Introduction

When it comes to industrial lighting, safety is a top priority. That's where explosion-proof lighting comes in. These specialized lights are designed to prevent the ignition of flammable gases and vapors in hazardous locations, making them essential for facilities with potentially explosive atmospheres. But when it comes to high bay vs. low bay fixtures, what's the difference? And what are the benefits of using LED light fixtures in these environments?

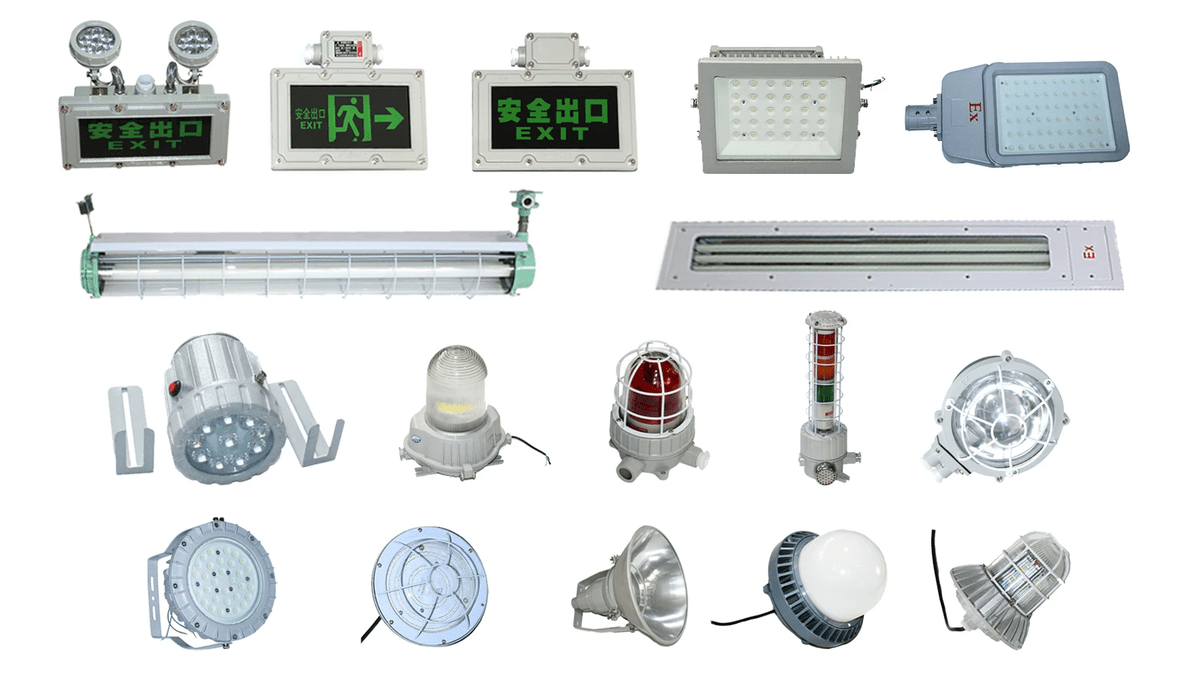

Understanding Explosion-Proof Lighting

Explosion-proof lighting is specifically engineered to contain sparks and prevent ignition in volatile areas such as chemical plants, refineries, and industrial manufacturing facilities. These lights are rigorously tested and certified to ensure they can withstand potential explosions without posing a risk to workers or the surrounding environment.

High Bay Vs. Low Bay: What's the Difference?

High bay explosion-proof lighting is designed for use in areas with ceiling heights of 20 feet or more, providing powerful illumination over large spaces such as warehouses and hangars. On the other hand, low bay fixtures are ideal for lower ceiling heights and offer more focused lighting for areas like workshops and garages.

Benefits of LED Light Fixtures

LED explosion-proof high bay lighting offers numerous advantages over traditional lighting options, including energy efficiency, longer lifespan, and superior durability. With their ability to produce bright, even light while consuming less energy, LED fixtures are an excellent choice for industrial settings looking to enhance safety and reduce operating costs.

