Introduction

In the world of electrical equipment, understanding NEMA ratings is crucial for ensuring safety and compliance in hazardous environments. NEMA, which stands for the National Electrical Manufacturers Association, provides a set of standards that help identify how well equipment can withstand various environmental conditions. This becomes particularly important when discussing what NEMA rating is explosion-proof, as these ratings play a pivotal role in protecting both personnel and property from potentially catastrophic incidents.

Understanding NEMA Ratings Basics

NEMA ratings are designed to specify the suitability of electrical enclosures for different environments, including those with explosive atmospheres. Among these ratings, certain classifications indicate whether equipment can be considered explosion-proof or flame-proof. For instance, while many might wonder if NEMA 6 is explosion-proof or if NEMA 4X is flame proof, it’s essential to grasp the technical details behind each rating to make informed decisions.

The Importance of Explosion-Proof Ratings

Explosion-proof ratings are not just regulatory checkboxes; they are vital for ensuring safety in industries where flammable gases or dust may be present. Equipment marked with a suitable NEMA explosion proof rating significantly reduces the risk of ignition and subsequent explosions in hazardous locations. Understanding these ratings helps businesses comply with safety regulations while protecting their employees and assets.

Overview of NEMA and ATEX Standards

While NEMA standards dominate in North America, ATEX (ATmosphères EXplosibles) regulations govern equipment used in explosive atmospheres across Europe. Many professionals often ask: Is ATEX the same as explosion-proof? While both aim to enhance safety by certifying equipment for hazardous environments, their criteria and applications differ significantly. Knowing when to use either standard can make all the difference in maintaining compliance and ensuring operational safety.

What NEMA Rating Is Explosion-Proof?

When it comes to safety in hazardous environments, understanding what NEMA ratings are explosion-proof is crucial. The term explosion-proof refers to a design that can contain an internal explosion and prevent it from igniting external explosive atmospheres. This means that equipment bearing a NEMA explosion proof rating has been engineered to minimize the risk of explosions in potentially dangerous settings.

Defining Explosion-Proof in NEMA Terms

In NEMA terms, explosion-proof is not just a catchy phrase; it's a serious classification that indicates how equipment will perform under extreme conditions. Specifically, it means the enclosure can withstand an internal explosion without allowing flames or hot gases to escape. This is vital for industries where flammable gases or dust are present, ensuring both worker safety and compliance with regulations.

Common NEMA Ratings for Hazardous Locations

Several common NEMA ratings help identify equipment suitable for hazardous locations, but not all of them are classified as explosion-proof. For instance, while NEMA 7 and 9 ratings explicitly denote explosion-proof capabilities, others like NEMA 4X focus on water and corrosion resistance rather than explosive containment. To answer the question: What NEMA rating is explosion-proof?, look primarily at these specialized classifications designed for safety in volatile environments.

