Introduction

Brief Overview of Explosion-Proof Lighting

Explosion-proof lighting is not your typical illumination system. It serves a vital purpose in environments where safety is paramount. Imagine locations like chemical plants, oil refineries, or mining tunnels—places where flammable gases, vapors, or dust particles lurk. In such hazardous settings, ordinary lighting fixtures could spell disaster.

In this article, we delve into the world of explosion-proof lighting. We’ll explore what makes these fixtures unique, their role in safeguarding lives, and the stringent compliance standards they adhere to. So fasten your seatbelt (or hard hat), because we’re about to shed light on safety!

Understanding Hazardous Environments

Defining Hazardous Locations

Hazardous locations are areas where the presence of flammable substances—such as gases, vapors, or dust—poses a significant risk. These environments include:

- Chemical Plants: Facilities handling volatile chemicals, where a single spark could lead to catastrophe.

- Oil Refineries: Oil processing sites with flammable hydrocarbons and potential ignition sources.

- Mining Sites: Underground tunnels where dust particles and gases accumulate.

Risks Associated with Flammable Substances

- Explosions: Flammable gases or vapors can ignite, causing violent explosions.

- Fire: Combustible dust particles can catch fire, endangering lives and property.

- Toxic Exposure: Inhaling toxic gases or dust can harm health.

The Imperative of Prevention

Preventing explosions in these settings is non-negotiable. Explosion-proof lighting plays a pivotal role by:

- Providing illumination without becoming an ignition source.

- Ensuring safe evacuation routes during emergencies.

- Complying with stringent regulations to safeguard lives and assets.

What Makes a Light Fixture Explosion Proof?

Design Features and Qualifications

An explosion-proof light fixture isn’t your run-of-the-mill lamp. It’s engineered to thrive in hazardous environments without becoming a ticking time bomb. Here’s what sets these fixtures apart:

- Materials Selection:

- Explosion-proof fixtures use non-sparking materials like brass, stainless steel, or aluminum.

- These materials prevent sparks or heat buildup, crucial in volatile settings.

- Enclosures and Seals:

- Robust enclosures shield the internal components from external hazards.

- Seals prevent flammable gases or dust from infiltrating the fixture.

- Certifications Matter:

- Look for certifications such as ATEX, UL, or IECEx.

- These labels ensure compliance with safety standards and suitability for hazardous locations.

- Robust Construction:

- Explosion-proof fixtures endure extreme conditions:

- Temperature Fluctuations: From scorching heat to freezing cold.

- Chemical Exposure: Resisting corrosive substances.

- Physical Impact: Withstanding bumps and jolts.

Remember, these fixtures aren’t just about illumination; they’re guardians of safety in the face of danger. Next, let’s explore the different types of explosion-proof lighting. 💡

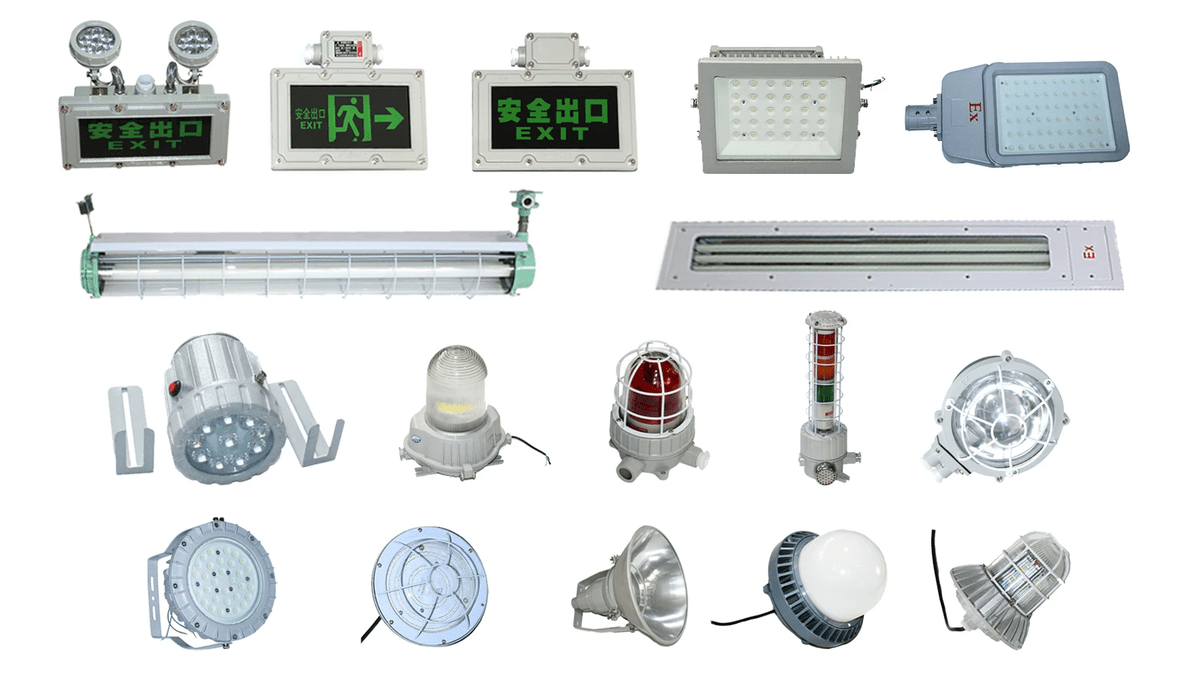

Types of Explosion-Proof Lighting

When it comes to explosion-proof lighting, there are several options available. Let’s explore the different types of fixtures and their characteristics:

- Fluorescent Explosion-Proof Lighting:

- Energy-Efficient: Fluorescent lights consume less power compared to traditional incandescent bulbs.

