Introduction

When it comes to the chemical industry, understanding hazardous equipment is crucial for ensuring safety and efficiency. The right tools are essential for protecting workers and facilities, from explosion-proof manufacturing to flame-proof equipment. Selecting top suppliers is critical in obtaining reliable and high-quality hazardous area equipment. At Jinrong, we pride ourselves on our expertise in ex-proof manufacturing, providing superior solutions for dangerous environments.

Understanding Hazardous Equipment for Chemical Industry

Hazardous equipment in the chemical industry encompasses a wide range of tools and machinery designed to operate safely in potentially explosive or flammable environments. This includes explosion-proof electrical systems, flameproof equipment, and other specialized gear that meets strict safety standards.

Importance of Selecting Top Suppliers

When working in hazardous environments, selecting suitable equipment suppliers is paramount. Here's why partnering with top suppliers for hazardous area equipment is crucial:

- Guaranteed Safety: Top suppliers prioritize safety by offering products rigorously tested and certified to meet industry standards, minimizing the risk of accidents.

- Performance Optimization: Their expertise ensures you receive equipment suited for your specific application, maximizing effectiveness in hazardous conditions.

- Reliable Support: They provide comprehensive support, including technical guidance and training, to keep your equipment functioning optimally throughout its lifespan.

By partnering with top hazardous area equipment suppliers, you prioritize safety, optimize performance, and gain access to valuable support, creating a safer and more efficient work environment.

Our Company Jinrong’s Expertise in Ex-Proof Manufacturing

Jinrong has over 27 years of experience manufacturing explosion-proof equipment, making us a trusted leader in the industry. Our commitment to quality, innovation, and safety has earned us a reputation as a go-to supplier for businesses seeking superior hazardous area solutions.

Jinrong's expertise in ex-proof manufacturing extends to various industries, including oil and gas, chemical processing, pharmaceuticals, and more. Our engineers and technicians are well-versed in the latest industry standards and regulations, ensuring that our products meet or exceed all safety requirements. With a focus on continuous improvement, we are constantly researching and developing new technologies to stay ahead of the curve in hazardous area solutions.

Exploring Hazardous Equipment

Various types of hazardous equipment are crucial for ensuring safety in chemical industry settings. These can include explosion-proof manufacturing equipment, flameproof equipment, and electrical equipment designed for hazardous areas.

Different Types of Hazardous Equipment

In hazardous environments with flammable materials, specialized equipment is crucial to ensure worker safety and prevent costly accidents. Here's a breakdown of the key types:

- Explosion-Proof Equipment: Designed to prevent ignition of flammable gases and dust in the first place. These machines are built with spark-resistant materials and sealed enclosures to eliminate ignition sources.

- Flame-Proof Equipment: Constructed to withstand an internal explosion without igniting the surrounding atmosphere. This equipment acts as a last line of defense, containing the blast and preventing further damage.

- Hazardous Location Electrical Equipment: This equipment plays a vital role in preventing electrical sparks that could ignite flammable materials. It is specially designed to minimize heat generation, prevent arcing, and ensure safe operation in hazardous areas.

By employing the right combination of these specialized solutions, industries like chemical plants and oil refineries can significantly reduce the risk of explosions and ensure a safe working environment for their employees.

Key Features to Look for in Hazardous Equipment

The right equipment for hazardous environments is crucial for worker safety and operational efficiency. Here are vital factors to consider:

- Durability and Quality: Look for equipment with robust construction, high-grade materials, and a proven track record of reliable performance.

- Environmental Resilience: To ensure equipment longevity, consider weather resistance, corrosion resistance, and suitability for specific operating conditions.

- Ease of Maintenance: Prioritize equipment that's easy to clean, inspect, and maintain to minimize downtime and maximize equipment lifespan.

- Spare Parts and Support: Accessibility of replacement parts and knowledgeable technical support are vital to ensure prompt repairs and continued safe operation.

