Introduction

In the world of hazardous environments, understanding the distinctions between Class 1 Division 1 and Division 2 is crucial for ensuring safety and compliance. These classifications dictate how equipment is designed, selected, and maintained in areas where flammable gases or vapors may be present. With the right knowledge of Class I Div 1 vs Div 2, industries can prevent accidents and safeguard their operations.

What Are Class 1 Div 1 and Div 2?

Class 1 Division 1 refers to locations where flammable gases or vapors are present continuously or for long periods, creating a high risk of ignition. In contrast, Class I Division 2 encompasses areas where such hazards are not present under normal conditions but may occur in certain situations. Understanding these definitions is vital for selecting appropriate equipment that meets class i division ii standards.

Importance of Class I Division Standards

Class I Division standards play a pivotal role in protecting workers and facilities from potential explosions or fires caused by ignitable substances. Compliance with these standards ensures that equipment operates safely in environments classified as class i division 2 or class ii division 1. By adhering to these regulations, businesses can mitigate risks while promoting a culture of safety.

The Role of Jinrong in Hazardous Areas

Jinrong has established itself as a leader in providing innovative solutions for hazardous areas through its range of explosion-proof products designed specifically for class i division ii applications. Their commitment to meeting stringent class 1 division 2 electrical requirements ensures that customers receive reliable equipment that complies with industry standards. With success stories from various distributors highlighting Jinrong's effectiveness, it’s clear they play an essential role in enhancing safety across diverse sectors.

Understanding Class 1 Division 1

Class I Division 1 (Class 1 Div 1) represents one of the most critical classifications in hazardous area standards, particularly concerning environments where flammable gases or vapors may be present. This classification is designed for locations where explosive atmospheres are not just a possibility but a certainty under normal operating conditions. In essence, any equipment used in these areas must be built to withstand potential ignition sources, making it vital for safety and compliance.

Definition and Key Characteristics

Class I Division 1 refers to locations that are classified as having a continuous or frequent presence of flammable gases or vapors. The key characteristics of this division include the likelihood of explosive mixtures forming under normal conditions, requiring the highest level of protection for electrical equipment. Unlike Class I Division 2, where hazardous conditions may only occur occasionally, Class I Div 1 mandates stringent safety measures and specialized equipment to mitigate risks effectively.

Common Applications for Class I Div 1

Common applications for Class I Division 1 include oil refineries, chemical plants, and wastewater treatment facilities—places where volatile substances are not just present but often in continuous operation. Additionally, industries like petrochemical manufacturing frequently utilize Class I Div 1 equipment due to the inherent risks associated with handling flammable materials. The need for reliable and compliant solutions in these settings underscores why understanding the nuances between Class I Div 1 vs Div 2 is essential for ensuring operational safety.

Safety Measures and Compliance

Safety measures within Class I Division 1 environments revolve around strict adherence to regulations such as the National Electrical Code (NEC) and other relevant standards that dictate design and installation practices. Compliance involves using explosion-proof enclosures and intrinsically safe devices specifically rated for use in these hazardous zones—ensuring that any potential ignition sources are eliminated or contained effectively. By prioritizing safety through proper design choices, organizations can navigate the complexities of Class I Division standards while maintaining operational efficiency.

Exploring Class 1 Division 2

In the world of hazardous area classifications, Class I Division 2 (Class I Div 2) stands out as a critical designation for environments where flammable gases, vapors, or liquids may be present. Unlike its counterpart, Class I Division 1, which deals with areas where these substances are constantly present, Class I Div 2 is reserved for locations where such materials are only likely to be present under abnormal conditions. This distinction is vital for ensuring proper safety measures and equipment selection in potentially explosive atmospheres.

Definition and Key Characteristics

Class I Division 2 refers to locations that can contain flammable gases or vapors but only under specific circumstances. The key characteristic of this classification is that the hazardous materials are not expected to be present during normal operations; they may appear due to equipment failure or other unusual events. Understanding the nuances of Class I Division 2 is essential for businesses operating in industries such as oil and gas, chemical processing, and pharmaceuticals, where safety standards must align closely with regulatory requirements.

