Introduction

When it comes to hazardous locations, the use of proper enclosures is crucial for ensuring safety and compliance. Hazardous enclosures are designed to prevent the ignition of flammable gases, vapors, or dusts, making them essential in environments where these hazards are present. ATEX enclosures and ex-proof manufacturing play a vital role in providing reliable protection against potential explosions, making them a key consideration for industries operating in hazardous locations.

Understanding Hazardous Enclosures for Hazardous Locations

Hazardous enclosures are specifically designed to contain and control any potential sources of ignition within hazardous areas. These enclosures are constructed using materials that can withstand the presence of flammable substances without creating a spark or heat that could lead to an explosion. In hazardous areas, the use of appropriate enclosures is critical for maintaining a safe working environment and preventing catastrophic incidents.

Exploring ATEX Enclosures and Ex-Proof Manufacturing

ATEX enclosures are designed to meet the stringent requirements set forth by the European Union for equipment used in potentially explosive atmospheres. These enclosures undergo rigorous testing and certification processes to ensure their effectiveness in hazardous locations. Ex-proof manufacturing refers to the production of equipment that is inherently safe from ignition sources, making it suitable for use in explosive environments.

The Importance of Ex-Proof Enclosures in Hazardous Locations

Ex-proof enclosures play a crucial role in safeguarding personnel and equipment from the dangers posed by flammable substances. By utilizing ex-proof enclosures, industries can effectively mitigate the risk of explosions and protect valuable assets within hazardous locations. The implementation of these specialized enclosures is essential for maintaining operational safety and regulatory compliance.

Types of Hazardous Enclosures

Understanding Hazardous Area Enclosures

When it comes to hazardous enclosures, understanding the different types is crucial for ensuring safety in hazardous locations. Hazardous area enclosures are designed to contain and protect electrical equipment from igniting flammable gases, vapors, or dusts in Class I and II hazardous locations. These enclosures are built to withstand harsh environments and prevent any potential hazards.

Understanding Hazardous Area Enclosures is essential for maintaining safety in potentially dangerous environments. There are several types of hazardous enclosures, each with its own specific features and capabilities. These include explosion-proof enclosures, flameproof enclosures, and increased safety enclosures, all of which are designed to prevent the ignition of flammable substances and protect electrical equipment.

Exploring Explosion-Proof Enclosure Types

Explosion-proof enclosure types are specifically designed to prevent the ignition of flammable gases or vapors within the enclosure, thus containing any explosion that may occur. These types of enclosures are essential in hazardous locations where the presence of combustible materials poses a constant threat. They provide a safe environment for electrical equipment and ensure the protection of personnel working in these areas.

In Class 1 Div 2 hazardous locations, it is crucial to use explosion-proof enclosures that are specifically designed to withstand and contain potential explosions. These enclosures must meet strict safety standards and regulations to ensure the protection of personnel and equipment in these high-risk areas. Additionally, they should be constructed with durable materials and equipped with features such as gasketed seals and secure locking mechanisms to prevent the ingress of flammable gases or vapors.

What Type of Enclosure Should be Used in Class 1 Div 2?

In Class 1 Div 2 hazardous locations, where flammable liquids or gases are present but not likely to be in quantities sufficient to produce explosive or ignitable mixtures, non-explosion-proof enclosures can be used as long as they meet specific requirements outlined by regulatory bodies such as OSHA and NEC. It's important to carefully assess the specific conditions of the location before determining the type of enclosure that should be used.

When considering the type of enclosure to use in Class 1 Div 2 hazardous locations, it's important to take into account the potential for the presence of flammable liquids or gases. While non-explosion-proof enclosures can be utilized in these environments, they must adhere to specific requirements set forth by regulatory bodies. These requirements may include features such as sealed seams and gaskets to prevent the entry of hazardous substances into the enclosure.

Choosing the Right Enclosure for Your Needs

When it comes to Class I hazardous locations, it's crucial to select the right enclosure to ensure safety. Hazardous Area Enclosures are suitable for use in Class I hazardous locations, providing the necessary protection against potential explosions and fires. These enclosures are designed to contain any sparks or heat generated within the enclosure, preventing them from igniting any surrounding flammable gases or vapors.

Which Enclosure is Suitable for Use in Class I Hazardous Locations?

In Class I hazardous locations where flammable gases or vapors are present, explosion-proof enclosures are the most suitable choice. These enclosures are constructed to withstand and contain an internal explosion without causing an external hazard. By utilizing robust materials and engineering designs, explosion-proof enclosures provide a safe solution for hazardous environments where the risk of explosion is high.

In addition to being explosion-proof, Class I Div 2 locations also require enclosures to be dust-ignition proof. These enclosures are designed to prevent the ingress of dust that could potentially ignite and cause an explosion in the presence of flammable gases or vapors. By meeting both explosion-proof and dust-ignition proof requirements, enclosures can provide comprehensive protection in hazardous environments where the risk of explosion and ignition is high.

Does Class 1 Div 2 Require Explosion Proof?

