Introduction

In an increasingly industrial world, understanding explosion proof panel boards is crucial for ensuring safety in hazardous environments. These specialized electrical panels are designed to contain any potential explosions within their enclosure, preventing catastrophic outcomes. With industries ranging from oil and gas to pharmaceuticals relying on these technologies, the importance of explosion proof panel boards cannot be overstated.

Understanding Explosion Proof Panel Boards

So, what is an explosion-proof panel? Simply put, it’s a type of electrical panel that prevents the ignition of flammable gases or dust within its enclosure. When comparing explosion proof to explosion resistant designs, the key difference lies in their construction; while both aim to safeguard against hazards, explosion proof panels are built specifically to withstand internal explosions without compromising external safety. This distinction is vital for industries where volatile substances are commonplace.

Importance of Safety in Hazardous Locations

Safety in hazardous locations isn't just a priority; it's a necessity. Industries such as chemical manufacturing or mining face risks that could lead to devastating explosions if proper precautions aren't taken with equipment like Crouse Hinds explosion proof panelboards. By employing these specialized electrical panels, businesses can significantly reduce the likelihood of accidents and protect both their workforce and infrastructure from potentially explosive situations.

Key Applications for Explosion Proof Panel Boards

Explosion proof panel boards find applications across various sectors where safety is paramount. From oil rigs drilling into volatile reserves to factories handling combustible materials, these panels serve as the first line of defense against unpredictable hazards. Additionally, understanding what are the three types of panel boards—explosion-proof, flameproof, and intrinsically safe—can help businesses select the right technology tailored for their specific operational needs.

What Are Explosion Proof Panel Boards?

Definition and Purpose

So, what is an explosion-proof panel? Simply put, it's an enclosure that prevents the ignition of hazardous materials within its confines. The primary purpose of these panels is to protect both personnel and equipment from explosive incidents while ensuring the safe operation of electrical systems in volatile environments. In places like oil refineries or chemical plants, the presence of flammable gases makes explosion proof panel boards a necessity for effective risk management.

How They Differ from Standard Boards

Now you might wonder, what are the three types of panel boards? While standard electrical panels serve typical residential or commercial purposes, explosion proof panel boards are built with enhanced features tailored for hazardous locations. The main difference lies in their construction; explosion-proof panels use robust materials and specialized designs that can withstand internal explosions without allowing flames or hot gases to escape into the surrounding area. This distinction is crucial when evaluating options for environments where safety cannot be compromised.

The Science Behind Explosion Proof Technology

The science behind explosion proof technology involves several engineering principles aimed at mitigating risks associated with explosive atmospheres. One key aspect is understanding the difference between explosion-proof and explosion-resistant designs; while both offer protection, only true explosion proof enclosures meet rigorous standards to contain explosions completely within their housing. Requirements for explosion-proof enclosures typically include specific testing and certification processes that ensure they can endure extreme conditions without failure—this includes models like Crouse Hinds explosion proof panelboards which exemplify these rigorous standards in action.

Essential Features of Explosion Proof Panel Boards

Durability Against Harsh Conditions

Durability is paramount when discussing what is an explosion-proof panel. Designed for extreme conditions, these panel boards are built to endure high temperatures, corrosive substances, and mechanical impacts that could compromise standard equipment. For instance, Crouse Hinds explosion proof panelboards are renowned for their robust construction, making them ideal for industries like oil and gas where harsh conditions are the norm.

The materials used in these panels often include heavy-duty metals and specialized coatings that resist wear and tear over time. This durability not only extends the lifespan of the equipment but also minimizes downtime due to maintenance or replacement needs. Ultimately, investing in a reliable explosion proof electrical panel means ensuring safety without sacrificing performance.

Sealing and Enclosure Ratings

Another critical aspect of explosion proof panel boards is their sealing and enclosure ratings, which determine how well they can protect against external elements like dust and moisture. The requirements for explosion-proof enclosures often include ratings such as IP (Ingress Protection) ratings that specify how resistant a product is to environmental factors. High enclosure ratings indicate that the board can effectively prevent hazardous materials from entering its casing.

