Introduction

Safety is of the utmost importance when it comes to electrical systems in hazardous areas. This is where hazardous area enclosures come into play. These specialized electrical cabinets, also known as explosion-proof enclosures or ex-proof junction boxes, are designed to contain any potential explosions or fires within the enclosure, preventing them from spreading to the surrounding environment.

Understanding Hazardous Area Enclosures

Hazardous area enclosures are engineered to withstand and contain potential explosions and fires in environments with flammable gases, vapors, or dust particles. These explosion-proof enclosures are crucial for ensuring the safety of personnel and protecting valuable equipment in hazardous locations.

Importance of Standard Enclosures

Standard electrical enclosures offer a vital layer of protection for electrical equipment in various environments. Here are some of the key benefits they provide:

- Environmental protection: Standard enclosures shield electrical components from dust, moisture, and corrosion, ensuring reliable operation.

- Improved safety: Enclosures prevent accidental contact with live electrical parts, minimizing the risk of injury.

- Enhanced organization: Enclosures provide a neat and organized way to house electrical components, simplifying maintenance and troubleshooting.

Standard electrical enclosures are cost-effective and versatile for safeguarding electrical equipment in non-hazardous environments. They offer various benefits that promote safety, reliability, and efficiency.

Key Differences and Considerations

Hazardous area enclosures and standard enclosures differ in their design and construction to meet specific safety requirements. When choosing between the two, carefully consider these three factors to ensure optimal protection:

- Environmental conditions: Hazardous areas may contain explosive gases, vapors, dust, or fibers, requiring special enclosure features to prevent ignition.

- Safety standards: Comply with relevant safety standards for the specific hazardous area classification, such as those for North America or the IEC international system.

- Compatibility with electrical equipment: Ensure the enclosure is compatible with the electrical equipment it houses to prevent sparking or overheating.

Selecting the right enclosure type is crucial for ensuring safety in hazardous environments. By considering these factors, you can choose an enclosure that meets your application's specific needs.

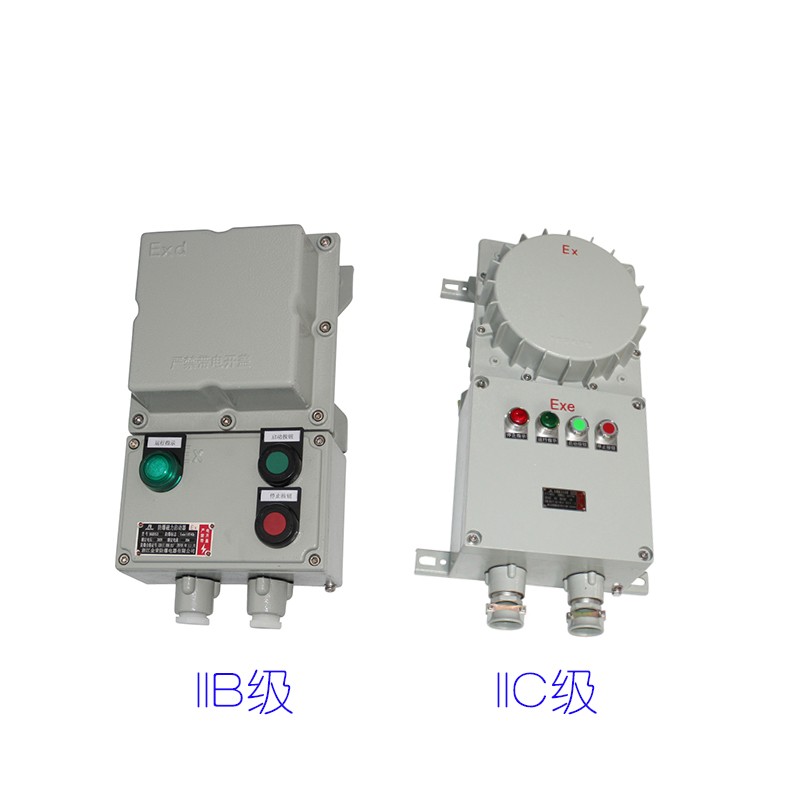

Hazardous Area Enclosures Explained

Hazardous area enclosures, also known as explosion-proof enclosures or electrical cabinets, are specifically designed to contain electrical equipment in dangerous environments with a risk of explosion due to flammable gases, vapors, or dust. These enclosures are constructed with robust materials and sealing mechanisms to prevent ignition and contain any potential explosions, ensuring the safety of personnel and equipment.

What Are Hazardous Area Enclosures?

Hazardous area enclosures are engineered to withstand harsh environmental conditions and provide secure housing for electrical components such as control panels, switches, and junction boxes. They are commonly used in industries such as oil and gas, chemical processing, pharmaceuticals, and mining, where flammable substances are present. The design of these enclosures complies with stringent safety standards to mitigate the risk of ignition and protect against potential hazards.

