Introduction

In the bustling world of manufacturing and warehousing, understanding the nuances of factory lights is essential for optimal operations. From brightening up a dim assembly line to ensuring safety during nighttime shifts, industrial lighting plays a pivotal role in productivity and security. This introduction will explore what factory lights are called, delve into the benefits of explosion-proof LED lighting, and highlight key features that make these lights indispensable for any facility.

Understanding Industrial Lighting Needs

Factory lights encompass a variety of lighting solutions tailored for specific tasks, environments, and safety standards. Whether it's high bay fixtures illuminating vast warehouse spaces or task lighting focused on intricate assembly work, understanding these needs is crucial for selecting the right lighting system.

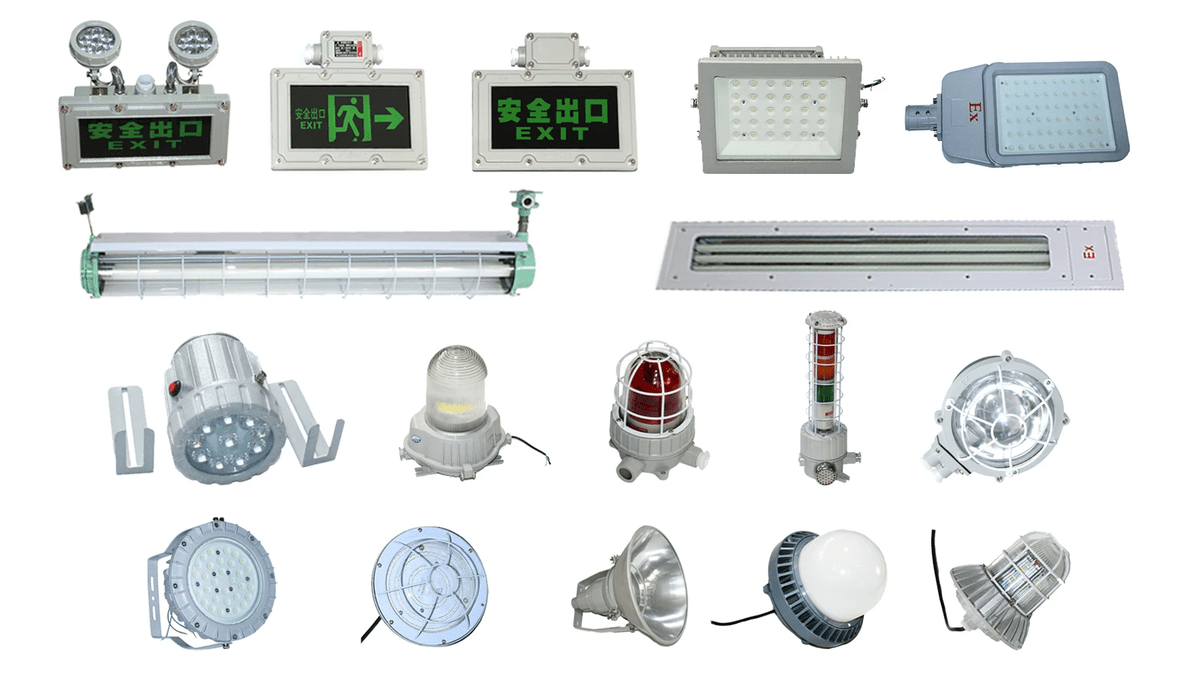

The Benefits of Explosion-proof LED Lighting

Explosion-proof LED lighting is not just a trend; it's a necessity in many industrial environments where flammable materials are present. These specialized lights provide enhanced safety by preventing ignition sources that could lead to catastrophic events. Additionally, they offer energy efficiency and longevity compared to traditional options—making them an ideal choice for facilities looking to upgrade their warehouse lighting.

Key Features of Factory Lights

Factory lights come with a range of features designed to meet the unique demands of industrial applications. Key characteristics include high lumen output for visibility, durability against harsh conditions, and energy-efficient technologies like LED High Bay light options. By examining what lights are used in factories and how they can be optimized for your specific needs, you can make informed decisions that enhance both functionality and safety in your workspace.

What Are Factory Lights Called?

When diving into the world of industrial lighting, you might wonder, What are factory lights called? The terminology used in industrial settings can be quite specific and varies depending on the type of lighting and its intended use. Understanding these terms not only helps in navigating your options but also ensures that you make informed decisions when selecting the right lights for your facility.

Terminology in Industrial Settings

In industrial environments, factory lights are often referred to by various names based on their design and application. You might hear terms like LED High Bay light, which is commonly used for high ceilings in warehouses or factories, or task lighting, aimed at illuminating specific work areas. Knowing what these terms mean will aid you in understanding what lights are used in factories and how they can enhance productivity.

