Introduction

Understanding hazardous location enclosures is crucial for ensuring safety and protecting critical assets in industrial settings. These enclosures are designed to prevent the ignition of flammable gases, vapors, and dust in Class I Div 2 or Class I Div 1 locations, making them essential for industries with potentially explosive atmospheres. By using explosion-proof or ATEX explosion-proof enclosures, businesses can benefit from enhanced safety measures and compliance with industry standards.

Understanding Hazardous Location Enclosures

Hazardous location enclosures are specifically engineered to contain any potential explosions within the enclosure itself, preventing them from igniting the surrounding dangerous atmosphere. These enclosures are commonly used in areas with flammable substances, such as chemical plants and oil refineries.

Importance of Protecting Critical Assets

Hazardous environments present a significant risk to critical assets, with a single spark or ignition source potentially leading to devastating consequences. Here's why robust protection strategies are crucial:

- Safety First: Protecting personnel working in these areas is paramount. Proper safeguards minimize the risk of injury or death from explosions or fires.

- Asset Preservation: Critical equipment failures due to hazardous conditions can be extremely costly. Proper enclosures prevent damage and ensure operational continuity.

- Environmental Protection: Equipment failure in hazardous environments can lead to environmental contamination. Protecting assets helps mitigate these risks.

Depending on the specific hazard level, utilizing Class I Div II or Class I Div 1 enclosures is an essential step in safeguarding equipment and personnel in these high-risk areas. By implementing appropriate protection measures, we can minimize the potential for disaster and ensure the safety of our people, assets, and the environment.

Benefits of Using Hazardous Location Enclosures

Hazardous location enclosures offer significant advantages that go far beyond just following regulations. Here are some key benefits:

- Enhanced Safety: Hazardous location enclosures are designed to contain explosions or fires within the enclosure, preventing them from spreading to the surrounding environment and protecting personnel from harm.

- Equipment Protection: These enclosures shield valuable equipment from hazardous materials like dust, corrosive fumes, or flammable liquids, extending equipment lifespan and reducing maintenance costs.

- Reduced Downtime: Hazardous location enclosures help businesses maintain operational continuity and minimize downtime due to repairs or replacements by preventing equipment damage and mitigating the risk of accidents.

Investing in quality hazardous location enclosures is wise for businesses operating in dangerous environments. These enclosures promote safety, protect equipment, and promote a healthy bottom line.