Exploring High Bay Explosion-Proof LED Light Fixtures

High bay explosion-proof LED light fixtures are designed to provide efficient illumination in spaces with high ceilings, such as warehouses, factories, and industrial facilities. These fixtures offer several benefits and are well-suited for specific applications. Let’s delve into the details:

Advantages of High Bay Lighting

- Energy Efficiency: LED technology ensures high energy efficiency, resulting in reduced electricity consumption compared to traditional lighting sources. This translates to cost savings over time.

- Long Lifespan: LED fixtures have a longer operational life, minimizing maintenance and replacement costs. They can last up to 50,000 hours or more, depending on the quality of the fixture.

- Instant Illumination: Unlike fluorescent lights that require warm-up time, LED high bay fixtures provide instant, flicker-free illumination. This is crucial in environments where immediate lighting is essential.

- Directional Light: High bay LEDs emit directional light, focusing illumination where it’s needed. This reduces light spillage and enhances overall visibility.

- Durability: Explosion-proof fixtures are built to withstand harsh conditions, including extreme temperatures, humidity, and vibrations. They are resistant to impact and corrosion.

Best Applications for High Bay Fixtures

High bay LED fixtures are particularly suitable for:

- Warehouses and Distribution Centers: These large spaces benefit from high bay lighting due to their expansive ceilings and the need for uniform illumination across storage racks and aisles.

- Manufacturing Plants: High bay fixtures enhance productivity by providing bright, consistent lighting for assembly lines, workstations, and machinery areas.

- Gyms and Sports Facilities: High ceilings in gyms and sports arenas require powerful lighting. LED high bays ensure optimal visibility for athletes and spectators.

- Retail Stores and Supermarkets: High bay fixtures create an inviting shopping environment by evenly illuminating shelves, displays, and checkout areas.

Cost-Effectiveness of High Bay LED Lights

While the initial investment in high bay LED fixtures may be higher than traditional options, the long-term benefits outweigh the costs. Consider the following cost-effective aspects:

- Energy Savings: Reduced energy consumption leads to lower utility bills, making high bay LEDs financially advantageous.

- Maintenance Costs: Longer lifespan means fewer replacements and maintenance expenses over time.

- Improved Productivity: Well-lit spaces enhance employee productivity and safety, contributing to overall operational efficiency.

In summary, high bay explosion-proof LED light fixtures offer a compelling combination of efficiency, durability, and cost-effectiveness, making them a smart choice for various industrial and commercial settings.

Delving into Low Bay Explosion-Proof LED Light Fixtures

When it comes to industrial lighting, low bay explosion-proof LED light fixtures offer several advantages. These fixtures are designed to provide reliable illumination in areas with lower ceiling heights, making them ideal for warehouses, storage facilities, and manufacturing plants. The durable construction of low bay lights ensures they can withstand harsh conditions and provide long-lasting performance in hazardous environments.

Best Applications for Low Bay Fixtures

Low bay explosion-proof LED light fixtures are best suited for facilities with ceiling heights ranging from 12 to 20 feet. These fixtures are commonly used in areas where high bay lighting is not necessary, such as walkways, assembly lines, and loading docks. Their compact design and focused light distribution make them an excellent choice for illuminating specific work areas while maintaining energy efficiency.

Cost-Effectiveness of Low Bay LED Lights

In addition to their practical applications, low bay explosion-proof LED light fixtures offer cost-effective lighting solutions for industrial facilities. These fixtures consume less energy than traditional lighting options, resulting in reduced utility bills and long-term savings. Furthermore, their low maintenance requirements and extended lifespan contribute to lower overall operational costs.

Low bay explosion-proof LED light fixtures are specifically designed for spaces with lower ceilings, such as workshops, garages, and storage areas. Let’s explore the features and applications of these fixtures:

Best Applications for Low Bay Fixtures

- Workshops and Garages: Low bay LED lights provide ample illumination for workbenches, machinery, and vehicle maintenance areas. Their compact design suits spaces with ceilings ranging from 10 to 20 feet.

- Storage Rooms and Warehouses: In areas where ceiling height is limited, low bay fixtures efficiently light up storage shelves, aisles, and inventory spaces.

- Retail Displays: Low bay LEDs are ideal for highlighting merchandise in retail stores. They create an inviting atmosphere while ensuring product visibility.