Common Types of Factory Lighting

Among the most common types of factory lighting are fluorescent, metal halide, and LED options. Fluorescent lights have been a staple for years due to their energy efficiency, while metal halide offers bright illumination ideal for large spaces. However, LED lighting for factories and manufacturing facilities has gained traction recently due to its longevity and reduced energy consumption; it's often seen as the future of factory lights.

Why Terminology Matters

Understanding the terminology around factory lights is crucial for several reasons. First, it helps eliminate confusion when discussing lighting needs with suppliers or contractors—after all, no one wants to mix up a “high bay” with a “low bay” light! Secondly, knowing what each type of light offers allows businesses to make better-informed choices about safety standards and energy efficiency—key factors when considering how much labor it costs to replace lights down the line.

What Lights Are Used in Factories?

Overview of Factory Lighting Options

In the realm of factory lights, there are several types commonly employed to meet diverse needs. From fluorescent tubes and metal halide fixtures to modern LED solutions, each type has its advantages and limitations. However, LED lighting for factories and manufacturing facilities is gaining traction due to its energy efficiency and longevity, making it a popular choice among facility managers.

LED high bay lights stand out as a prime option for larger spaces with high ceilings, offering bright illumination without excessive energy consumption. Traditional options like fluorescent or halide may still be found in some settings, but they often fall short compared to the benefits offered by LED technology. As industries evolve, so does their approach to lighting—favoring solutions that enhance productivity while reducing overhead costs.

LED High Bay Light Explained

One of the most effective types of factory lights is the LED high bay light, specifically designed for large areas with elevated ceilings. These fixtures provide uniform light distribution that minimizes shadows and increases visibility across expansive workspaces. The construction of an LED high bay light typically includes durable materials capable of withstanding industrial environments while delivering exceptional brightness.

What sets these lights apart is their energy efficiency; they consume significantly less power than traditional lighting options while offering a longer lifespan—often exceeding 50,000 hours! This translates into lower maintenance costs over time and reduced labor expenses associated with replacing lights frequently—a common concern when considering how much labor is needed to replace lights in industrial settings. Additionally, many models come equipped with advanced features like dimming capabilities or motion sensors that further enhance their utility.

Choosing the Right Lights for Your Facility

Selecting the appropriate factory lights involves evaluating various factors unique to your facility's needs and layout. Start by assessing ceiling height since this will influence whether you should go for standard fixtures or opt for specialized options like LED high bay lights designed for taller spaces. Consider also your operational requirements—different tasks may necessitate varying levels of brightness and color temperature.

Another critical aspect is understanding your facility's energy consumption goals; investing in LED lighting can lead to significant long-term savings compared to traditional alternatives due to lower operational costs over time. Finally, don't overlook safety standards when choosing your warehouse lighting; explosion-proof models may be essential if you're operating in hazardous environments where flammable materials are present.

By carefully considering these elements when deciding on what lights are used in factories, you can create an efficient workspace that not only enhances productivity but also prioritizes safety and cost-effectiveness.

What Is a Factory Light?

When diving into the world of industrial spaces, understanding what factory lights are and their purpose is essential. Factory lights, often referred to as industrial lighting solutions, are specifically designed to illuminate workspaces in manufacturing and production environments. Their primary goal is to enhance visibility, safety, and productivity while accommodating the unique needs of each facility.

Defining Factory Lights and Their Purpose

So, what exactly are factory lights called? They encompass a range of lighting types tailored for various industrial applications. From LED High Bay lights to fluorescent fixtures, these lights serve to create an efficient workspace where tasks can be performed safely and effectively. The right factory lights not only elevate visibility but also contribute significantly to the overall ambiance of the facility.

How LED Lighting for Factories and Manufacturing Facilities Works

LED lighting for factories and manufacturing facilities operates on a principle that maximizes energy efficiency while providing superior brightness. Unlike traditional incandescent or fluorescent options, LED technology converts a higher percentage of energy into light rather than heat, resulting in longer-lasting bulbs with reduced energy consumption. This means that when considering what lights are used in factories today, LEDs have become the go-to choice due to their durability and cost-effectiveness.

Comparing Different Light Types for Factories

When evaluating what is a factory light in terms of performance and suitability, it’s crucial to consider various types available on the market. Common options include LED High Bay lights known for their ability to illuminate large areas with high ceilings efficiently; fluorescent fixtures that offer decent brightness at lower costs; and metal halide lamps that provide excellent color rendering but consume more energy. Each type has its pros and cons—understanding these differences can help facility managers make informed decisions about lighting upgrades or replacements.

Cost Considerations for Lighting Replacement

How Much Is Labor to Replace Lights?

Labor costs for replacing factory lights can vary widely depending on several factors such as location, complexity of the installation, and the types of lights being replaced. Typically, hiring a professional electrician can cost anywhere from $50 to $100 per hour, and this includes both labor and expertise in handling specific fixtures like LED High Bay lights or other specialized factory lighting options. It's essential to factor in these labor costs when considering what lights are used in factories because improper installation could lead to additional expenses down the line.