Furthermore, understanding the difference between explosion-proof and explosion-resistant technologies can help clarify why sealing matters so much; while both aim to protect against explosions, only true explosion-proof designs contain any potential blasts within their structure. When selecting a panel board for hazardous locations, it's essential to consider these ratings carefully to ensure compliance with safety standards while enhancing operational efficiency.

Customization Options for Specific Needs

Customization options play a significant role in meeting the unique demands of various industries when it comes to explosion proof panel boards. Manufacturers often provide tailored solutions that accommodate specific configurations or additional features required by different applications—whether that's extra circuits or specialized controls for monitoring purposes. This flexibility ensures that businesses can optimize their setups without compromising on safety or functionality.

Moreover, customization allows companies to select materials best suited for their environment—be it temperature extremes or exposure to corrosive substances—ensuring longevity and reliability in even the most challenging conditions. By choosing customized solutions like those offered by reputable brands such as Crouse Hinds, organizations can enhance both safety measures and operational efficiency seamlessly.

Materials Used in Explosion Proof Panel Boards

Common Materials for High Resistance

The backbone of any reliable explosion proof panel board is its construction material. Typically, manufacturers use robust metals like aluminum and stainless steel, known for their high resistance to impact and pressure. These materials are essential because they provide the structural integrity needed to withstand explosive forces while ensuring that the internal components remain protected, making them ideal choices for applications requiring stringent safety standards.

In addition to metals, some manufacturers may incorporate composite materials designed specifically for high resistance scenarios. These composites can be engineered to provide lightweight yet durable solutions without compromising safety features. When asking What is an Explosion-Proof panel? it's important to note that these materials play a crucial role in defining what makes a panel truly explosion-proof.

The Role of Corrosion-Resistant Coatings

Corrosion-resistant coatings are another vital aspect of explosion proof panel boards that enhance their longevity and reliability in challenging environments. Such coatings protect against moisture, chemicals, and other corrosive elements that can degrade metal surfaces over time. For instance, Crouse Hinds explosion proof panelboards often feature specialized coatings designed to meet industry standards while providing additional protection against corrosion.

These coatings not only extend the life of the panels but also contribute significantly to maintaining safety levels in hazardous locations where chemical exposure is prevalent. Understanding What are the requirements for Explosion-Proof enclosures? includes recognizing how effective corrosion resistance helps ensure compliance with regulatory standards while safeguarding personnel and equipment alike.

Weight Considerations in Design

Weight considerations are crucial when designing explosion proof electrical panels because they directly affect installation logistics and structural support requirements. While heavier materials like steel offer excellent protection, they can complicate installation processes if not properly accounted for during planning stages. Balancing weight with durability ensures that installations remain practical without sacrificing safety features essential for compliance with regulations regarding explosion-proof systems.

Additionally, advancements in material science have led to lighter alternatives that still provide high levels of resistance without adding unnecessary weight — think composites or advanced alloys! This evolution raises interesting questions about “What is the difference between Explosion-Proof and explosion resistant?” as both categories increasingly rely on innovative materials tailored for specific applications while still adhering to stringent safety protocols.

Regulatory Standards and Certifications

Overview of ATEX and IECEx Standards

ATEX (Atmosphères Explosibles) is a set of European Union directives that govern equipment used in potentially explosive environments, while IECEx (International Electrotechnical Commission Ex) provides international certification for electrical equipment intended for use in explosive atmospheres. Both standards ensure that products like explosion proof panel boards are designed to prevent ignition sources that could lead to catastrophic explosions. Understanding these regulations is essential for manufacturers and users alike, as they dictate what is required for safe operation in hazardous locations.

The Importance of Compliance in Manufacturing

Compliance with these standards isn't just about ticking boxes; it’s about safeguarding lives and property. Products that meet ATEX or IECEx requirements undergo rigorous testing to ensure they can withstand harsh conditions without becoming an ignition source. For manufacturers of explosion proof electrical panels, adherence to these regulations not only enhances product reliability but also builds trust with customers who depend on their systems for safety.

