Introduction

When it comes to manufacturing, ensuring a safe and productive work environment is crucial. Understanding OSHA lighting standards is essential for meeting the necessary requirements for lighting in industry. The right lighting not only enhances safety but also boosts productivity, making it a key aspect of manufacturing operations. Jinrong, a leader in ex-proof manufacturing, provides reliable lighting solutions that adhere to OSHA standards.

Understanding OSHA Lighting Standards

OSHA sets specific requirements for lighting in manufacturing facilities to ensure the safety and well-being of workers. It outlines the necessary illumination levels and guidelines for different areas within a factory to minimize the risk of accidents and hazards.

Proper lighting in manufacturing facilities is essential for maintaining a safe and productive work environment. OSHA's specific requirements help to ensure that all areas of the factory are adequately illuminated, reducing the risk of accidents and hazards. By following these guidelines, employers can demonstrate their commitment to the well-being of their workers and avoid potential fines or penalties for non-compliance.

Importance of OSHA Lighting in Manufacturing

Proper lighting is vital for creating a safe and efficient work environment in manufacturing. Adequate illumination not only reduces the likelihood of accidents but also promotes productivity by enabling workers to perform their tasks effectively.

Furthermore, OSHA regulations require specific lighting levels in different areas of manufacturing facilities to ensure the safety and well-being of workers. Proper lighting can help prevent slips, trips, and falls by illuminating potential hazards and obstacles. In addition, well-lit workspaces can reduce eye strain and fatigue, leading to improved employee morale and job satisfaction.

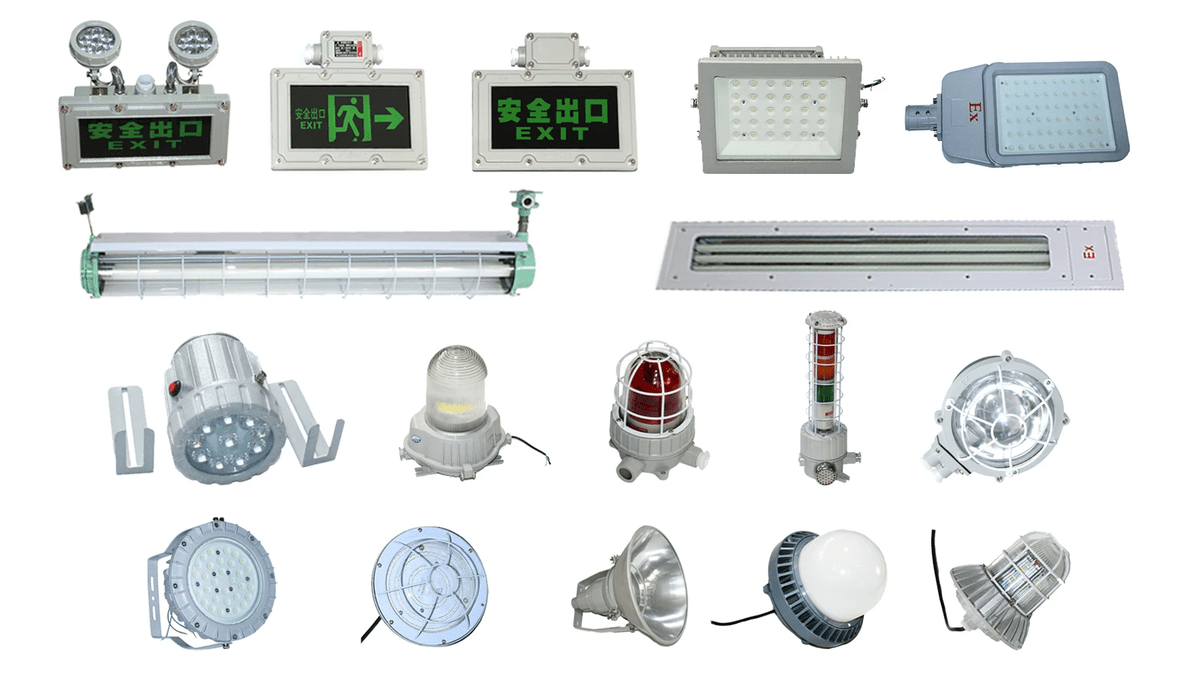

Jinrong: A Leader in Ex-Proof Manufacturing

Jinrong specializes in ex-proof lighting solutions that meet OSHA lighting requirements for manufacturing. With its expertise in this field, Jinrong provides high-quality products designed to enhance safety and efficiency in industrial settings.