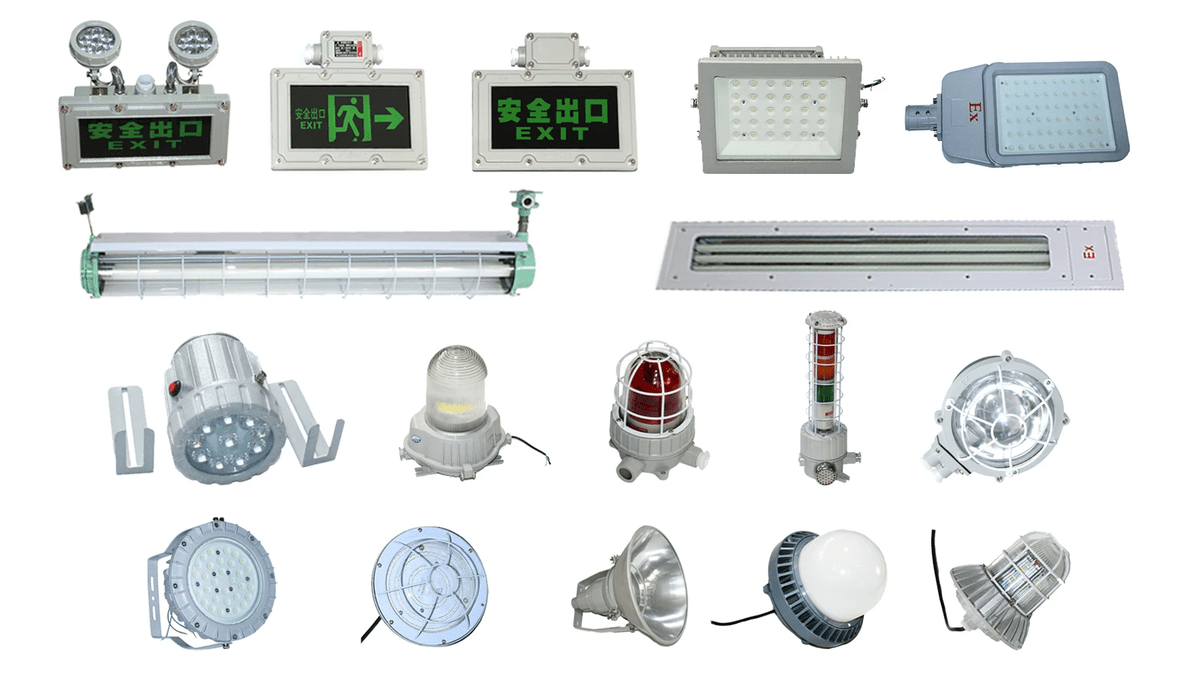

Types of Hazardous Location Enclosures

Several types of enclosures are used to protect critical assets in hazardous locations. These include explosion-proof enclosures, flameproof enclosures, and increased safety enclosures. Each type is designed to provide a specific level of protection against potential hazards such as flammable gases, vapors, and dust.

Explosion Proof Enclosures

Explosion-proof enclosures are specifically engineered to contain any internal explosion without allowing it to propagate outside the enclosure. They are commonly used in Class I Div 1 and Class I Div 2 hazardous locations where flammable gases or vapors may be present. These robust enclosures are designed to withstand harsh environments and provide high protection for electrical components.

Explosion-proof enclosures are essential for ensuring the safety of personnel and equipment in hazardous environments. By containing internal explosions, these enclosures prevent fire spread and protect against potential damage or injury. This level of protection is crucial in industries such as oil and gas, chemical processing, and mining, where the presence of flammable substances poses a constant risk.

Flameproof Enclosures

Flameproof enclosures are another type of hazardous location enclosure designed to prevent the ignition of flammable gases or vapors within the enclosure from causing an explosion outside the enclosure. They are commonly used in Class I Division II locations where the presence of flammable substances is less frequent but still possible. These enclosures offer a reliable solution for protecting electrical equipment in hazardous areas.

Flameproof enclosures are known for their robust construction and ability to withstand high temperatures and pressure, making them an ideal choice for hazardous environments. These enclosures are meticulously designed to contain any potential explosions within the enclosure, ensuring the safety of personnel and equipment. With their reliable performance and adherence to strict safety standards, flameproof enclosures provide peace of mind in volatile work settings.

Increased Safety Enclosures

Increased safety enclosures provide higher protection for electrical components by minimizing the risk of sparks or excessive temperatures that could ignite flammable substances in the surrounding atmosphere. They are commonly used in Class I Division II and ATEX explosion-proof areas where additional protective measures are required to ensure safety.

Key Features to Look for

When selecting a hazardous location enclosure, it's crucial to prioritize robust construction to withstand the harsh conditions of industrial settings. Look for enclosures made from durable materials such as stainless steel or aluminum, with reinforced seams and robust locking mechanisms to ensure the safety of critical assets.

Robust Construction

The robust construction of an enclosure ensures that it can effectively contain any potential explosion or fire within, protecting personnel and equipment in hazardous environments. Enclosures designed for Class I Div 1 and Class I Div 2 locations must meet stringent safety standards and undergo rigorous testing to ensure their durability and reliability.

The robust construction of an enclosure not only ensures safety in hazardous environments but also provides long-term durability, reducing the need for frequent maintenance and replacement. This reliability is crucial for industries where downtime can be costly and disruptive. Additionally, the sturdy design of these enclosures can offer peace of mind to personnel working in potentially dangerous locations, knowing that a robust barrier protects them.

