Introduction

Propane is a widely used fuel, but it comes with its hazards. Understanding the hazard class of propane is crucial for ensuring safety in handling and storage. Propane tanks pose serious dangers, making it essential to recognize their potential risks. Knowing the propane tank explosion class prevents accidents and ensures proper emergency response procedures.

Understanding the Hazard Class of Propane

Propane is a flammable gas that requires careful handling and storage due to its potential for fire and explosion hazards. To ensure safe propane usage, it is essential to adhere to the following guidelines:

- Proper Ventilation: Always use propane in well-ventilated areas to prevent gas buildup and reduce the risk of ignition.

- Regular Inspections: Conduct regular inspections of propane tanks for signs of damage, leaks, or wear.

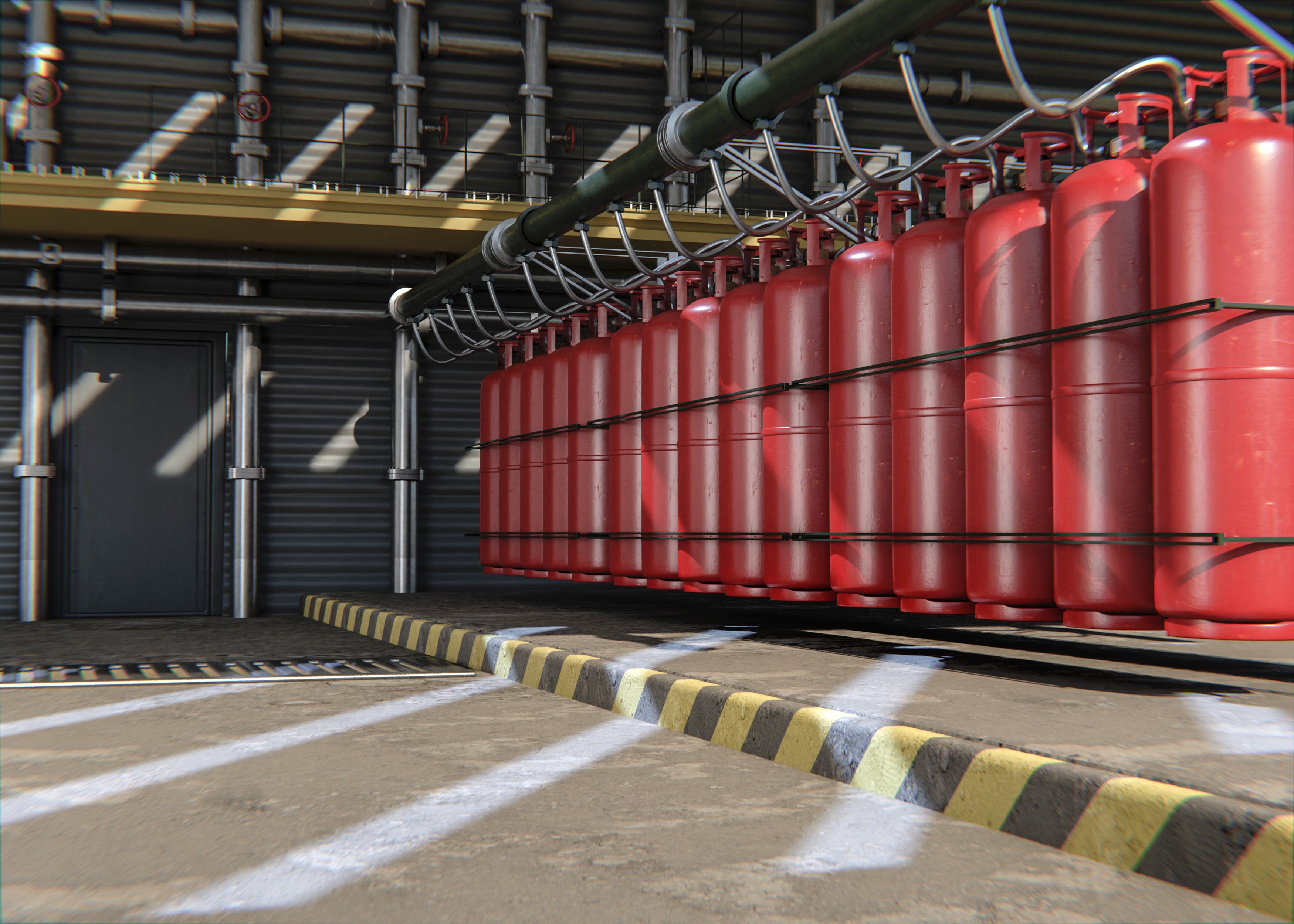

- Secure Storage: Store propane tanks in a cool, dry location away from heat, open flames, and ignition sources.

- Avoid Ignition Sources: Protect propane tanks from sparks, flames, and other potential ignition sources.

- Emergency Preparedness: Have a fire extinguisher readily available and familiarize yourself with emergency procedures in case of a propane-related incident.

By following these safety precautions, you can significantly reduce the risks associated with propane usage and ensure a safe environment.

Recognizing the Dangers of Propane Tanks

Propane tanks are pressurized containers that hold a significant amount of flammable gas, making them susceptible to leaks, ruptures, or even explosions if not handled properly. Understanding these dangers helps individuals take necessary precautions when dealing with propane tanks to prevent accidents and injuries.

Importance of Knowing Propane Tank Explosion Class

Propane tank explosions can have devastating consequences. It is crucial to know the different classes of these explosions to understand the potential risks and take appropriate safety measures. Here is a breakdown of the various classes:

- Deflagration: This is a relatively slow-burning explosion characterized by a flame front propagating through the mixture at a subsonic speed. While still dangerous, deflagrations typically cause less damage compared to detonations.

- Detonation: This is a highly destructive explosion characterized by a shock wave propagating through the mixture at a supersonic speed. Detonations can cause significant structural damage, injuries, and even fatalities.

- BLEVE (Boiling Liquid Expanding Vapor Explosion): A pressurized container containing a volatile liquid is subjected to intense heat, causing the liquid to vaporize rapidly and rupture the container. The resulting explosion can be mighty and destructive.