Why They Are Essential for Safety

Hazardous area enclosures are crucial for maintaining a safe working environment in facilities where explosive atmospheres can occur. By containing any potential explosions within the enclosure, these specialized cabinets prevent the spread of fire and minimize the risk of catastrophic accidents. This proactive approach to safety protects personnel and safeguards critical electrical equipment from damage caused by hazardous conditions.

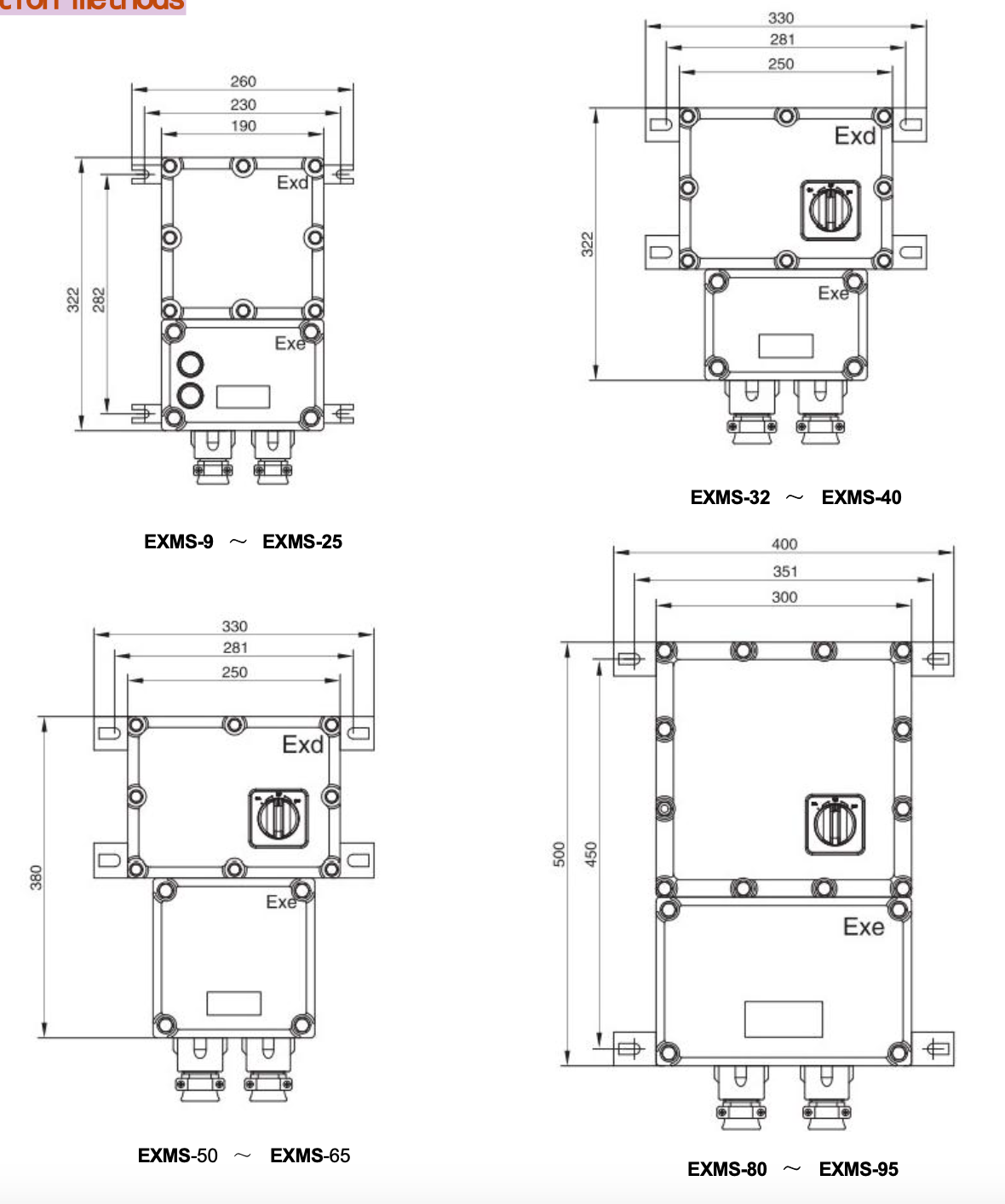

Features and Specifications

Hazardous area enclosures are equipped with flameproof seals, heavy-duty hinges, robust locking mechanisms, and corrosion-resistant coatings to ensure maximum protection against external elements. They are available in various sizes and configurations to accommodate different types of electrical equipment while maintaining compliance with explosion-proof ratings such as ATEX or IECEx standards. These specifications make them suitable for diverse industrial applications with specific environmental challenges.

