Introduction

In environments where flammable gases, vapors, or dust are present, understanding the difference between explosion proof and intrinsically safe equipment is crucial. These terms often surface in discussions about safety standards, but what do they really mean? The distinction between these two safety concepts can significantly impact operational efficiency and personnel safety in hazardous areas.

Understanding Explosion Proof and Intrinsically Safe

At first glance, explosion proof might sound like a superhero cape for machinery, but it has a specific meaning in industrial contexts. Essentially, explosion proof refers to equipment designed to contain any explosion within its housing, preventing ignition of surrounding flammable materials. On the other hand, the intrinsically safe symbol represents technology that limits energy output to prevent sparks from igniting hazardous substances—two approaches to achieving safety but with differing methodologies.

Importance of Safety in Hazardous Areas

Ensuring safety in hazardous areas isn’t just a regulatory checkbox; it’s a matter of life and death. The consequences of inadequate protection can be catastrophic—explosions can lead to loss of life and significant property damage. Therefore, understanding what is considered explosion proof or intrinsically safe is vital for anyone working in environments where dangerous materials are handled.

Key Certifications and Standards

Navigating the labyrinth of safety certifications can feel daunting; however, familiarizing oneself with key standards such as ATEX and IECEx can simplify the process. These certifications provide guidelines that clarify what is considered explosion proof versus intrinsically safe equipment. Additionally, understanding the difference between explosion proof and ATEX helps ensure compliance while maximizing workplace safety.

Defining Explosion Proof

When we think about safety in hazardous environments, the term explosion proof often comes to mind. But what does it really mean? In essence, explosion proof refers to equipment designed to contain any explosion that might occur within its housing, preventing flames or hot gases from escaping and igniting the surrounding atmosphere.

What is Explosion Proof Meaning?

The explosion proof meaning is rooted in the concept of containing explosive forces. Equipment labeled as explosion proof has been rigorously tested and constructed to withstand internal explosions without compromising safety. This classification is crucial for industries where flammable gases or dust are present, ensuring that any potential ignition source is effectively managed.

Understanding what is considered explosion proof involves knowing that not all equipment can simply be deemed safe for hazardous areas. It must meet stringent standards and undergo specific testing processes to gain certification. This leads us into a discussion of how this differs from other safety measures, such as intrinsically safe technology.

Real-World Applications and Examples

Real-world applications of explosion proof technology are abundant in industries like oil and gas, chemical manufacturing, and mining. For instance, you might find explosion proof lights illuminating a drilling site or an explosion proof camera monitoring activities in a volatile environment. These applications highlight the importance of using specialized equipment designed to minimize risks associated with explosive atmospheres.

Additionally, many facilities rely on these devices for compliance with regulations regarding worker safety in hazardous locations. The use of explosion proof tools ensures that operations can continue without unnecessary risk to personnel or property. However, it’s essential to differentiate between what is considered explosion proof versus other classifications like intrinsically safe systems.