By understanding these different classes of propane tank explosions, individuals can better assess the potential risks and take appropriate precautions to prevent or mitigate their occurrence. To ensure the safe handling and storage of propane, it is essential to follow safety guidelines, inspect tanks regularly, and be aware of the signs of potential hazards.

What is Propane Hazard Class

Propane hazard class refers to propane's classification based on its potential to cause harm. It is categorized as a flammable gas, which means it poses a high risk of fire and explosion if mishandled. Understanding propane's hazard class is crucial in determining the appropriate safety measures for handling and storage.

Definition and Explanation

Propane is classified as Hazard Class 2.1, a flammable gas with a boiling point below 20°C. This means that it can easily ignite and has the potential to form explosive mixtures with air when released from its container. It requires careful handling and storage to prevent accidents and ensure safety.

Propane's flammability and potential for explosive mixtures mean that it poses a significant risk if not handled properly. Storing propane in well-ventilated areas away from potential ignition sources is crucial. Regular inspections and maintenance of storage tanks and equipment are essential to prevent leaks and ensure safe handling. Proper training for personnel who work with propane is also necessary to minimize the risk of accidents and ensure that safety protocols are followed at all times.

Understanding the Risk Level

The risk level associated with the propane hazard class is high due to its flammability and potential for explosion. Specific precautions must be taken to minimize the risk of fire or explosion, especially in confined spaces or poorly ventilated areas. Understanding the risk level helps implement appropriate safety measures to protect against potential hazards.

It is crucial to ensure that all personnel handling propane are properly trained in safely handling and storing this highly flammable gas. This includes understanding the proper use of personal protective equipment, such as gloves and safety goggles, and the correct procedures for transferring propane from one container to another. Regular safety inspections should also be conducted to identify and address any potential hazards or risks associated with propane storage and handling.

Safety Measures for Propane Handling

Proper storage, transportation, and usage protocols for propane include safety measures. These involve using approved containers, ensuring adequate ventilation during use, and implementing leak detection systems to prevent accidental releases of propane gas into the environment. Training on safe handling practices is also essential for anyone working with or around propane.