Common Applications for Class I Div 2

You’ll find Class I Division 2 applications in various industries that handle flammable substances but do not operate under constant exposure conditions. For instance, refineries may use this classification in areas near storage tanks or loading docks where vapors can escape during transfers but are generally safe otherwise. Similarly, chemical plants often designate certain processing areas as Class I Div 2 due to occasional releases of volatile compounds during maintenance activities.

Safety Measures and Compliance

Safety measures in Class I Division 2 environments focus on reducing risks associated with potential exposure to flammable materials while still allowing for operational efficiency. Compliance with class i division ii regulations mandates the use of explosion-proof equipment that meets stringent standards designed specifically for these conditions—think intrinsically safe devices and proper ventilation systems to disperse any accumulated vapors safely. Regular inspections and maintenance checks further ensure adherence to class 1 division 2 electrical requirements, allowing facilities to operate within legal frameworks while prioritizing worker safety.

Class 1 Div 1 vs Div 2: Key Differences

When it comes to hazardous locations, understanding the distinctions between Class 1 Division 1 and Class I Division 2 is crucial for safety and compliance. Both classifications are designed to protect workers and equipment in environments where flammable gases or vapors may be present, but they differ significantly in terms of environmental conditions, equipment requirements, and regulatory considerations. By examining these differences, businesses can make informed decisions about the types of equipment needed for their specific applications.

Environmental Conditions and Risks

Class 1 Division 1 environments are more hazardous than those classified as Class I Division 2. In Division 1 areas, flammable gases or vapors can exist continuously or frequently during normal operations, posing a higher risk of ignition. Conversely, Class I Division 2 areas may only experience the presence of these hazards under abnormal conditions—like a leak—which makes them less risky overall.

The environmental conditions dictate not only the classification but also how businesses approach safety measures. In a Class I Div 2 setting, while there may be some risks present, they are generally considered manageable with proper precautions. This distinction influences everything from employee training to emergency response protocols.

Equipment Requirements and Design

When comparing Class 1 Div 1 vs Div 2 in terms of equipment requirements, the differences become apparent quickly. Equipment intended for use in Division 1 must meet stringent design standards to ensure it can operate safely even when flammable materials are present continuously or intermittently. This often results in more robust construction materials and specialized features that prevent ignition sources.

On the other hand, equipment used in Class I Division II settings is typically less complex since it is designed for areas where hazards are not always present. While still adhering to safety standards—such as those outlined by class I division ii regulations—these devices may have fewer protective measures than their Division 1 counterparts. Understanding these nuances helps organizations select appropriate devices that meet both operational needs and safety regulations.

Regulatory Considerations and Compliance

Regulatory considerations play a significant role in distinguishing between Class I Division standards; compliance requirements differ based on potential risks associated with each classification. Organizations operating within Class I Divisions must adhere strictly to guidelines set forth by authorities such as the National Fire Protection Association (NFPA) and Occupational Safety and Health Administration (OSHA). Meeting these regulations ensures that all necessary precautions are taken to protect personnel from potential hazards inherent in their work environment.

In contrast, while compliance is still critical for Class I Division II settings, the requirements may not be as rigorous due to lower risk levels associated with intermittent exposure to hazardous materials. Businesses need to stay updated on evolving regulations governing both class divisions so they remain compliant without over-engineering their solutions unnecessarily. Ultimately, understanding these regulatory distinctions helps organizations avoid costly penalties while ensuring employee safety remains paramount.

Electrical Requirements for Class I Division 2

When dealing with hazardous environments, understanding the electrical requirements for Class I Division 2 is crucial. This division outlines specific standards to ensure that equipment operates safely in areas where flammable gases or vapors may be present but are not typically found in hazardous concentrations. The distinction between Class 1 Div 1 vs Div 2 becomes particularly relevant here, as it influences how equipment is designed and selected.