- Safety System Compatibility: Choose equipment compatible with existing safety systems for seamless integration and enhanced overall hazard management.

By carefully evaluating these factors, businesses can make informed decisions about selecting hazardous equipment, promote a safer work environment, and optimize operational efficiency.

Importance of Quality and Reliability

In hazardous environments, the quality and reliability of equipment can mean the difference between safety and disaster. Investing in top-notch products that have been rigorously tested and certified to meet industry standards for safety and performance is crucial. Choosing high-quality and reliable hazardous area equipment is a non-negotiable aspect of maintaining a safe work environment.

Investing in top suppliers in the industry is essential for ensuring the quality and reliability of hazardous area equipment. Look for companies with a proven track record of providing high-performance products that have undergone rigorous testing and certification. By choosing reputable suppliers, you can have confidence in the safety and effectiveness of the equipment you use in hazardous environments.

Top Suppliers in the Industry

Regarding hazardous equipment, Jinrong is a top supplier with extensive experience in manufacturing high-quality and reliable products for dangerous environments. With a proven track record of excellence, Jinrong offers a wide range of explosion-proof and flame-proof equipment designed to meet the strict safety standards of the chemical industry.

Other leading suppliers in the market also provide a variety of hazardous area equipment, but not all can match Jinrong's level of expertise and commitment to safety. It's crucial to consider the supplier's reputation, product quality, certifications, and customer support when choosing the right partner for your hazardous equipment needs.

Factors to consider when choosing a supplier include their compliance with industry regulations, ability to customize products according to specific requirements and track record for delivering on time and within budget. Partnering with a reputable supplier like Jinrong ensures that you have access to top-notch hazardous equipment that meets the highest safety standards.

Explosion Proof Manufacturing

The Process of Manufacturing Hazardous Equipment

At Jinrong, we take great pride in our meticulous process of manufacturing hazardous equipment. Our team of skilled engineers and technicians carefully designs and constructs explosion-proof equipment to ensure maximum safety and reliability in hazardous environments. From the initial concept to the final product, every step is executed with precision and attention to detail, guaranteeing top-notch quality for our clients.

Our commitment to quality and safety extends beyond the manufacturing process. We also ensure that our explosion-proof equipment meets all necessary certifications and standards for use in hazardous environments. Our products are rigorously tested and certified by reputable third-party organizations to guarantee compliance with industry regulations and guidelines. This dedication to meeting and exceeding safety standards sets us apart as a leader in providing reliable hazardous equipment solutions.

Certifications and Standards for

Explosion-Proof Equipment

Adhering to industry certifications and standards is paramount when it comes to explosion-proof equipment. At Jinrong, we strictly follow international regulations such as ATEX, IECEx, and NEC to ensure that our products meet the highest safety requirements for hazardous areas. Our dedication to compliance gives our clients peace of mind, knowing that they are investing in equipment that meets rigorous safety standards.

In addition to adhering to industry certifications and standards, Jinrong invests in ongoing research and development to stay ahead of the curve in explosion-proof equipment technology. Our team of engineers and experts is constantly exploring new materials, designs, and manufacturing processes to improve the safety and performance of our products. This commitment to innovation ensures that our clients receive cutting-edge equipment that meets current safety standards and anticipates future industry requirements.

Jinrong's 27 Years of Expertise in Ex-Proof Manufacturing

With over 27 years of experience in ex-proof manufacturing, Jinrong has established itself as a trusted leader in providing top-quality hazardous area equipment. Our extensive knowledge and expertise enable us to deliver innovative solutions that cater to the specific needs of various industries operating in dangerous environments. When you partner with Jinrong, you will benefit from decades of proven excellence in manufacturing explosion-proof equipment.

Flame Proof Equipment

Flame-proof equipment is classified based on its ability to withstand and contain an internal explosion without allowing it to propagate to the surrounding atmosphere. Understanding these classifications is crucial for ensuring safety in hazardous environments. Different classifications determine the level of protection the equipment offers, making it essential to choose the right type for specific applications.