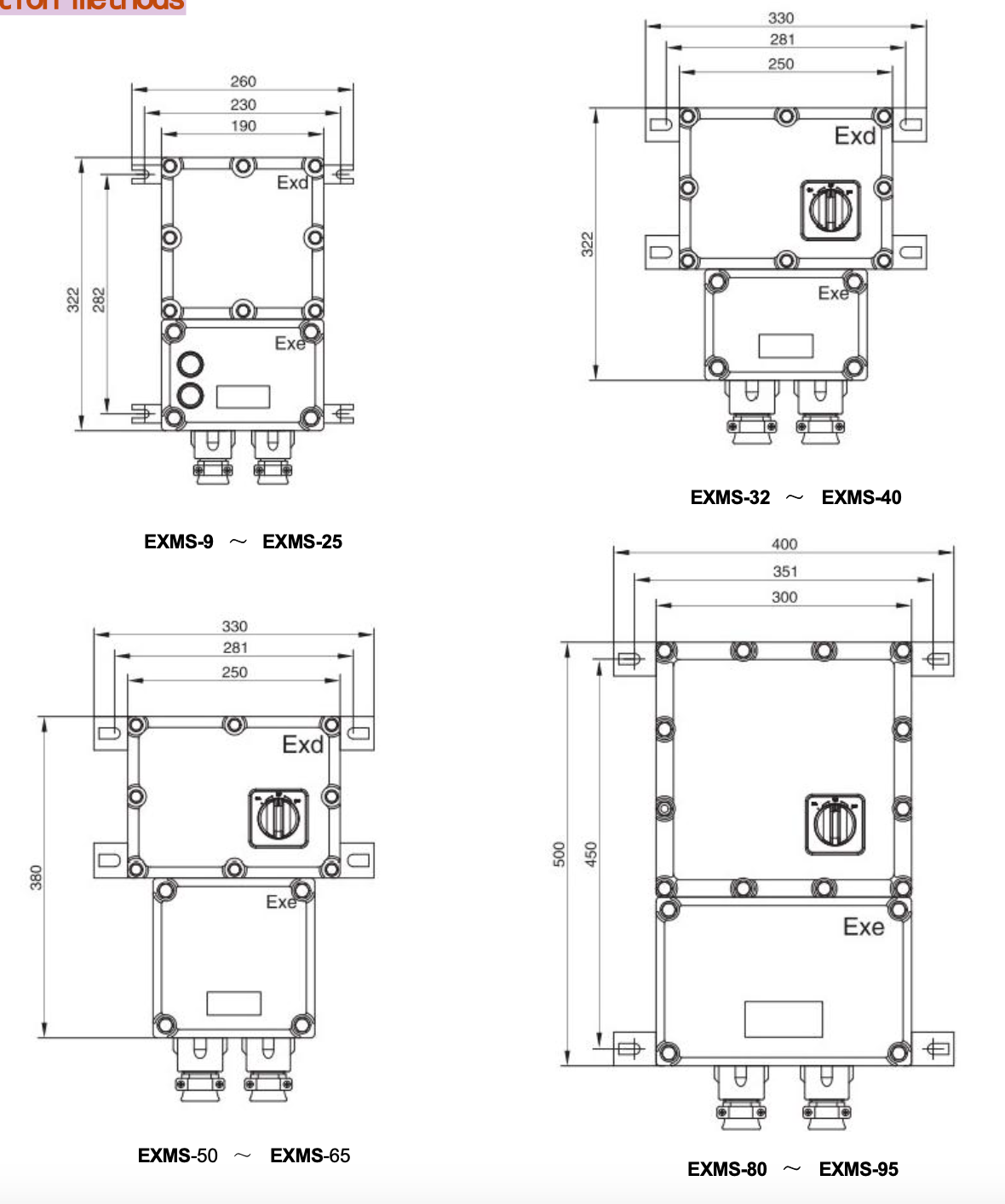

Examples of Equipment with NEMA Explosion-Proof Ratings

Equipment with NEMA explosion proof ratings includes various types of electrical enclosures, junction boxes, and lighting fixtures specifically designed for hazardous areas. For example, you might find explosion-proof motors and switches used in oil refineries or chemical plants where volatile substances are commonplace. These devices ensure that even if an internal failure occurs, the risk of igniting surrounding materials remains minimal.

Is NEMA 6 Explosion-Proof?

When discussing NEMA ratings, it’s essential to clarify what qualifies as explosion-proof. This leads us to the question: Is NEMA 6 explosion-proof? Understanding the NEMA 6 classification is crucial for anyone working in environments where safety and compliance are paramount.

NEMA 6 Classification Explained

NEMA 6 is classified as a type of enclosure that provides protection against water and dust ingress, but it does not inherently mean it is explosion-proof. Specifically, NEMA 6 enclosures can withstand temporary submersion in water and are designed to prevent the entry of both dust and moisture. However, when we ask What NEMA rating is explosion-proof?, we need to consider other classifications that explicitly indicate capabilities against explosive atmospheres.

While NEMA 6 offers robust protection from environmental factors, it does not meet the stringent requirements outlined for true explosion-proof ratings like those found in classes such as NEMA 7 or 9. Therefore, if you’re looking for equipment that can operate safely in hazardous locations with flammable gases or dust, you’ll need to look beyond just the NEMA 6 rating.

Practical Applications for NEMA 6 Equipment

Despite its limitations regarding explosion-proof capabilities, NEMA 6-rated equipment has practical applications across various industries. For instance, it's commonly used in outdoor settings where exposure to rain or splashing water could compromise less-protected devices. This makes it ideal for applications in wastewater treatment facilities or marine environments where moisture resistance is critical.

Moreover, many manufacturing plants utilize NEMA 6 enclosures for control panels and electrical equipment located near washdown areas or within humid environments. While they might not be classified as nema explosion proof, their durability ensures reliable operation without compromising safety standards in non-explosive settings.

