Introduction

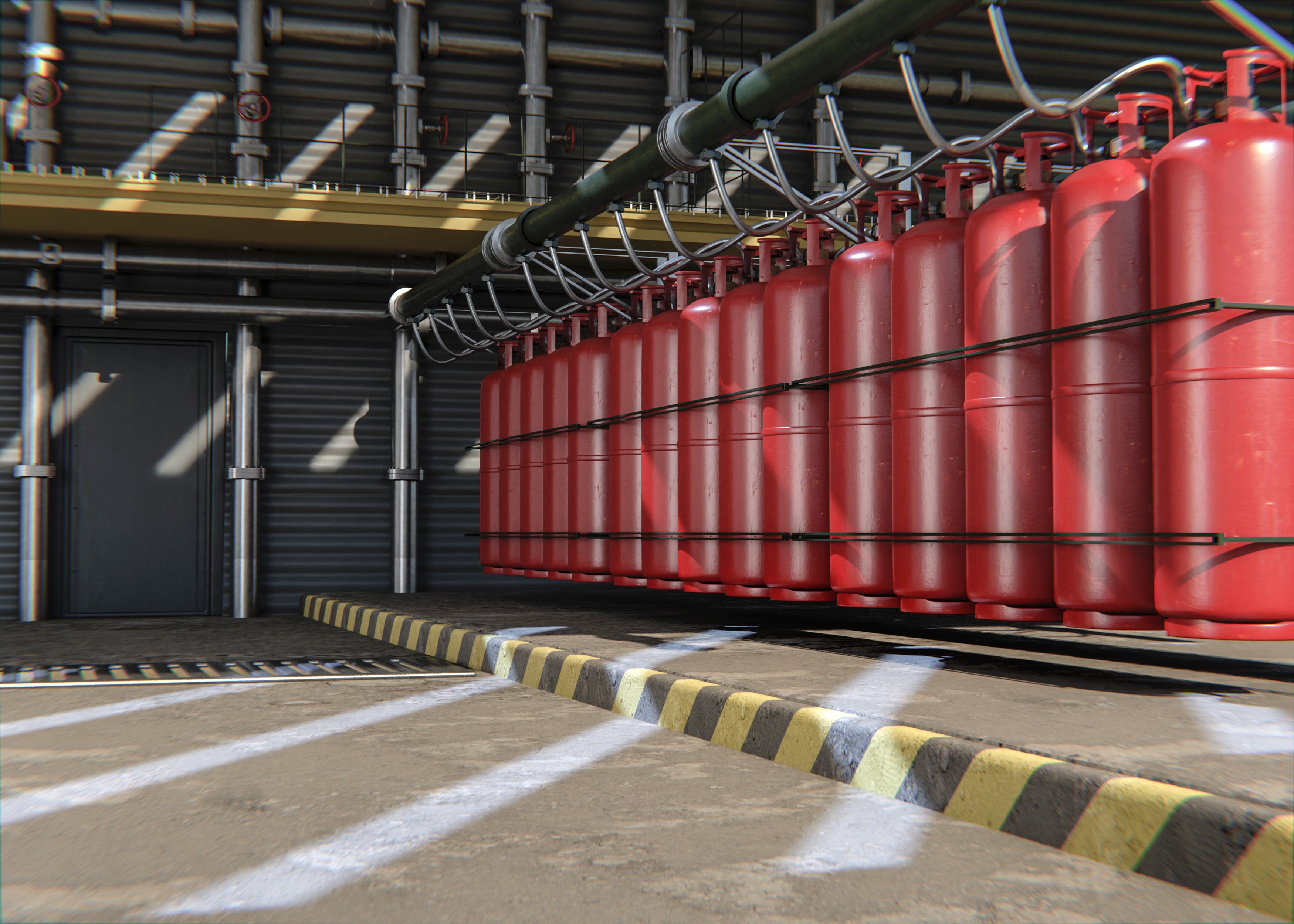

Understanding the different classes of hazardous materials is crucial for safe handling and management. One of the most important classes to be aware of is flammable liquids, which pose a significant risk if not handled properly. Ensuring safety in flammable liquid management is essential to protecting both people and the environment from potential hazards.

Understanding the Hazardous Materials Classes

Hazardous materials are classified based on their properties and potential risks. It's important to be familiar with these classes to identify and handle them appropriately. Flammable liquids fall under Class 3 of hazardous materials, requiring special precautions due to their explosive nature.

Importance of Proper Handling of Flammable Liquids

Properly handling of flammable liquids is essential for preventing accidents and protecting people and property. These substances can pose significant risks if not managed carefully. To ensure safety, follow these key guidelines:

- Store flammable liquids in a cool, well-ventilated area away from ignition sources.

- Use only approved containers for storage and transportation.

- Wear appropriate personal protective equipment (PPE) when handling flammable liquids.

- Never smoke or use open flames near flammable liquids.

- Regularly inspect containers for leaks or damage.

Adhering to these safety measures can significantly reduce the risk of fires, explosions, and other hazards associated with flammable liquids.