Understanding Flame Proof Equipment Classifications

Flame-proof equipment is classified into different groups and zones, each indicating its suitability for specific hazardous areas. For example, Group I equipment is suitable for mines, while Group II is designed for surface industries. Similarly, Zone 0, 1, and 2 classifications indicate the likelihood of explosive atmospheres in a particular area.

Flame-proof equipment classifications are essential for ensuring the safety of workers in hazardous areas. By clearly indicating the suitability of equipment for specific environments, these classifications help prevent accidents and minimize the risk of explosions. This protects workers and property and ensures compliance with safety regulations, ultimately leading to a more efficient and secure work environment.

Advantages of Using

Flame-Proof Equipment

The primary advantage of using flameproof equipment is its ability to prevent explosions from spreading beyond the enclosed space. This not only protects personnel and assets but also ensures uninterrupted operations in hazardous areas. Additionally, flameproof equipment offers a cost-effective solution for mitigating explosion risks without compromising on performance.

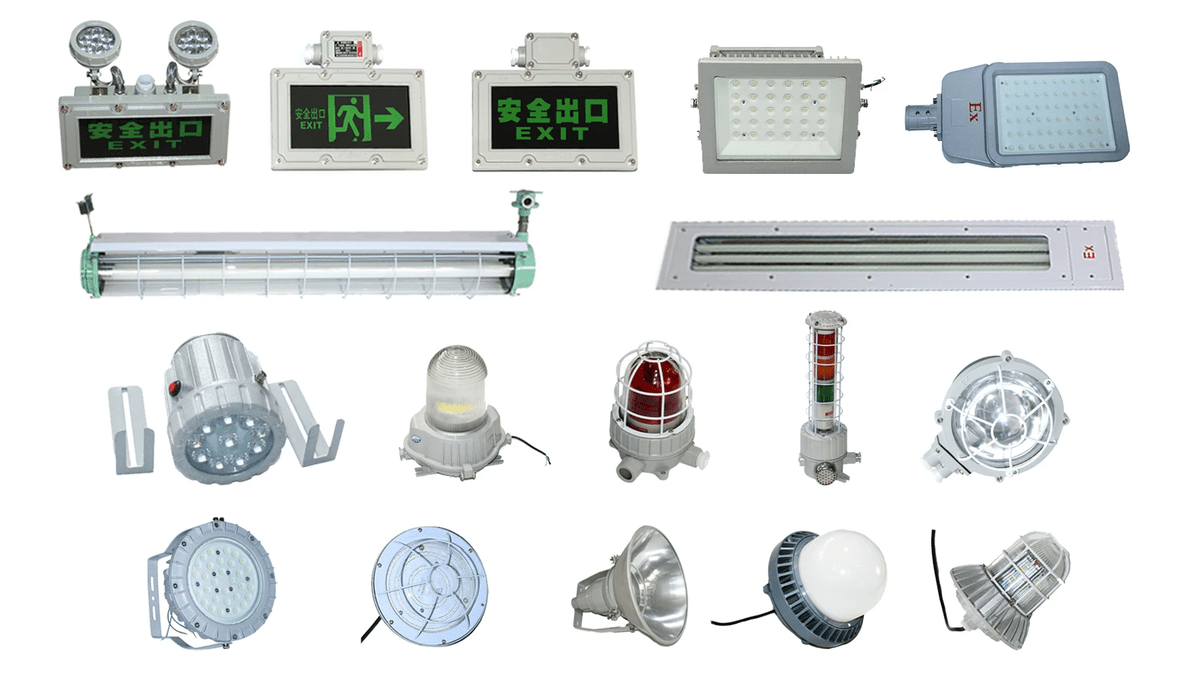

Jinrong's Range of

Flame-Proof Equipment

Jinrong offers a comprehensive range of flameproof equipment designed to meet diverse industry needs. From lighting fixtures and control panels to enclosures and junction boxes, our products are meticulously engineered to provide reliable protection in hazardous environments. With a focus on quality and compliance with international standards, Jinrong's flameproof equipment delivers unmatched safety and performance.