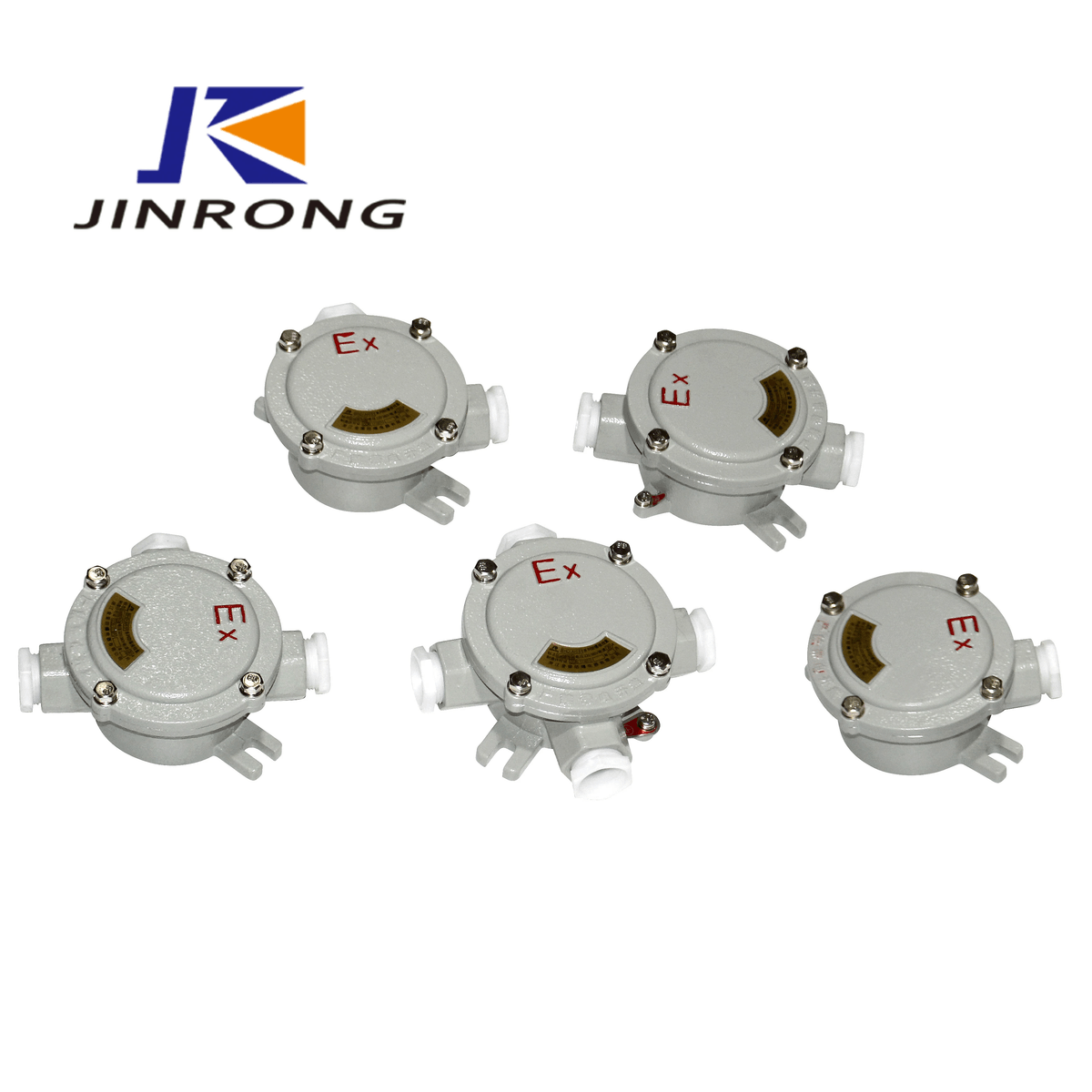

Jinrong’s Commitment to Quality Certifications

Jinrong stands out in the industry by prioritizing quality certifications that align with ATEX and IECEx standards. Their explosion proof panel boards are meticulously designed and tested to meet stringent regulatory requirements, ensuring maximum safety in hazardous locations. By committing to these high-quality benchmarks, Jinrong reinforces its reputation as a reliable provider of explosion-proof solutions, giving customers peace of mind when selecting their panel boards.