Corrosion Resistance

Corrosion resistance is another key feature when choosing a hazardous location enclosure, especially in industries such as oil and gas or chemical plants where exposure to corrosive substances is everyday. Look for enclosures with protective coatings or materials that can withstand the corrosive effects of chemicals, moisture, and other environmental factors.

Temperature Ratings

Temperature ratings ensure the hazardous location enclosure can withstand extreme temperatures without compromising its structural integrity. The enclosure must maintain its protective properties under varying temperature conditions, whether it's extreme heat in a refinery or frigid cold in a pharmaceutical facility.

Extreme temperatures can cause materials to expand and contract, leading to potential weaknesses in the enclosure's structure. Therefore, it's crucial to select an enclosure with temperature ratings that align with the specific environmental conditions of your facility. This proactive approach will help mitigate the risk of equipment failure and ensure continuous protection of your assets in hazardous locations.

By prioritizing these key features when selecting a hazardous location enclosure, you can ensure the safety and protection of your critical assets in volatile environments while complying with industry standards.

Applications of Hazardous Location Enclosures

Oil and Gas Industry

Hazardous location enclosures play a crucial role in the oil and gas industry, where flammable gases and vapors are often present. Class I Division 2 enclosures are commonly used to protect critical equipment in these environments, ensuring safe operations and compliance with industry regulations.

Hazardous location enclosures play a crucial role in the oil and gas industry, where flammable gases and vapors are often present. Class I Division 2 enclosures are commonly used to protect critical equipment in these environments, ensuring safe operations and compliance with industry regulations. These enclosures are designed to withstand harsh conditions, such as extreme temperatures and corrosive substances, providing a reliable barrier against potential hazards. In addition, they are equipped with features such as explosion-proof seals and secure locking mechanisms to enhance safety measures in the oil and gas facilities.

Chemical Plants

The presence of hazardous materials in chemical plants increases the risk of explosion or fire. Class I Division II enclosures provide the necessary protection for electrical components, preventing ignition sources from causing potential disasters in these facilities.

Pharmaceutical Facilities

Pharmaceutical facilities require reliable protection against combustible specks of dust and flammable liquids to maintain a safe working environment. Explosion-proof enclosures are essential in these settings, ensuring that electrical equipment can operate without posing a risk to personnel or products.

Pharmaceutical facilities must also consider the potential for corrosion in their equipment due to exposure to harsh chemicals and cleaning agents. Stainless steel enclosures are an ideal choice for these environments, providing superior resistance to corrosion and ensuring the longevity of electrical components. Additionally, stainless steel enclosures are easy to clean and maintain, helping to uphold strict cleanliness standards in pharmaceutical facilities.

Choosing the Right Enclosure for Your Needs

When it comes to selecting the right hazardous location enclosure, it's crucial to consult with experts who understand your industry's specific requirements. Whether you're dealing with Class I Div 2 or ATEX explosion-proof environments, expert advice can help you navigate the complexities and find the perfect solution for your needs.

Consultation with Experts

Consulting with experts in hazardous location enclosures ensures you choose the right product for your specific environment. With their in-depth knowledge of Class I Div II and Class I Division 2 requirements, these professionals can provide valuable insights into the best enclosure options that meet your industry's safety standards and regulatory compliance.

By consulting with experts in hazardous location enclosures, you can gain valuable insights into the specific environmental factors that may impact the performance and safety of your chosen product. Their in-depth knowledge of Class I Div II and Class I Division 2 requirements allows them to offer customized solutions tailored to your industry's needs. This level of customization ensures that you are meeting safety standards and regulatory compliance and optimizing the enclosure's functionality in your unique environment.

Customization Options

Customization options are also a key factor in choosing the proper hazardous location enclosure. Whether you need a specific size, material, or additional features such as temperature control or corrosion resistance, having the ability to customize your enclosure ensures that it meets all your unique needs and provides optimal protection for critical assets. In addition to these features, customization options can include specialized mounting solutions, maintenance access points, and monitoring equipment visibility requirements. These customizations ensure that the enclosure protects against hazardous conditions and allows for easy access and monitoring.