Electrical Equipment in Hazardous Areas

Safety is of the utmost importance when it comes to electrical equipment in hazardous areas. Factors like potential ignition sources and the presence of flammable substances must be considered. Selecting the right electrical equipment for hazardous areas involves careful consideration of explosion-proof classifications and compliance with industry standards. At Jinrong, we offer specialized electrical equipment designed specifically for hazardous areas, ensuring maximum safety and reliability.

Safety Considerations for Electrical Equipment

Safety considerations for electrical equipment in hazardous areas revolve around preventing potential ignition sources that could lead to explosions or fires. This includes protection against sparks, arcs, and high temperatures that could ignite flammable substances present in the environment. Adhering to explosion-proof classifications and standards ensures that electrical equipment is suitable for use in hazardous areas without posing a risk of ignition.

In addition to preventing potential ignition sources, it's essential to consider the environmental conditions in hazardous areas when selecting electrical equipment. Factors such as temperature, humidity, and corrosive substances can impact the performance and safety of electrical devices. Therefore, it's crucial to choose equipment designed to withstand these conditions and maintain its integrity in the presence of flammable materials.

Selecting the Right Electrical Equipment for Hazardous Areas

Selecting the right electrical equipment for hazardous areas involves understanding the specific environmental requirements and choosing products that meet those needs. This includes considering factors such as temperature ratings, ingress protection, corrosion resistance, and compliance with explosion-proof standards. It's essential to work with reputable suppliers who can guide you in selecting the most suitable electrical equipment for a given hazardous area.

When selecting electrical equipment for hazardous areas, it's crucial to consider the specific environmental requirements. For instance, if the area is prone to high temperatures, choosing equipment with appropriate temperature ratings is essential to ensure safe operation. Additionally, considering factors such as ingress protection and corrosion resistance can help prevent damage and malfunctions in challenging environments. By working with reputable suppliers who can guide these considerations, you can ensure that the electrical equipment chosen is well-suited for the hazardous area.

Jinrong's Specialized Electrical Equipment for Hazardous Areas

At Jinrong, we specialize in manufacturing electrical equipment designed for hazardous areas. Our products are built to meet stringent explosion-proof classifications and standards, ensuring maximum safety and reliability in challenging environments. With our extensive experience in ex-proof manufacturing, we offer a comprehensive range of electrical equipment tailored to the unique requirements of different hazardous areas.

Ensure Safety and Reliability in Hazardous Environments

When choosing the right hazardous equipment supplier, it's crucial to prioritize safety, reliability, and quality. Selecting a supplier with extensive experience in explosion-proof manufacturing and a wide range of flameproof equipment is essential for ensuring the highest level of protection in hazardous environments. Partnering with Jinrong for superior hazardous equipment guarantees top-notch products that meet all necessary standards and certifications.

Choosing the Right Hazardous Equipment Supplier

Selecting a reliable supplier for hazardous equipment is paramount in maintaining a safe work environment. Look for suppliers with a proven track record in explosion-proof manufacturing and a comprehensive range of flame-proof equipment. When making this critical decision, consider factors such as expertise, certifications, and quality.

Safety and reliability are non-negotiable in hazardous environments. The use of explosion-proof classification, explosion-proof electrical, and other specialized equipment is vital for protecting personnel and assets from potential dangers. It's imperative to prioritize these aspects when selecting hazardous area equipment to ensure maximum safety.

Partnering with Jinrong for Superior Hazardous Equipment

Partnering with Jinrong guarantees access to top-quality hazardous equipment that meets the highest industry standards. With an extensive range of explosion-proof manufacturing capabilities and flame-proof equipment, Jinrong offers solutions that prioritize safety without compromising on performance or durability.