Introduction

When it comes to working in hazardous environments, understanding Hazardous Atmosphere Classification is crucial for ensuring safety. Whether it's the importance of Class/Division Hazardous Location or the differences between Division and Zone Ratings, having a solid grasp of these concepts is essential for anyone working in such areas.

Understanding Hazardous Atmosphere Classification

Hazardous Atmosphere Classification refers to the categorization of areas where explosive atmospheres may occur due to flammable gases, vapors, liquids, combustible dusts, or ignitable fibers. This classification system helps identify potential risks and implement necessary safety measures to protect workers in such environments.

Importance of Class/Division Hazardous Location

Class/Division Hazardous Location plays a critical role in ensuring the safety of individuals working in hazardous environments. It provides a framework for understanding the types of hazards present and implementing appropriate protections to mitigate risks and prevent accidents.

The Differences Between Division and Zone Ratings

Understanding the differences between Division and Zone Ratings is essential for accurately assessing the level of risk in a hazardous environment. While both systems aim to classify hazardous locations, they have distinct criteria and requirements that must be considered when implementing safety measures.

Now that we've set the stage with an overview of Hazardous Atmosphere Classification, let's delve deeper into each aspect to gain a comprehensive understanding.

Hazardous Location Classifications

When it comes to hazardous location classifications, understanding the concept of Class/Division Hazardous Location is crucial. This system categorizes hazardous areas into different classes and divisions based on the type and level of potential hazards present. By doing so, it helps to ensure that proper safety measures and equipment are in place to mitigate the risks associated with these environments.

Class/Division Hazardous Location Explained

Class/Division Hazardous Location is a classification system used to identify and manage hazardous areas in industrial settings. It consists of three divisions (Divisions 1, 2, and 3) for each class (Classes I, II, and III), which are based on the likelihood of flammable gases or vapors, combustible dusts, or ignitable fibers being present. This classification system provides a clear framework for implementing safety protocols and selecting suitable equipment for each specific hazardous area.

Class/Division Hazardous Location is a classification system that plays a crucial role in ensuring the safety of industrial environments. By categorizing hazardous areas into different divisions and classes based on the presence of flammable gases, combustible dusts, or ignitable fibers, this system allows for targeted safety protocols and equipment selection. This not only minimizes the risk of potential accidents but also ensures compliance with industry regulations and standards. Additionally, it provides a clear and organized framework for facility managers and safety professionals to effectively mitigate the dangers associated with hazardous materials.