In addition to proper storage and transportation, it is crucial to regularly inspect propane containers for any signs of damage or wear that could lead to leaks. This can be done through visual inspections and pressure testing to ensure the integrity of the containers. Furthermore, it is important to have a designated area for propane storage that is away from potential ignition sources and easily accessible for emergency response personnel. Maintaining a safe and secure storage area can significantly reduce the risk of accidents and injuries.

Remember that understanding propane's hazard class can help you stay informed about its risks and take necessary precautions when handling this highly flammable gas!

Propane Tank Explosion Class

When it comes to understanding propane tank explosions, it's crucial to identify the class of explosions. The class of an explosion is determined by its severity and impact. Propane tank explosions are classified based on their size, intensity, and potential damage.

A key factor affecting the class of a propane tank explosion is the amount of propane present at the time of the explosion. The more propane there is, the higher the potential for a larger and more destructive explosion. Other factors, such as temperature, pressure, and external ignition sources, also play a significant role in determining the class of a propane tank explosion.

Preventing propane tank explosions involves strict adherence to safety protocols and guidelines for handling and storing propane tanks. Regular maintenance, proper ventilation, and ensuring that tanks are not exposed to extreme heat or open flames are essential in minimizing the risk of explosions.

Now that we've covered how to identify and prevent propane tank explosions let's move on to safety standards for propane tanks to ensure safe handling and usage.

Safety Standards for Propane Tanks

When it comes to ensuring the safety of propane tanks, regulatory agencies, and guidelines play a crucial role in setting the standards for handling and storage. The Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) are some of the key authorities that provide comprehensive regulations and safety protocols for propane tank management.

Regulatory Agencies and Guidelines

OSHA establishes and enforces workplace safety regulations, including propane handling. It sets forth guidelines for the safe storage, transportation, and use of propane and ensures that employers comply with necessary safety measures to protect workers from potential hazards.

In addition to OSHA, the National Fire Protection Association (NFPA) also plays a crucial role in establishing safety regulations for propane handling. Their guidelines cover various aspects of propane use, including installation, maintenance, and emergency response procedures. By adhering to NFPA standards, employers can further ensure the safety of their workers and minimize the risk of accidents or incidents involving propane.

Compliance with Safety Standards

Compliance with safety standards is essential in preventing accidents related to propane tank explosions. Businesses and individuals should adhere to OSHA and NFPA guidelines, which cover various aspects such as proper maintenance, training requirements, emergency response procedures, and more.

In addition to adhering to OSHA and NFPA guidelines, businesses and individuals should prioritize regular inspections of propane tanks to ensure their safety and functionality. Regular inspections can help identify potential hazards or issues before they escalate into dangerous situations, ultimately preventing accidents and injuries. By staying proactive with inspections, businesses and individuals can demonstrate their commitment to safety standards and the well-being of their employees and the surrounding community.

Importance of Regular Inspections

Regular inspections of propane tanks are crucial for maintaining safety and preventing accidents. You can identify and address potential risks by conducting routine checks before they escalate. Here's a step-by-step guide to ensure your propane system is operating safely:

- Visual Inspection: Examine the tank for any signs of damage, such as dents, corrosion, or leaks. Check the valves, fittings, and hoses for cracks, wear, or loose connections.

- Pressure Test: Have your propane tank pressure tested periodically by a qualified technician. This test helps identify any internal damage or structural integrity issues.

- Leak Detection: Use a propane leak detector to check for gas leaks around the tank, valves, and fittings. If you detect a leak, immediately shut off the gas supply and contact a professional for repairs.

- Expiration Date: Verify that your propane tank has not expired. Tanks have a lifespan, and using them beyond their expiration date can increase the risk of accidents.

- Professional Maintenance: Schedule regular maintenance checks with a licensed propane technician. They can inspect the system, identify potential problems, and perform necessary repairs or adjustments.

By following these guidelines and prioritizing regular inspections, you can significantly reduce the risk of propane-related accidents and ensure your and your loved ones' safety.