Compliance with Industry Standards

Compliance with industry standards such as Class I Div 1 and explosion-proof ratings is non-negotiable when selecting a hazardous location enclosure. Ensuring that your chosen enclosure meets all necessary certifications and standards will guarantee the protection required for your specific dangerous environment.

Safety should always be the top priority when it comes to hazardous location enclosures. That's why ensuring compliance with industry standards is crucial in protecting your dangerous specific environment. By adhering to these standards, you can have peace of mind knowing that your chosen enclosure meets all necessary certifications and ratings, minimizing the risk of potential hazards in the workplace.

Maintaining and Servicing Hazardous Location Enclosures

Regular Inspections

Regular inspections are crucial to ensuring the ongoing safety and reliability of hazardous location enclosures. Class I Division 2, also known as Class I Div 2 or Class I Div II, requires thorough checks for any signs of damage or wear. These inspections help identify potential hazards and address them before they become a problem.

Proper Cleaning and Maintenance

Proper cleaning and maintenance of hazardous location enclosures are essential for their longevity and effectiveness of dangerous environments. Whether it's an explosion-proof or ATEX explosion-proof enclosure, regular cleaning helps to prevent the buildup of debris and contaminants that could compromise its integrity. This ensures that the enclosure continues to provide the necessary protection for critical assets.

Jinrong's Expertise in Ex-Proof Manufacturing

As a leader in ex-proof manufacturing, Jinrong offers unparalleled expertise in producing high-quality hazardous location enclosures. Their extensive knowledge of Class I Division 1 (Class I Div 1) and Class I Division II (Class I Div II) requirements allows them to design and manufacture enclosures that meet the most stringent industry standards. With Jinrong, you can trust that your hazardous location enclosures are in capable hands.

Ensure Safety and Compliance with Hazardous Location Enclosures

When it comes to ensuring safety and compliance with hazardous location enclosures, choosing the right solution for your specific needs is crucial. Whether you require Class I Div 1 or Class I Div 2 enclosures, you must partner with a trusted manufacturer like Jinrong for quality solutions that meet ATEX explosion-proof standards. Investing in protective measures safeguards your assets and ensures long-term benefits for your operations.

Protecting critical assets in hazardous environments requires a deep understanding of dangerous location enclosures' different classes and divisions. It's essential to ensure that the chosen enclosure meets the specific requirements of your industry, whether it's Class I Div II or Class I Division 2. By partnering with Jinrong, you can rest assured that your hazardous location enclosure is designed and manufactured to the highest safety and compliance standards.

Partnering with Jinrong for Quality Solutions

Choosing the proper manufacturer for your hazardous location enclosure is crucial in guaranteeing the safety and reliability of your operations. With Jinrong's expertise in explosion-proof manufacturing, you can customize enclosures to fit your unique needs while adhering to industry standards such as explosion-proof and corrosion-resistance requirements. Partnering with Jinrong means investing in quality solutions that prioritize safety without compromising performance.

Long-term Benefits of Investing in Protective Measures

Protecting your equipment in hazardous environments is critical for business continuity. Hazardous location enclosures offer several advantages to ensure your equipment functions safely and reliably.

Here are some key benefits of implementing robust enclosures:

- Enhanced Asset Protection: Durable enclosures safeguard your critical equipment from physical damage, corrosion, and extreme temperatures.

- Ensured Operational Continuity: By preventing equipment failure, enclosures help maintain uninterrupted operations and avoid costly downtime.

- Sustainable Investment: Jinrong's high-quality enclosures are designed for long-lasting performance, maximizing your return on investment.

Invest in peace of mind with Jinrong's hazardous location enclosures. Contact us today to discuss your specific needs and ensure your equipment receives the protection it deserves.