In addition to meeting OSHA lighting requirements, Jinrong's ex-proof lighting solutions are also designed to withstand harsh industrial environments, including areas with the presence of flammable gases or dust. By utilizing advanced technology and materials, Jinrong's products offer long-lasting performance and reliability, reducing the need for frequent maintenance and replacements. This not only saves time and resources for manufacturing facilities but also contributes to a more sustainable and eco-friendly operation.

OSHA Standards for Lighting in Manufacturing

When it comes to OSHA lighting requirements for manufacturing, it's important to understand the standards set in place to ensure safety and productivity in the workplace. OSHA has specific regulations regarding the level of lighting required in a factory, as well as the lighting requirements for industrial and warehouse facilities. These standards are crucial for creating a safe and efficient work environment.

OSHA Lighting Requirements for Manufacturing

OSHA has established specific lighting requirements for manufacturing facilities to ensure the safety and well-being of workers. Adequate lighting is essential for preventing accidents and maintaining productivity in a factory setting. By adhering to these regulations, manufacturers can create a safer work environment while also complying with OSHA standards.

What is the OSHA standard for lighting in industry?

The OSHA standard for lighting in industry is designed to provide guidelines on the minimum level of illumination required in various work areas within manufacturing facilities. This includes specific requirements for different tasks such as assembly lines, equipment operation, and storage areas. By meeting these standards, manufacturers can enhance safety and efficiency throughout their operations.

What are the lighting standards for manufacturing?

The lighting standards for manufacturing set by OSHA encompass various factors such as light intensity, distribution, color rendering, and glare control. These standards are tailored to different types of work environments within manufacturing facilities to ensure that adequate lighting is provided based on specific tasks and potential hazards present in each area.

Now that we have delved into the OSHA standards for lighting in manufacturing, it's clear that these regulations play a critical role in creating a safe and productive workplace environment. By understanding and implementing these standards effectively, manufacturers can prioritize the well-being of their employees while also optimizing operational efficiency.

The Significance of Adequate Lighting

What level of lighting is required in a factory?

In a factory, the OSHA standard for lighting in industry requires a minimum of 5 foot-candles for general areas and 10-30 foot-candles for specific tasks or workstations. Proper lighting is crucial for ensuring safety and productivity in manufacturing facilities.

Importance of proper lighting for safety and productivity

Adequate lighting not only prevents accidents and injuries, but also plays a vital role in boosting employee morale and efficiency. It reduces the risk of errors and improves overall work quality, making it essential for maintaining a productive work environment.

OSHA Lighting Requirements for Industrial and Warehouse

For industrial and warehouse settings, OSHA mandates that all areas should have sufficient lighting to ensure safe working conditions. This includes proper illumination for walkways, stairwells, storage areas, and other high-traffic zones to minimize potential hazards.

Remember to always prioritize safety by adhering to OSHA's lighting standards to create a secure work environment while simultaneously enhancing productivity.

Implementing OSHA Lighting Standards

In order to comply with OSHA lighting regulations, manufacturing facilities must ensure that their lighting systems meet the specific requirements set by the organization. This includes providing adequate illumination levels, ensuring proper maintenance of lighting fixtures, and implementing measures to prevent glare and shadows in work areas.

To meet OSHA lighting standards, manufacturing facilities can conduct regular audits of their lighting systems to identify any deficiencies and take corrective actions. This may involve upgrading existing lighting fixtures, installing additional lights in dimly lit areas, or adjusting the positioning of lights to minimize shadows and improve visibility.

Ensuring safe and effective lighting in manufacturing facilities is crucial for maintaining a productive and hazard-free work environment. By adhering to OSHA lighting requirements, companies can significantly reduce the risk of accidents and injuries while also improving overall operational efficiency.

Remember that implementing OSHA lighting standards is not just about compliance—it’s about creating a safer and more efficient workplace for everyone involved. By prioritizing proper illumination in manufacturing facilities, companies can protect their employees while also enhancing productivity.

Enhancing Safety and Efficiency

Impact of proper lighting on accident prevention

Proper lighting in manufacturing facilities is crucial for accident prevention. According to OSHA lighting requirements for manufacturing, adequate illumination can help workers identify potential hazards and navigate the workspace safely, reducing the risk of slips, trips, and falls. With the right lighting, employees can spot obstacles and avoid accidents, promoting a safer work environment.

Improving productivity through adequate lighting

Meeting the OSHA standard for lighting in industry not only enhances safety but also improves productivity. Well-lit workspaces contribute to better visibility and focus, allowing employees to perform tasks more efficiently. Adequate lighting can reduce eye strain and fatigue, leading to higher job satisfaction and increased output. By adhering to the lighting standards for manufacturing, companies can create a conducive environment for optimal productivity.