Class 1 Div 2 locations do not always require explosion-proof enclosures, as they may only have occasional flammable gas or vapor presence. In these instances, a non-incendive type of enclosure may be sufficient to provide adequate protection against potential ignition sources. It's essential to carefully assess the specific conditions of the location and consult with experts to determine whether explosion-proof enclosures are necessary.

What is an ATEX Enclosure?

ATEX enclosures are designed and certified for use in potentially explosive atmospheres in European countries. These specialized enclosures adhere to strict ATEX directives and regulations, ensuring their suitability for hazardous environments with flammable substances. ATEX enclosures offer a high level of protection against potential ignition sources, making them a reliable choice for hazardous locations across various industries.

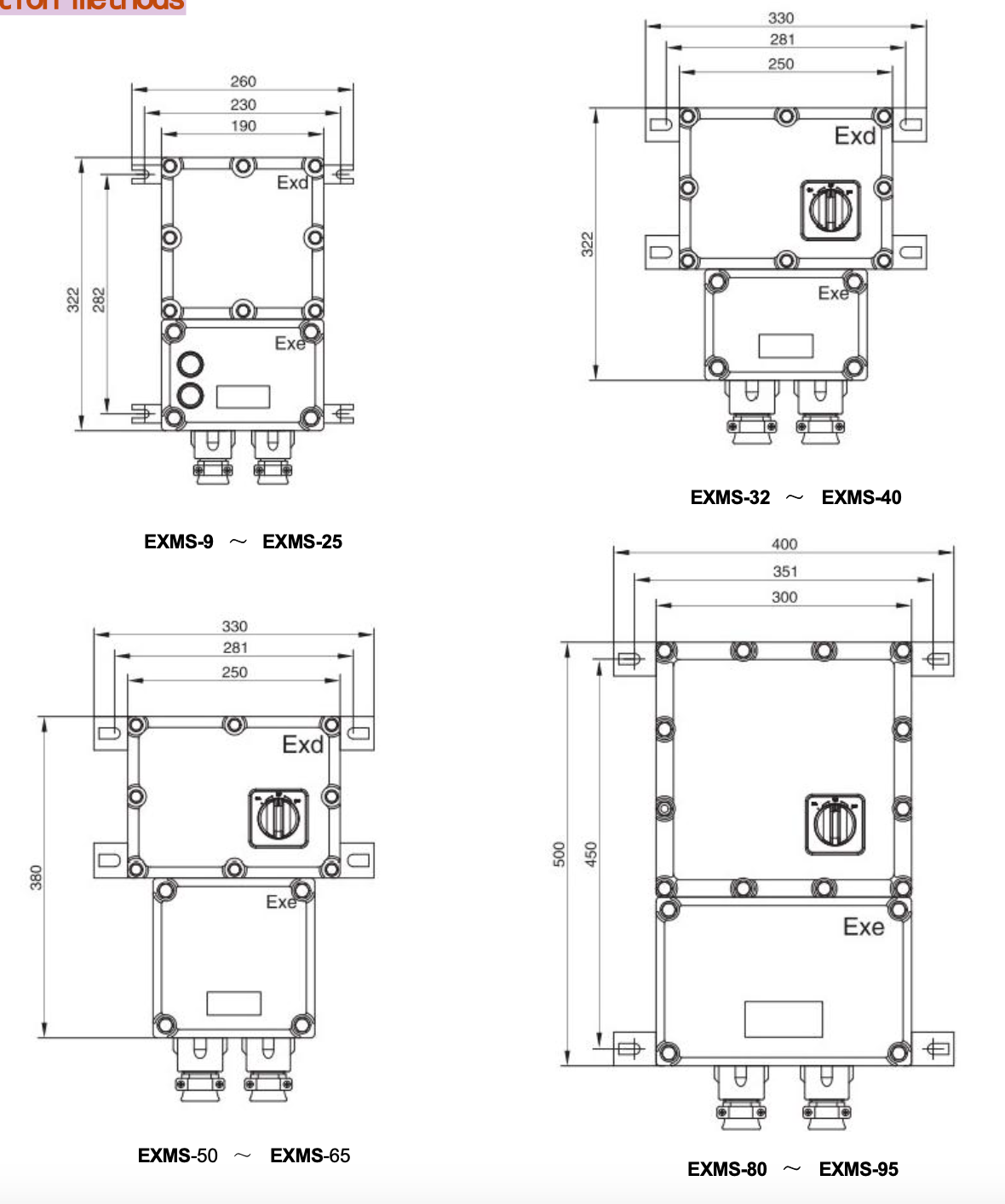

ATEX enclosures are available in a range of sizes and materials to accommodate different industry requirements, offering flexibility and versatility for various applications. These enclosures can be used in industries such as oil and gas, chemical processing, pharmaceuticals, and more, providing a safe solution for protecting equipment and personnel in hazardous environments. With their robust construction and reliable performance, ATEX enclosures are a crucial component in ensuring compliance with safety standards and regulations.