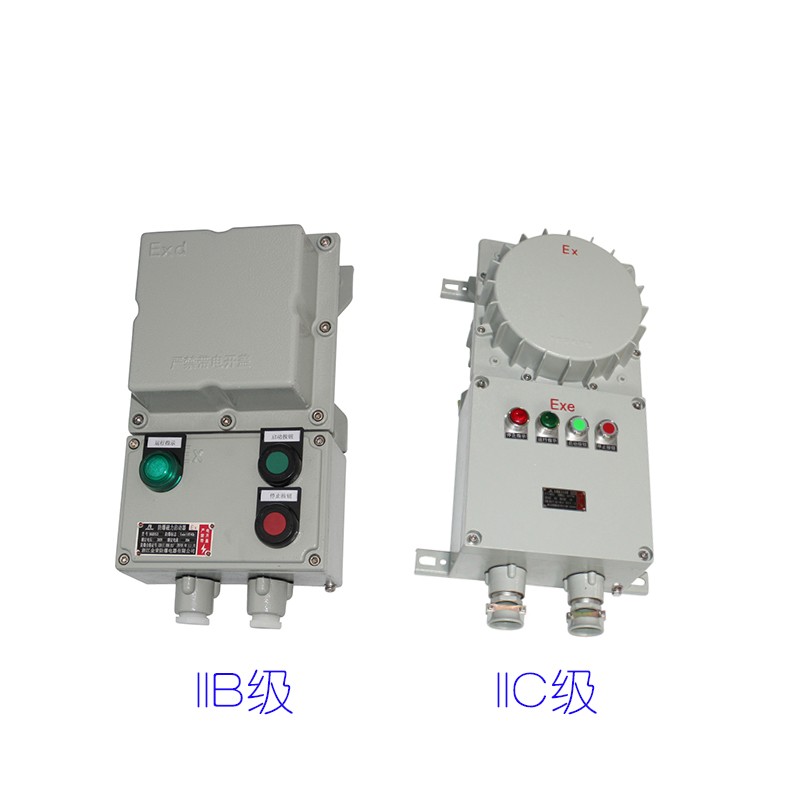

Explosion Proof Classification Explained

Explosion proof classification involves several key standards that dictate how equipment should be designed and tested for use in hazardous environments. These classifications often include specific ratings based on the type of explosive atmosphere they can safely operate within—be it gas or dust-related hazards.

For example, when discussing the difference between explosion proof and ATEX (the European Union's directive on equipment used in explosive atmospheres), it's important to note that ATEX-compliant devices may also be classified under general standards for being explosion resistant. However, understanding these classifications helps clarify misconceptions about terms like “explosion resistant” versus “explosion proof.”

In summary, while both types aim for safety in dangerous conditions, their definitions hinge on different testing requirements and operational capabilities—ultimately guiding users toward making informed choices about their safety needs.

Grasping Intrinsically Safe

When discussing safety in hazardous environments, understanding the concept of intrinsically safe is crucial. This technology is designed to prevent ignition in explosive atmospheres by limiting the energy available for ignition. As we delve into this topic, we will explore the intrinsically safe symbol, its applications in industrial settings, and the advantages it offers over traditional explosion proof methods.

What is Intrinsically Safe Symbol?

The intrinsically safe symbol is a distinctive mark that signifies a device's compliance with safety standards for use in hazardous locations. Typically depicted as an i within a circle, this symbol assures users that the equipment has been rigorously tested and meets specific criteria to prevent ignition under normal operating conditions. Understanding this symbol is essential when comparing explosion proof vs intrinsically safe technologies, as it highlights devices designed specifically to mitigate risks associated with explosive atmospheres.

Applications in Industrial Environments

Intrinsically safe technology finds application across various industrial environments where flammable gases or dust are present. Common sectors include oil and gas, chemical manufacturing, pharmaceuticals, and mining—areas where safety is paramount due to potentially explosive conditions. By utilizing intrinsically safe devices, operators can ensure compliance with safety regulations while enhancing operational efficiency without compromising on safety measures.

Advantages of Intrinsically Safe Technology

The advantages of intrinsically safe technology are manifold and play a vital role in ensuring workplace safety. Firstly, these devices can operate safely without additional protective measures required for explosion proof equipment; they limit energy output to levels incapable of igniting an explosive atmosphere. Secondly, unlike traditional explosion proof classifications which focus on containing explosions within the device itself, intrinsically safe systems offer flexibility in design and deployment—making them ideal for dynamic work environments where adaptability is key.

In conclusion, understanding the intricacies of intrinsic safety not only clarifies what is considered explosion proof but also distinguishes it from other classifications like ATEX standards or explosion-resistant technologies. The distinction between these systems becomes especially crucial when evaluating their effectiveness against potential hazards present in various industries.

Comparing Explosion Proof and Intrinsically Safe

Explosion Proof vs Intrinsically Safe: Key Differences

The terms explosion proof and intrinsically safe often lead to confusion, yet they represent fundamentally different approaches to safety. Explosion proof devices are designed to contain any explosion that occurs within them, preventing ignition of surrounding flammable gases or dusts. On the other hand, intrinsically safe technology ensures that any electrical sparks produced are too weak to ignite a hazardous atmosphere—essentially making it safe by design.

In practical terms, this means that explosion proof devices can be bulkier and more robust due to their containment features, while intrinsically safe equipment is typically lighter and easier to handle. The explosion proof classification focuses on structural integrity under extreme conditions, whereas intrinsically safe systems prioritize limiting energy output during normal operation. Understanding these distinctions is vital for selecting appropriate equipment based on specific industrial needs.