What to Do in Case of Propane Tank Explosion

When facing a propane tank explosion, it is crucial to have clear emergency response procedures in place. First, ensure that everyone is safe and accounted for, then immediately call emergency services for assistance. Following evacuation and safety protocols is important to prevent further harm and damage. Contacting authorities and professionals trained in propane emergencies is essential for a swift and effective response.

Emergency Response Procedures

In the event of a propane tank explosion, the first step is to ensure the safety of everyone in the vicinity. If possible, shut off the gas supply to prevent further fueling of the fire or explosion. Call 911 or your local emergency number immediately and provide as much information as possible about the situation. Follow any specific emergency response procedures outlined by regulatory agencies or local authorities.

After calling for emergency assistance, it is important to direct people away from the area of the explosion to a safe location. Keep a safe distance from the site, and do not attempt to extinguish the fire unless you have been trained. Follow any evacuation protocols and ensure that everyone is accounted for. It is crucial to remain calm and follow the instructions of emergency responders to ensure a safe and efficient response to the situation.

Evacuation and Safety Protocols

Evacuation should be swift but calm, ensuring that everyone moves away from the site of the explosion to a safe distance. Establish a predetermined meeting point where everyone can gather to confirm their safety. If there are any injured individuals, prioritize their evacuation and seek medical attention as soon as possible.

After ensuring the safe evacuation of all individuals, it is important to contact the authorities and emergency services to report the explosion and provide any necessary information. This will help ensure the appropriate response and resources are deployed to address the situation. Additionally, it may be necessary to contact professionals such as structural engineers or hazardous materials experts to assess the area's safety and determine any potential risks that need to be addressed. Keeping communication lines open with relevant authorities and professionals is crucial for a coordinated and effective response to the explosion.

Contacting Authorities and Professionals

After ensuring the safety of all individuals involved, it's important to contact relevant authorities, such as fire departments, hazardous materials response teams, or propane professionals, who can assess the situation and provide guidance on how to manage any remaining hazards safely.

Remember that being prepared for such emergencies can make all the difference in minimizing potential risks and damages caused by a propane tank explosion.

Ensure Propane Safety

It is crucial to prioritize propane safety by understanding the hazard class of propane and recognizing the dangers of propane tanks. By staying informed and prepared, individuals can take responsibility for propane use and promote safe handling practices.

By staying informed about propane's properties and characteristics, individuals can better understand the potential risks associated with its use. This knowledge can empower them to make informed decisions about how to handle and store propane safely, reducing the likelihood of accidents or incidents. Additionally, staying prepared with proper safety equipment and emergency response plans can further mitigate the dangers of propane use.

Staying Informed and Prepared

Staying informed about propane's risk level and being prepared for emergency situations can significantly reduce the likelihood of a propane tank explosion. Regular inspections and compliance with safety standards are essential in maintaining a safe environment when handling propane. It is crucial to educate all individuals handling propane on the proper safety protocols and procedures to follow in an emergency. By providing comprehensive training and resources, businesses can ensure that their employees are equipped to handle propane safely and effectively.

Promoting Safe Propane Handling Practices

Promoting safe propane handling practices involves educating others about the importance of knowing what class a propane tank explosion is and encouraging safety training and education. By raising awareness, individuals can contribute to creating a safer community when it comes to using propane.

Taking Responsibility in Propane Use

Taking responsibility for propane use also means staying updated on the latest safety protocols and procedures. This may involve attending regular safety training sessions and staying informed about new propane handling and storage developments. By actively participating in safety education, individuals can ensure they have the knowledge and skills to handle propane safely and effectively.

Encouraging Safety Training and Education

Encouraging safety training and education ensures that individuals are equipped with the knowledge to respond effectively in case of a propane tank explosion. This proactive approach can minimize risks and create a safer environment for everyone involved.

By prioritizing these key aspects, individuals can contribute to promoting a culture of safety when using propane. Staying informed, taking responsibility, and encouraging education are essential steps towards ensuring that everyone remains safe while utilizing this valuable resource.