Introduction

In industries where flammable gases, vapors, or dust are commonplace, safety is paramount. This is where ATEX explosion proof standards come into play, providing guidelines that help ensure equipment operates safely in hazardous environments. Understanding ATEX and its importance is essential for anyone involved in the manufacturing or use of equipment in potentially explosive atmospheres.

Understanding ATEX and Its Importance

ATEX stands for ATmosphères EXplosibles, which translates to explosive atmospheres. It encompasses a set of European directives aimed at ensuring that equipment used in such environments meets stringent safety requirements. As businesses strive for compliance with these regulations, the question often arises: Does ATEX mean explosion-proof? The answer lies in understanding that while ATEX certification signifies adherence to safety standards, it does not guarantee absolute explosion-proofness; rather, it indicates that the equipment has been tested and deemed suitable for use in specific hazardous conditions.

Key Terminology in ATEX Standards

Navigating the world of ATEX can be daunting due to its specialized terminology. Key terms such as Zones, Categories, and Equipment Groups define the parameters within which equipment must operate safely. Familiarity with these terms is crucial when discussing what is ATEX protection and how it applies to various industries—especially for professionals who need to ensure compliance with regulations while maintaining operational efficiency.

The Need for Explosion-Proof Equipment

The necessity of explosion-proof equipment cannot be overstated; it serves as a critical line of defense against catastrophic incidents in workplaces where explosive materials are present. Industries like oil and gas, chemicals, and mining face unique risks that demand robust safety measures—hence the emphasis on compliance with both ATEX and IEC standards. Moreover, many wonder: Is ATEX accepted in the USA? While international acceptance varies by region, understanding these standards helps organizations implement best practices globally and protect their workforce effectively.

Overview of ATEX Explosion Proof Standards

What is ATEX?

ATEX refers to the European Union directives that govern equipment used in explosive atmospheres. Specifically, it consists of two main directives: ATEX 2014/34/EU for equipment and protective systems intended for use in potentially explosive atmospheres, and ATEX 1999/92/EC which focuses on minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres. Essentially, what is ATEX protection? It’s about creating a safer working environment by enforcing strict guidelines on how equipment should be designed and tested.

Does ATEX mean explosion-proof?

Many people wonder: Does ATEX mean explosion-proof? The answer is nuanced; while all ATEX-certified equipment must meet stringent safety standards to reduce the risk of explosions, explosion-proof is a term often misused or misunderstood. In reality, not all products certified under the ATEX umbrella are technically “explosion-proof.” Instead, they are designed to prevent ignition sources from causing an explosion in hazardous locations by using various protective measures.

Historical Background of ATEX Regulations

The roots of ATEX regulations can be traced back to increasing concerns over workplace safety in environments where flammable substances are present. Initially introduced in the early 1990s with Directive 94/9/EC, these regulations have evolved significantly over time due to technological advancements and changing industry needs. Understanding this historical background helps clarify why compliance with these standards is critical—especially when considering global acceptance like whether Is ATEX accepted in the USA? The answer lies within international cooperation on safety standards that continues to develop.

Key Components of ATEX Certification

When it comes to ATEX certification, understanding its key components is crucial for ensuring safety in hazardous environments. The ATEX explosion proof standards are designed to protect equipment and systems used in potentially explosive atmospheres. This section will delve into the categories of ATEX equipment, the implications of different zones, and the importance of risk assessment.

Categories of ATEX Equipment

ATEX categorizes equipment based on its suitability for use in explosive atmospheres. Generally, there are two main categories: Category 1 (for areas with a constant or frequent presence of explosive mixtures) and Category 2 (for areas where explosive mixtures may occur occasionally). In addition, Category 3 covers equipment intended for areas where explosive atmospheres are unlikely but could still occur under abnormal conditions.

Understanding these categories helps businesses determine what type of atex explosion proof equipment they need for their specific environments. Notably, does ATEX mean explosion-proof? The answer is nuanced; while all ATEX-certified equipment is designed to prevent explosions, not all explosion-proof devices meet the stringent requirements set forth by ATEX standards. This distinction is essential for compliance and safety.

Zones and Their Implications

The concept of zones plays a pivotal role in understanding how to implement atex explosion proof measures effectively. Zones are classified based on the frequency and duration of the presence of an explosive atmosphere: Zone 0 (continuous), Zone 1 (likely), and Zone 2 (unlikely). Each zone has specific requirements for equipment used within them, making it vital to assess your environment accurately.