What is Considered Explosion Proof?

To determine what is considered explosion proof, we must refer to rigorous testing standards that define this classification. Generally speaking, an explosion-proof device must withstand an internal explosion without allowing flames or hot gases to escape into the external environment—essentially acting as a protective fortress against potential hazards. Such devices are often constructed from heavy-duty materials like cast aluminum or steel.

Certification bodies like Underwriters Laboratories (UL) provide guidelines for manufacturers on achieving this classification through extensive testing protocols. These tests ensure that each product adheres strictly to safety regulations before being deemed suitable for use in hazardous locations such as oil refineries or chemical plants. In summary, if a device meets these stringent criteria and carries appropriate markings indicating its compliance with safety standards, it can be confidently labeled as explosion proof.

Is ATEX the Same as Intrinsically Safe?

A common question arises: Is ATEX the same as intrinsically safe? The short answer is no; while both relate to safety in explosive environments, they serve different purposes within regulatory frameworks. ATEX (ATmosphères EXplosibles) refers specifically to European Union directives governing equipment used in explosive atmospheres—providing guidelines for both intrinsic safety measures and explosion-proof classifications.

Intrinsically safe systems may fall under ATEX regulations if they are applied within EU jurisdictions; however, not all ATEX-certified devices are intrinsically safe by definition since some may also be classified as explosion proof depending on their construction methods and intended use cases. Therefore, while there’s overlap between these concepts within certain contexts—such as compliance with international standards—they should not be conflated when discussing safety measures for hazardous areas.

Safety Standards and Regulations

When it comes to safety in hazardous areas, understanding the relevant standards is paramount. Two of the most recognized sets of regulations are ATEX and IECEx, which provide frameworks for ensuring equipment can operate safely in explosive atmospheres. Familiarity with these standards can help organizations make informed decisions regarding equipment selection, ultimately minimizing risks associated with explosion proof vs intrinsically safe technologies.

Overview of ATEX and IECEx Standards

ATEX (Atmosphères Explosibles) is a European directive that outlines the requirements for equipment used in explosive environments, while IECEx (International Electrotechnical Commission Explosive) offers an international certification system for similar purposes. Both standards focus on preventing ignition sources in hazardous areas, but they differ slightly in their approach and application scope. Understanding these differences is crucial for determining what is considered explosion proof or intrinsically safe under varying regulatory frameworks.

The Role of Certifications in Safety

Certifications play a vital role in ensuring that equipment meets safety standards before being deployed in hazardous environments. They provide assurance that products have undergone rigorous testing to verify their compliance with regulations like ATEX and IECEx. This leads to greater confidence among users when distinguishing between explosion proof vs intrinsically safe devices; knowing that certified equipment minimizes risks associated with potential explosions.

What is the Difference Between Explosion Proof and ATEX?

While both terms relate to safety measures against explosions, they are not interchangeable. Explosion proof refers specifically to devices designed to contain any explosions within them, preventing external ignition; however, ATEX pertains more broadly to regulatory compliance within Europe concerning any equipment used in potentially explosive atmospheres. Therefore, understanding what is the difference between explosion proof and ATEX can help organizations navigate their safety needs effectively.

Common Misconceptions

When it comes to hazardous environments, understanding the nuances of safety equipment is crucial. Many people often confuse terms like explosion proof and explosion resistant, leading to potentially dangerous situations. Clearing up these misconceptions can help ensure that the right equipment is used in the right contexts, ultimately enhancing safety.

What is the Difference Between Explosion Proof and Explosion Resistant?

The terms explosion proof and explosion resistant are often used interchangeably, but they have distinct meanings that are important to grasp. Essentially, explosion proof means that a device can contain an explosion within its housing, preventing any flames or sparks from escaping into the surrounding area. On the other hand, explosion resistant refers to equipment designed to withstand external explosions without being damaged but does not necessarily contain an internal explosion. Understanding these differences is vital for selecting appropriate equipment in hazardous environments.