Comparing NEMA 6 to Other Ratings

When comparing NEMA ratings, particularly with regards to hazardous environments, it's important to understand how different classifications measure up against each other. For example, while both NEMA 4X and NEMA 6 provide excellent protection from water intrusion, only certain ratings like ATEX-certified equipment can guarantee safety against explosive atmospheres—raising the question: Is ATEX the same as explosion-proof?

In contrast with other ratings such as NEMA 7 or even some ATEX-rated enclosures which are specifically designed for flammable gas environments, a simple comparison reveals that while all these ratings serve distinct purposes within their realms of application; they do not overlap entirely when it comes down to safety against explosions.

In summary, while asking Is NEMA 6 explosion-proof? might seem straightforward at first glance due to its robust protective features; understanding its limitations compared with more specialized ratings is essential for ensuring workplace safety.

Is NEMA 4X Flame-Proof?

When it comes to understanding the nuances of NEMA ratings, one question often arises: Is NEMA 4X flame-proof? The answer is a bit more complex than a simple yes or no. While NEMA 4X does provide robust protection against various environmental factors, it isn't classified as explosion-proof in the traditional sense.

Understanding NEMA 4X Specifications

NEMA 4X is designed for equipment that needs to withstand harsh conditions, including moisture and corrosion. This rating signifies that the enclosure can protect against water ingress from any direction and can also resist corrosion from chemicals and other environmental factors. However, while it excels in protective features, it's essential to clarify that NEMA 4X does not inherently provide explosion-proof capabilities like some other ratings do.

Flame-Resistant Features of NEMA 4X

While discussing whether NEMA 4X is flame-proof, it's vital to highlight its flame-resistant characteristics. Equipment rated under NEMA 4X can resist flames and prevent ignition in the presence of flammable materials, which is crucial for safety in hazardous environments. Nonetheless, being flame-resistant does not equate to being explosion-proof; thus, those working with potentially explosive substances should consider additional certifications alongside their NEMA ratings.

Industries That Benefit from NEMA 4X

Various industries find immense value in utilizing equipment with a NEMA 4X rating due to its durability and resistance to corrosive elements. Chemical processing plants, food and beverage manufacturing facilities, and marine applications are just a few sectors where this rating shines bright. In these environments where moisture and chemicals abound, having reliable equipment helps maintain safety standards without compromising functionality.

ATEX vs. NEMA: Are They the Same?

When navigating the world of hazardous location equipment, understanding the differences between ATEX and NEMA is crucial. While both standards aim to enhance safety in environments prone to explosions, they originate from different regulatory frameworks and cater to distinct geographical markets. So, what’s the real story behind these two systems? Let’s dive into their key differences and implications.

Key Differences Between ATEX and NEMA

The primary distinction between ATEX and NEMA lies in their origins and focus areas. ATEX, which stands for ATmosphères EXplosibles, is a European directive that governs equipment used in potentially explosive atmospheres within EU countries. On the other hand, NEMA ratings are developed by the National Electrical Manufacturers Association in the United States, focusing on electrical enclosure types and their protection levels against environmental conditions.

Another notable difference is how each standard defines explosion-proof capabilities. While both standards aim for safety, what qualifies as explosion-proof under NEMA might not meet ATEX's stringent criteria for certification—especially when we ask ourselves, “Is ATEX the same as explosion-proof?” In essence, while both standards address safety concerns in hazardous locations, they do so through different lenses.

Global Standards and Their Implications

Understanding global standards like ATEX and NEMA is essential for manufacturers aiming to market their products internationally. Companies must ensure compliance with local regulations to avoid costly penalties or product recalls due to non-compliance with safety standards. For instance, if you're selling equipment designed with a specific NEMA explosion proof rating in Europe without obtaining an appropriate ATEX certification, you may find yourself facing significant roadblocks.

Moreover, navigating these regulations can be tricky; manufacturers must decide whether to pursue one standard over another based on target markets or specific applications of their equipment. This decision can impact everything from design processes to marketing strategies—so it's essential to weigh your options carefully! Ultimately, understanding these global standards can lead you toward better market positioning while ensuring safety compliance across borders.

