Introduction

In a world where safety is paramount, understanding anti-explosion control panels becomes crucial for industries that handle flammable materials. These specialized devices are designed to prevent catastrophic events by containing potential explosions within their robust enclosures. But what is an explosion-proof panel, and how does it work? This introduction will delve into the significance of explosion-proof equipment, the mechanisms behind it, and the industry standards that govern its use.

Understanding Anti-Explosion Control Panels

Anti-explosion control panels serve as the frontline defense against hazardous situations in environments prone to explosive atmospheres. These panels are engineered to ensure that if an internal explosion occurs, it doesn't breach the enclosure, thereby protecting both personnel and equipment. The question of how does an explosion-proof box work? often arises; essentially, these boxes utilize heavy-duty materials and design principles that allow them to withstand significant pressure without failing.

Importance of Explosion-Proof Equipment

The importance of explosion-proof equipment cannot be overstated; it safeguards lives and property in industries such as oil and gas, chemical manufacturing, and mining. By using these protective devices, companies can mitigate risks associated with volatile substances while adhering to safety regulations. Moreover, understanding what are the requirements for explosion-proof enclosures is essential for compliance with industry standards and ensuring operational safety.

Overview of Industry Standards

Industry standards play a vital role in establishing guidelines for the design and implementation of explosion-proof technology like explosion proof control boxes and enclosures. Various organizations set forth regulations that dictate how these devices should perform under duress while maintaining safety protocols for users. Familiarity with these standards ensures that businesses not only meet legal requirements but also foster a culture of safety within their operations.

What is an Explosion-Proof Panel?

Definition and Purpose

An explosion-proof panel, often referred to as an anti-explosion control panel, is engineered to contain any potential explosion that occurs within its confines. The primary purpose of such panels is to protect both personnel and equipment from the dangers associated with volatile substances. By containing explosions internally, these panels help maintain safety standards in industries where flammable materials are commonplace.

Key Components of Explosion-Proof Panels

The effectiveness of an explosion-proof panel hinges on several key components that work together seamlessly. These include robust housing materials, sealing mechanisms, and pressure relief features designed to withstand internal explosions without compromising safety. Additionally, components like gaskets and specialized fasteners ensure that the enclosure remains airtight, further enhancing its protective capabilities.

Common Applications

Explosion-proof panels have a wide range of applications across various industries where flammable materials are handled or processed. Commonly found in oil refineries, chemical plants, and grain storage facilities, these panels play a critical role in maintaining operational safety. Furthermore, industries such as mining and pharmaceuticals also utilize explosion-proof control boxes to prevent accidents related to combustible dust or gases.

How Does an Explosion-Proof Box Work?

Mechanisms of Protection

The primary mechanism of protection in an explosion-proof box is its robust construction. Built from durable materials like steel or aluminum, these boxes can withstand high-pressure blasts without compromising their integrity. Additionally, the design often includes sealing techniques that prevent gases or vapors from entering and igniting inside the enclosure—keeping everything under control.

Another critical aspect is the use of flame paths; these are precisely engineered routes that allow flames to escape safely if an internal explosion occurs. This way, any potential ignition source is contained within the enclosure itself, minimizing risks outside it. Essentially, understanding how does an explosion-proof box work involves recognizing its ability to act as a fortress against explosive forces.

Different Types of Explosion-Proof Enclosures

Explosion-proof enclosures come in various types tailored for specific applications, each with unique features and benefits. For instance, some are designed for indoor use while others are ruggedized for outdoor environments where weather conditions could be a factor. Knowing what is an explosion-proof panel helps users choose between options like junction boxes or control panels based on their operational needs.

Another type includes purged and pressurized enclosures which maintain a safe atmosphere by keeping potentially explosive gases out through positive pressure systems. Then there are intrinsically safe enclosures that limit energy levels to prevent ignition even under fault conditions—perfect for sensitive electronic equipment! Understanding what are the requirements for explosion-proof enclosures ensures you select the right type for your application.

Case Studies of Effective Use

To illustrate effective utilization of explosion-proof technology, consider a case study from an offshore oil rig where anti-explosion control panels played a pivotal role in safety management. The installation of specialized explosion proof control boxes allowed operators to monitor drilling operations without risking ignition from flammable gases present in the environment.

In another example from a chemical processing plant, implementing explosion protected control boxes improved safety protocols during material handling processes significantly reducing incidents related to electrical sparks igniting volatile substances nearby. These real-world applications demonstrate not only how effective these systems can be but also highlight best practices when deciding where do you use explosion-proof switches effectively.

Requirements for Explosion-Proof Enclosures

General Safety Standards

General safety standards serve as the foundation for designing and implementing explosion-proof enclosures. Organizations like the National Fire Protection Association (NFPA) and the International Electrotechnical Commission (IEC) provide guidelines that outline essential safety measures. These standards detail how an explosion-proof box should be constructed, ensuring it can withstand internal pressures without allowing flames or sparks to escape.

