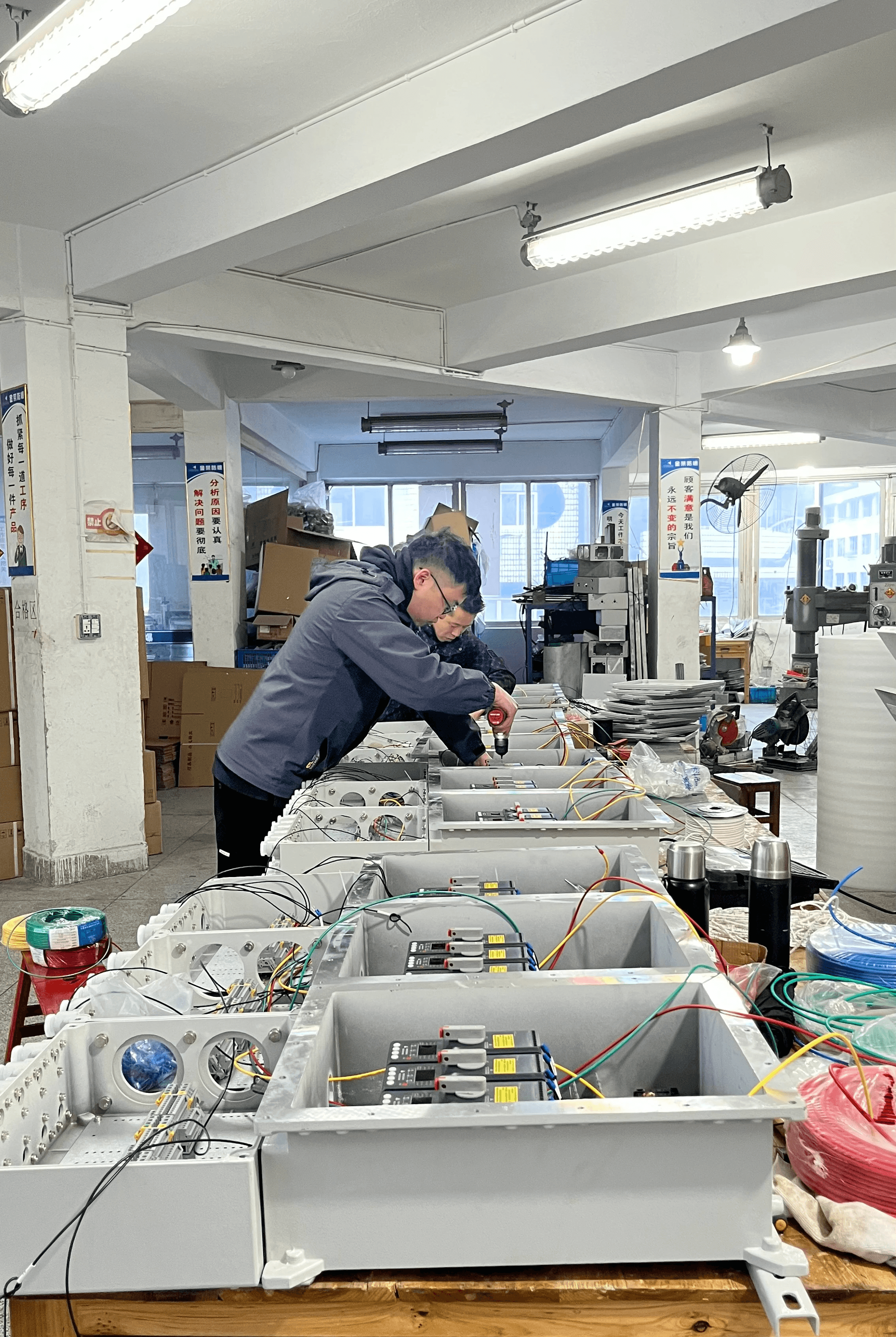

Range of Products in Ex-Proof Series

Jinrong offers an impressive array of products within their Ex-Proof series, catering specifically to industries that demand high levels of safety and reliability. Their lineup includes various types of ex d terminal boxes designed for different applications, ensuring compatibility with diverse ex equipment requirements. These junction boxes are engineered to provide maximum protection against environmental factors while facilitating easy installation.

Among their offerings are compact junction box electrical models suitable for tight spaces as well as larger enclosures designed for more extensive setups. Each product is meticulously crafted using materials that resist corrosion, impact damage, and extreme temperatures—perfect for hazardous locations where traditional enclosures might fail. This versatility makes Jinrong’s products an ideal choice for companies looking for dependable electrical box enclosures.

