Introduction

Understanding Hazardous Electrical Locations

So, what is typically considered a hazardous electrical location? It's any area where the potential for fire or explosion exists due to the presence of flammable substances. This includes environments found in industries like oil and gas, chemical manufacturing, and food processing—places where safety must be prioritized at every level.

Importance of Proper Conduit Fittings

The significance of using appropriate conduit fittings cannot be overstated in these hazardous environments. Improper fittings can lead to catastrophic failures, making it imperative to choose reliable hazardous location conduit fittings that comply with stringent regulations such as the NEC hazardous location option. Ensuring these fittings are correctly installed can greatly reduce risks associated with electrical failures.

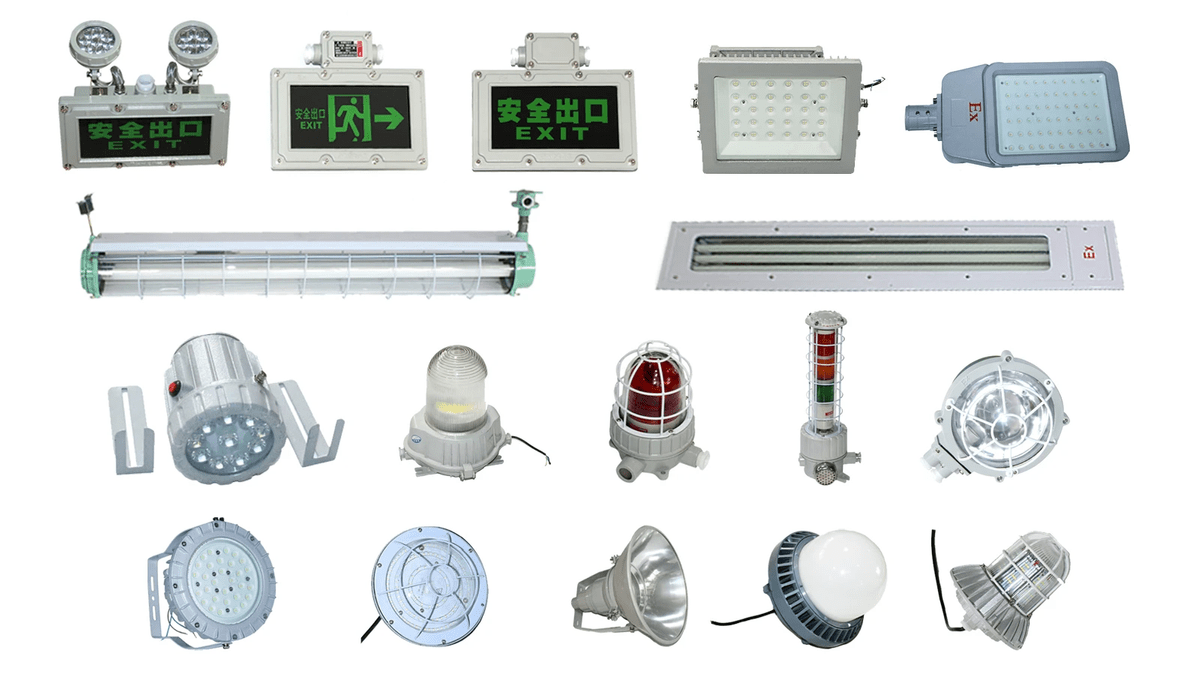

Overview of Jinrong's Expertise

At Jinrong, we understand the complexities surrounding hazardous locations and are committed to providing top-notch solutions tailored to your needs. Our extensive range includes everything from explosion-proof fittings cataloged for easy access to installation guides that simplify the process for professionals in the field. With our expertise and quality products, you can ensure compliance while maintaining safety in even the most challenging environments.

Defining Hazardous Locations

Understanding what constitutes a hazardous location is crucial for ensuring safety in environments where electrical equipment operates. These locations pose risks due to the presence of flammable gases, vapors, or dust that could ignite and cause explosions or fires. Thus, knowing how to identify these areas and the appropriate hazardous location conduit fittings is essential for both compliance and safety.