For example, using Category 1 devices in Zone 0 ensures maximum safety as they are built to withstand constant exposure to flammable gases or vapors. However, using less robust devices in high-risk zones can lead to catastrophic consequences—hence why knowing your zone is paramount when considering what is ATEX protection? This knowledge helps businesses comply with regulations while safeguarding lives.

Risk Assessment in Hazardous Areas

Conducting a thorough risk assessment is non-negotiable when working with potentially explosive atmospheres. It involves identifying hazards associated with flammable materials and evaluating risks before implementing any atex explosion proof solutions. Businesses must consider factors like ignition sources, material properties, and operational processes during this assessment.

Furthermore, risk assessments should be revisited regularly as conditions change over time—what was safe yesterday might not be safe tomorrow! By continuously assessing risks and ensuring compliance with both ATEX standards and what is the IEC standard for explosion-proof applications, companies can mitigate potential dangers effectively. Ultimately, proactive risk management leads to safer workplaces and better compliance with international regulations.

Global Acceptance of ATEX Standards

The acceptance of ATEX standards on a global scale is an essential consideration for industries that operate in hazardous environments. While ATEX explosion proof equipment is widely recognized in Europe, questions about its acceptance elsewhere, particularly in the USA, arise frequently. Understanding these nuances helps businesses ensure compliance and safety across borders.

Is ATEX accepted in the USA?

The short answer is that while ATEX standards are not directly accepted in the USA, there are parallels that can be drawn. The National Electrical Code (NEC) and the Occupational Safety and Health Administration (OSHA) provide guidelines for explosion-proof equipment similar to those outlined by ATEX regulations. However, manufacturers must ensure their products meet both sets of standards to be compliant with U.S. regulations, leading to some confusion about whether “Does ATEX mean explosion-proof?” The answer lies in understanding that while they serve similar purposes, compliance with one does not automatically guarantee compliance with the other.

Comparison with IECEx Standards

When comparing ATEX and IECEx standards, it becomes clear that both aim to enhance safety in hazardous environments but differ significantly in approach and application. IECEx provides a more globally recognized framework for certification and testing of equipment intended for explosive atmospheres—this makes it appealing for international trade. While both systems address What is ATEX protection? through rigorous testing protocols, IECEx often boasts a streamlined process that can facilitate quicker market entry compared to navigating multiple national regulations under the ATEX umbrella.

International Regulatory Landscape

The international regulatory landscape surrounding explosion-proof equipment is evolving as industries become more interconnected globally. Countries outside Europe increasingly recognize either ATEX or IECEx standards as benchmarks for safety; however, local adaptations may still apply based on specific regional needs or industry practices. As businesses expand their operations internationally, understanding how “What is the IEC standard for explosion-proof?” fits into this complex web of regulations will be crucial for ensuring product compliance while maintaining high safety standards across various jurisdictions.

IEC Standards for Explosion Proof Equipment

In the realm of explosion-proof equipment, IEC standards play a pivotal role in ensuring safety and reliability. These standards provide a framework for manufacturers to create products that can withstand hazardous environments, much like ATEX explosion proof regulations do in Europe. Understanding these standards is crucial for anyone involved in industries where explosive atmospheres are a concern.

What is the IEC standard for explosion-proof?

The International Electrotechnical Commission (IEC) has established several standards that govern the design and testing of explosion-proof equipment. The most notable among them is IEC 60079, which outlines various methods of protection against ignition sources in potentially explosive atmospheres. This raises an interesting question: Does ATEX mean explosion-proof? While ATEX focuses on equipment used within the EU, IEC standards provide a globally recognized benchmark for safety in similar contexts.

Major IEC Standards Explained

Several key IEC standards are essential when discussing explosion-proof equipment. For instance, IEC 60079-0 defines general requirements for electrical equipment used in explosive atmospheres, while IEC 60079-1 specifically addresses flameproof enclosures—one of the most common forms of ATEX protection. Additionally, IEC 60079-31 covers equipment designed to operate safely in dust-laden environments, further expanding on what it means to be compliant with international safety norms.

Understanding these major IEC standards not only helps manufacturers design safer products but also aids users in selecting appropriate equipment for their specific needs. With increasing globalization, knowing whether Is ATEX accepted in the USA or how it relates to these international standards becomes vital for compliance and operational success.