- Widely Used: They have been a staple in industrial settings for years.

- Pros:

- Energy savings.

- Even illumination.

- Long lifespan.

- Cons:

- Contains mercury (requires proper disposal).

- Sensitive to temperature fluctuations.

- Initial cost may be higher.

- LED Explosion-Proof Lighting:

- Growing Popularity: LEDs are gaining traction due to their numerous advantages.

- Longevity: LED bulbs can last significantly longer than other types.

- Low Maintenance: Reduced need for frequent replacements.

- Pros:

- Energy-efficient.

- Instant illumination (no warm-up time).

- Durable and shock-resistant.

- Cons:

- Higher upfront cost.

- Heat management required for optimal performance.

- Limited color temperature options.

- Incandescent Explosion-Proof Lighting:

- Traditional Choice: Incandescent bulbs have been around for a long time.

- Less Common: Their use is decreasing due to energy inefficiency.

- Pros:

- Warm, familiar light.

- Low initial cost.

- Wide availability.

- Cons:

- High energy consumption.

- Short lifespan.

- Fragile (susceptible to breakage).

Choose the type of explosion-proof lighting that best suits your specific needs, considering factors like energy efficiency, durability, and maintenance requirements. Safety should always be the top priority!

Applications and Industries

Explosion-proof lighting is indispensable in various industries where the potential for explosive environments is a constant reality. Let’s explore some key sectors:

Oil and Gas Industry:

- Oil Refineries: These facilities handle volatile hydrocarbons, making explosion-proof lighting crucial.

- Offshore Drilling Platforms: Harsh marine environments demand robust fixtures.

- Petrochemical Plants: Flammable gases and liquids are part of daily operations here12.

Chemical Processing Plants:

- Chemical factories deal with hazardous substances, including flammable vapors.

- Explosion-proof lighting ensures safety during production, maintenance, and emergencies.

Mining Tunnels:

- Underground mining environments are prone to dust and gas accumulation.

- Proper illumination is vital for miners’ safety and efficient operations3.

Grain Silos:

- Grain storage facilities can harbor combustible dust.

- Explosion-proof lighting prevents ignition during handling and storage.

Real-World Examples:

- In an oil refinery, explosion-proof fixtures illuminate critical areas near pipelines and storage tanks, minimizing the risk of accidents.

- Mining tunnels rely on explosion-proof lighting to guide miners safely through dark, dusty passages.

- Chemical processing plants implement these fixtures in hazardous zones, protecting workers and preventing disasters.

Remember, explosion-proof lighting isn’t just about illumination—it’s a lifeline in the face of danger.

The Future of Explosion Proof Lighting

Innovations in Ex-Proof Manufacturing

In the rapidly evolving world of explosion proof lighting, manufacturers are constantly innovating to improve safety and efficiency. From advanced materials that enhance durability to cutting-edge designs that maximize illumination, ex-proof manufacturing is at the forefront of technological advancements in the industry.

Emerging Trends in Explosion Proof Lighting Technology

LED explosion proof lighting is paving the way for the future with its energy efficiency, long lifespan, and superior brightness. As technology continues to advance, we can expect to see even more innovative features such as smart lighting controls and integrated sensors that further enhance the performance and safety of explosion proof lighting fixtures.

The Role of

Jinrong in Advancing the Evolution of Explosion Proof Lighting

Jinrong has been a driving force behind the evolution of explosion proof lighting, consistently pushing boundaries and setting new standards for quality and innovation. With a strong commitment to research and development, Jinrong continues to lead the way in developing cutting-edge solutions that address the ever-changing needs of hazardous environments.

Remember to always stay updated on these emerging trends and innovations to ensure you are making informed decisions when investing in explosion proof lighting for your industrial or portable needs.

Conclusion

Investing in explosion proof lighting is a critical decision for ensuring safety and compliance in hazardous environments. LED explosion proof lighting stands out as a cost-effective and energy-efficient option, making it a wise investment for any industrial or portable setting. With the evolution of explosion proof lighting technology, the future looks bright for enhanced safety and efficiency.

Making Informed Decisions When Investing in Explosion Proof Lighting

When considering explosion proof lighting fixtures, it's important to weigh the benefits of LED explosion proof lighting against traditional options. LED explosion proof lighting offers long-term cost savings and superior illumination, making it a smart choice for any industrial or portable application. By making an informed decision, you can ensure that your investment in explosion proof lighting will provide long-lasting value.

Ensuring Safety and Compliance with Explosion Proof Lighting Standards

Compliance with explosion proof lighting class 1 division 1 standards is crucial for maintaining safety in hazardous environments. It's essential to choose explosion proof lighting fixtures that meet these rigorous standards to prevent potential hazards and ensure the well-being of workers. By prioritizing safety and compliance, you can create a secure environment with reliable illumination.

Harnessing the Potential of Explosion Proof Lighting for the Future

As innovations continue to emerge in ex-proof manufacturing, the potential for advancements in explosion proof lighting technology is limitless. With ongoing developments in LED explosion proof lighting and other cutting-edge solutions, the future holds promise for even greater efficiency and performance in hazardous environments. By embracing these advancements, you can stay ahead of the curve and maximize the benefits of explosion proof lighting.