What is a hazardous electrical location?

A hazardous electrical location is typically defined as any area where flammable gases, vapors, or combustible dust are present in sufficient quantities to create an explosion risk when mixed with air. This definition encompasses various environments such as oil refineries, chemical plants, and grain storage facilities. Understanding what is typically considered a hazardous electrical location helps in selecting the right conduit in those areas to prevent accidents.

Classification of hazardous areas

Hazardous areas are classified based on the nature of the hazards present and their likelihood of occurrence. The National Electric Code (NEC) categorizes these locations into Classes (Class I for gases and vapors; Class II for dusts; Class III for fibers), Divisions (Division 1 where ignitable concentrations exist under normal operating conditions; Division 2 where they may exist under abnormal conditions), and Zones (Zone 0 being continuously hazardous). Knowing how these classifications affect the choice of hazardous location conduit fittings can help ensure compliance with safety standards.

Common industries affected

Numerous industries must contend with hazardous locations due to their operations involving combustible materials. The oil and gas industry frequently encounters such environments during extraction and refinement processes. Similarly, chemical manufacturing plants face risks from volatile substances, while food processing facilities must manage flour dust hazards—making proper installation of hazardous location conduit fittings vital across these sectors.

The Role of Conduit in Hazardous Locations

In hazardous locations, the role of conduit is crucial for ensuring safety and compliance with electrical standards. Conduit serves as a protective channel for electrical wiring, safeguarding it from environmental factors that could lead to dangerous situations, such as explosions or fires. Understanding what conduit is in a hazardous location helps businesses implement effective safety measures.

What is conduit in a hazardous location?

Conduit in a hazardous location refers to specialized tubing that houses electrical wires and cables while protecting them from external hazards like moisture, chemicals, and physical damage. It’s designed to meet stringent codes and standards that govern installation in areas where flammable gases or dust may be present. Typically considered a hazardous electrical location are environments like chemical plants, oil refineries, and grain storage facilities where the risk of ignition is heightened.

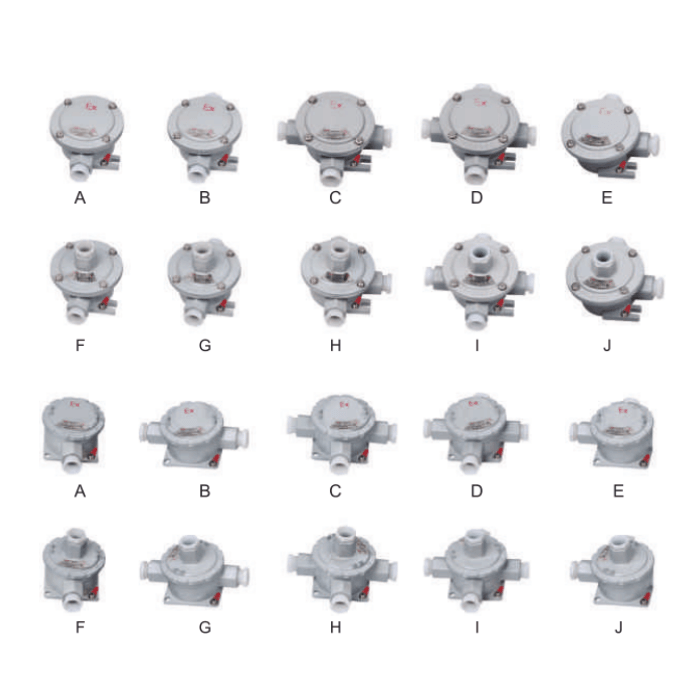

Types of hazardous location conduit fittings

When it comes to hazardous location conduit fittings, there are several types tailored for specific applications. Explosion-proof fittings are designed to contain any explosion within the fitting itself, preventing flames from escaping into the surrounding area. Other types include watertight fittings for moisture-prone environments and non-metallic options for corrosive settings—each serving a unique purpose while adhering to regulations such as the NEC hazardous location option.

