Introduction

In a world where safety is paramount, understanding explosion proof technology is crucial for industries that operate in hazardous environments. This technology is designed to prevent ignition of flammable gases or dust, making it essential for maintaining safe electrical connections. Among the various components that contribute to this safety are explosion proof plugs and sockets, which are engineered to withstand extreme conditions while ensuring reliable performance.

Understanding Explosion Proof Technology

At its core, explosion proof technology refers to equipment designed to contain any potential explosions within a sealed enclosure, preventing the ignition of surrounding flammable materials. This involves specific design standards and certifications that ensure these products can withstand harsh environments without compromising safety. When asking What is an explosion proof plug? one must consider how these plugs play a vital role in connecting power sources while maintaining the integrity of the system against explosive risks.

Importance of Safe Electrical Connections

Safe electrical connections are not just a matter of convenience; they are critical for protecting lives and property in potentially explosive atmospheres. An unreliable connection can lead to sparks or overheating, which might ignite combustible substances nearby. Therefore, using certified explosion proof plugs and sockets ensures that electrical systems remain secure and compliant with industry regulations, significantly reducing the risk associated with electrical failures.

Overview of Explosion Proof Plug Types

Explosion proof plugs come in various types tailored for different applications across industries such as oil and gas, mining, and chemical processing. These plugs are designed with unique features like robust housing materials and sealing mechanisms to prevent ingress from hazardous substances. Additionally, understanding What is an ATEX plug? highlights another category within explosion proof technology that meets stringent European safety standards for equipment used in explosive atmospheres.

What is an Explosion Proof Plug?

Definition and Purpose

An explosion proof plug is a robust electrical connector engineered to contain any potential explosions within its housing, preventing them from spreading to the surrounding environment. The primary purpose of these plugs is to ensure safe electrical connections in locations that may have flammable gases or vapors, thereby minimizing the risk of ignition. By using an explosion proof plug and socket system, businesses can enhance workplace safety and comply with stringent industry regulations.

Key Features and Standards

Explosion proof plugs are characterized by their durable construction, which often includes materials resistant to corrosion and impact. They must meet specific industry standards such as IECEx or ATEX certifications that dictate how they can be used in explosive atmospheres. Key features include sealing mechanisms that prevent gas ingress, high-temperature resistance, and secure locking systems that maintain connection integrity under harsh conditions.

Common Applications in Industry

Explosion proof plugs find common applications across various industries including oil and gas, chemical manufacturing, mining, and pharmaceuticals. In these sectors, where volatile substances are frequently handled, utilizing explosion proof technology is not only advisable but often mandatory for compliance with safety regulations. Moreover, these plugs play a vital role in ensuring operational continuity while safeguarding personnel from potential hazards associated with electrical failures.

What is an ATEX Plug?

Explanation of ATEX Certification

ATEX certification stems from the European Union directive aimed at providing guidelines for equipment used in explosive environments. The term ATEX itself is derived from the French phrase ATmosphères EXplosibles. To earn this certification, plugs and sockets must undergo rigorous testing and adhere to strict safety standards that ensure they can withstand potentially explosive conditions without causing ignition.

Understanding what explosion proof technology entails is crucial here; the ATEX certification signifies that these plugs are engineered specifically to prevent sparks or heat generation that could lead to explosions. This makes them indispensable in various sectors where safety cannot be compromised.

Differences Between ATEX and Non-ATEX Plugs

One of the main distinctions between ATEX and non-ATEX plugs lies in their construction and safety features. While standard plugs may suffice for everyday use, they lack the robust design necessary for hazardous environments where flammable materials are present. An explosion proof plug and socket must incorporate additional protective elements such as flameproof enclosures or intrinsic safety measures that prevent ignition.

Moreover, non-ATEX plugs do not undergo the same stringent testing protocols as their certified counterparts. This difference highlights why using an ATEX plug is essential when working within industries that face risks associated with explosive atmospheres—safety should never take a backseat!

Industries That Require ATEX Plugs

Several industries operate under conditions where using an explosion proof plug is not just recommended but mandated by law. The oil and gas sector frequently utilizes these specialized connectors due to their exposure to volatile substances during extraction or refining processes. Similarly, chemical manufacturing facilities rely on ATEX-certified plugs for safe electrical connections amid potentially dangerous chemicals.

Other sectors include pharmaceuticals, mining, and food processing—each requiring stringent adherence to safety regulations due to the presence of combustible dust or gases during operations. Understanding what explosion proof technology entails helps businesses recognize the importance of investing in reliable solutions like Explosion Proof Plugs, Connectors, and Cord Caps tailored for their unique needs.