- Parking Garages: These fixtures enhance safety by illuminating parking spaces, ramps, and pedestrian walkways.

Cost-Effectiveness of Low Bay LED Lights

- Energy Savings: Like their high bay counterparts, low bay LED fixtures are energy-efficient. They consume less electricity, resulting in reduced utility bills.

- Long Lifespan: Low bay LEDs have a longer operational life, minimizing replacement costs and maintenance efforts.

- Focused Illumination: Their directional light distribution ensures efficient use of energy by targeting specific areas.

In summary, low bay explosion-proof LED light fixtures offer practical solutions for spaces with lower ceilings, combining efficiency, durability, and cost-effectiveness.

Differences Between Low Bay and High Bay Explosion-Proof LED Light Fixtures

When choosing between low bay and high bay explosion-proof LED light fixtures, several factors come into play. Let’s explore the key differences:

Ceiling Height and Space Requirements

- Ceiling Height:

- High Bay: These fixtures are designed for spaces with high ceilings, typically exceeding 20 feet. They provide broad illumination across large areas.

- Low Bay: In contrast, low bay fixtures are suitable for spaces with lower ceilings, ranging from 10 to 20 feet. They offer focused lighting in more compact environments.

- Space Considerations:

- High Bay: Due to their broader coverage, high bay fixtures are ideal for open, expansive areas such as warehouses and manufacturing plants.

- Low Bay: Low bay fixtures are better suited for smaller spaces, including workshops, garages, and retail displays.

Light Intensity and Distribution

- Light Intensity:

- High Bay: These fixtures provide higher light intensity to cover vast spaces. They ensure consistent brightness even in large warehouses.

- Low Bay: Low bay LEDs offer lower intensity, which is sufficient for localized tasks and smaller zones.

- Light Distribution:

- High Bay: The light distribution is wider and more uniform, reaching distant corners. It minimizes shadows and enhances visibility.

- Low Bay: Low bay fixtures have a more focused beam, directing light precisely where needed. This reduces light spillage.

Energy Efficiency and Maintenance Costs

- Energy Efficiency:

- High Bay: LED high bays are energy-efficient, resulting in lower electricity bills over time.

- Low Bay: Similarly, low bay LEDs consume less energy, contributing to cost savings.

- Maintenance:

- High Bay: Longer lifespan means fewer replacements and reduced maintenance efforts.

- Low Bay: Low bay fixtures also enjoy an extended operational life, minimizing ongoing costs.

In summary, the choice between low bay and high bay fixtures depends on ceiling height, space requirements, and the desired level of illumination. Assess your specific needs to make an informed decision for your facility.

Case Studies: Real-Life Applications of High Bay and Low Bay Explosion-Proof LED Light Fixtures

Let’s explore practical examples of how high bay and low bay explosion-proof LED light fixtures are making a difference in various settings:

Warehouse Lighting Solutions

- Large Distribution Centers:

- High Bay: In sprawling warehouses, high bay LEDs provide consistent illumination across vast storage areas. They enhance visibility for workers navigating aisles and handling inventory.

- Low Bay: Smaller storage rooms within the warehouse benefit from low bay fixtures. These compact lights ensure well-lit shelves and organized inventory management.

- Cold Storage Warehouses:

- High Bay: Cold storage facilities require reliable lighting even in low temperatures. High bay LEDs withstand extreme conditions and maintain brightness in refrigerated environments.

- Low Bay: Low bay fixtures are suitable for walk-in freezers and smaller cold storage spaces.

Industrial Manufacturing Facilities

- Assembly Lines and Workstations:

- High Bay: Manufacturing plants rely on high bay fixtures to illuminate assembly lines, machinery, and workstations. The directional light ensures precision and safety.

- Low Bay: Low bay LEDs find applications in smaller work areas, such as quality control stations and inspection zones.

- Automotive Manufacturing Plants:

- High Bay: High bay explosion-proof LEDs enhance visibility in large automotive factories. They illuminate production lines, welding stations, and storage areas.

- Low Bay: Low bay fixtures are used in specific sections like paint booths and maintenance bays.

