Introduction

In today's oil and gas industry, ensuring the safety of workers in hazardous environments is paramount. This is where the importance of intrinsically safe lighting comes into play. By understanding the basics of intrinsically safe lighting, companies can benefit from enhanced safety measures and compliance with regulations. Factors such as durability, performance, and environmental considerations must be considered when choosing intrinsically safe lighting solutions for oil and gas operations in Australia. Compliance with industry standards and regulations is also crucial to ensure workers' highest level of safety.

Importance of Intrinsically Safe Lighting in Oil & Gas Industry

Intrinsically safe lighting is vital in mitigating the dangers of hazardous environments within the oil and gas industry. Here's how this specialized technology safeguards workers:

- Prevents Ignitions: Intrinsically safe lights are meticulously engineered to limit their energy output and eliminate the potential for sparks. This significantly reduces the risk of ignition in areas filled with flammable gases or dust, preventing catastrophic explosions.

- Regulatory Compliance: These lighting solutions adhere to stringent safety standards and regulations established by governing bodies. Utilizing intrinsically safe lighting ensures compliance and avoids potential consequences such as fines or operational shutdowns.

- Enhanced Worker Safety: By minimizing the chance of explosions and fires, intrinsically safe lighting directly translates to a safer work environment for personnel, fostering a culture of safety within the industry.

Intrinsically safe lighting is a critical safeguard in the oil and gas industry. Its implementation prioritizes worker safety, fosters regulatory compliance, and promotes a risk-averse work environment.

The Basics of Intrinsically Safe Lighting

Intrinsically safe lighting is crucial in safeguarding personnel and preventing accidents in environments where flammable materials pose a significant risk. Here's a breakdown of its key characteristics:

- Designed for Hazardous Locations: Intrinsically safe lighting is specifically built to operate in areas with flammable gases, vapors, or dust.

- Ignition Prevention: This equipment prioritizes preventing any potential spark or excessive heat that could ignite the surrounding flammable materials.

- Rigorous Testing and Certification: Intrinsically safe lights undergo strict testing and evaluation to ensure they meet safety standards and won't cause explosions or fires.

Intrinsically safe lighting offers a reliable solution for illuminating hazardous environments while minimizing the risk of explosions and fires. By implementing this type of lighting, workplaces can prioritize worker safety and adhere to crucial safety regulations.

Benefits of Using Intrinsically Safe Lighting in Hazardous Environments

Intrinsically safe lighting offers significant advantages for operations involving flammable materials or explosive atmospheres. Here's how it enhances safety and efficiency:

- Uncompromising Safety: Intrinsically safe lighting prevents ignition by limiting electrical energy and heat generation below the threshold required to ignite surrounding hazardous materials. This significantly reduces the risk of explosions and accidents, protecting workers and the entire facility.

- Enhanced Visibility: These lights provide optimal illumination in low-light or dark environments, ensuring clear visibility for workers. This minimizes the potential for errors and allows tasks to be completed efficiently and safely, even in challenging conditions.

- Simplified Maintenance: Unlike explosion-proof alternatives, intrinsically safe lighting often doesn't require complete area shutdown for maintenance or repairs. This translates to increased operational efficiency and reduced downtime.

Intrinsically safe lighting is crucial in safeguarding personnel and preventing costly incidents in hazardous environments. Prioritizing safety and promoting clear visibility fosters a productive and secure work atmosphere.

Factors to Consider When Choosing Intrinsically Safe Lighting

Selecting the appropriate lighting for hazardous environments like oil and gas rigs in Australia requires careful consideration. Here are key factors to prioritize:

- Hazard Classification: Identify the specific hazardous area classification (e.g., Zone 0, Zone 1, Zone 2) to ensure the lighting complies with the level of flammable gas, vapor, or dust present.

- Performance: Lighting needs to provide adequate illumination for safe and efficient work. Consider factors like light output, beam pattern, and color temperature to suit various tasks and visibility requirements.

- Durability: Harsh environmental conditions demand robust lighting solutions. Look for fixtures built with corrosion-resistant materials that can withstand extreme temperatures, vibrations, and impacts.

- Environmental Impact: Energy efficiency is crucial. Opt for LED lighting solutions that offer superior energy savings and minimal heat generation, reducing the overall environmental footprint.

- Operational Requirements: Consider ease of installation, maintenance accessibility, and compatibility with existing electrical systems.

By carefully evaluating these factors, you can ensure intrinsically safe lighting that illuminates your workspace while prioritizing worker safety, operational efficiency, and environmental responsibility.