Ensuring Safety in Flammable Liquid Management

Managing flammable liquids safely involves adhering to strict storage requirements, legal regulations, and best practices for handling and storing these substances. Organizations can minimize the potential dangers associated with flammable liquids by implementing proper safety measures while maintaining compliance with hazardous materials classes.

What Class is Flammable Liquids?

Regarding hazardous materials classes, flammable liquids fall under Hazmat Class 3. These liquids are defined by their low flash point and ability to ignite easily, making them a high fire risk. It's crucial to identify and properly label Class 3 flammable liquids to ensure safe handling and storage.

Identifying Hazmat Class 3 Flammable Liquids

Class 3 flammable liquids include gasoline, ethanol, and acetone. These liquids are characterized by their ability to produce flammable vapors at or below room temperature, posing a significant fire hazard. Proper identification of these substances is essential for implementing the necessary safety measures in handling and storing them.

Flammable liquids must be stored in approved containers specifically designed to withstand the potential hazards of these substances. These containers should be labeled with the appropriate hazard class and have proper ventilation to prevent the buildup of flammable vapors. Additionally, storage areas for flammable liquids should be located away from ignition sources such as open flames, sparks, or electrical equipment to minimize fire risk. It is also crucial to regularly inspect storage containers for any signs of damage or leaks to prevent accidents and ensure safe handling.

Storage Requirements for Flammable Liquids

Proper storage of flammable liquids is crucial for preventing fires and explosions.

To ensure safe handling, follow these guidelines:

- Use only approved containers designed for the specific liquid.

- Maintain adequate ventilation in storage areas.

- Keep flammable liquids away from heat sources and incompatible materials.

- Clearly label all containers with appropriate hazard warnings.

- Conduct regular inspections of storage areas for leaks, damage, and safety compliance.

Adhering to these practices can significantly reduce the risk of accidents and create a safer working environment.

Legal Regulations for Handling Flammable Liquids

Legal regulations governing the handling of flammable liquids protect workers and the environment from potential hazards. These regulations outline specific guidelines for safely storing, transporting, and using Class 3 flammable liquids. Compliance with these regulations is crucial for maintaining a safe work environment and avoiding costly penalties or accidents.

Furthermore, these regulations also require that flammable liquids be stored in approved flammable cabinets to minimize the risk of fire and explosion. When choosing the right flammable cabinet, it is important to consider factors such as the type and quantity of flammable liquids being stored, the available space in the workplace, and any specific requirements outlined in local regulations. Additionally, properly labeling flammable cabinets is essential for easy identification and ensuring that workers are aware of the potential hazards associated with these substances.

Choosing the Right Flammable Cabinet

A flammable cabinet plays a crucial role in ensuring safety when storing hazardous materials like flammable liquids. These cabinets are designed to provide a secure and fire-resistant storage solution for Class 3 flammable liquids.

Understanding the Role of a Flammable Cabinet

A flammable cabinet is a designated storage unit for flammable liquids. It offers protection against potential fire hazards and minimizes the risk of accidents in the workplace. It is essential for complying with legal regulations and ensuring the safety of employees and the surrounding environment.

A flammable cabinet should have sturdy construction, double-walled steel, and a built-in grounding connector to prevent static electricity buildup. Additionally, adjustable shelves and proper ventilation are important for organizing and safely storing different types of flammable liquids. The cabinet should also be labeled clearly with the appropriate hazard warnings and safety instructions to ensure employees can easily identify and handle the contents.

Features to Look for in a Flammable Cabinet

When selecting a flammable cabinet, consider features such as double-walled steel construction, built-in grounding connections, and adjustable shelving to accommodate various container sizes. Additionally, look for FM-approved cabinets that meet OSHA and NFPA standards for storing hazardous materials.

In addition to the construction and safety features, it's also important to consider the capacity of the flammable cabinet. Ensure the cabinet has enough space to accommodate all your flammable liquids, with room for growth if needed. It's also beneficial to look for cabinets with self-closing doors to prevent accidental exposure to flames or sparks. Proper ventilation is another key feature, as it helps reduce the risk of igniting flammable vapors within the cabinet.

Best Practices for Storing Flammable Liquids

To ensure the safe storage of Class 3 flammable liquids, they must be stored in approved containers within the flammable cabinet. The cabinet should be kept away from potential sources of ignition, such as heat-producing equipment or direct sunlight. To maintain its integrity, it should be regularly inspected for any signs of damage or leaks.

After ensuring that your Class 3 flammable liquids are stored in approved containers within the flammable cabinet, it's important to label these containers clearly with the contents and any associated hazards. This will help prevent confusion and ensure everyone handling the liquids knows the potential risks. Additionally, it's crucial to keep a record of all flammable liquids stored, including their quantities and locations, to facilitate efficient inventory management and emergency response in case of spills or accidents. By maintaining clear labeling and accurate records, you can enhance overall safety in your workplace.