Overview of Class 1 Division 2 Electrical Standards

Class I Division 2 electrical standards are designed to mitigate risks associated with the presence of flammable substances. Unlike Class I Division 1, where hazardous materials are present continuously, Class I Division 2 allows for occasional exposure, necessitating different safety measures. These standards dictate that equipment must be constructed to prevent ignition sources from entering the area, ensuring a safer working environment.

The National Electrical Code (NEC) provides guidelines that detail these requirements, including specifications for wiring methods and installation practices suitable for Class I Division 2 environments. Equipment must meet stringent performance criteria to withstand potential hazards while still functioning effectively under normal conditions. Compliance with these standards is not just a regulatory obligation; it's a commitment to safety in potentially dangerous settings.

Impact on Equipment Selection

Choosing the right equipment for Class I Division 2 applications involves careful consideration of various factors influenced by electrical requirements. Equipment must be specifically rated for use in environments where flammable gases or vapors may occasionally occur, which can significantly narrow down options compared to Class II Division 1 scenarios. When comparing class 1 div 1 vs div 2, it's essential to recognize that equipment designed for Div 1 may not always be suitable or necessary for Div 2 applications.

Manufacturers often provide detailed specifications and ratings that indicate whether their products meet the necessary electrical standards for Class I Division II environments. This information is vital when selecting devices such as lighting fixtures, motors, and control panels because improper selection can lead to catastrophic failures or accidents. Ultimately, understanding these distinctions helps ensure both compliance and operational efficiency.

Ensuring Safety and Compliance

Ensuring safety and compliance within a Class I Division II environment requires ongoing diligence from all stakeholders involved—from engineers designing systems to operators maintaining them. Regular inspections and maintenance routines should be established based on the unique characteristics of class i division ii areas since even occasional exposure can pose risks if left unchecked over time. Furthermore, training personnel on proper handling techniques and emergency procedures is essential in fostering a culture of safety.

Documentation plays an equally critical role; keeping thorough records of inspections, maintenance activities, and compliance checks helps organizations stay accountable while also preparing them for any regulatory audits regarding class i division ii requirements they might face down the line. By prioritizing safety through adherence to established electrical requirements tailored specifically for this division type, companies can minimize risks associated with hazardous materials while maximizing productivity.

The Role of Jinrong in Class I Division Solutions

In the realm of hazardous area solutions, Jinrong stands out as a beacon of innovation and reliability. With a strong focus on developing Ex-proof products, Jinrong is committed to ensuring safety in environments classified under Class I Division 1 and Division 2 standards. The company's expertise not only enhances operational efficiency but also guarantees compliance with stringent regulatory requirements.