When to Use ATEX or NEMA Certifications

Choosing between ATEX or NEMA certifications depends largely on where your equipment will be used and sold. If you’re operating within Europe or working with clients who require compliance with EU regulations, then opting for an ATEX certification makes perfect sense—especially if you're dealing with questions like “What NEMA rating is explosion-proof?” But if your target audience lies primarily within North America or regions adhering closely to U.S.-based codes, then focusing on obtaining a suitable NEMA rating will be more beneficial.

Additionally, consider industry-specific requirements when making this choice; certain sectors may have preferences for one standard over another due to historical practices or existing partnerships with suppliers compliant with either system. For example: Is NEMA 6 explosion-proof? Yes! But it may not align perfectly with all international requirements that an ATEX-rated device would fulfill.

In summary, knowing when to use either standard can significantly influence your operational success while enhancing overall safety measures through appropriate certifications tailored specifically for various environments.

Choosing the Right NEMA Rating for Your Equipment

Selecting the appropriate NEMA rating for your equipment is crucial, especially when dealing with hazardous environments. The right rating ensures compliance with safety standards and protects both personnel and equipment from potential explosions or damage. With various NEMA ratings available, understanding which one suits your needs can be a daunting task, but it’s essential for maintaining safety and efficiency.

Factors to Consider for NEMA Ratings

When deciding on a NEMA explosion-proof rating, several factors come into play. First, consider the environment where the equipment will be used—will it be exposed to moisture, dust, or corrosive substances? Additionally, assess the specific hazards present; knowing What NEMA rating is explosion-proof? can guide you in selecting equipment that meets those challenges effectively.

Another important factor is temperature; certain NEMA ratings are designed to withstand higher temperatures than others. For example, if you're working in a high-temperature area where ignition risks are prevalent, you might want to explore ratings like NEMA 7 or 9. Ultimately, understanding these factors will help ensure that your equipment not only complies with regulations but also performs reliably under pressure.

Common Mistakes in NEMA Rating Selection

One of the most common mistakes companies make is assuming that all explosion-proof ratings are interchangeable. For instance, many people wonder: Is NEMA 6 explosion-proof? While it offers excellent water resistance and protection against dust ingress, it's not specifically classified as explosion-proof like some other ratings such as NEMA 7 or 9. Misunderstanding these distinctions can lead to improper selections that jeopardize safety.

Another frequent pitfall involves neglecting environmental conditions when choosing a rating. Just because an item has a certain level of protection doesn’t mean it’s suitable for every situation; failing to consider factors like humidity or chemical exposure can result in costly damages down the line. Always conduct thorough assessments before making decisions about which rating best fits your unique requirements.