Safe Handling and Transfer of Flammable Liquids

When handling flammable liquids, using the proper containers is crucial for ensuring safety. It's important to choose containers specifically designed for storing and transporting hazardous materials such as class 3 flammable liquids. These containers should be made of materials compatible with the specific properties of the flammable liquid, and they should be properly labeled to indicate their contents.

Using Proper Containers for Flammable Liquids

To prevent spills and accidents, it's essential to use containers with secure closures that are designed to withstand the pressure and temperature changes that can occur during storage and transportation. Look for containers that meet safety standards and regulations for handling hazardous materials, including hazmat class 3 flammable liquids. Additionally, containers should be regularly inspected for any signs of damage or wear that could compromise their integrity.

When selecting containers for flammable liquids, it's important to consider the material of the container. Metal containers are often recommended for their durability and resistance to corrosion, while plastic containers may be suitable for certain types of flammable liquids. Be sure to choose containers compatible with the type of flammable liquid you are handling, as different materials may react differently with certain substances. This will help ensure the safety and integrity of the container and its contents.

Preventing Spills and Accidents

In addition to using proper containers and spill prevention measures, it's essential to equip employees with the appropriate personal protective equipment (PPE) when handling flammable liquids. This can include gloves, goggles, and flame-resistant clothing to minimize the risk of exposure to hazardous materials. Providing PPE helps protect workers from potential harm and demonstrates a commitment to their safety and well-being in the workplace.

Personal Protective Equipment for Handling Flammable Liquids

Personal protective equipment (PPE) is essential for ensuring the safety of employees when working with class 3 flammable liquids. This can include fire-resistant clothing, chemical-resistant gloves, safety goggles, and respirators designed specifically for use with flammable liquids. Providing employees with the necessary PPE protects their well-being and helps prevent accidents and exposure to hazardous materials.

Emergency Response for Flammable Liquid Accidents

When dealing with hazardous materials classes such as flammable liquids, it's crucial to have an emergency action plan in place. This plan should outline the steps to take in case of a spill or accident involving class 3 flammable liquids, ensuring that employees know how to respond quickly and effectively.

Creating an Emergency Action Plan

A comprehensive emergency action plan is crucial for handling incidents involving flammable liquids. The plan should clearly outline procedures for three key areas:

- Evacuation: Establish clear and accessible evacuation routes, identify assembly points, and assign personnel responsible for employee accounting.

- Spill Containment: Detail methods for controlling the spread of spilled flammable liquids, including using appropriate containment materials and equipment.

- Emergency Services: Provide contact information for local emergency services and outline procedures for notifying them of the incident.

Designating specific roles and responsibilities for employees during an emergency is essential for an efficient response. Regular drills and plan updates will ensure preparedness and effectiveness.

Training Employees for Emergency Situations

Proper training is essential for employees handling hazardous materials like flammable liquids. They should be familiar with the properties of class 3 flammable liquids and understand how to handle them safely. Training should also cover emergency response procedures, including using fire extinguishers and other safety equipment.

Utilizing Safety Equipment and Resources

The right safety equipment is crucial when dealing with flammable liquids. This includes fire extinguishers, personal protective gear, spill containment kits, and eye wash stations. Regular maintenance and inspection of this equipment are necessary to ensure it's always ready for use in an emergency.

Best Practices for Flammable Liquid 3 Management

Regular Inspections and Maintenance of Storage Areas

Regularly inspecting storage areas for hazardous materials, including flammable liquids, is crucial to ensure compliance with safety regulations. It is important to check for leaks, container damage, and proper labeling of the storage units. Maintenance should be conducted promptly to address any issues found during inspections.

Proper Disposal of Flammable Liquids

Proper disposal of flammable liquids is essential to prevent environmental contamination and potential hazards. It is important to follow legal regulations for disposal and use designated disposal facilities or services. A clear protocol for the disposal process ensures that it is done safely and responsibly.

Jinrong's Expertise in Ex-Proof Manufacturing for Safe Handling

Jinrong specializes in ex-proof manufacturing, providing solutions for safely handling and storing hazardous materials such as class 3 flammable liquids. Their expertise includes designing and producing high-quality flammable cabinets that meet safety standards and regulations. Partnering with Jinrong ensures reliable equipment for the safe management of flammable liquids.

Implement Safety Measures for Flammable Liquids

Ensuring Compliance with Hazardous Materials Classes

Businesses must understand the hazardous materials classes, particularly hazmat class 3 flammable liquids, to ensure compliance with legal regulations and safety standards. Properly handling and storing flammable liquids are essential for preventing accidents and protecting employees and the environment.

By choosing the right flammable cabinet, following storage requirements, and utilizing best practices for safely handling and transferring flammable liquids, businesses can significantly reduce the risk of accidents and ensure a safe working environment. It is important to prioritize safety measures and properly train employees for emergency response.

Partnering with Jinrong for Expertise in Ex-Proof Manufacturing

For businesses looking to enhance their explosive liquid management, partnering with Jinrong can provide expertise in ex-proof manufacturing solutions. With a focus on safety and compliance, Jinrong offers high-quality flammable cabinets and storage solutions that meet legal regulations and ensure the safe handling of hazardous materials.