In addition to these guidelines, manufacturers of Anti-explosion control panels must consider environmental factors such as temperature extremes and moisture exposure. The materials used in the construction of explosion-protected control boxes are also specified within these standards to ensure durability and longevity. Adhering to these general safety standards is crucial for anyone asking, What are the requirements for explosion-proof enclosures?

Specific Regulations by Industry

Different industries have unique challenges when it comes to explosion-proof equipment, leading to specific regulations tailored to their needs. For instance, oil and gas industries often face more stringent requirements due to higher risks associated with flammable gases and vapors compared to other sectors like pharmaceuticals or food processing. Understanding where do you use explosion-proof switches becomes critical when navigating these industry-specific regulations.

Regulatory bodies such as OSHA (Occupational Safety and Health Administration) in the United States enforce rules that dictate how companies must implement safety measures using equipment like Explosion Proof Control Boxes or Explosion Protected Control Boxes. Compliance with these regulations not only ensures worker safety but also helps organizations avoid hefty fines and legal repercussions down the line. Thus, knowing both general safety standards and specific industry regulations is vital for effective risk management.

Certifications and Compliance

Certification plays a significant role in validating that an Anti-explosion control panel meets all necessary safety requirements before being put into service. Various organizations offer certifications based on rigorous testing protocols designed specifically for explosion-proof enclosures; examples include ATEX (Europe), IECEx (International), and UL (United States). These certifications assure users that products like Explosion Proof Control Enclosures have undergone thorough evaluations regarding their ability to prevent ignition in hazardous locations.

Moreover, compliance with local laws often mandates obtaining certification from recognized bodies before installing any type of explosive containment system in a workplace setting. This step not only enhances credibility but also fosters trust among clients regarding product reliability—essential when considering what is an explosion-proof panel? As industries continue evolving with new technologies, staying updated on certification changes ensures ongoing compliance with best practices in equipment safety.

Where Do You Use Explosion-Proof Switches?

Common Industry Applications

Explosion-proof switches find their home in a variety of industries, including oil and gas, chemical manufacturing, pharmaceuticals, and mining. In these sectors, the risk of explosive atmospheres is high due to the presence of volatile substances; thus, using an anti-explosion control panel becomes necessary. Facilities that handle flammable liquids or gases must prioritize the installation of explosion-proof control boxes to mitigate risks.

Additionally, industries such as food processing may require explosion-proof control enclosures to protect against dust accumulation from ingredients like flour or sugar. The use of these specialized switches ensures not only compliance with safety regulations but also safeguards operational continuity in potentially dangerous settings. Understanding what is an explosion-proof panel helps companies recognize the importance of integrating these devices into their systems.

Best Practices for Installation

Installing explosion-proof switches requires meticulous attention to detail to ensure they function correctly under hazardous conditions. First and foremost, it's vital to follow manufacturer guidelines and industry standards when installing any explosion protected control boxes or enclosures. Ensuring proper sealing and mounting techniques can significantly reduce the risk of ignitable materials entering the enclosure.

Moreover, periodic inspections should be part of your maintenance routine; this ensures that any wear or damage is addressed promptly before it leads to catastrophic failures. Proper training for personnel on how does an explosion-proof box work is equally important; workers need to understand operational protocols associated with these devices for optimal safety measures. Lastly, always keep a record of installations and modifications made over time as part of your compliance documentation.

Safety Considerations

Safety should always be at the forefront when dealing with explosion-proof switches and related equipment such as anti-explosion control panels. One critical consideration is ensuring that all components meet specific requirements for explosion-proof enclosures; this includes certifications from recognized regulatory bodies like ATEX or IECEx standards. Regular audits can help identify potential hazards before they escalate into serious threats.

It's also essential to take into account environmental factors such as temperature fluctuations and humidity levels that could affect equipment performance over time—these can compromise even the best-designed systems if not monitored closely. Personnel training on emergency response procedures related to explosions must be prioritized so that everyone knows how to react swiftly in case something goes awry while using an explosion proof control box.

Overview of Explosion Proof Control Boxes

Features of Explosion Protected Control Boxes

Explosion protected control boxes boast several key features that set them apart from standard enclosures. Firstly, they are constructed from robust materials that can withstand high-pressure explosions without rupturing, ensuring safety in volatile environments. Additionally, these boxes often include advanced sealing mechanisms that prevent the ingress of hazardous substances, thereby maintaining the integrity of the internal components.

Moreover, an anti-explosion control panel typically includes temperature regulation systems to manage heat buildup during operation. This is crucial because excessive heat can lead to ignition in explosive atmospheres. Lastly, many explosion proof control enclosures come equipped with monitoring systems that provide real-time feedback on environmental conditions, further enhancing operational safety.