Protections for Hazardous Area Classifications

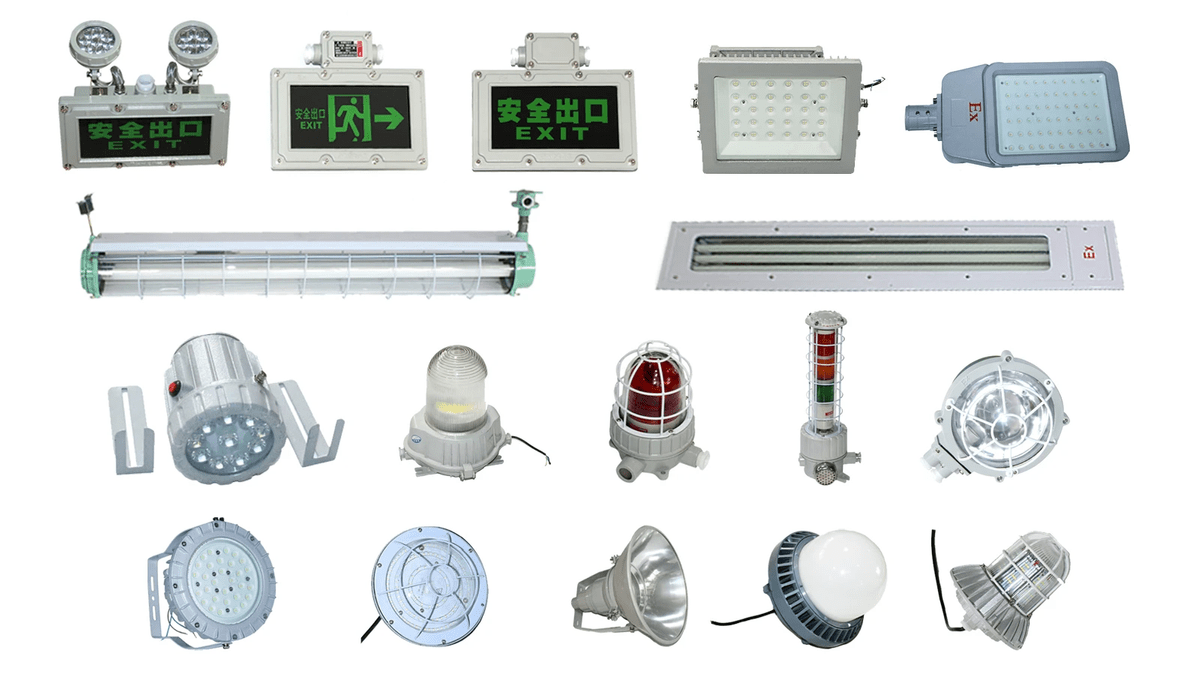

Protections for hazardous area classifications involve various measures such as using explosion-proof enclosures, intrinsically safe devices, or purged systems to prevent ignition sources from causing an explosion in these environments. Additionally, proper ventilation systems and regular inspections are essential to maintain a safe working environment within classified hazardous locations.

In addition to the use of explosion-proof enclosures and intrinsically safe devices, it is crucial to implement proper training and safety protocols for employees working in hazardous areas. This includes regular safety drills, education on the potential risks, and clear communication of emergency procedures. By ensuring that all personnel are well-informed and prepared, the overall safety of the environment can be greatly enhanced.

Core Differences Between Division and Zone Ratings

One of the key differences between Division and Zone ratings lies in their approach to defining hazardous areas. Division ratings are primarily used in North America and classify locations based on the likelihood of an explosive atmosphere being present continuously (Division 1) or intermittently (Division 2). On the other hand, Zone ratings are commonly used internationally and categorize areas based on the frequency and duration of the presence of explosive atmospheres (Zones 0, 1, and 2).

Another significant difference between Division and Zone ratings is the method of protection required for each classification. Division ratings typically require equipment designed to contain any potential explosion within the device itself, such as explosion-proof enclosures. In contrast, Zone ratings often call for equipment that prevents the ignition of explosive atmospheres, such as intrinsically safe devices or increased safety options. This difference in approach to protection highlights the varying priorities and strategies employed in different regions and industries.

The Origins of Hazardous Atmosphere Classification

Hazardous Area Classifications have a rich historical background, dating back to the early 20th century when industrial accidents prompted the need for safety measures. The first Hazardous Location Classifications were introduced in the 1920s to protect workers from potential explosions and fires in hazardous environments. Over time, these classifications have evolved to encompass a wide range of industries and technologies, reflecting advancements in safety standards and regulations.

Historical Background of Hazardous Area Classifications

The historical roots of Hazardous Atmosphere Classification can be traced back to the tragic incidents that occurred during the industrial revolution, where workers were exposed to dangerous conditions without proper protection. As a response, regulatory bodies began developing standards for classifying hazardous areas based on the types of substances present and the likelihood of ignition. These early efforts laid the foundation for modern Hazardous Location Classifications that prioritize worker safety in potentially dangerous environments.

The evolution of Hazardous Location Classifications has been marked by advancements in technology and a deeper understanding of the potential risks posed by different substances. As industries have expanded and diversified, so too have the classifications for hazardous areas, taking into account new materials and processes. This ongoing evolution reflects a commitment to staying ahead of potential hazards and ensuring that workers are protected in all types of environments.

Evolution of Hazardous Location Classifications

The evolution of Hazardous Area Classifications has been marked by significant advancements in technology and industry practices. From the initial focus on flammable gases and vapors, Hazardous Atmosphere Classification has expanded to include combustible dusts and fibers, as well as more precise methods for identifying and mitigating potential hazards. This evolution reflects a growing understanding of the complex factors that contribute to hazardous conditions in industrial settings.

Impact of Technological Advancements on Hazardous Atmosphere Classification

Technological advancements have played a crucial role in shaping Hazardous Area Classifications over time. Improved detection methods, such as advanced sensors and monitoring systems, have enhanced our ability to identify potential risks within hazardous areas more accurately. Additionally, innovations in protective equipment and engineering controls have contributed to greater safety measures within hazardous environments, further refining Hazardous Location Classifications.

By understanding the historical context and evolution of Hazardous Atmosphere Classification, we gain valuable insights into how these classifications have developed over time to ensure workplace safety. As technological advancements continue to drive progress in this field, it is essential for industries to stay abreast of current trends and predictions for future developments in Class/Division Hazardous Location standards.