What is the Safest Plug Socket in the World?

In a world where safety is paramount, identifying the safest plug socket can feel like searching for a needle in a haystack. The safest plug socket combines advanced technology with robust design to ensure that it can withstand harsh environments, particularly those prone to explosions or electrical hazards. So, what exactly makes a plug and socket worthy of this title?

Examination of Safety Features

When discussing safety features in an explosion proof plug and socket, several key elements come into play. First and foremost, these sockets often include weatherproof designs that prevent water ingress and dust accumulation, which are critical for maintaining safe operations in industrial settings. Additionally, many explosion proof plugs are equipped with locking mechanisms that secure connections against accidental disconnection or vibration—an essential feature when working in volatile environments.

Another important aspect is the use of materials designed to withstand extreme temperatures and corrosive substances. High-quality insulation helps prevent short circuits while flame-retardant housings minimize fire risks. Ultimately, these features work together to create an environment where electrical systems can operate safely without compromising performance.

Comparison of Popular Safe Socket Solutions

When it comes to choosing the safest plug socket in the world, several popular solutions stand out from the crowd. For instance, ATEX-certified plugs are specifically designed for explosive atmospheres and meet stringent European safety standards; they offer peace of mind where risk factors are high. On the other hand, NEMA-rated products provide excellent protection against environmental hazards but may not always be suitable for explosive conditions.

Moreover, some manufacturers have developed unique designs that incorporate both explosion proof characteristics and user-friendly features like color-coded connections or ergonomic shapes for ease of handling. When comparing these options, it's crucial to assess your specific needs—whether you require an explosion proof plug or simply a robust connector that meets general safety standards will influence your choice significantly.

Importance of Certification and Testing

Certification plays a pivotal role in ensuring that any explosion proof plug and socket lives up to its claims regarding safety features and reliability. Regulatory bodies such as IECEx or UL conduct rigorous testing procedures to verify compliance with technical standards related to electrical equipment used in hazardous areas; this means you’re not just taking someone’s word for it when they say their product is safe.

Additionally, ongoing testing ensures that products remain compliant with evolving industry standards over time—a vital consideration given how quickly technology advances today. Investing in certified products minimizes risks associated with using subpar equipment while maximizing operational efficiency across various industries.

Ultimately, when searching for what is the safest plug socket in the world—or even pondering questions like What is an ATEX plug?—it pays off handsomely to prioritize certification and rigorous testing as part of your decision-making process.

Understanding Explosion Proof for Electrical Systems

In industries where hazardous materials are present, ensuring safety is paramount. This is where explosion proof technology comes into play, particularly with explosion proof plugs and sockets that are designed to prevent ignition in explosive atmospheres. Understanding the technical standards and functionality of these systems can significantly enhance workplace safety.

Technical Standards for Explosion Proof Equipment

Explosion proof equipment must comply with strict international standards to ensure reliability and safety in hazardous environments. These standards include IECEx and ATEX certifications, which dictate the design, testing, and performance criteria for explosion proof plugs and sockets. Adhering to these technical standards not only guarantees compliance but also instills confidence among workers that they are using safe electrical systems.

The classification of equipment based on its protection level is crucial; it helps determine the appropriate use of specific explosion proof plugs in various environments. For instance, equipment rated for Zone 1 may be suitable for areas with a frequent presence of flammable gases, while Zone 2 equipment is designed for less hazardous locations. Understanding these classifications ensures that businesses select the right components when implementing explosion proof technology.

How Explosion Proof Systems Work

At their core, explosion proof systems are engineered to contain any potential explosions within their housing. When an ignition source occurs inside an explosion proof plug or socket, the design prevents flames or hot gases from escaping into the surrounding environment. This containment mechanism is critical in protecting against catastrophic incidents in volatile industrial settings.

Moreover, these systems often incorporate features like reinforced materials and seals to further enhance their protective capabilities. For example, an ATEX plug will have specific construction requirements that allow it to withstand extreme conditions without compromising safety. By understanding how these components function together, companies can better appreciate the importance of investing in high-quality explosion proof plugs and connectors.

Benefits of Using Explosion Proof Technology

Utilizing explosion proof technology offers numerous benefits beyond mere compliance with safety regulations; it fundamentally protects lives and property from potential disasters. The primary advantage is risk reduction; by employing certified products like explosion proof plugs and sockets, businesses can minimize hazards associated with explosive atmospheres effectively.