Importance of Compliance with IEC Standards

Compliance with IEC standards is not just a regulatory checkbox; it's a commitment to safety and quality assurance that protects both workers and assets alike. Adhering to these guidelines ensures that products are tested rigorously against potential hazards, thereby reducing risks associated with explosive atmospheres significantly. Moreover, aligning with these international benchmarks enhances marketability and trustworthiness across borders—crucial factors as industries continue to globalize.

In summary, understanding what is the IEC standard for explosion-proof equipment can help clarify its relevance alongside ATEX regulations and other global norms. By ensuring compliance with both sets of regulations—ATEX and relevant IEC standards—manufacturers can effectively navigate the complex landscape of industrial safety while fostering innovation within their product lines.

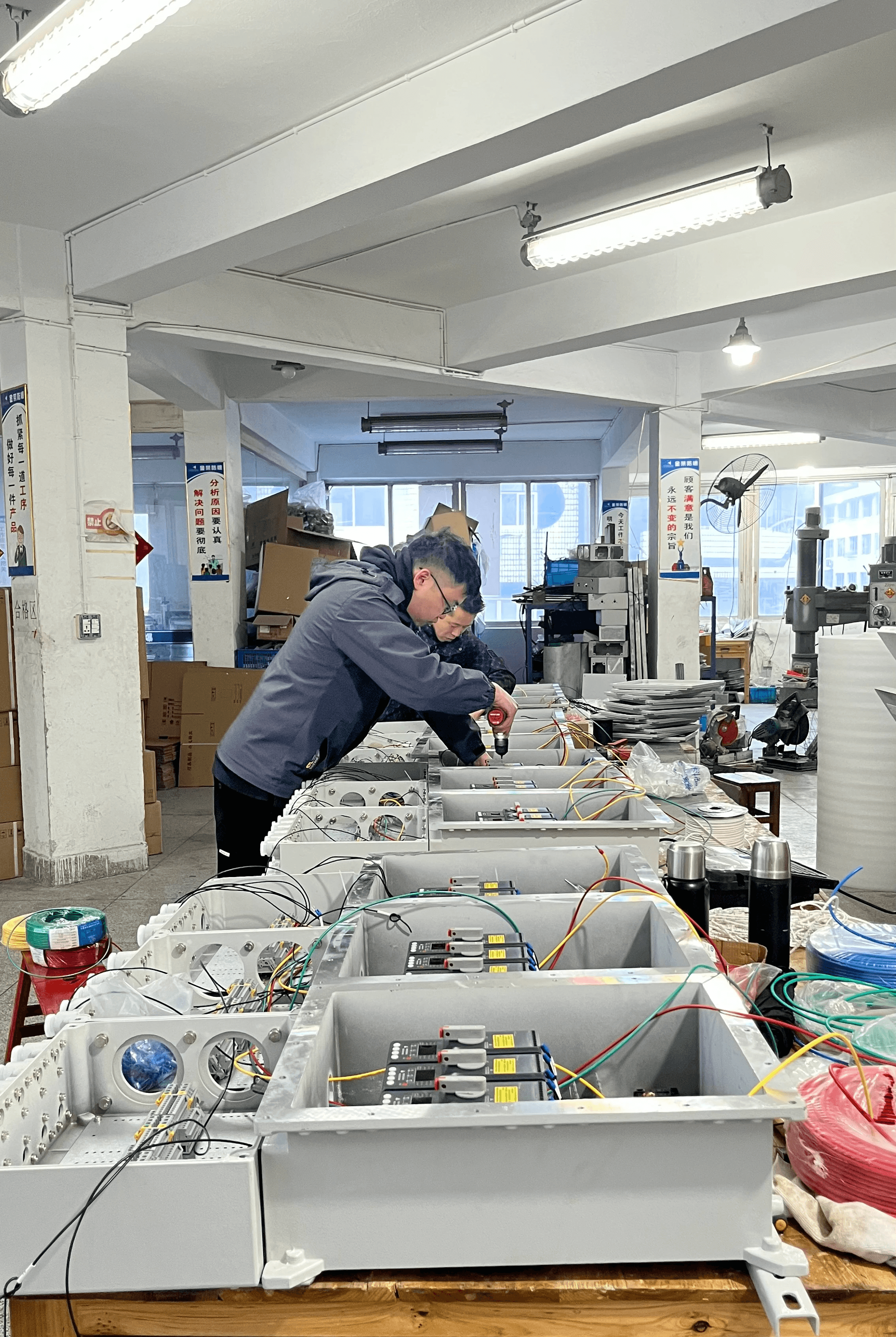

The Role of Jinrong in Ex-Proof Manufacturing

When it comes to atex explosion proof solutions, Jinrong has carved out a significant niche in the industry. Our journey began with a commitment to safety and innovation, ensuring that our products meet the rigorous standards set forth by ATEX regulations. Over the years, we’ve evolved into a trusted name in explosion-proof manufacturing, addressing both local and international needs.

Our Journey in Ex-Proof Solutions

Our adventure in ex-proof solutions started with a simple question: Does ATEX mean explosion-proof? With this inquiry as our guiding star, we dove deep into understanding what ATEX protection truly entails. As we navigated through various challenges and regulations, we quickly recognized the importance of creating equipment that not only meets but exceeds safety standards for hazardous environments.

As we grew, so did our expertise in designing and manufacturing equipment that is compliant with both ATEX and IEC standards. We embraced the complexities of risk assessment and zone classification, which are essential components of effective explosion-proof design. This dedication has allowed us to develop products that are not only reliable but also tailored to meet diverse industrial demands.

Range of ATEX Compliant Products

Jinrong offers an extensive range of atex explosion proof products designed for various applications across multiple industries. From lighting fixtures to control panels, each product is crafted with precision to ensure compliance with stringent safety standards. Our commitment extends beyond just meeting regulatory requirements; we aim to provide innovative solutions that enhance operational efficiency while ensuring safety.

Our team continually researches advancements in technology to improve our product offerings further. For instance, understanding what is the IEC standard for explosion-proof equipment allows us to implement best practices across our manufacturing processes. As such, customers can trust that they are receiving top-notch equipment capable of performing under hazardous conditions without compromising on safety.