In addition to their robust protective features, hazardous area enclosures also offer customizable options for ventilation, cable entry, and mounting accessories to ensure compatibility with a wide range of electrical equipment. This flexibility allows seamless integration into existing industrial setups without compromising safety or efficiency. Furthermore, these enclosures are designed to withstand harsh environmental conditions, including extreme temperatures and chemical exposure, making them ideal for use in oil and gas facilities, chemical plants, and other high-risk settings.

Standard Enclosures: An Overview

Standard enclosures are crucial in providing protection and security for electrical equipment. They are designed to house various electrical components and safeguard them from environmental factors such as dust, moisture, and corrosion. Whether it's an electrical cabinet or an electronic enclosure, standard enclosures offer a reliable solution for keeping sensitive equipment safe and operational.

Role of Standard Enclosures

Standard enclosures serve as a protective barrier for electrical components, shielding them from external elements that could potentially cause damage or malfunction. These enclosures are essential for maintaining the integrity of electrical equipment and ensuring the safety of personnel working near these systems. Whether it's an explosion-proof junction box or an ex-proof junction box, standard enclosures provide secure housing for critical electrical infrastructure.

Applications in Different Industries

Standard enclosures have widespread applications across various industries, safeguarding sensitive equipment in diverse environments. Here are some key applications:

- Manufacturing: Protecting electrical components from dust, debris, and physical impact.

- Oil and Gas: Shielding electronics in hazardous locations prone to explosions and fire.

- Chemical Processing: Safeguarding equipment from corrosive materials and washdowns.

- Pharmaceuticals: Ensuring cleanliness and sterility for sensitive electronic components.

- Telecommunications: Protecting equipment from environmental factors like dust, moisture, and extreme temperatures, guaranteeing uninterrupted communication.

From explosion-proof enclosures to general-purpose electrical cabinets, standard enclosures offer a versatile solution for ensuring the safety and reliability of critical infrastructure in a wide range of industries. In conclusion, by protecting vital equipment, standard enclosures play an essential role in maintaining the smooth operation of our everyday processes.

Limitations and Considerations

While standard enclosures offer robust protection for electrical equipment, they have limitations that must be considered. Factors such as size constraints, material compatibility with the environment, and adherence to specific industry standards must be considered when selecting an enclosure for a particular application. Understanding these limitations is crucial in choosing the right enclosure that meets both safety requirements and operational needs.

In addition to the physical constraints and material compatibility, it's important to consider the level of protection required for the electrical equipment. Standard enclosures may not provide adequate protection in hazardous environments with a risk of explosion or fire. In these cases, dangerous specialized area enclosures are designed to meet stringent safety requirements and prevent flammable gases or dust ignition. Understanding the specific hazards present in the environment is crucial in determining whether a standard or hazardous area enclosure is most suitable for the application.

Hazardous Area Enclosures vs. Standard Enclosures

When comparing hazardous area enclosures with standard enclosures, it's important to consider your application's specific requirements. Hazardous area enclosures are designed to withstand explosive atmospheres and protect electrical equipment from potential ignition sources, while standard enclosures are more suited for general industrial use. The construction materials and design features of hazardous area enclosures are specifically engineered to prevent the release of sparks or heat that could lead to an explosion.

A Detailed Comparison

Hazardous area enclosures, also known as explosion-proof enclosures, are constructed with robust materials such as stainless steel or aluminum to prevent the ignition of flammable gases, vapors, or dust in hazardous environments. These enclosures undergo rigorous testing and certification processes to ensure compliance with international safety standards such as ATEX and IECEx. On the other hand, standard enclosures may not have the same level of protection against explosive atmospheres and may not be suitable for use in hazardous locations.

Advantages and Disadvantages

The primary advantage of hazardous area enclosures is their ability to mitigate the risk of explosions in volatile environments by containing any potential ignition sources within the enclosure. This significantly enhances safety for personnel working in these areas and protects valuable equipment from damage. However, a potential disadvantage is that these specialized enclosures may be more costly than standard alternatives due to their advanced design and certification requirements.

Choosing the Right Enclosure for Your Needs

When selecting between hazardous area enclosures and standard enclosures, it's crucial to assess your application's specific environmental conditions and safety requirements. Consider factors such as flammable substances, temperature extremes, corrosive elements, and mechanical impact risks. It's also essential to ensure that your chosen enclosure complies with relevant safety standards and certifications to guarantee its suitability in hazardous areas.

Now that we've explored the differences between hazardous area enclosures and standard enclosures, it's clear that making an informed choice is crucial for ensuring safety in potentially explosive environments while maintaining operational efficiency. Let's discuss key factors you should consider when evaluating your enclosure options.

