Introduction

When it comes to hazardous materials classification, understanding the different classes is crucial for ensuring safety in various industries. One of the most important classes to identify is Class 3 flammable liquids, which pose a significant risk if improperly handled. In this article, we will explore the specifics of Hazmat Class 3 flammable liquids and the associated regulations and safety measures.

Understanding Hazardous Materials Classification

Hazardous materials classification involves categorizing substances based on their potential risks and properties. This system helps identify and safely handle these materials, preventing accidents and environmental harm.

Identifying flammable liquids is a crucial aspect of hazardous materials classification. Flammable liquids pose a significant risk due to their potential to ignite and cause fires or explosions. By categorizing these substances appropriately, it becomes easier to implement safety measures and protocols to minimize the associated risks. Understanding the specific properties of flammable liquids also allows for proper storage, transportation, and disposal procedures, reducing the likelihood of accidents and environmental damage.

Importance of Identifying Flammable Liquids

Identifying flammable liquids is crucial for preventing fires and explosions. Accurate identification enables the implementation of essential safety protocols. To effectively identify flammable liquids, consider the following key characteristics:

- Flashpoint: The lowest temperature at which a liquid can produce enough flammable vapor to ignite.

- Vapor pressure: The pressure exerted by the vapor of a liquid in equilibrium with its liquid phase at a given temperature.

- Flammability limits: The range of concentrations of a flammable gas or vapor in air that will burn when ignited.

- Ignition temperature: The minimum temperature required to ignite a flammable substance without a spark or flame.

Understanding these properties and following proper handling procedures can significantly reduce the risk of accidents involving flammable liquids.