In discussing explosion proof vs intrinsically safe technologies, it's essential to note that each serves a specific purpose in different contexts. While both aim to enhance safety in explosive atmospheres, they do so through different mechanisms and classifications. Recognizing what is considered explosion proof helps organizations make informed decisions about their safety protocols.

Misunderstandings about Safety Ratings

Safety ratings can be a minefield of confusion for many professionals working in hazardous areas. One common misunderstanding revolves around how these ratings are assigned and what they actually mean for equipment performance—especially when comparing standards like ATEX and IECEx with intrinsic safety certifications. For instance, just because a device has an intrinsically safe symbol doesn’t automatically qualify it as suitable for every explosive environment; context matters!

Moreover, many individuals assume that all devices labeled as explosion proof meet stringent requirements without fully understanding what those requirements entail. This misconception can lead to improper applications of equipment that could compromise safety rather than enhance it. It's essential for teams working with potentially explosive materials to educate themselves on these distinctions.

Real-Life Scenarios: Misuse of Equipment

Misuse of equipment due to misconceptions about safety standards can have dire consequences in industrial settings. Imagine a scenario where workers use non-intrinsically safe tools in an area classified as hazardous because they mistakenly believe all explosion-proof devices are interchangeable with intrinsically safe ones—this could lead to catastrophic results!

Another common scenario involves using explosion-resistant gear instead of actual explosion-proof equipment when handling volatile substances; this misjudgment may expose workers and facilities alike to unnecessary risks during operations involving flammable materials or gases. It’s critical for organizations to ensure their teams understand the real-world implications of choosing between options like ATEX-certified devices versus those marked only as explosion resistant.

In conclusion, taking time to clarify these common misconceptions about safety ratings and classifications will significantly improve workplace safety protocols across various industries dealing with hazardous materials.

Conclusion

In the world of hazardous environments, understanding the nuances between explosion proof and intrinsically safe equipment is crucial for ensuring safety and compliance. Choosing the right equipment for your specific needs can significantly impact workplace safety and operational efficiency. By familiarizing yourself with concepts like explosion proof meaning, classifications, and the intricacies of standards such as ATEX, you can make informed decisions that protect both personnel and assets.

Choosing the Right Equipment for Your Needs

When it comes to selecting between explosion proof vs intrinsically safe technologies, it's essential to assess the specific risks associated with your environment. What is considered explosion proof? This term typically refers to equipment designed to contain an explosion within its housing, preventing ignition in surrounding areas. On the other hand, intrinsically safe devices are engineered to limit energy output so that even in a fault condition, they cannot ignite flammable materials—making them ideal for many industrial settings.

Understanding these differences not only helps in compliance but also aids in optimizing operational efficiency. For example, if your environment has volatile gases or dust, choosing intrinsically safe devices could be a more effective solution than relying solely on explosion-proof classifications. Moreover, when evaluating options like “Is ATEX the same as intrinsically safe?”, it's vital to recognize that while ATEX provides guidelines for both types of equipment, they serve different purposes based on their design principles.

Importance of Professional Guidance in Safety

Navigating through safety regulations and standards can be daunting without professional guidance. The complexities surrounding what is the difference between explosion proof and ATEX often confuse decision-makers; thus consulting experts who understand these distinctions is invaluable. They can help clarify misconceptions about safety ratings and provide insights into proper equipment usage tailored to your unique situation.

Moreover, professionals can assist in determining what is the difference between explosion proof and explosion resistant technologies—helping you avoid costly mistakes related to improper equipment selection or installation practices. This expertise ensures that you not only comply with relevant regulations but also foster a culture of safety within your organization.

How Jinrong Can Help You Navigate These Standards

At Jinrong, we specialize in helping businesses navigate these intricate standards with ease and confidence. Our team understands that choosing between explosion proof vs intrinsically safe options requires careful consideration of various factors including environmental hazards and operational needs. We offer comprehensive consultations aimed at equipping you with knowledge about intrinsic safety symbols as well as practical applications of both technology types.

We pride ourselves on demystifying concepts such as what is considered explosion proof or how ATEX applies across different industries—ensuring you have all necessary information at your fingertips when making critical decisions about safety equipment procurement. Partnering with Jinrong means gaining access to expert advice tailored specifically to meet your organizational requirements while adhering strictly to relevant safety regulations.