Comparing Different Types

When exploring what is an explosion-proof panel, it’s important to note that not all explosion proof control boxes are created equal; they vary significantly based on their intended use and industry requirements. For example, some designs are tailored for specific environments like oil refineries or chemical processing plants where flammable gases are prevalent. In contrast, others may be better suited for mining operations where dust accumulation poses a risk.

Additionally, different types of explosion proof enclosures may offer varying levels of protection classified under standards such as ATEX and IECEx. These classifications help users determine which box meets their specific needs based on environmental conditions and potential hazards present in their operations. Therefore, understanding how does an explosion-proof box work in relation to its type is crucial for making informed decisions.

Recommendations for Purchase

When considering a purchase for an explosion protected control box, there are several factors to keep in mind to ensure compliance with what are the requirements for explosion-proof enclosures? First and foremost, always verify that the product adheres to relevant industry standards and certifications—this is non-negotiable when safety is at stake!

Next, evaluate the specific needs of your application: Are you working in a high-temperature environment? Do you need additional features like remote monitoring? Finally, consult with reputable suppliers who specialize in explosion proof equipment; they can provide valuable insights into selecting the right solution tailored for your unique requirements.

In conclusion, whether you're looking into general applications or specific installations like where do you use explosion-proof switches?, understanding these aspects will guide you toward making educated choices about your equipment's safety and efficiency.

Conclusion

In a world where safety is paramount, understanding the intricacies of the anti-explosion control panel becomes essential for various industries. These panels are not just pieces of equipment; they are critical components designed to protect lives and property from potential explosions. By grasping concepts like “What is an explosion-proof panel?” and “How does an explosion-proof box work?”, professionals can make informed decisions that enhance workplace safety.

Insights on Anti-Explosion Control Panel Usage

The usage of anti-explosion control panels spans multiple sectors, including oil and gas, chemical manufacturing, and even food processing. These panels serve as a first line of defense against hazardous conditions by controlling electrical systems in environments where flammable gases or dust may be present. Understanding “What are the requirements for explosion-proof enclosures?” can aid companies in selecting the right equipment tailored to their specific operational needs.

Best Practices for Equipment Safety

When it comes to ensuring safety with explosion-proof switches and control boxes, adhering to best practices is non-negotiable. Regular maintenance checks and thorough inspections should be part of any safety protocol to ensure that these critical devices function correctly over time. Additionally, proper installation according to guidelines related to “Where do you use explosion-proof switches?” can significantly mitigate risks associated with explosive environments.

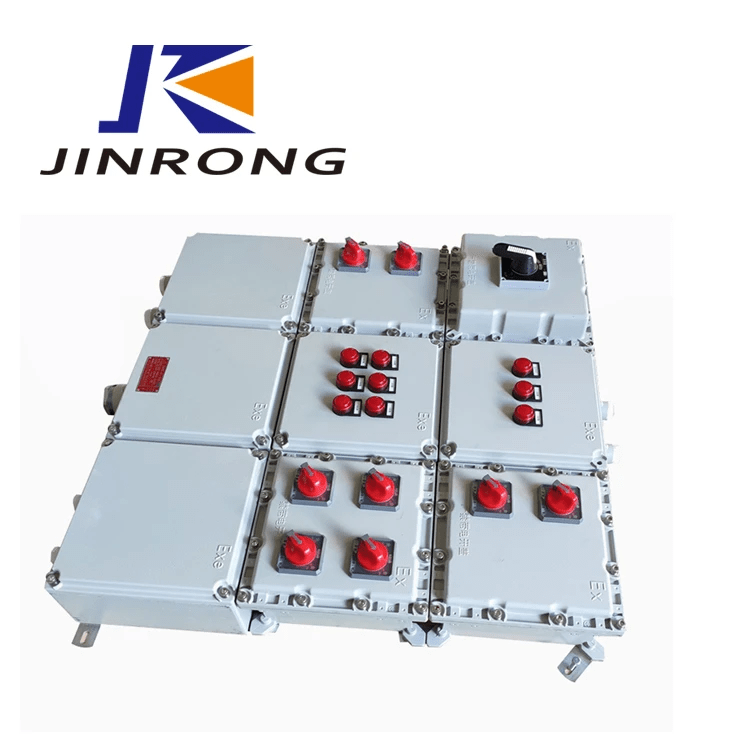

Jinrong’s Commitment to Quality and Safety

At Jinrong, quality and safety are not just buzzwords; they are commitments we uphold in every product we design, including our explosion proof control enclosures and explosion protected control boxes. We understand the importance of compliance with industry standards while providing durable solutions that meet stringent requirements for safety and reliability. With our products, you can trust that your operations will be safeguarded against potential hazards while maintaining peak performance.