Compliance and Regulations for Intrinsically Safe Lighting in Oil & Gas Industry

Compliance with industry standards and regulations is essential for intrinsically safe lighting in the oil and gas sector. Ensuring all equipment meets certification requirements is crucial for maintaining a safe working environment.

The Significance of Intrinsically Safe Lighting

Intrinsically safe lighting ensures safety in hazardous environments by eliminating the risk of sparks and overheating. This type of lighting is specifically designed to prevent accidents and explosions, making it an essential component in the oil & gas industry. Furthermore, intrinsically safe lighting enhances visibility in challenging work conditions, providing workers with the necessary illumination to carry out their tasks safely and efficiently.

1. Ensuring Safety in Hazardous Environments

Intrinsically safe lighting is instrumental in ensuring the safety of workers in hazardous environments such as oil rigs, refineries, and chemical plants. By utilizing technology that prevents the occurrence of sparks and excessive heat, this type of lighting significantly reduces the risk of igniting flammable substances in these environments. As a result, workers can carry out their duties with peace of mind, knowing they are protected from potential hazards.

2. Preventing Accidents and Explosions

One of the primary benefits of intrinsically safe lighting is its ability to prevent accidents and explosions caused by traditional lighting sources. With intrinsically safe LED lighting, for example, the risk of electrical failures leading to catastrophic events is greatly minimized. This not only safeguards the well-being of workers but also protects valuable equipment and infrastructure from damage due to unforeseen incidents.

3. Enhancing Visibility in Challenging Work Conditions

Intrinsically safe portable lighting solutions are designed to provide optimal visibility in challenging work conditions commonly found in the oil & gas industry. Whether it's maintenance work on offshore platforms or emergency response activities at remote locations, these portable lighting options ensure that workers have adequate illumination to perform their tasks effectively. Additionally, intrinsically safe emergency lighting offers a reliable light source during critical situations, enhancing safety protocols.

By integrating intrinsically safe lighting into their operations, companies in the oil & gas industry can prioritize worker safety while maintaining compliance with regulatory standards.