Partnership and Growth with Distributors

Building strong partnerships has been central to Jinrong’s growth strategy within the realm of atex explosion proof solutions. By collaborating closely with distributors worldwide, we've expanded our reach while ensuring consistent quality across all markets—yes, even Is ATEX accepted in the USA? Through these partnerships, we've been able to share knowledge about compliance requirements and best practices related to ATEX certification.

Together with our distributors, we strive for excellence by providing comprehensive training programs on how best to utilize our products safely and effectively. This synergy not only bolsters product knowledge but also enhances customer confidence when choosing Jinrong’s ex-proof solutions over competitors’. Ultimately, these relationships have played an integral role in establishing Jinrong as a leader in the field of explosion-proof manufacturing.

Conclusion

As we wrap up our exploration of ATEX standards and their significance in ensuring safety in hazardous environments, it’s clear that understanding ATEX explosion proof regulations is more crucial than ever. The future of ATEX standards will likely see advancements that adapt to emerging technologies and evolving industrial demands. With the growing emphasis on workplace safety, the relevance of these standards will continue to expand across various sectors.

The Future of ATEX Standards

Looking ahead, the future of ATEX standards promises to be dynamic, with a focus on enhancing safety protocols and integrating new technologies into existing frameworks. As industries evolve, so too will the interpretations of Does ATEX mean explosion-proof?—the answer will hinge on continual updates to regulatory criteria and best practices. Organizations must remain vigilant in their compliance efforts while embracing innovation that aligns with these evolving standards.

Advances in Explosion-Proof Technology

The landscape of explosion-proof technology is rapidly advancing, driven by the need for increased efficiency and improved safety measures. Innovations such as smart sensors and IoT integration are set to redefine what What is ATEX protection? means for manufacturers and end-users alike. By leveraging these advancements, companies can enhance their operational capabilities while ensuring they meet stringent requirements like those outlined in What is the IEC standard for explosion-proof? regulations.

Ensuring Safety in Hazardous Environments

Ensuring safety in hazardous environments requires a multi-faceted approach that incorporates rigorous adherence to both ATEX and IEC standards worldwide. Questions like Is ATEX accepted in the USA? highlight the importance of global harmonization of safety regulations as businesses operate across borders. Ultimately, a commitment to understanding and implementing effective explosion-proof solutions will safeguard not only equipment but also lives within potentially dangerous workspaces.