Hazardous Location Lighting

- Chemical Processing Plants:

- High Bay: High bay explosion-proof fixtures are essential in chemical plants. They withstand corrosive chemicals, extreme temperatures, and potential explosions.

- Low Bay: Low bay LEDs are suitable for control rooms and administrative areas within the plant.

- Oil Refineries and Petrochemical Facilities:

- High Bay: High bay LEDs illuminate oil rigs, storage tanks, and processing units. Their durability ensures uninterrupted operation in hazardous environments.

- Low Bay: Low bay fixtures provide localized lighting in maintenance workshops and equipment storage zones.

- Mining Operations:

- High Bay: Mines utilize high bay explosion-proof fixtures for underground tunnels and shafts. These rugged lights withstand dust, vibrations, and moisture.

- Low Bay: Low bay LEDs are used in mining offices, rest areas, and surface facilities.

In summary, both high bay and low bay explosion-proof LED light fixtures play critical roles in diverse industries, ensuring safety, efficiency, and productivity.

Making the Right Choice for Your Facility

When it comes to selecting the best lighting solution for your facility, it's crucial to consider consultation services and custom solutions offered by experts in explosion-proof lighting. With their in-depth knowledge and experience, they can assess your specific needs and provide tailored recommendations for explosion-proof high bay lighting that meet safety standards and enhance productivity.

Consultation Services and Custom Solutions

Consultation services are essential for understanding the unique requirements of your facility, whether it's industrial manufacturing, hazardous locations, or warehouse environments. Experts in explosion-proof lighting can conduct on-site assessments to determine the most suitable explosion-proof LED high bay lighting fixtures based on ceiling height, layout, and potential hazards. Custom solutions ensure that your lighting system is optimized for maximum safety and efficiency.

Long-Term Benefits and ROI

Investing in high-quality explosion-proof LED lights offers significant long-term benefits and return on investment (ROI). These energy-efficient fixtures not only reduce operational costs but also require minimal maintenance, resulting in lower overall expenses. Additionally, their extended lifespan means fewer replacements over time, translating to substantial savings for your facility.

Jinrong: Your Trusted Partner in Explosion-Proof Lighting Solutions

Jinrong is a leading provider of industrial lighting solutions, specializing in explosion-proof high bay lighting and LED low bay fixtures designed for hazardous environments. With a commitment to safety and reliability, Jinrong offers a comprehensive range of explosion-proof lights that comply with industry regulations while delivering superior performance. Partnering with Jinrong ensures access to top-notch products and expert guidance throughout the decision-making process.

Now that you have a better understanding of the benefits of consultation services, long-term ROI, and Jinrong's expertise in explosion-proof lighting solutions, you can confidently make an informed decision for your facility's lighting needs. By choosing the right LED light fixture tailored to your specific requirements, you can maximize safety and efficiency while optimizing productivity.

Conclusion

When it comes to choosing the right LED light fixture for your facility, explosion-proof high bay lighting is the way to go. With its superior safety features and energy-efficient design, it's the perfect solution for industrial settings. By maximizing safety and efficiency with explosion-proof lights, you can create a productive and secure work environment for your employees.

Choosing the Right LED Light Fixture for Your Facility

When selecting the ideal lighting solution for your facility, consider the benefits of explosion-proof LED high bay lighting. These fixtures offer unparalleled durability and protection in hazardous environments, making them an excellent choice for industrial settings. By choosing explosion-proof lights, you can ensure a safe and well-lit workspace for your employees.

Maximizing Safety and Efficiency

Explosion-proof high bay lighting not only provides ample illumination but also enhances safety by minimizing the risk of accidents in volatile environments. With their durable construction and reliable performance, these fixtures are designed to withstand harsh conditions while maximizing energy efficiency. By investing in explosion-proof LED high bay lighting, you can prioritize safety without compromising on productivity.

Partnering with Jinrong for Expert Guidance

For expert guidance on selecting the right explosion-proof lighting solutions for your facility, partner with Jinrong. With their extensive experience in industrial lighting and commitment to customer satisfaction, they can provide tailored consultation services and custom solutions to meet your specific needs. Trust Jinrong as your partner in creating a safe and efficient work environment with top-of-the-line explosion-proof LED lights.