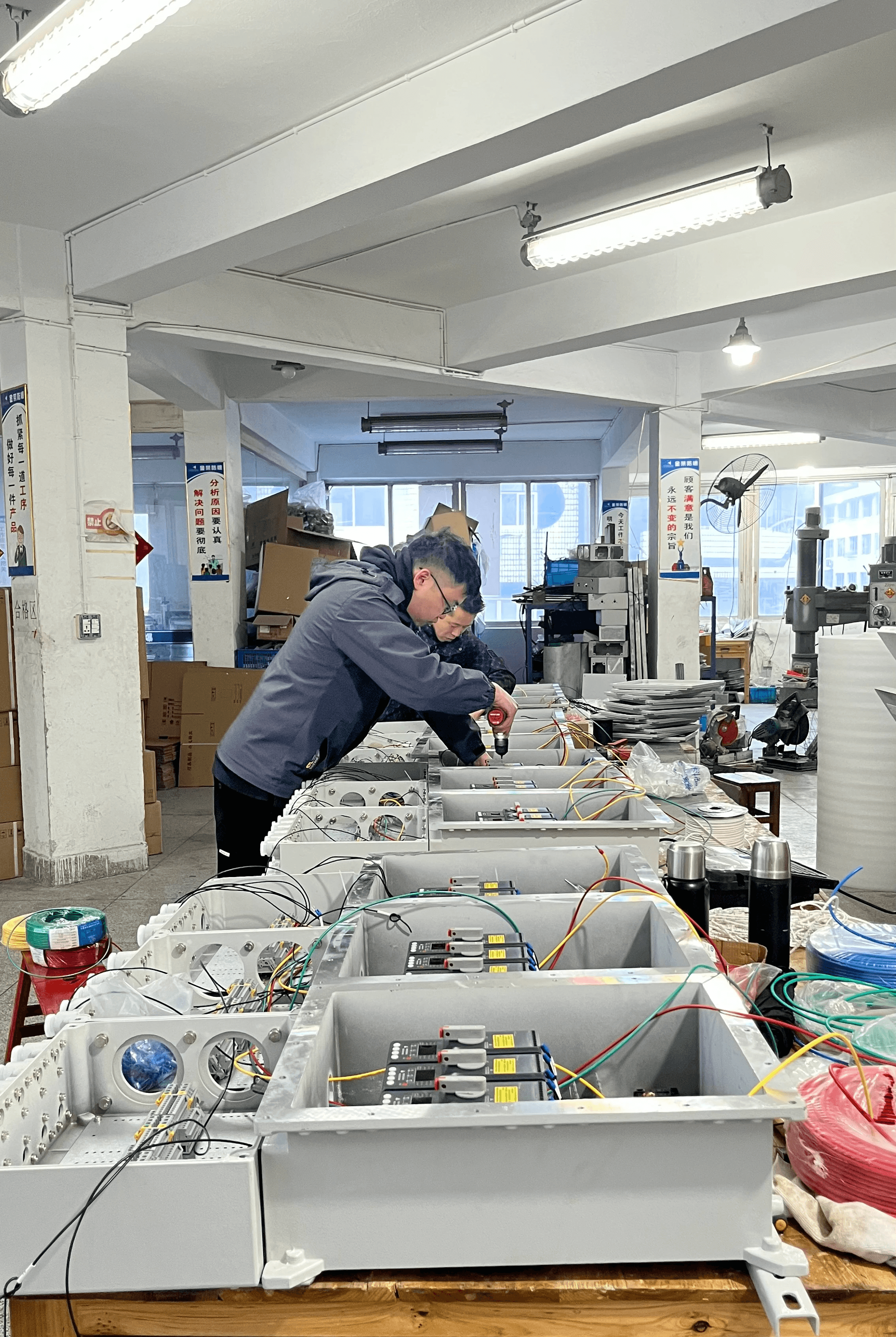

How Jinrong Can Help with NEMA Compliance

Navigating through the maze of NEMA ratings can be overwhelming—but that's where Jinrong steps in! Our team specializes in helping businesses understand their compliance needs related to Is ATEX the same as explosion-proof? We provide tailored solutions that clarify how various standards apply to your operations and what specific ratings you should pursue.

With our expertise in evaluating environments and recommending suitable equipment based on proper classifications—like whether Is NEMA 4X flame proof?—we ensure you're well-informed throughout the process. By partnering with us at Jinrong, you gain peace of mind knowing that your choices align with industry standards while enhancing workplace safety.

Conclusion

In summary, understanding NEMA explosion-proof ratings is crucial for ensuring safety in hazardous environments. These ratings define the ability of electrical equipment to withstand potential explosions, thus protecting both personnel and property. Knowing what NEMA rating is explosion-proof helps in selecting the right equipment for specific applications, particularly in industries where flammable substances are present.

Recap of NEMA Explosion-Proof Ratings

NEMA ratings serve as a benchmark for assessing the safety and reliability of electrical equipment in potentially explosive atmospheres. Among these, certain classifications explicitly denote explosion-proof capabilities, such as NEMA 7 and 9, designed for use in Class I and II locations respectively. Additionally, while exploring whether Is NEMA 6 explosion-proof?, we find that it primarily offers protection against water and dust ingress rather than explosive hazards.

The Necessity of Understanding NEMA Standards

Understanding NEMA standards is not just a regulatory requirement; it’s an essential practice that can save lives and prevent costly accidents. By grasping the differences between various ratings—such as Is NEMA 4X flame proof?—users can make informed decisions about the equipment they choose for their operations. Moreover, awareness of global standards like ATEX allows companies to align their practices with international safety regulations, ensuring compliance across borders.

Enhancing Safety with Proper NEMA Ratings

Properly selecting equipment based on accurate NEMA explosion proof ratings enhances workplace safety significantly. When businesses prioritize understanding which ratings apply to their environments—like discerning if ATEX is the same as explosion-proof—they create a safer atmosphere for employees handling hazardous materials. Ultimately, investing time into learning about these standards pays off through minimized risks and improved operational integrity.