Introduction

In the complex and often hazardous environment of refineries, safe LED lighting is not just a luxury—it's a necessity. Proper illumination is critical for ensuring the safety of workers and maintaining operational efficiency. As refineries continue to modernize, the shift to LED lighting for refineries has become increasingly popular due to its myriad benefits.

Importance of Safe LED Lighting in Refineries

Safety is paramount in any industrial setting, especially in refineries where flammable materials are present. Safe LED lighting plays a crucial role in preventing accidents and ensuring that workers can navigate their surroundings without risk. Moreover, effective lighting enhances visibility for maintenance tasks and emergency situations, underscoring its importance in refinery operations.

The Shift to LED Lighting for Refineries

The transition from traditional lighting systems to LED lighting for refineries marks a significant advancement in energy efficiency and safety standards. LEDs consume less power while providing superior brightness, which leads to reduced energy costs—a vital consideration when evaluating Are LED lights profitable? This shift not only helps meet environmental regulations but also promotes sustainability within the oil and gas sector.

Key Considerations in LED Lighting Choices

When selecting the right refinery LED lighting solutions, several factors must be taken into account, including lumen output and compatibility with existing systems. Questions like What is a good lumen for LED lights? become essential as they directly impact performance and safety. Additionally, understanding What is a power supply for LED lights? ensures that chosen fixtures will operate effectively within the refinery’s infrastructure.

Understanding LED Lighting for Refineries

When it comes to illuminating hazardous environments like refineries, understanding LED lighting is crucial. These lights not only enhance visibility but also play a pivotal role in safety and efficiency. With the right knowledge, refinery operators can leverage LED technology to create a safer workplace.

Benefits of LED Lighting in Hazardous Areas

LED lighting offers several advantages in hazardous areas typical of refineries. First off, they produce less heat compared to traditional lighting, reducing the risk of fire hazards—a significant concern in oil and gas settings. Additionally, their durability means fewer replacements are needed, which translates into lower maintenance costs over time.

Moreover, LED lights are highly energy-efficient, which is particularly beneficial for facilities looking to cut down on operational expenses. This brings us to the question: **Are LED lights profitable?** Absolutely! The long lifespan and reduced energy consumption make them a wise financial choice for refinery operators aiming for sustainability without sacrificing safety.

Lastly, LEDs provide instant illumination without flickering or warm-up time—essential features when immediate visibility is crucial during emergencies or routine operations in oil and gas environments.

Key Features of LED Lighting for Refineries

Understanding the key features of LED lighting for refineries helps in making informed decisions about installations. One standout feature is their high lumen output relative to power consumption; this leads us to ponder **what is a good lumen for LED lights?** Generally speaking, a higher lumen count translates into brighter light—ideal for illuminating expansive refinery spaces where visibility can be compromised.

Another important aspect is their robust construction designed specifically for challenging conditions found in refineries. Many models come with weatherproofing and resistance to corrosive elements common in oil and gas operations. This ensures that your investment stands the test of time against harsh environments while providing reliable performance.

Finally, LEDs are available with various color temperatures that can be tailored to specific tasks within the refinery setting—whether you need bright white light for detailed inspections or softer tones that reduce glare during long shifts.

Safety Standards for LED Lighting

Safety standards play an essential role when selecting LED lighting solutions for refineries. Compliance with regulations such as those set by ATEX (for explosive atmospheres) ensures that your chosen lighting meets rigorous safety criteria necessary in hazardous locations like oil rigs or processing plants.

Many manufacturers have adopted these standards diligently; this brings us back to why many lights manufacturers are choosing LED for lights—they offer enhanced safety features alongside energy efficiency that traditional options simply cannot match.

Furthermore, it's vital that any installed systems undergo regular inspections and maintenance checks to ensure they continue meeting safety regulations over time—after all, safety should never take a backseat in high-risk environments like these!

Evaluating Lumen Output for Safety

When it comes to refinery LED lighting, understanding lumen output is crucial for ensuring safety and efficiency. The right level of brightness not only enhances visibility but also minimizes the risk of accidents in hazardous environments. In this section, we will delve into what constitutes a good lumen output for LED lights, how to balance brightness with energy efficiency, and the potential consequences of insufficient lumen levels.