Benefits of using appropriate conduit

Using appropriate hazardous location conduit fittings offers numerous benefits that extend beyond mere compliance with regulations. First and foremost, they enhance safety by minimizing the risk of electrical failures that could lead to catastrophic events like fires or explosions—an essential consideration given what is typically considered a hazardous electrical location. Additionally, investing in quality fittings can result in long-term cost savings; although initial costs may vary (with prices influenced by factors such as material type), proper installation reduces maintenance needs over time.

Understanding Regulatory Standards

Navigating the world of hazardous electrical locations can feel like walking through a minefield—metaphorically speaking, of course. One critical aspect to grasp is the regulatory standards that govern these areas, particularly when it comes to hazardous location conduit fittings. These regulations ensure safety and compliance, which is essential for preventing accidents and protecting both personnel and property.

What is the NEC hazardous location option?

The National Electrical Code (NEC) provides guidelines specifically tailored for hazardous locations, ensuring that installations are safe and effective. The NEC hazardous location option outlines what is conduit in a hazardous location, detailing various classifications based on the types of hazards present—be it flammable gases, vapors, or combustible dusts. Understanding this option helps businesses select appropriate hazardous location conduit fittings that meet safety requirements while minimizing risks.

Key regulations governing hazardous areas

Several key regulations govern the installation and use of equipment in hazardous areas, with the NEC being one of the most prominent references. In addition to the NEC guidelines, organizations must also consider local building codes and industry-specific regulations that dictate how to manage electrical systems safely in potentially dangerous environments. This multifaceted approach ensures that all aspects are covered when choosing hazardous location conduit fittings and other necessary equipment.

Compliance and its importance

Compliance with these regulatory standards is not just a box to check; it's a vital component of workplace safety and operational integrity. Non-compliance can lead to severe penalties, including fines or even shutdowns during inspections—a nightmare scenario for any business relying on continuous operations! Moreover, using compliant hazardous location conduit fittings significantly reduces the risk of accidents such as explosions or fires caused by electrical failures.

Installation Best Practices

Installing hazardous location conduit fittings is not just a matter of connecting pipes; it’s about ensuring safety, compliance, and functionality in environments where the stakes are high. Proper installation can significantly mitigate risks associated with electrical hazards, including explosions or fires that could arise from improper fittings. Here, we’ll delve into essential tips for installing these fittings effectively while also highlighting common pitfalls to avoid.

Hazardous location conduit fittings installation tips

When installing hazardous location conduit fittings, it’s crucial to start with a thorough understanding of what is typically considered a hazardous electrical location. First and foremost, ensure that all materials used are compliant with the NEC hazardous location option guidelines; this means selecting products specifically designed for explosive or flammable environments. Additionally, when laying out your installation plan, consider the type of conduit you’ll be using—explosion-proof fittings catalog will provide insights into which products suit your specific needs.

Next, pay attention to sealing methods and junction boxes to prevent any ingress of dust or moisture that could compromise safety. Properly securing connections is vital; loose fittings can lead to arcing or short circuits in hazardous locations. Lastly, always double-check your work against local regulations and standards before finalizing the installation—this ensures compliance and enhances safety.

Common mistakes to avoid

One of the most significant mistakes made during hazardous location conduit fittings installation is using unsuitable materials that do not meet regulatory standards like those outlined in the NEC hazardous location option. Such oversights can lead to severe consequences if an explosion occurs due to inadequate protection against environmental factors. Another common error is neglecting proper grounding; without effective grounding practices, even high-quality fittings can fail under stress.

Additionally, many installers underestimate the importance of following manufacturer instructions precisely—deviating from these guidelines can void warranties and lead to unsafe conditions in what is already a risky environment. Furthermore, failing to account for thermal expansion in conduits can result in cracking or misalignment over time; proper allowances must be made during installation for temperature variations typical in industrial settings.