Budgeting for LED Lighting Upgrades

When budgeting for LED lighting upgrades in your facility, it's crucial to consider not only the initial purchase price of the new factory lights but also any associated installation costs and potential downtime during the transition. A well-planned budget should account for all aspects of the upgrade process, including materials needed for installation and any necessary modifications to existing electrical systems. Additionally, don't forget about potential rebates or incentives offered by local utilities or governments that encourage businesses to switch to more energy-efficient options like LED lighting for factories and manufacturing facilities.

Long-Term Savings with LED Solutions

Investing in LED solutions may seem daunting at first due to upfront costs; however, long-term savings can significantly outweigh initial expenditures. LED factory lights typically consume less energy than traditional incandescent or fluorescent bulbs, leading to lower utility bills over time—often reducing energy consumption by up to 75%. Furthermore, LEDs have a longer lifespan compared to conventional bulbs; fewer replacements mean reduced labor costs while ensuring consistent warehouse lighting quality that enhances safety throughout your facility.

The Role of Warehouse Lighting in Safety

Importance of Proper Lighting in Warehouses

Proper lighting in warehouses is paramount because it directly affects how well employees can perform their tasks. Poorly lit areas can lead to mishaps such as trips, falls, and collisions with equipment or other workers. By investing in high-quality factory lights and ensuring that all areas are well-lit, companies can significantly reduce accidents and foster a safer work environment.

Moreover, understanding what lights are used in factories helps in selecting the right type for specific needs. For instance, LED High Bay lights are ideal for high ceilings commonly found in warehouses because they provide bright illumination over large areas. This kind of targeted lighting not only improves visibility but also boosts morale among workers who feel safer and more comfortable doing their jobs.

How Explosion-proof Lights Enhance Safety

In certain industrial settings where flammable materials are present, using standard factory lights could pose serious risks. Explosion-proof lights come into play as a crucial safety measure by preventing ignition sources that could lead to catastrophic events like fires or explosions. These specialized fixtures are designed to contain any internal explosion and prevent flames from escaping into the surrounding environment.

The effectiveness of explosion-proof lights means they should be a staple consideration when evaluating what is a factory light suitable for hazardous locations. Additionally, these fixtures often utilize LED technology for energy efficiency while ensuring maximum safety—two birds with one stone! By implementing these advanced lighting solutions, facilities can enhance their safety protocols significantly while adhering to industry regulations.

Jinrong’s Commitment to Safety Standards

At Jinrong, we understand that safety standards must never be compromised when it comes to warehouse lighting solutions. Our commitment goes beyond simply providing quality products; we prioritize creating environments where employees feel secure while performing their duties. We ensure our factory lights meet rigorous testing criteria so you can trust they will perform reliably under various conditions.

We offer an array of LED lighting options tailored specifically for factories and manufacturing facilities that adhere strictly to international safety standards. With our focus on innovation and quality control, you can rely on us for effective solutions that improve both visibility and overall workplace safety without breaking the bank on labor costs associated with replacing outdated systems—how much is labor to replace lights? Not as much when you choose efficient upgrades!

By integrating advanced technologies like LED High Bay light fixtures into your warehouse setup, you’re not just investing in better illumination; you’re investing in the future of your workforce's safety and productivity.

Conclusion

In summary, selecting the right factory lights is crucial for ensuring optimal productivity and safety in industrial environments. Understanding what factory lights are called and how they function helps facility managers make informed decisions that align with their specific needs. As we move forward, investing in LED lighting for factories and manufacturing facilities will undoubtedly yield significant benefits.

Best Practices for Factory Lighting Choices

Consider what lights are used in factories, as different settings may require specific lighting solutions like LED high bay lights or explosion-proof options. Additionally, maintaining a proper balance between illumination levels and energy consumption can lead to long-term savings while enhancing workplace conditions.

Investing in Reliable LED Solutions

Investing in reliable LED solutions is more than just a trend; it's a strategic move towards sustainability and cost-effectiveness. With the growing popularity of LED lighting for factories and manufacturing facilities, businesses can expect lower energy bills alongside reduced maintenance costs due to longer lifespans of these bulbs. Moreover, understanding how much labor to replace lights can help companies budget effectively while planning upgrades that improve overall operational efficiency.

The Future of Industrial Lighting Technology

The future of industrial lighting technology looks promising as innovations continue to emerge within the sector. Enhanced smart lighting systems integrated with IoT capabilities will revolutionize how we approach warehouse lighting by offering real-time monitoring and adjustment features tailored to specific tasks or areas within a facility. As manufacturers embrace these advancements, factory lights will become not only more efficient but also smarter—streamlining operations while prioritizing safety.