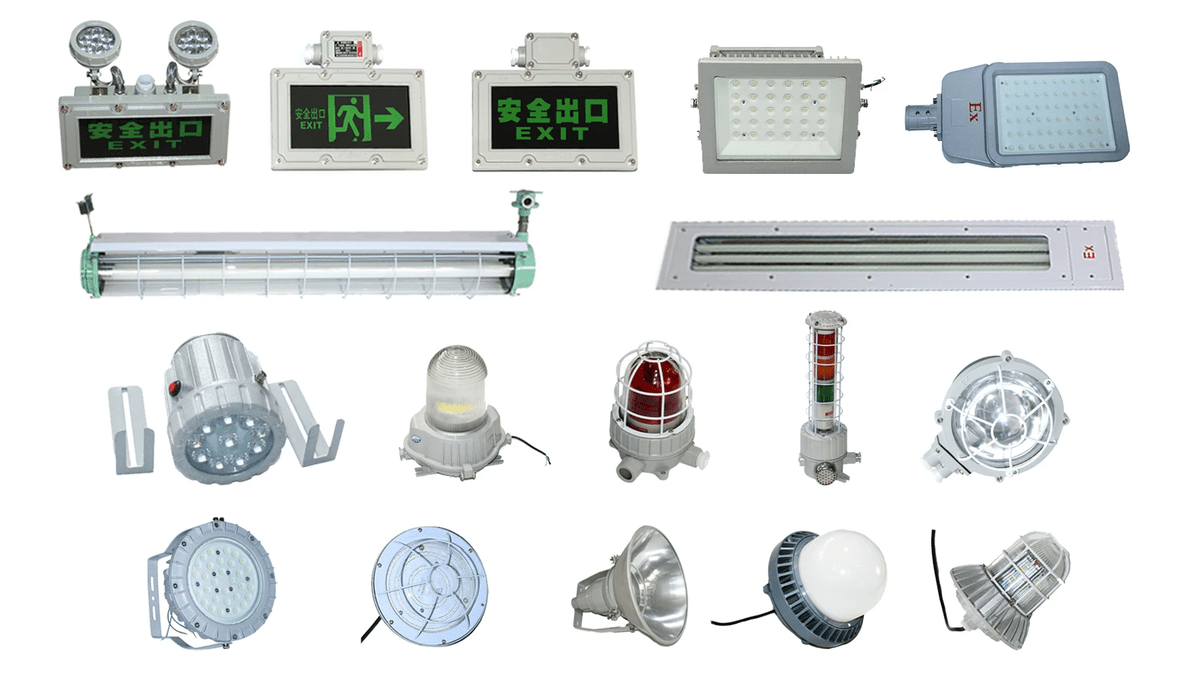

Types of Intrinsically Safe Lighting

Overview of LED Lighting for Oil & Gas Industry

When it comes to intrinsically safe lighting, LED is a top choice for the oil and gas industry. These lights are designed to provide bright, efficient illumination while ensuring safety in hazardous environments. With their long lifespan and low energy consumption, intrinsically safe LED lighting is a cost-effective solution for various industry applications.

Portable Lighting Solutions for Versatile Applications

Intrinsically safe portable lighting is essential for workers moving around different areas within the oil and gas facilities. These portable lights are designed to be lightweight, durable, and resistant to impact, making them ideal for versatile applications. Whether it's for maintenance work or emergencies, intrinsically safe portable lighting provides reliable illumination wherever it's needed.

Emergency Lighting Options for Critical Situations

Reliable emergency lighting is crucial in hazardous environments to ensure workers' safety during critical situations. Intrinsically safe emergency lighting is designed to provide immediate illumination during power outages or emergencies, allowing workers to safely navigate through dark and dangerous conditions. These lights are built with robust materials and advanced technology to withstand extreme conditions and deliver consistent performance when it matters most.

Remember that safety should always be a top priority when working in hazardous environments like those in the oil and gas industry. It is important to choose the right type of intrinsically safe lighting that meets your needs while adhering to compliance standards and regulations.

Selecting the Right Intrinsically Safe Lighting

When selecting the right intrinsically safe lighting for the oil & gas industry, it's crucial to understand the specific needs of this sector. With hazardous environments and challenging work conditions, intrinsically safe portable lighting is a must-have. Whether for maintenance, inspections, or emergencies, reliable and durable intrinsically safe LED lighting is essential for ensuring safety and productivity.

Understanding the Specific Needs of Oil & Gas Industry

Safety is paramount in the oil & gas industry, and this extends to the lighting used in hazardous areas. Intrinsically safe lighting in Australia, for example, must adhere to strict regulations to ensure it can withstand harsh environmental conditions and potential exposure to flammable substances. Understanding these specific needs is crucial when choosing intrinsically safe lighting solutions that can withstand this industry's demands.

Evaluating Performance and Durability

When evaluating intrinsically safe lighting options, performance and durability are key factors. The right intrinsically safe LED lighting should provide high-lumen output while maintaining energy efficiency. Additionally, it should withstand rugged use in challenging environments without compromising performance or safety standards. It's important also to consider the impact of environmental factors such as extreme temperatures, humidity, and exposure to chemicals or solvents. A robust lighting solution should operate effectively in a wide range of environmental conditions without degradation in performance.

Considering Environmental and Operational Factors

Environmental and operational factors are significant in selecting intrinsically safe lighting solutions. The chosen lighting must operate reliably under these conditions from extreme temperatures to corrosive substances in oil & gas facilities. Intrinsically safe emergency lighting should also be considered for critical situations where visibility is crucial for ensuring personnel safety.

Considering these considerations, choosing intrinsically safe lighting for the oil & gas industry requires careful assessment of specific needs, performance capabilities, and environmental factors. By prioritizing safety and reliability, companies can ensure that their workforce operates under well-lit conditions without compromising compliance with industry regulations.

Stay tuned for more insightful information on how JinrongEx provides cutting-edge, intrinsically safe lighting solutions tailored to industrial safety needs!

Compliance and Regulations for Intrinsically Safe Lighting

Intrinsically safe lighting is subject to strict industry standards and requirements for safety in hazardous environments. These standards encompass designing, constructing, and testing intrinsically safe lighting products, focusing on preventing ignition sources that could lead to explosions in volatile atmospheres. Compliance with these standards is essential for using intrinsically safe lighting in Australia's oil & gas industry, where safety is paramount.

Overview of Industry Standards and Requirements

Intrinsically safe lighting must adhere to standards such as IEC 60079 and ANSI/UL 913, which outline the specific criteria for designing equipment that can operate safely in potentially explosive atmospheres. These standards cover aspects like temperature ratings, energy limitations, and protection against electrical faults to minimize the risk of ignition. Adhering to these requirements ensures that intrinsically safe portable and LED lighting meets the necessary safety benchmarks for use in hazardous locations.