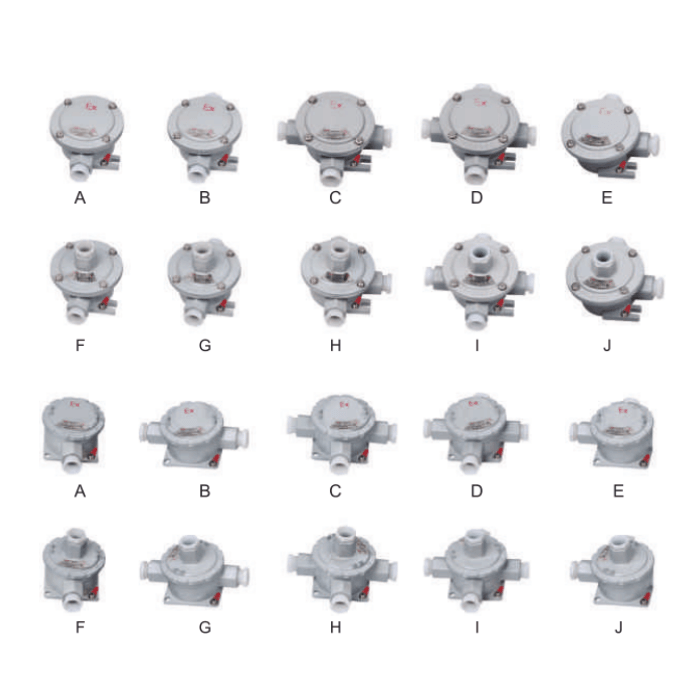

Innovation in Ex-Proof Products

Jinrong’s approach to innovation is rooted in understanding the distinct needs of Class I Division 2 environments. By leveraging advanced technology and materials, they create Ex-proof products that are robust enough to withstand the rigors of hazardous conditions while ensuring maximum safety. Their innovative designs cater specifically to the differences highlighted in class 1 div 1 vs div 2, allowing for tailored solutions that meet diverse industry demands.

Moreover, Jinrong's commitment to research and development means they are continually evolving their product range. This dedication results in equipment that not only meets but often exceeds class i division ii standards, ensuring customers have access to cutting-edge technology for their operations. As industries shift towards greater safety measures, Jinrong remains at the forefront with its innovative offerings.