What is a Good Lumen for LED Lights?

Determining what is a good lumen for LED lights in refineries can feel like navigating a maze. Generally speaking, higher lumen output equates to brighter lighting; however, the specific requirements can vary based on the application and area being illuminated. For instance, areas with heavy machinery or intricate operations may require upwards of 10,000 lumens to ensure optimal visibility and safety.

In contrast, general walkways or storage areas might only need around 2,000 to 5,000 lumens. It’s essential that refinery operators assess their unique needs when selecting LED lighting for refineries—after all, too little light can be just as hazardous as too much! By focusing on appropriate lumen levels tailored to their environment, facilities can create safer working conditions while maximizing productivity.

Balancing Brightness and Energy Efficiency

In the quest for ideal refinery LED lighting solutions, balancing brightness with energy efficiency becomes paramount. While it’s tempting to crank up the lumens for maximum illumination, doing so without considering energy use can lead to inflated operational costs—something no one wants in today's economy! The key lies in selecting fixtures that provide adequate brightness while also being energy-efficient.

Utilizing advanced technologies such as smart sensors or dimming capabilities allows refineries to optimize their lighting systems further. This strategic approach not only enhances safety but also contributes positively towards sustainability goals—a win-win situation! Manufacturers are increasingly recognizing this balance between illumination and efficiency as they innovate within the realm of LED lighting for oil and gas applications.

Impacts of Insufficient Lumen Output

The impacts of insufficient lumen output in refinery settings cannot be overstated; they can lead directly to dangerous situations that compromise worker safety and operational integrity. Low-light conditions may obscure hazards or make it difficult for personnel to perform critical tasks effectively—resulting in costly mistakes or accidents that could have been avoided with proper illumination standards met by quality LED lights.

Moreover, inadequate lighting can hinder emergency response efforts during critical incidents by reducing visibility when every second counts. Thus investing in high-quality LED Lighting for Refineries not only meets compliance standards but also fosters an environment where safety takes precedence over cost-cutting measures!

By evaluating lumen output carefully and making informed decisions about energy-efficient options available on the market today—refinery operators set themselves up not just for profitability but also long-term sustainability!

Cost-Effectiveness of LEDs

When it comes to refinery LED lighting, the financial implications can be as illuminating as the lights themselves. The transition from traditional lighting to LED lighting for refineries is not just about aesthetics; it's also about profitability. Understanding the cost-effectiveness of LEDs involves examining their initial investment, long-term savings, and overall return on investment.

Are LED Lights Profitable?

Absolutely! When evaluating if LED lights are profitable, consider both direct and indirect savings. While the upfront cost of LED lighting for refineries might seem higher than traditional options, the longevity and energy efficiency of LEDs often lead to significant cost reductions over time—making them a smart choice for any refinery operation.

In fact, many refiners find that their decision to switch to LED lighting pays off sooner than expected due to lower electricity bills and reduced maintenance costs. So yes, investing in refinery LED lighting is not just a trend; it's a financially savvy move that aligns with modern operational needs.

Long-Term Savings on Energy and Maintenance

One of the most compelling reasons to choose LED lighting for refineries is the substantial long-term savings on energy consumption and maintenance costs. LEDs consume significantly less power than conventional bulbs while providing higher lumen output—so what is a good lumen for LED lights? Generally, 100 lumens per watt or more is considered efficient in industrial applications.

Moreover, these lights have an impressive lifespan that can exceed 50,000 hours compared to traditional bulbs which may last only 1,000 hours or so. This means fewer replacements and less downtime—two critical factors in maintaining operational efficiency in oil and gas settings.

Return on Investment for Refinery Lighting

Calculating the return on investment (ROI) for switching to refinery LED lighting involves looking at several factors: energy savings, reduced labor costs associated with maintenance, and improved safety through better illumination standards. Many businesses report an ROI within two years due to decreased energy bills alone.

Furthermore, when considering what is a power supply for LED lights? It's essential that your power supply matches your new setup efficiently; this compatibility ensures that you're maximizing your investment by optimizing performance without additional costs down the line. In summary, making informed choices about LED lighting can yield lucrative returns while enhancing safety measures in refining operations.