OSHA Lighting Standards for a safer work environment

The OSHA Lighting Requirements for Industrial and Warehouse settings are designed to ensure a safer work environment for employees. These standards specify the minimum level of illumination required in different areas of a facility, taking into account factors such as task complexity and potential hazards. By following OSHA lighting regulations, companies demonstrate their commitment to providing a secure workspace while also complying with legal requirements.

Jinrong’s Commitment to Safety

Jinrong is a trusted leader in ex-proof manufacturing, specializing in providing high-quality lighting solutions for hazardous environments. With extensive experience in meeting OSHA lighting requirements for manufacturing, Jinrong ensures that its products adhere to the OSHA standard for lighting in industry.

Jinrong’s expertise in ex-proof manufacturing

Jinrong's expertise lies in designing and producing ex-proof lighting solutions that meet the strictest safety standards for industrial facilities. Their team of engineers and technicians are well-versed in OSHA lighting standards and work diligently to create reliable products that comply with the lighting requirements of an industrial facility.

Jinrong's expertise in ex-proof manufacturing extends beyond just meeting safety standards. Their team is dedicated to staying ahead of industry trends and technological advancements, ensuring that their products are not only safe but also innovative. By constantly researching and implementing new materials and designs, Jinrong is able to offer cutting-edge lighting solutions that improve the overall efficiency and productivity of industrial facilities.

Providing quality ex-proof lighting solutions

Jinrong is dedicated to delivering top-notch ex-proof lighting solutions that not only meet but exceed OSHA Lighting Requirements for Industrial and Warehouse settings. Their commitment to quality ensures that their products provide the level of lighting required in a factory, promoting a safe and productive work environment.

Jinrong's ex-proof lighting solutions are designed to withstand the harshest industrial environments, ensuring reliability and longevity. By utilizing advanced technology and high-quality materials, Jinrong's products are able to provide consistent lighting that meets the stringent OSHA requirements. This level of durability and performance not only ensures a safe work environment but also reduces maintenance costs, making Jinrong's lighting solutions a smart investment for any industrial or warehouse setting.

Partnering with Jinrong for reliable lighting products

By partnering with Jinrong, businesses can rest assured that they are getting reliable lighting products that adhere to OSHA Lighting Standards. With a focus on safety and efficiency, Jinrong's offerings contribute to creating a safer work environment while enhancing productivity.

With their expertise in ex-proof manufacturing and dedication to providing quality lighting solutions, Jinrong is the ideal partner for businesses looking to ensure compliance with OSHA standards while prioritizing safety and efficiency.

Conclusion

Creating a safer work environment with OSHA lighting standards is crucial for the manufacturing industry. Adhering to OSHA regulations not only ensures improved safety and productivity but also reduces the risk of accidents. By partnering with Jinrong for effective lighting solutions, companies can guarantee compliance with OSHA Lighting Standards and provide a secure work environment for their employees.

Creating a safer work environment with OSHA lighting standards

Adhering to OSHA lighting requirements for manufacturing is essential in creating a safe work environment. Proper illumination not only enhances visibility but also reduces the risk of accidents in industrial facilities. By following the lighting standards set by OSHA, companies can prioritize the safety and well-being of their workers while maintaining compliance with regulations.

In addition to reducing the risk of accidents, proper lighting in manufacturing facilities can also improve worker productivity. Adequate illumination can help employees focus on their tasks more effectively and reduce the strain on their eyes, leading to increased efficiency and output. By adhering to OSHA lighting standards, companies can create a work environment that not only prioritizes safety but also promotes optimal performance.

Adhering to OSHA regulations for improved safety and productivity

Meeting the OSHA standard for lighting in industry is not just about compliance; it's about ensuring improved safety and productivity in manufacturing facilities. Adequate lighting levels are necessary to prevent workplace hazards and promote efficiency among workers. By adhering to OSHA lighting requirements, companies can create an environment that fosters both safety and productivity.

Partnering with Jinrong for effective lighting solutions

Partnering with Jinrong for reliable ex-proof lighting solutions is the key to meeting OSHA Lighting Standards effectively. With Jinrong's expertise in ex-proof manufacturing, companies can access quality lighting products that guarantee compliance with OSHA regulations. By choosing Jinrong as their partner, businesses can ensure a safe and well-lit environment for their employees.

By partnering with Jinrong for effective lighting solutions, businesses can also benefit from cost-effective options that help save on energy consumption and maintenance costs. Jinrong's commitment to providing efficient lighting solutions means companies can reduce their carbon footprint while improving their bottom line. With Jinrong as a partner, businesses can enjoy the peace of mind that comes with reliable and long-lasting lighting solutions.