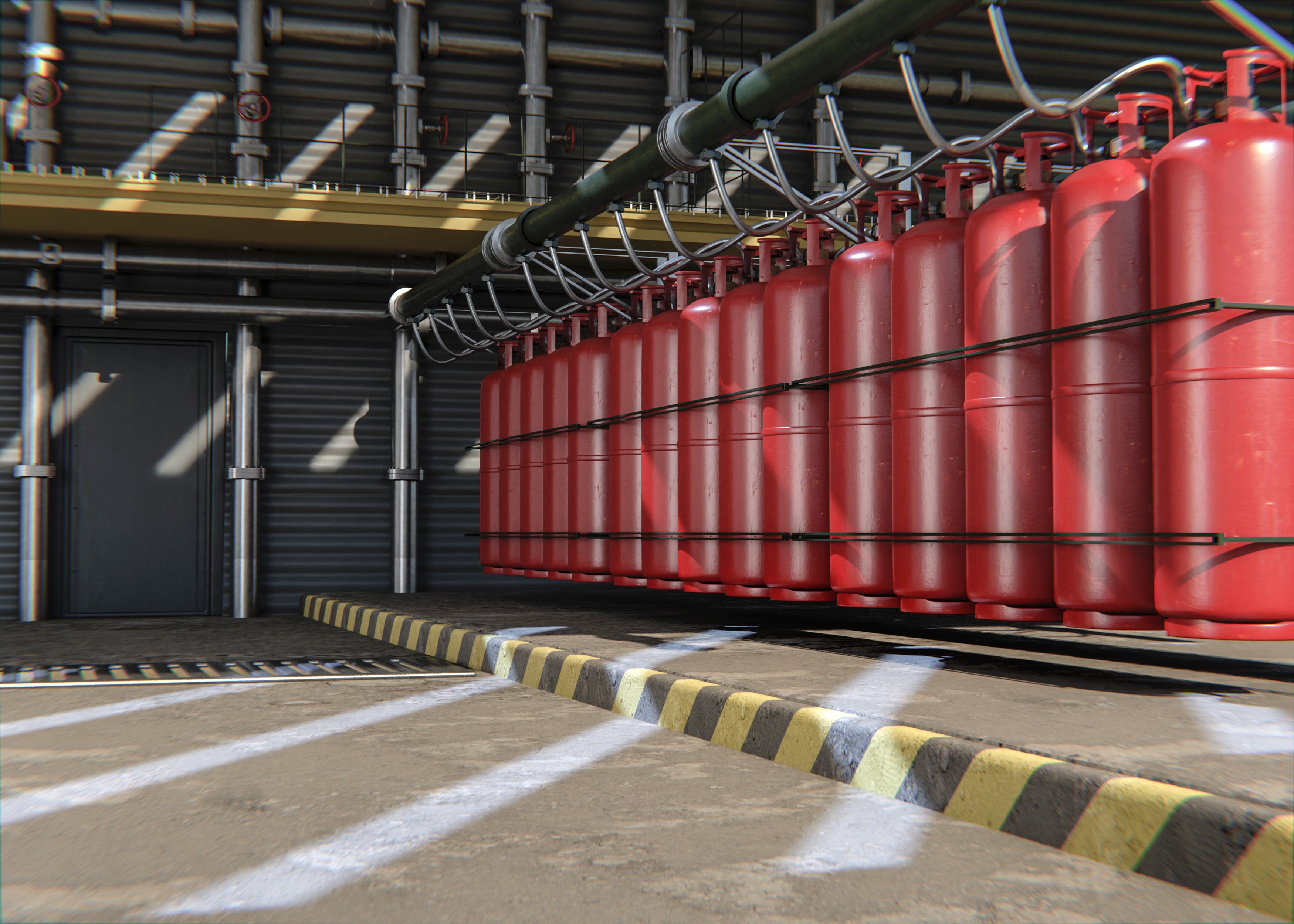

Exploring Hazmat Class 3 Flammable Liquids

Class 3 hazardous materials encompass flammable liquids, which include various substances with different ignition points and volatility levels. Understanding the specific characteristics of these liquids is essential for mitigating risks associated with their use.

Flammable liquids are categorized as Class 3 hazardous materials due to their potential to ignite and burn. These substances can range from gasoline and diesel fuel to alcohol-based products and solvents. Each flammable liquid has unique properties, such as flashpoint and boiling point, which must be carefully considered when handling or transporting them. By understanding these specific characteristics, individuals can take appropriate precautions to minimize the risk of fire or explosion.

What Class is Flammable Liquids?

Definition and Characteristics of Flammable Liquids

Flammable liquids have a flash point below 100 degrees Fahrenheit and a vapor pressure not exceeding 40 psi at 100 degrees Fahrenheit. These highly volatile liquids can easily ignite and burn at normal working temperatures. They are often used in various industrial processes, making it crucial to understand their properties for safety purposes.

Flammable liquids pose a significant risk in the workplace, as their volatile nature makes them prone to accidental ignition. Understanding the characteristics of these substances is essential for implementing proper safety measures and protocols. Additionally, workers handling flammable liquids must be trained to safely store, transport, and use these materials to minimize potential accidents and injuries.

Hazmat Class 3 Flammable Liquids Regulations

The transportation of hazardous materials, including class 3 flammable liquids, is regulated by the Department of Transportation (DOT) in the United States. The regulations include packaging requirements, labeling, marking, placarding, and documentation for the safe transportation of these materials. Businesses must comply with these regulations to ensure the safe handling and transport of flammable liquids.

Flammable liquids are defined as those with a flashpoint below 100 degrees Fahrenheit, while combustible liquids have a flashpoint above 100 degrees Fahrenheit. This means that flammable liquids ignite easily at lower temperatures, making them more hazardous to transport. Because of this increased risk, the DOT has specific regulations for transporting class 3 flammable liquids to minimize the potential for accidents and ensure the safety of everyone involved.

Differences Between Flammable and Combustible Liquids

One key difference between flammable and combustible liquids lies in their flash points. Flammable liquids have lower flash points than combustible liquids, making them more prone to ignition at lower temperatures. While both types pose fire hazards, understanding their differences is crucial for implementing appropriate safety measures in handling and storage.

One important consideration when dealing with flammable liquids is the potential for vapor ignition. Due to their lower flash points, flammable liquids can easily produce vapors that ignite with a small spark or heat source. This means extra precautions must be taken when handling and storing flammable liquids to minimize the risk of fire or explosion. Understanding the behavior of these vapors is essential for creating a safe environment to work with these substances.

Now, let's dive into the critical aspect of Ex-Proof Manufacturing for flammable liquids.

Ex-Proof Manufacturing of Flammable Liquids

Importance of Ex-Proof Equipment for Flammable Liquids

Safety is paramount when working with hazardous materials like Class 3 flammable liquids. Ex-proof equipment provides critical protection by preventing flammable gases and vapors ignition.

- Protects against ignition: Ex-proof equipment is designed to contain sparks and heat, reducing the risk of fire or explosion.

- Ensures compliance: Investing in ex-proof manufacturing demonstrates a commitment to safety regulations.

- Safeguards workers and the environment: Ex-proof equipment helps protect both employees and the surrounding area by minimizing accidents.

Prioritizing safety using ex-proof equipment is crucial for any industry handling flammable liquids.

Diving Into Ex-Proof Manufacturing with Jinrong

Jinrong is a leading provider of ex-proof equipment for hazardous materials, including class 3 flammable liquids. Their expertise in this area allows them to create top-notch solutions that adhere to strict safety standards and regulations. With Jinrong, you can trust that your flammable liquids are handled carefully.