Power Supply and Compatibility

When it comes to effective refinery LED lighting, understanding the power supply is crucial. The power supply for LED lights not only ensures that the lights function properly but also affects their overall performance and lifespan. Choosing the right power supply can make a significant difference in energy efficiency and operational safety within hazardous environments like refineries.

What is a Power Supply for LED Lights?

A power supply for LED lights converts electrical energy into a form that LEDs can use, typically transforming high voltage AC (alternating current) into low voltage DC (direct current). This conversion is essential because most LEDs operate on low voltage, which enhances their efficiency and longevity. In the context of LED lighting for refineries, selecting an appropriate power supply ensures that these lights perform optimally while adhering to safety standards.

Importance of Choosing the Right Power Supply

Choosing the right power supply is vital for several reasons, especially in refinery settings where safety cannot be compromised. An inadequate or incompatible power supply can lead to flickering lights, reduced lumen output, or even complete failure of your LED lighting system—none of which are desirable in a critical environment like an oil or gas facility. Furthermore, with questions like Are LED lights profitable? often arising due to initial costs, ensuring maximum efficiency through proper power supplies can significantly enhance long-term savings.

Compatibility with Existing Systems

Compatibility with existing systems is another key factor when considering refinery LED lighting solutions. Many facilities have legacy systems that may require specific types of power supplies or configurations to integrate seamlessly with new LED installations. By ensuring compatibility between your new LEDs and existing electrical infrastructure, you not only save on potential retrofitting costs but also maintain operational continuity—critical in industries where downtime can be costly.

The Manufacturer's Perspective

When it comes to lighting solutions in the oil and gas industry, manufacturers are increasingly turning to LED technology. This shift towards LED lighting for refineries is motivated by several factors, including energy efficiency, longevity, and safety. The advantages of LED lights make them a compelling choice for environments where hazardous conditions are prevalent.

Why Many Lights Manufacturers Choose LED for Lights

Many lights manufacturers are choosing LED for lights due to their superior energy efficiency compared to traditional lighting options. Refinery LED lighting not only reduces electricity costs but also minimizes heat output, which is crucial in preventing potential ignition sources in sensitive areas. Additionally, LEDs have a longer lifespan, which means less frequent replacements and lower maintenance costs—making the question of Are LED lights profitable? an emphatic yes!

Manufacturers recognize that investing in LED technology aligns with sustainability goals as well. With growing concerns about environmental impact, switching to more efficient lighting solutions resonates with both regulatory standards and corporate responsibility initiatives within the oil and gas sector. Thus, the trend toward adopting LED lighting for refineries reflects a broader commitment to innovation while ensuring compliance with safety regulations.