Class/Division Hazardous Location in Industry

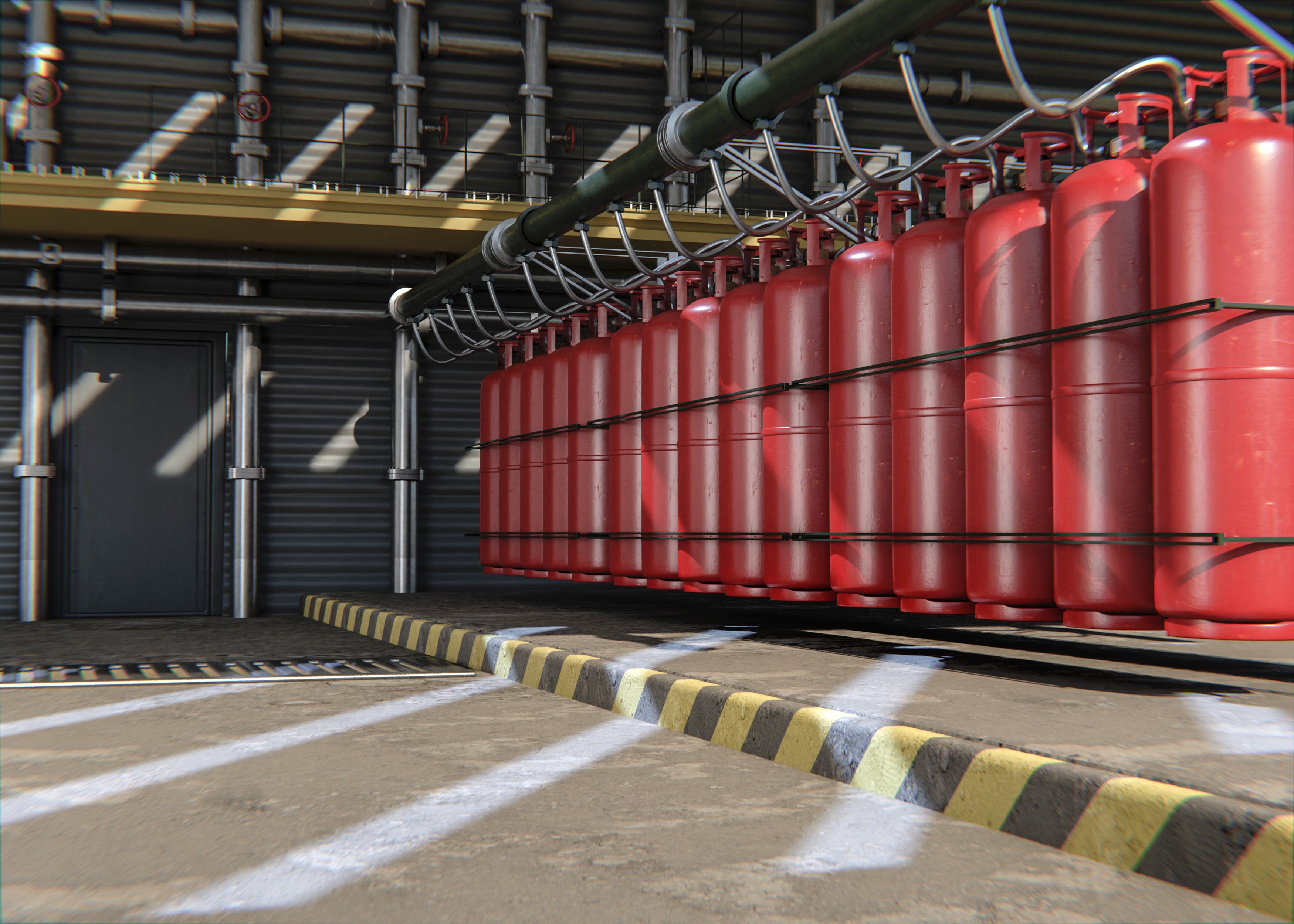

Class/Division Hazardous Location plays a critical role in ensuring workplace safety in various industries. With different divisions for each hazardous atmosphere classification, it provides specific guidelines for the installation of electrical equipment and wiring to prevent ignition of flammable gases, vapors, or dusts. These classifications are crucial in hazardous environments such as chemical plants, refineries, and manufacturing facilities.

Practical Applications of Hazardous Area Classifications

In practical terms, Class/Division Hazardous Location is applied to designate areas where potential hazards exist due to the presence of flammable substances. It helps determine the type of electrical equipment that can be safely used in these environments based on the likelihood of an explosive atmosphere occurring. This classification system ensures that appropriate precautions are taken to mitigate the risks associated with combustible materials.