Jinrong's ex-proof equipment for hazardous materials goes beyond just meeting safety standards. Its innovative designs and advanced technology ensure that your flammable liquids are handled with care and stored and transported as efficiently and effectively as possible. This means you can have peace of mind knowing that your operations are not only safe but also optimized for maximum productivity.

Benefits of Using Ex-Proof Equipment for Flammable Liquids

Ex-proof equipment is essential for safely handling flammable liquids. By investing in these specialized tools, businesses can significantly enhance safety measures and reduce the risk of fire or explosion.

Key benefits of using ex-proof equipment include:

- Enhanced safety: Protects employees and the environment from potential hazards.

- Reduced risk: Minimizes the chance of fire or explosion incidents.

- Regulatory compliance: Ensures adherence to industry standards and regulations.

- Operational efficiency: Streamlines processes and reduces downtime.

- Cost savings: Prevents costly accidents and potential business disruptions.

Let's delve deeper into the safety measures required for handling class 3 hazardous materials.

Class 3 Flammable Liquid Safety Measures

Handling and Storage Guidelines for Flammable Liquids

When dealing with hazmat class 3 flammable liquids, following proper handling and storage guidelines is crucial to minimize the risk of accidents. Always store flammable liquids in approved containers that are designed to withstand the potential hazards they pose. Additionally, ensure that these containers are kept in well-ventilated areas away from heat sources and ignition points.

Furthermore, it's important to label all containers with the appropriate hazard warnings and safety information to ensure that anyone handling flammable liquids is aware of the potential risks. In addition, regular inspections should be conducted to check for any signs of damage or leaks in the containers and ensure that they are stored securely. Following these guidelines can help prevent accidents and protect employees and the environment from the dangers associated with class 3 hazardous materials.

Regulatory Compliance for Class 3 Hazardous Materials

Regulatory compliance for class 3 hazardous materials, such as flammable liquids, is essential to ensure the safety of workers and the surrounding environment. It's important to stay updated with the latest regulations set forth by organizations such as OSHA and EPA to guarantee that your handling and storage practices align with industry standards. Non-compliance can result in severe penalties and pose significant risks.

Ensuring regulatory compliance for class 3 hazardous materials, such as flammable liquids, requires a comprehensive understanding of the requirements outlined by OSHA and EPA. This includes proper labeling, storage, and handling procedures to minimize potential accidents or environmental harm. Staying informed about any updates or changes to regulations is crucial to maintaining a safe and compliant workplace environment.

Best Practices for Safe Handling of Flammable Liquids

Implementing best practices for safely handling flammable liquids prevents accidents and minimizes potential hazards. This includes providing proper training for employees handling these materials, ensuring they understand the risks and how to mitigate them effectively. Regularly inspecting storage areas and equipment can help identify potential issues before they escalate.

Furthermore, it is important to establish clear protocols for handling and storing flammable liquids, including proper labeling and storage procedures. This can help minimize the risk of accidental spills or leaks, which could lead to fires or other dangerous situations. By implementing these protocols and ensuring strict adherence, businesses can create a safer work environment for their employees and reduce the likelihood of incidents occurring.

Proper Handling and Storage of Flammable Liquids

Ensuring Safety with Hazardous Materials Classes

Understanding hazardous materials classes is crucial for ensuring workplace safety and compliance with regulations. By identifying and properly classifying flammable liquids, businesses can take the necessary precautions to prevent accidents and protect their employees. Proper handling and storage of flammable liquids is essential to minimize the risk of fire or explosions in the workplace. This includes using appropriate containers, labeling them correctly, and storing them in designated areas away from potential ignition sources.

To minimize the risk of fire or explosion, strict guidelines for handling and storage of class 3 flammable liquids must be followed. Safety measures such as using appropriate containers, labeling, and ventilation systems can greatly reduce the potential hazards associated with these hazardous materials.

Following these guidelines is crucial for the safety of both employees and the surrounding environment. By adhering to proper handling and storage procedures, companies can prevent costly accidents and potential harm to personnel. Additionally, implementing safety measures demonstrates a commitment to responsible environmental stewardship, which can enhance a company's reputation and credibility.

Partnering with Jinrong for Ex-Proof Solutions

When manufacturing flammable liquids, partnering with a company like Jinrong, which specializes in ex-proof equipment, is a smart choice. Their expertise in designing and producing explosion-proof solutions ensures businesses can safely handle and process hazardous materials without compromising efficiency or productivity.

Remember, when dealing with hazardous materials like class 3 flammable liquids, it's always better to err on the side of caution. By understanding the classification, regulations, and safety measures associated with these substances, businesses can create a safer work environment for everyone involved. By partnering with experts in ex-proof solutions like Jinrong, they can further enhance their safety protocols while maintaining operational excellence.