Installation and Maintenance Best Practices

Preparing the Site for Installation

Before diving into installing an explosion proof electrical panel, it's vital to prepare the site thoroughly. Start by assessing the environment where the explosion proof panel boards will be located; ensure it meets all necessary requirements for explosion-proof enclosures such as proper ventilation and distance from potential ignition sources. Additionally, a clean workspace free from debris is essential to facilitate a smooth installation process while minimizing risks associated with hazardous materials.

Once you've ensured that your site is ready, consider factors like accessibility for maintenance later on. Remember that what is an explosion-proof panel? It's not just about being tough; it's also about being strategically placed to allow easy access for any future inspections or repairs. A well-prepared site can significantly enhance the efficiency of both installation and ongoing maintenance.

Routine Checks and Maintenance Tips

Routine checks are paramount when dealing with explosion proof panel boards; after all, safety is non-negotiable in hazardous locations! Regular inspections should include checking seals, gaskets, and enclosure ratings to ensure they remain intact over time. Don't forget to look out for signs of wear or corrosion—early detection can save you from significant issues down the line.

In addition to visual inspections, it's wise to maintain a log of any maintenance performed on your Crouse Hinds explosion proof panelboard or similar models. This log serves as valuable documentation that can help in understanding patterns over time or identifying recurring issues that may need addressing more urgently than anticipated. Remember: prevention is always better than cure!

Importance of Professional Installation Teams

While DIY projects can be fun, installing an explosion proof electrical panel is not one of them! The expertise required goes beyond simply knowing what are the three types of panel boards available; it involves a deep understanding of safety regulations and best practices specific to hazardous locations. Engaging professional installation teams ensures compliance with industry standards while significantly reducing risks during setup.

Moreover, trained professionals will have experience dealing with different types of installations—whether you're opting for traditional models or exploring newer technologies like smart panels designed specifically for explosive environments. Their knowledge allows them to navigate potential challenges effectively while also providing insights into what is the difference between explosion-proof and explosion-resistant systems when making decisions tailored to your needs.

In summary, prioritizing professional assistance during installation not only guarantees adherence to safety protocols but also enhances overall performance in risk-prone areas—ultimately making your environment safer for everyone involved.

Conclusion

Selecting the right explosion proof panel boards is crucial for ensuring safety in hazardous environments. With various types available, including Crouse Hinds explosion proof panelboards, understanding the specific needs of your location is essential. Whether you're asking, What is an Explosion-Proof panel? or pondering What are the three types of panel boards?, having clarity on these aspects will guide you to make an informed choice.

Selecting the Right Explosion Proof Panel Board

When it comes to selecting explosion proof panel boards, consider factors like location, environmental conditions, and compliance with essential regulations. Different applications may require different features; for instance, some industries might need a robust Crouse Hinds explosion proof panelboard while others may opt for lighter alternatives. Additionally, understanding the difference between explosion-proof and explosion-resistant designs can help ensure that you choose a board that meets your specific safety requirements.

Enhancing Safety in Risk-Prone Areas

Safety should always be a priority in risk-prone areas where flammable gases or vapors are present. By integrating high-quality explosion proof electrical panels into your infrastructure, you significantly reduce the risk of catastrophic failures and accidents. Moreover, adhering to requirements for explosion-proof enclosures ensures that your equipment can withstand harsh conditions while maintaining optimal functionality.

The Future of Explosion Proof Technology

The future of explosion proof technology looks promising as advancements continue to evolve standards and materials used in construction. Innovations will likely lead to lighter yet equally robust designs that enhance both safety and efficiency in hazardous locations. As industries increasingly prioritize safety measures, we can expect more sophisticated solutions like smart monitoring systems integrated into explosion proof panel boards to emerge on the market.