How Jinrong Meets Class 1 Division Standards

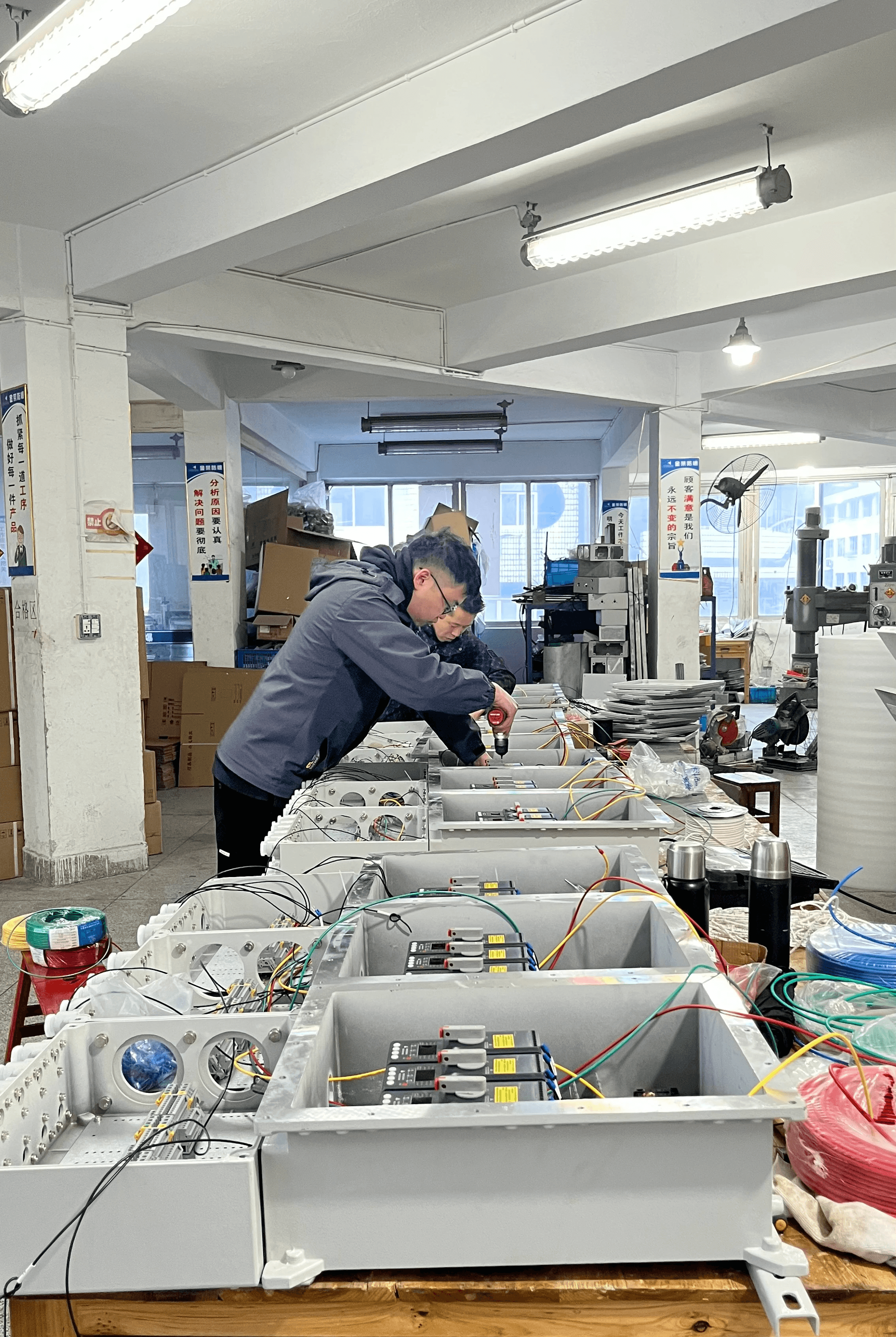

Meeting Class I Division standards requires more than just adhering to regulations; it necessitates a deep understanding of the unique challenges presented by hazardous environments. Jinrong excels in this arena by rigorously testing its products against class 1 division 2 electrical requirements and other relevant benchmarks. This meticulous attention to detail ensures that each product can operate safely within both Class I Divisions.

Jinrong’s manufacturing processes incorporate industry best practices that align with regulatory compliance for both class i div 2 and class ii division 1 applications. By using high-quality materials and implementing strict quality control measures, they ensure that every piece of equipment is built for durability and reliability under pressure. Customers can trust that when they choose Jinrong, they are selecting products designed specifically for their environment.

Success Stories from Our Distributors

The success stories shared by Jinrong's distributors highlight how effectively their products perform in real-world applications across various industries dealing with hazardous materials. For instance, one distributor reported remarkable improvements in operational safety after transitioning from standard equipment to Jinrong's Ex-proof solutions designed explicitly for class i division ii settings. These success stories underscore the tangible benefits businesses experience when choosing reliable partners like Jinrong.

Additionally, distributors have noted increased productivity due to reduced downtime associated with equipment failures or safety incidents—an essential factor when considering class 1 div 1 vs div 2 distinctions in environmental conditions and risks involved. As more companies recognize these advantages, demand for Jinrong’s innovative solutions continues to grow across sectors requiring stringent adherence to safety protocols.

Conclusion

In summary, understanding the differences between Class 1 Div 1 and Class 1 Div 2 is crucial for ensuring safety in hazardous environments. While Class I Division 1 is designed for areas where flammable gases or vapors are present continuously, Class I Division 2 accommodates locations where these hazards are only likely to occur under abnormal conditions. Recognizing these distinctions helps in selecting appropriate equipment and adhering to safety regulations.

Recap of Class 1 Div 1 vs Div 2

To recap, the key differences between Class 1 Div 1 and Class I Division 2 lie primarily in their environmental conditions and risks associated with explosive materials. In Class 1 Division 1, equipment must be robust enough to withstand constant exposure to hazardous substances, while Class I Division II allows for less stringent requirements due to lower risk scenarios. Understanding these classifications is essential for compliance with safety standards and ensuring proper protection against potential hazards.

Choosing the Right Equipment for Safety

Selecting the right equipment involves a careful evaluation of the specific environment in which it will be used—especially when considering class i division ii versus class i division i applications. Equipment that meets class 1 division 2 electrical requirements can often be more versatile, but it’s vital to ensure it complies with all necessary regulations. Ultimately, making informed choices about equipment not only enhances safety but also promotes operational efficiency in hazardous areas.

Jinrong's Commitment to Excellence in Hazardous Areas

Jinrong stands at the forefront of innovation when it comes to providing solutions for hazardous environments, emphasizing quality and compliance with both class I division II and class II division I standards. Our commitment extends beyond just meeting regulatory requirements; we strive for excellence by delivering products that enhance safety without compromising performance. With numerous success stories from our distributors highlighting our reliability, Jinrong continues to build a reputation as a trusted partner in navigating the complexities of hazardous area classifications.