Features and Considerations

When it comes to hazardous enclosures, understanding the different types and their suitability for specific hazardous locations is crucial. Hazardous Area Enclosures are designed to provide protection in potentially explosive atmospheres, while ATEX enclosures are specifically certified for use in European hazardous locations. It's important to know which enclosure is suitable for use in class I hazardous locations, as well as whether class 1 div 2 requires explosion proof or not.

Enclosure Types and Hazardous Locations

Hazardous Area Enclosures come in various types, including flameproof enclosures, increased safety enclosures, and intrinsic safety enclosures. Each type is designed for specific hazardous areas based on the potential presence of explosive gases or dust. Understanding the features and limitations of each type is essential in choosing the right enclosure for a particular hazardous location.

Key Considerations for Hazardous Enclosures

When considering hazardous enclosures, factors such as temperature ratings, ingress protection (IP) ratings, material construction, and certification standards play a critical role. The ability of an enclosure to withstand extreme temperatures and protect against dust or water ingress can determine its suitability for use in hazardous locations. Additionally, compliance with international standards such as ATEX and IECEx is crucial in ensuring the safety and reliability of an enclosure.

Understanding the Features of Hazardous Enclosures

Hazardous enclosures are equipped with features that mitigate the risk of ignition in volatile environments. These features may include robust construction materials such as stainless steel or aluminum, specialized gasket seals for ingress protection, and secure locking mechanisms to prevent unauthorized access. Understanding these features allows users to make informed decisions when selecting an enclosure that meets their specific requirements.

Jinrong's Expertise in Ex-Proof Manufacturing

Jinrong has established itself as a leader in the field of hazardous enclosures, specializing in ex-proof manufacturing for over 27 years. Their expertise in producing top-quality hazardous area enclosures and ATEX enclosures has made them a go-to choice for businesses operating in class I hazardous locations.

Jinrong: Leading the Way in Hazardous Enclosures

Jinrong's commitment to excellence sets them apart as leaders in the production of hazardous enclosures. Their dedication to providing explosion-proof enclosure types that meet the highest safety standards makes them a trusted partner for businesses seeking reliable solutions for their hazardous location needs.

Jinrong's dedication to excellence extends beyond just the quality of their products. They also prioritize exceptional customer service, ensuring that businesses receive the support and guidance they need when selecting and implementing hazardous enclosures. With a team of knowledgeable experts, Jinrong is able to provide valuable insights and recommendations, making the process of choosing the right explosion-proof enclosure types a seamless and informed experience for their clients.

Diving into Ex-Proof Manufacturing with Jinrong

When it comes to ex-proof manufacturing, Jinrong dives deep into every aspect of the process to ensure that their hazardous area enclosures are of the highest quality. Their attention to detail and thorough understanding of what is an ATEX enclosure sets them apart as experts in providing tailored solutions for various class I hazardous locations.

Jinrong's 27 years of expertise in ex-proof manufacturing have allowed them to perfect their processes and develop a deep understanding of the specific requirements for hazardous area enclosures. With a focus on continuous improvement, they stay ahead of industry standards and regulations to ensure that their products meet the highest quality and safety standards. This commitment to excellence has earned Jinrong a reputation as a trusted partner for businesses operating in hazardous environments, providing peace of mind and reliable solutions for their unique needs.

Jinrong's 27 Years of Expertise in Ex-Proof Manufacturing

With over 27 years of experience, Jinrong has honed their expertise in ex-proof manufacturing, making them a trusted name in the industry. Their track record of delivering top-notch explosion-proof enclosure types and understanding which enclosure is suitable for use in class I hazardous locations makes them a reliable choice for businesses looking to enhance safety measures.

With a strong focus on quality and safety, Jinrong has become a go-to choice for businesses in need of explosion-proof enclosures. Their dedication to delivering top-notch products that meet industry standards is evident in their long-standing reputation. Businesses can trust Jinrong to provide the right enclosure for their specific needs, ensuring a safe and compliant working environment.

Conclusion

Selecting the Right Enclosure for Your Hazardous Location

When it comes to selecting the right enclosure for your hazardous location, it's crucial to consider the specific requirements of your environment. Understanding the different types of hazardous enclosures, such as explosion-proof and ATEX enclosures, is key to ensuring the safety of your operations. Always consult with experts in hazardous enclosures to make an informed decision that meets all safety standards.

Choosing the Best Hazardous Enclosure for Your Needs

Choosing the best hazardous enclosure for your needs involves evaluating factors such as the classification of your hazardous location and the specific hazards present in that environment. It's important to consider whether class 1 div 2 requires explosion proof and what type of enclosure should be used in a class 2 div 2. By understanding these requirements, you can make an informed decision that prioritizes safety and compliance.

Enhancing Safety with Jinrong's Hazardous Enclosures

Jinrong's expertise in ex-proof manufacturing ensures that you have access to high-quality hazardous enclosures that meet all necessary safety standards. With over 27 years of experience in this field, Jinrong is dedicated to enhancing safety in hazardous locations through their top-notch enclosures. Trust Jinrong to provide you with reliable solutions for your hazardous enclosure needs.