Importance of Certification and Testing

Certification from reputable organizations like ATEX or CSA Group validates that intrinsically safe lighting products have undergone rigorous testing to verify their compliance with industry standards. This certification assures that the products are designed to operate safely in hazardous environments without posing a risk of ignition or explosion. Users must look for certified intrinsically safe flashlight suppliers in Muscat or other regions to ensure the reliability of their lighting solutions.

Certification from reputable organizations like ATEX or CSA Group helps ensure the reliability and safety of intrinsically safe lighting products and compliance with regulatory authorities. By choosing certified intrinsically safe flashlight suppliers in Muscat or other regions, users can be confident that their lighting solutions meet the necessary standards set by regulatory bodies. This helps avoid potential fines or penalties for non-compliance and demonstrates a commitment to upholding safety regulations in hazardous environments.

Ensuring Compliance with Regulatory Authorities

Regulatory authorities such as SafeWork Australia are pivotal in overseeing compliance with intrinsically safe lighting regulations within the oil & gas industry. Companies must demonstrate adherence to these regulations through proper documentation, maintenance records, and employee training programs related to intrinsically safe emergency lighting and other safety equipment. Organizations can uphold a safety culture by aligning with regulatory requirements while operating within hazardous areas.

Discover JinrongEx's Safe, Durable Lighting for Hazardous Area

JinrongEx is a trusted leader in providing intrinsically safe lighting solutions for the oil & gas industry. With over two decades of expertise in the field, their commitment to safety and innovation has made them a go-to choice for companies looking to enhance workplace safety.

Decades of Industry Expertise: JinrongEx Since 1998

With a history dating back to 1998, JinrongEx has been at the forefront of developing and manufacturing intrinsically safe lighting solutions. Their extensive experience and knowledge in this specialized field make them a reliable partner for ensuring safety in hazardous environments.

Cutting-Edge Technology for Explosion-Proof Lighting

JinrongEx utilizes cutting-edge technology to design and produce explosion-proof lighting that meets the highest industry standards. Their commitment to innovation ensures that their products are safe but also efficient and durable, providing peace of mind in challenging work conditions.

Bespoke Solutions for Industrial Safety Needs

Understanding that every industrial setting has unique safety requirements, JinrongEx offers bespoke intrinsically safe lighting solutions tailored to specific needs. Whether intrinsically safe portable or emergency lighting, they have the expertise to deliver customized solutions that prioritize safety without compromising performance. With a team of experienced engineers and designers, JinrongEx can assess the specific safety needs of any industrial environment and create tailored lighting solutions that meet all necessary regulations and standards. By prioritizing safety without sacrificing performance, JinrongEx ensures that their bespoke intrinsically safe lighting solutions provide peace of mind for workers and management alike.

Conclusion

In conclusion, the oil & gas industry must prioritize safety by investing in intrinsically safe lighting solutions. With the right intrinsically safe lighting, such as portable LED options and emergency lighting, companies can ensure a safe working environment and make informed choices for enhanced safety measures. By embracing innovation in intrinsically safe lighting, companies can stay compliant with regulations and protect their workforce from potential hazards.

Ensuring a Safe Working Environment with Intrinsically Safe Lighting

Intrinsically safe lighting is vital in ensuring a safe working environment in hazardous areas of the oil & gas industry. Companies can effectively illuminate workspaces using intrinsically safe LED lighting and emergency lighting without risking explosions or accidents. With the right intrinsically safe lighting solutions, workers can carry out their tasks with confidence and peace of mind.

Making Informed Choices for Intrinsically Safe Lighting Solutions

When choosing intrinsically safe lighting solutions, companies must consider factors such as performance, durability, and compliance with industry standards. Whether selecting portable LED options or flashlight suppliers in Muscat, making informed choices ensures that the chosen lighting solutions meet specific needs and provide reliable illumination in challenging work conditions.

Embracing Innovation for Enhanced Safety Measures

Embracing innovation in intrinsically safe lighting allows companies to stay ahead of safety measures while complying with regulations. Companies can enhance workplace safety and protect their workforce from potential hazards by investing in cutting-edge technology for explosion-proof lighting and bespoke solutions tailored to industrial safety needs.

This concludes our comprehensive guide on the importance of intrinsically safe lighting in the oil & gas industry. Remember to prioritize safety by choosing the right intrinsically safe lighting solutions that meet compliance requirements while providing reliable illumination in hazardous environments.