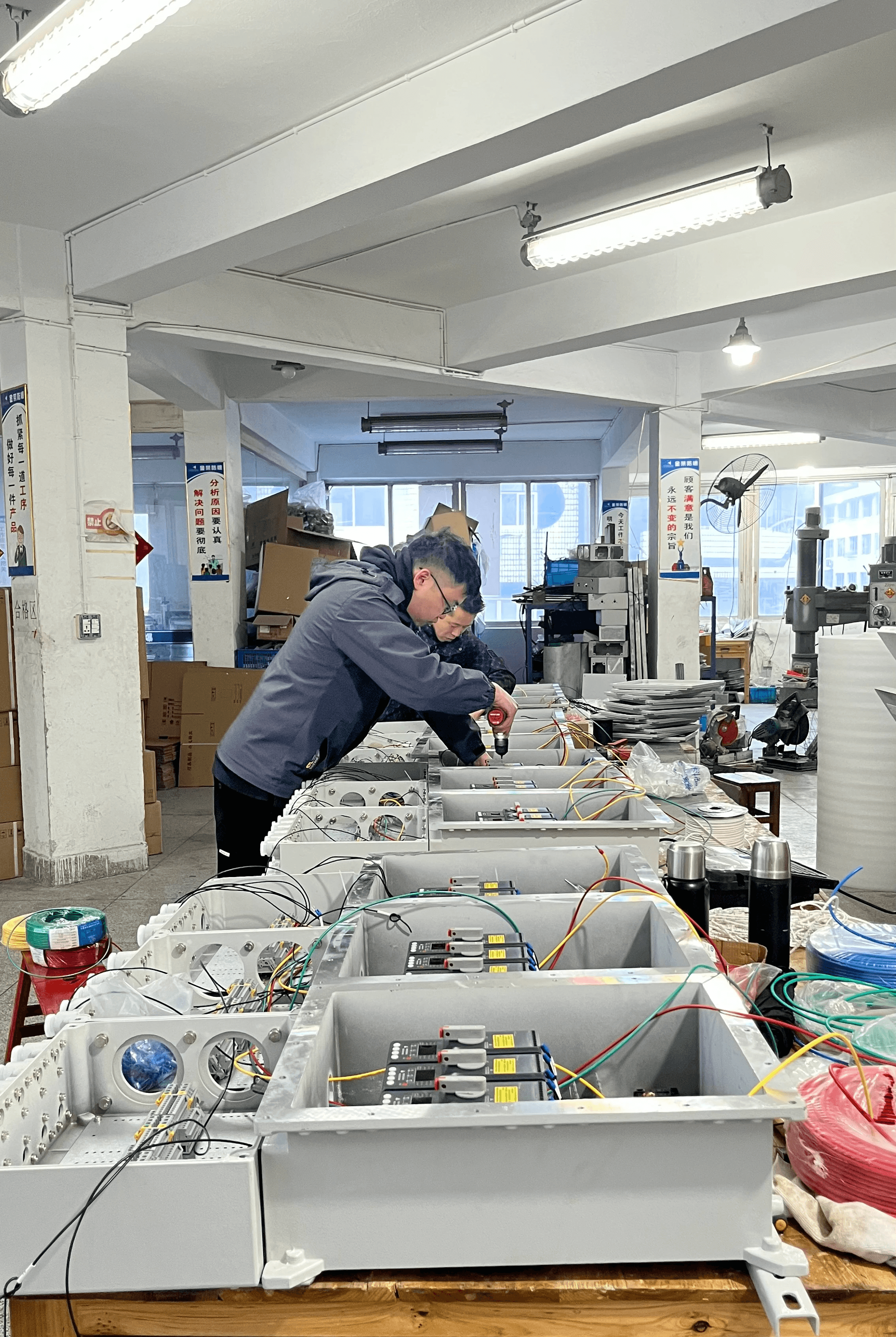

Importance of professional installation

While DIY projects might seem tempting when considering hazardous location conduit fittings installation costs, opting for professional assistance often pays off in terms of safety and compliance assurance. Professionals bring expertise that ensures every fitting meets regulatory requirements while adhering strictly to industry best practices—something critical when dealing with potentially explosive environments. Moreover, they have access to specialized tools and knowledge about current codes such as HS code for conduit fittings which may not be readily available at home improvement stores.