Additionally, investing in reliable equipment enhances operational efficiency by reducing downtime caused by accidents or maintenance issues related to non-compliant products. Companies can also enjoy peace of mind knowing they have taken proactive measures toward creating a safer work environment—a factor that boosts employee morale as well as productivity levels.

In summary, understanding what constitutes safe electrical connections through specialized products like ATEX plugs can lead organizations toward better safety practices overall while reaping significant operational benefits along the way.

Explosion Proof Plugs, Connectors, and Cord Caps

In the world of hazardous environments, having the right equipment is crucial for maintaining safety and efficiency. This section delves into the various types of explosion proof plugs, connectors, and cord caps available on the market. Understanding these products can help ensure that electrical connections remain secure and compliant with industry standards.

Overview of Product Types

Explosion proof plugs and sockets come in a variety of designs tailored to specific applications. These products are engineered to prevent ignition from sparks or heat generated by electrical components within explosive atmospheres. Common types include standard explosion proof plugs, ATEX plugs designed for compliance with European regulations, and specialized connectors that enhance safety in industrial settings.

Additionally, explosion proof cord caps play a vital role in safeguarding electrical junctions from external hazards while ensuring reliable connectivity. Each product type features unique specifications that cater to different industries such as oil and gas, pharmaceuticals, or mining—where safety is paramount. By choosing the appropriate explosion proof plug and socket combination, businesses can significantly reduce risks associated with electrical failures.

Choosing the Right Equipment for Your Needs

Selecting the right explosion proof equipment requires careful consideration of several factors including environmental conditions and regulatory compliance. Start by assessing your specific application: What is an explosion proof plug? It's essential to understand how these devices function under varying pressures or temperatures typical in your industry environment.

Next, evaluate certification standards such as ATEX or IECEx to ensure that your chosen products meet necessary safety requirements—especially if you’re asking yourself: What is an ATEX plug? Understanding these distinctions will guide you toward making informed decisions about which products are best suited for your operations.

Finally, consider compatibility with existing systems when choosing connectors or cord caps; this ensures seamless integration without compromising safety features. Remember that investing in high-quality explosion proof plugs can ultimately save lives while preventing costly downtime due to equipment failure.