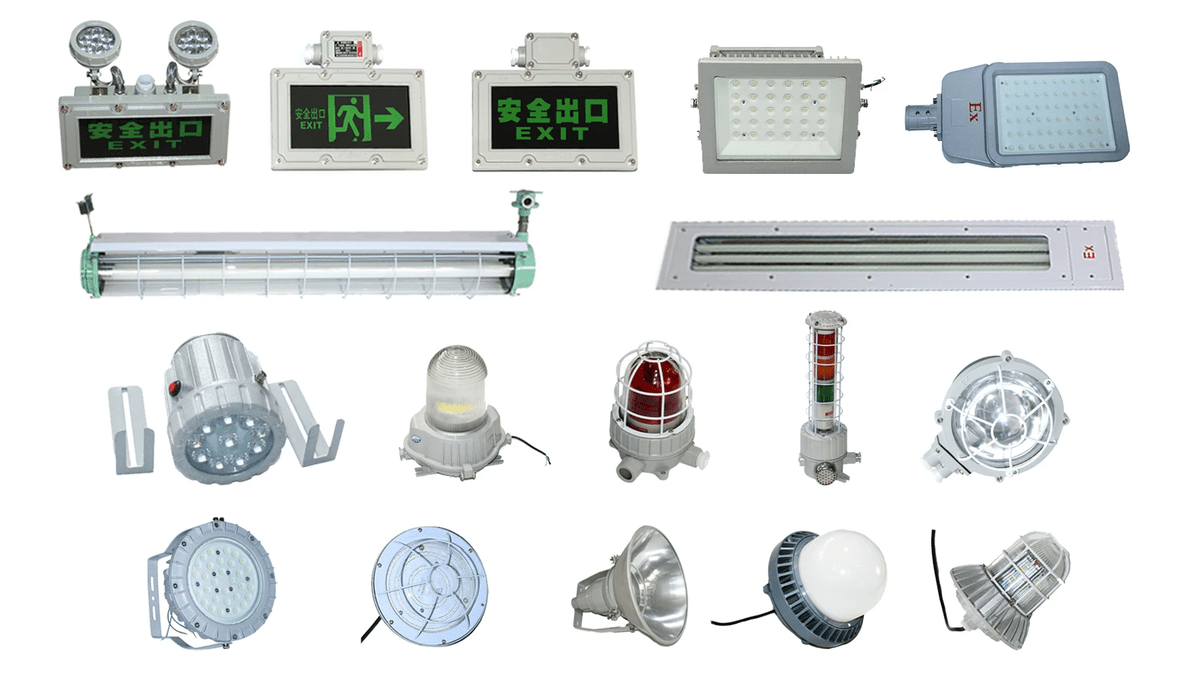

Jinrong’s Legacy in Ex-Proof Manufacturing

Jinrong has established itself as a leader in ex-proof manufacturing specifically tailored for hazardous environments like refineries. Their expertise ensures that every aspect of their products meets stringent safety standards required in these volatile settings. By focusing on quality and reliability, Jinrong’s refinery LED lighting solutions provide peace of mind alongside exceptional performance.

The company has continually evolved its product line by integrating cutting-edge technology with practical design principles that cater specifically to the needs of oil and gas facilities. This legacy not only enhances operational efficiency but also prioritizes worker safety—a critical component when discussing what is a power supply for LED lights designed for such environments. Jinrong's commitment ensures that every light they produce can withstand the rigors of refinery operations while maintaining optimal functionality.

Innovation and Safety in Oil and Gas Lighting

Innovation plays a pivotal role in enhancing safety within oil and gas operations through advanced lighting solutions like those offered by Jinrong. Their focus on developing high-quality refinery led lighting systems includes features such as robust construction materials that resist corrosion and impact damage—essential characteristics when addressing potential hazards present in these settings. Furthermore, continuous advancements mean that manufacturers can deliver brighter illumination without compromising energy consumption or increasing operational costs.

Safety is paramount; thus understanding what is a good lumen for LED lights becomes essential when designing effective refinery illumination systems. Manufacturers strive to strike a balance between adequate brightness levels necessary for safe operations while ensuring energy efficiency remains at the forefront of their designs—demonstrating how innovation directly correlates with enhanced safety measures within the industry landscape.

Conclusion

In the ever-evolving landscape of refinery operations, ensuring safety and efficiency through proper lighting choices is paramount. The transition to LED lighting for refineries not only enhances visibility but also aligns with stringent safety standards that govern hazardous environments. As we look towards the future, it becomes increasingly clear that a strategic approach to LED lighting will play a crucial role in optimizing refinery operations.

Ensuring Compliance and Safety Standards

Compliance with safety standards is non-negotiable in the world of refinery LED lighting. The right LED lighting for refineries must meet rigorous regulations designed to protect workers and the environment from potential hazards. By adhering to these standards, facilities can mitigate risks associated with inadequate illumination and ensure a safe working environment for all personnel.

Making Informed Decisions on LED Lighting

When it comes to making informed decisions about LED lighting for refineries, understanding key factors such as lumen output is essential. So, what is a good lumen for LED lights? It's about finding the right balance between brightness and energy efficiency while considering specific operational needs. Additionally, evaluating whether are LED lights profitable involves assessing both upfront costs and long-term savings on energy consumption and maintenance.

Future of LED Lighting in Refineries

The future of LED lighting in refineries looks bright—pun intended! With many lights manufacturers choosing LED for lights due to their durability and energy efficiency, we can expect continued innovation in this sector. As technology advances, the integration of smart systems will further enhance the functionality of refinery led lighting, paving the way for safer and more efficient operations within oil and gas industries.