Engaging professionals also helps mitigate risks associated with improper installations that could lead not only to financial loss but also endanger lives due to accidents caused by faulty wiring or equipment failures. Investing in quality workmanship ultimately saves money by reducing future repair costs linked with non-compliance issues or system failures down the line.

Cost Considerations

Understanding the cost implications of hazardous location conduit fittings is essential for any project involving electrical installations in potentially dangerous areas. The price of these fittings can vary widely based on several factors, including material, design, and compliance with regulatory standards. As you navigate the costs associated with hazardous location conduit fittings, it's crucial to consider both upfront expenses and long-term benefits.

Hazardous location conduit fittings price analysis

When examining hazardous location conduit fittings prices, you'll find that they typically range from budget-friendly options to high-end solutions designed for extreme environments. The price often reflects the quality and durability of the materials used; for instance, explosion-proof fittings made from robust metals may carry a higher price tag than standard plastic alternatives. Additionally, specialized designs that comply with NEC hazardous location options can also affect pricing as they ensure safety in potentially explosive atmospheres.

Factors influencing costs

Several factors influence the costs associated with hazardous location conduit fittings beyond just material choices. For example, installation complexity plays a significant role; more intricate setups may require additional labor and expertise, driving up overall expenses. Furthermore, regional market conditions and availability of specific products—like those found in an explosion-proof fittings catalog—can impact pricing as well.

Budgeting for compliance

Budgeting for compliance with regulations surrounding hazardous locations is not just about purchasing the right materials; it also involves planning for installation and maintenance costs over time. When determining your budget for hazardous location conduit fittings installation, consider both initial outlays and potential future expenses related to inspections or upgrades needed to meet evolving safety standards. By taking a comprehensive approach to budgeting that includes all facets of compliance, you can ensure your project remains within financial limits while maintaining safety.

Conclusion

In the realm of electrical safety, understanding hazardous locations is paramount. These areas require specialized solutions, such as hazardous location conduit fittings, to ensure both compliance and safety. By grasping the significance of these fittings and their proper installation, industries can mitigate risks associated with potentially explosive environments.

Essential Takeaways on Hazardous Locations

What is typically considered a hazardous electrical location? These are environments where flammable gases, vapors, or dust may exist, posing serious risks during electrical operations. Recognizing such locations helps in selecting appropriate equipment and ensuring adherence to regulations like the NEC hazardous location option.

Furthermore, the classification of these areas is critical for determining the types of hazardous location conduit fittings needed. From Class I locations with flammable gases to Class II areas with combustible dusts, each classification demands specific solutions that comply with safety standards. Thus, understanding these classifications is essential for any business operating in a potentially dangerous environment.

The Value of Quality Fittings

Investing in quality hazardous location conduit fittings cannot be overstated; they serve as the first line of defense against potential hazards. High-quality fittings are designed to withstand extreme conditions while providing reliable protection against sparks and explosions. This not only ensures compliance but also enhances overall workplace safety—an invaluable asset in any industry.

Moreover, when considering hazardous location conduit fittings price, it’s essential to remember that cheaper options may lead to costly failures down the line. Quality fittings often come equipped with features that enhance durability and reduce maintenance costs over time. Therefore, choosing reliable products from reputable manufacturers can save businesses both money and headaches in the long run.

How Jinrong Supports Your Needs

At Jinrong, we understand that navigating through the complexities of hazardous locations can be daunting. That’s why we offer a comprehensive Explosion-Proof Fittings Catalog tailored specifically for your needs—providing you access to high-quality products designed for safety and efficiency in challenging environments. Our team is dedicated not only to supplying top-tier hazardous location conduit fittings but also to offering guidance on installation best practices.

Additionally, we recognize that what is conduit in a hazardous location? It’s more than just a protective tube; it’s an integral part of your safety strategy! With our expertise at your side, you can rest assured knowing you’re making informed decisions about your installations while maintaining full compliance with regulations like those found within NEC guidelines.