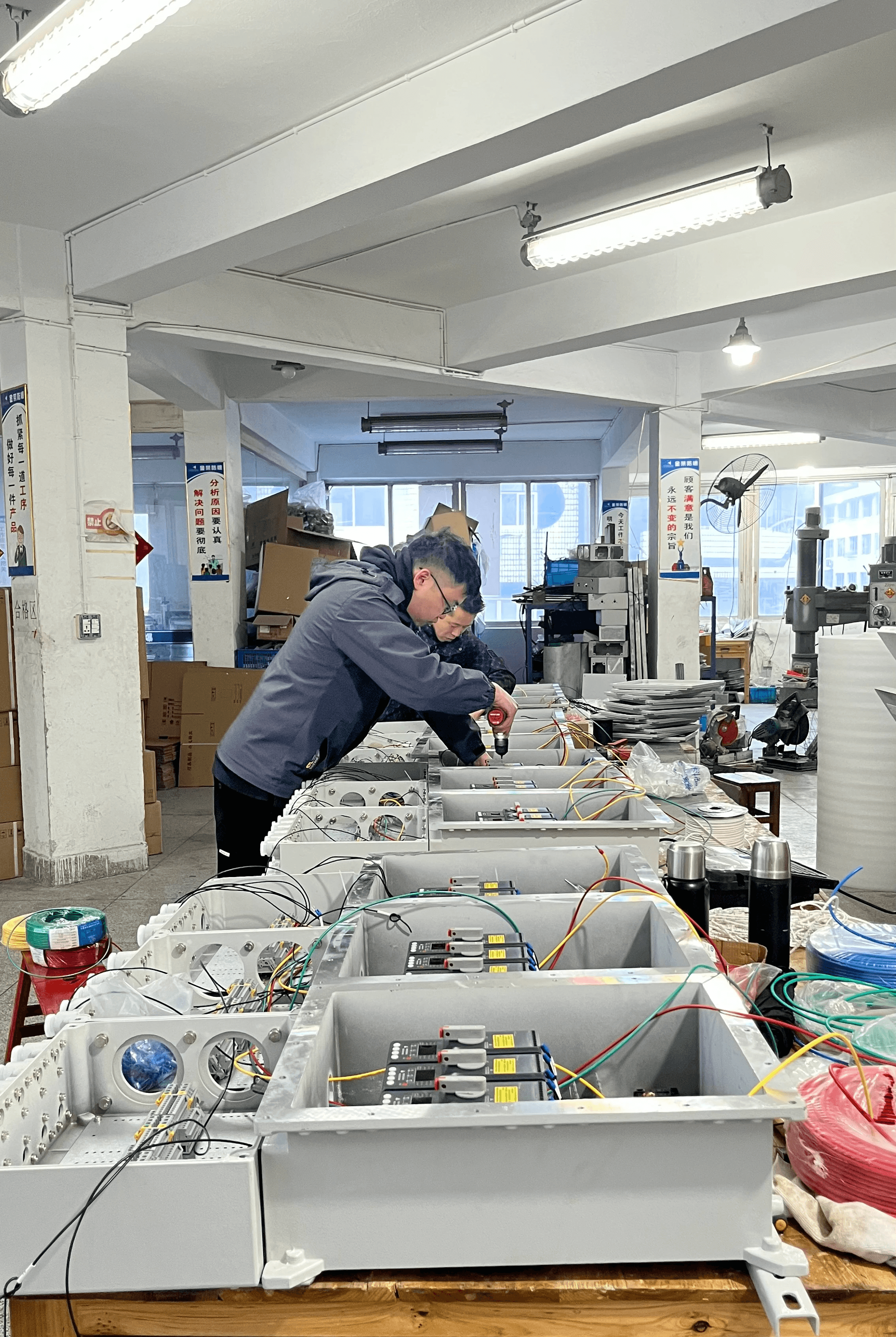

Leading Manufacturers Like Jinrong

Jinrong’s expertise in producing durable solutions allows companies across multiple sectors—from chemical processing plants to construction sites—to maintain safe electrical connections without hesitation about their equipment's performance under pressure or adverse conditions. As you explore options for enhancing workplace safety through effective use of technology like explosion proof systems; remember that partnering with reputable manufacturers can make all the difference.

In summary, understanding various product types within Explosion Proof Plugs, Connectors, and Cord Caps helps streamline decision-making processes while fostering safer operational practices across industries reliant on electricity amidst hazardous situations.

Conclusion

In the world of industrial safety, understanding explosion proof technology is paramount. With the proper knowledge and equipment, businesses can significantly reduce risks associated with hazardous environments. This conclusion will summarize key takeaways regarding explosion proof safety, explore future trends in the industry, and highlight how Jinrong can support your business growth.

Key Takeaways on Explosion Proof Safety

The significance of an explosion proof plug and socket cannot be overstated; they are essential for preventing catastrophic incidents in volatile environments. Understanding what is an explosion proof plug? is crucial for anyone working in industries where flammable materials are present. Additionally, knowing what is explosion proof for electrical systems ensures that companies invest in the right safety measures to protect both their employees and assets.

Another critical aspect of explosion proof safety involves recognizing certification standards such as ATEX. What is an ATEX plug? plays a vital role in ensuring that equipment meets stringent safety requirements for specific environments. Companies must also consider what is the safest plug socket in the world? when selecting products to ensure maximum protection against potential electrical hazards.

Future Trends in Explosion Proof Technology

As industries evolve, so too does technology related to explosion proof plugs, connectors, and cord caps. The future holds exciting advancements such as increased automation and smarter monitoring systems designed to enhance safety measures further. Innovations will likely focus on improving connectivity while maintaining compliance with rigorous standards like ATEX.

Moreover, sustainability will become a driving force behind new designs and materials used in creating safe electrical connections. Companies will increasingly seek environmentally friendly solutions without compromising on safety features or performance capabilities of their explosion proof equipment. By staying ahead of these trends, businesses can ensure they remain competitive while prioritizing worker safety.

How Jinrong Can Help Your Business Grow

Jinrong stands out as a leading manufacturer specializing in high-quality explosion proof plugs and sockets tailored to various industrial applications. By partnering with Jinrong, companies gain access to cutting-edge technology that adheres strictly to international standards like ATEX certification—ensuring reliable performance even under extreme conditions.

With a commitment to innovation and quality assurance, Jinrong provides customized solutions designed specifically for your operational needs—helping you navigate challenges associated with hazardous environments effectively. Investing in Jinrong's products not only enhances workplace safety but also fosters business growth through improved efficiency and reduced downtime caused by accidents or equipment failures.