Key Factors to Consider

When selecting hazardous area enclosures, several key factors must be considered to ensure safety and compliance. Environmental conditions play a significant role in determining the type of enclosure needed for specific locations. Safety standards and certifications ensure the enclosure meets industry regulations and guidelines. Additionally, compatibility with electrical equipment is vital to guarantee seamless integration and functionality.

Environmental Conditions

Understanding the environmental conditions where the hazardous area enclosures will be installed is critical for selecting the right type. Here are some key factors to consider:

- Temperature: Extreme high and low temperatures can affect the performance of electrical components housed within the enclosure.

- Humidity: High humidity can lead to condensation and corrosion within the enclosure.

- Exposure to Corrosive Substances: Certain chemicals can degrade the enclosure material, compromising its integrity.

By carefully assessing these conditions, you can choose an enclosure that will provide optimal protection for your equipment and ensure long-term safe operation in hazardous environments.

Safety Standards and Certifications

Compliance with safety standards and certifications regarding hazardous area enclosures is non-negotiable. These standards ensure that the enclosures are designed and manufactured to meet strict safety requirements, minimizing the risk of accidents or malfunctions in hazardous environments. Look for certified enclosures in explosive atmospheres, such as explosion-proof junction boxes or ex-proof enclosures, to guarantee their reliability in high-risk areas.

In addition to safety standards and certifications, it's important to consider the compatibility of hazardous area enclosures with electrical equipment. Look for enclosures that accommodate a wide range of electrical components, ensuring seamless integration and optimal performance in hazardous environments. Compatibility with electrical equipment also minimizes the need for customization or modifications, saving time and resources during installation and maintenance.

Compatibility with Electrical Equipment

Hazardous area enclosures' compatibility with electrical equipment is crucial for seamless integration and optimal performance. Whether it's an electrical cabinet or an electronic enclosure box, it's essential to ensure that the dimensions, mounting options, and cable entry points align with the specific electrical components they will house. This compatibility not only ensures a secure fit but also simplifies installation and maintenance processes.

In addition to ensuring compatibility with electrical equipment dimensions and mounting options, it's also important to consider the environmental factors that the hazardous area enclosures will be exposed to. Factors such as temperature, humidity, and potential exposure to corrosive substances can impact the performance and longevity of the enclosure and the electrical components inside. By choosing enclosures specifically designed to withstand these conditions, you can ensure optimal performance and minimize maintenance requirements in the long run.

Stay tuned for more information on how Jinrong’s superior quality hazardous area enclosures can meet your specific needs!

The Jinrong Advantage

At Jinrong, we take pride in providing superior quality and expertise in manufacturing hazardous area enclosures. Our team of experienced engineers and technicians ensures that each electrical cabinet and enclosure electronic meets the highest standards for safety and reliability. With a focus on precision engineering and attention to detail, we guarantee that our explosion-proof junction box and ex-proof junction box products are built to last in even the most challenging environments.

Superior Quality and Expertise

Our commitment to superior quality is evident in every aspect of our production process. From the selection of materials to the final assembly, each step is carefully executed to meet strict industry standards for hazardous area enclosures. We understand these enclosures' critical role in ensuring safety, which is why we go above and beyond to deliver products that exceed expectations.

Extensive Manufacturing Experience

With decades of experience in manufacturing explosion-proof enclosures, we have honed our skills to perfection. Our extensive knowledge allows us to anticipate and address potential challenges, ensuring that our products are compliant with regulations and optimized for performance. Whether it's an explosion-proof enclosure or an ex-proof junction box, our expertise shines through in every product we deliver.

Customer Success Stories

Our track record speaks for itself, as countless customers have experienced success with our hazardous area enclosures. From large industrial facilities to niche applications, our customers rely on us for their electrical enclosure box needs because they know they can trust our products to deliver exceptional performance under demanding conditions.

Now you know why Jinrong is a leader in providing top-quality hazardous area enclosures!

Make the Right Enclosure Choice

When it comes to choosing the right enclosure for your electrical equipment, it's crucial to prioritize safety and compliance. Whether you need an explosion-proof enclosure, an ex-proof junction box, or a standard electrical cabinet, Jinrong has you covered with top-notch quality and expertise.

Choosing the right hazardous area enclosures is essential for protecting your electrical equipment from potential hazards. Jinrong offers a wide range of options, including explosion-proof junction boxes and electronic enclosures, so you can confidently select the perfect fit for your specific needs.

Ensuring Safety and Compliance

Safety and compliance should always be top priorities regarding electrical enclosures. By opting for explosion-proof enclosures from Jinrong, you can rest assured that your equipment is well-protected in hazardous environments and meets all necessary safety standards and regulations.

Partnering with Jinrong for Your Enclosure Needs

When finding the ideal electronic or electrical enclosure box, partnering with Jinrong is a smart choice. With our extensive manufacturing experience and proven track record of customer success stories, we are dedicated to providing superior quality solutions tailored to your unique requirements.