In addition to determining the type of electrical equipment that can be safely used in hazardous areas, Class/Division Hazardous Location classification also helps in establishing proper maintenance and inspection protocols for such environments. By clearly defining the potential hazards and the likelihood of an explosive atmosphere occurring, this system enables businesses to implement effective safety measures and emergency response plans. This proactive approach not only safeguards personnel and assets but also ensures compliance with industry regulations and standards.

Real Life Examples of Hazardous Atmosphere Classification

One real-life example of hazardous atmosphere classification is found in oil refineries where there are different divisions for each hazardous atmosphere classification based on the level of risk associated with various areas within the facility. For instance, areas with a high concentration of flammable gases may fall under Division 1, while areas with lower concentrations may fall under Division 2. This ensures that electrical equipment installed in these locations is suitable for the level of risk present.

In addition, hazardous atmosphere classification plays a crucial role in ensuring the safety of workers in industrial settings. By clearly identifying and classifying areas with different levels of risk, employers can implement appropriate safety measures and protocols to protect their employees from potential hazards. This may include providing specialized training, personal protective equipment, and emergency response procedures tailored to the specific hazardous atmosphere classification of each area within the workplace.

Role of Hazardous Atmosphere Classification in Workplace Safety

The role of Hazardous Atmosphere Classification in workplace safety cannot be overstated. By clearly defining and categorizing hazardous locations, it allows for proper risk assessment and implementation of safety measures to protect workers and property from potential explosions or fires caused by electrical equipment. It also guides employers and employees on best practices for handling electrical installations in these settings.

Furthermore, as technology continues to advance, the future of hazardous atmosphere classification will also evolve. New innovations in electrical equipment and industrial processes may lead to the creation of new types of hazardous locations that need to be classified and regulated. This means that ongoing research and updates to classification standards will be necessary to ensure that workplace safety measures remain effective and up-to-date.

The Future of Hazardous Atmosphere Classification

Innovations in Hazardous Location Classifications

Innovations in hazardous location classifications are revolutionizing workplace safety. Advanced technologies such as wireless gas detection systems and smart sensors are enhancing the monitoring and detection of hazardous atmospheres, ensuring timely alerts and preventive measures. These innovations are crucial for minimizing the risks associated with Class/Division Hazardous Location.

Current Trends in Hazardous Area Classifications

Current trends in hazardous area classifications emphasize the integration of IoT (Internet of Things) devices for real-time data analysis and predictive maintenance. This trend allows for proactive measures to be taken, reducing the potential for accidents in hazardous locations. Additionally, there is a growing focus on creating standardized global guidelines for Hazardous Location Classifications to ensure consistency and safety across industries.

Predictions for the Future of Class/Division Hazardous Location

The future of Class/Division Hazardous Location is poised to witness further advancements in technology, including the use of artificial intelligence and machine learning algorithms to enhance hazard identification and risk assessment. Moreover, there will be a shift towards more sustainable solutions, such as renewable energy sources and eco-friendly materials, to mitigate the impact of hazardous atmospheres on the environment.

Remember that it's important to stay updated with these innovations and trends in Hazardous Atmosphere Classification to ensure optimal safety measures are implemented within your workplace.

Conclusion

Hazardous Location Classifications play a crucial role in ensuring workplace safety, with Class/Division Hazardous Location being the cornerstone of protection. Understanding the Differences Between Division and Zone Ratings is essential for implementing Protections for Hazardous Area Classifications effectively. In addition, knowing how many divisions are there for each hazardous atmosphere classification is vital for successful implementation.

Ensuring Safety with Hazardous Atmosphere Classification

In conclusion, it is clear that Hazardous Location Classifications are indispensable for ensuring safety in industrial settings. By understanding the nuances of Class/Division Hazardous Location and the Protections for Hazardous Area Classifications, companies can create a safer work environment. It is imperative to prioritize safety by implementing these classifications effectively.

Best Practices for Hazardous Area Classifications

When it comes to best practices for Hazardous Area Classifications, companies should prioritize regular training and education on the topic. This will ensure that employees are well-informed about how to navigate hazardous environments safely. Additionally, staying updated on the latest industry standards and regulations is crucial for maintaining a safe workplace.

Implementing Class/Division Hazardous Location Successfully

To implement Class/Division Hazardous Location successfully, companies should invest in reliable equipment and technology that aligns with their specific hazardous area classifications needs. It's also important to conduct regular inspections and maintenance to ensure that all protections are functioning as intended. By prioritizing these measures, companies can create a secure work environment.

Overall, understanding the intricacies of these classifications and their practical applications is essential for creating a safe work environment in industries where hazardous materials are present. By prioritizing safety measures and staying informed about industry advancements, companies can effectively navigate hazardous atmospheres while safeguarding their employees' well-being.