Commitment to Quality and Compliance

Quality assurance is at the heart of Jinrong's manufacturing process; they adhere strictly to international standards governing Ex equipment production. Every ex d terminal box undergoes rigorous testing procedures before reaching customers' hands—ensuring compliance with safety regulations like ATEX or IECEx certifications. This unwavering commitment not only guarantees durability but also instills confidence among users who rely on these critical components.

Moreover, Jinrong invests heavily in research and development to keep pace with evolving technologies within the field of electrical enclosures and junction boxes. Their proactive approach allows them to innovate continuously while staying compliant with global safety standards—making them a trusted partner in hazardous area operations worldwide. By prioritizing quality control throughout their processes, Jinrong reinforces its reputation as an industry leader committed to excellence.

Installation and Maintenance Best Practices

When it comes to ensuring the longevity and reliability of your Ex D terminal box, proper installation and maintenance are key. The right techniques can prevent costly downtimes and ensure that your Ex equipment operates safely in hazardous environments. Let’s dive into some best practices that will keep your electrical enclosures functioning optimally.

Proper Installation Techniques

Installing an Ex D terminal box is not just about fitting it into place; it's a meticulous process that demands attention to detail. Start by ensuring that the junction box electrical connections are secure and compliant with relevant standards, as improper connections can lead to failures or even unsafe conditions. Additionally, consider the orientation of the electrical box enclosure; it should be installed in a way that allows for proper drainage and prevents any accumulation of debris or moisture.

Moreover, always use certified components when assembling your junction box. This will not only enhance compatibility with other Ex equipment but also ensure adherence to safety regulations. Finally, document every step of the installation process; this will be invaluable for future maintenance checks or troubleshooting.

Routine Maintenance Checks

Routine maintenance is essential for any electrical enclosures operating in hazardous areas, including Ex D terminal boxes. Schedule regular inspections to check for signs of wear and tear, corrosion, or loose connections within the junction box electrical system. Keeping an eye on these elements helps mitigate risks before they escalate into serious issues.

During these checks, ensure that seals and gaskets are intact to maintain the integrity of the enclosure against dust or moisture ingress. It’s also crucial to clean any accumulated dirt or contaminants as they can compromise performance over time. Remember, a little preventive care goes a long way in extending the lifespan of your electrical box enclosure!

Troubleshooting Common Issues

Despite all precautions taken during installation and maintenance, issues may still arise with your Ex D terminal box from time to time. One common problem is overheating due to poor ventilation; if you notice unusual heat levels during operation, inspect airflow around the junction box electrical setup immediately!

Another frequent issue involves faulty connections leading to intermittent power supply—check all wiring thoroughly for signs of damage or loose terminals within the junction box system. If you're experiencing persistent problems despite troubleshooting efforts, don't hesitate to consult professionals who specialize in Ex equipment; their expertise could save you from further complications.

In conclusion, adhering to these installation and maintenance best practices will help ensure that your Ex D terminal boxes remain reliable under challenging conditions while enhancing overall safety in hazardous environments.

Conclusion

In the world of hazardous environments, understanding the compatibility of Ex D terminal boxes with various Ex equipment is paramount. These robust electrical box enclosures are designed to protect sensitive connections from explosive atmospheres, ensuring safety and functionality. By adhering to established standards and selecting the right junction box electrical, users can mitigate risks associated with electrical failures in volatile settings.

Summary of Ex D Terminal Box Compatibility

Ex D terminal boxes are specifically engineered to house electrical components safely in hazardous locations, making their compatibility with other Ex equipment critical. When selecting an electrical box enclosure, factors such as material, size, and environmental conditions must be carefully considered to maintain integrity and compliance. Ultimately, ensuring that each junction box meets industry standards is essential for operational safety and efficiency.

Importance of Choosing the Right Electrical Enclosures

Choosing the right electrical enclosures goes beyond aesthetics; it’s about safeguarding lives and assets in potentially dangerous situations. The appropriate electrical box enclosure not only provides physical protection but also ensures that all components work harmoniously within an Ex environment. Selecting a quality junction box can prevent catastrophic failures caused by environmental factors or improper installation.

Future Trends in Ex Equipment Technology

As technology advances, we can expect significant innovations in Ex D terminal boxes and related equipment. Future trends may include smart monitoring systems integrated into junction boxes that provide real-time data on performance metrics and potential hazards. Additionally, improvements in materials used for electrical enclosures could lead to lighter yet more durable solutions that enhance safety without compromising functionality.