Introduction

When it comes to industrial and hazardous environments, the need for explosion-proof LED light fixtures is crucial. Not only do these fixtures provide efficient illumination, but they also ensure safety in potentially volatile areas. Understanding the grounding requirements for LED lights is essential for their proper functioning and longevity. Key considerations for explosion-proof lighting include durability, reliability, and compliance with industry standards.

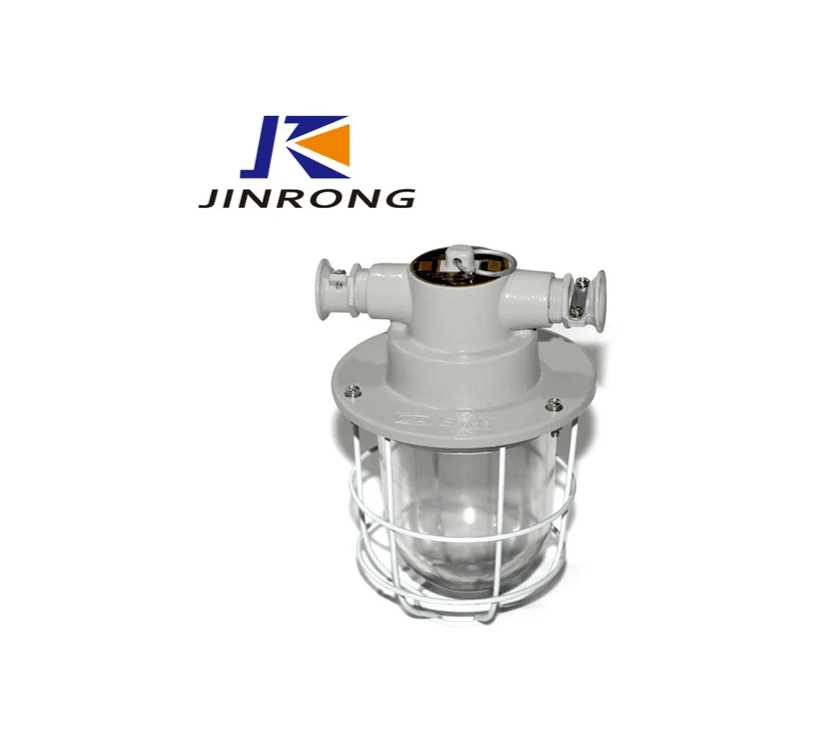

Exploring Explosion-Proof LED Light Fixtures

Exploring explosion-proof LED light fixtures involves delving into their unique design and construction, which are specifically engineered to prevent ignition of flammable substances. These fixtures are built to withstand harsh conditions, making them suitable for use in hazardous locations where traditional lighting may pose a fire or explosion risk.

Understanding Grounding Requirements for LED Lights

Do LED light fixtures need to be grounded? Yes, proper grounding is essential to ensure the safe operation of LED lights in hazardous environments. Grounding helps protect against electrical faults and reduces the risk of static discharge, ensuring that the fixtures remain safe and functional.

Key Considerations for Explosion-Proof Lighting

When considering explosion-proof lighting options, it's important to prioritize factors such as ingress protection ratings, corrosion resistance, and temperature tolerance. These key considerations ensure that the lighting fixtures can effectively withstand the challenges posed by hazardous locations while providing reliable illumination.

Class 1 Div 2 LED Lighting

When it comes to explosion-proof LED lighting, understanding the Class 1 Div 2 classification is crucial. This classification refers to hazardous locations where flammable gases, vapors, or liquids are not normally present in sufficient quantities to be explosive or ignitable. Explosion-proof LED fixtures designed for Class 1 Div 2 areas provide a safe and reliable lighting solution without the risk of causing an explosion.

Explaining Class 1 Div 2 Classification

Class 1 Div 2 locations are those where flammable gases or vapors may be present only under abnormal conditions. This means that under normal operating conditions, the area is not classified as hazardous, making it less likely for an explosion to occur. Explosion-proof LED fixtures designed for these environments must meet specific safety standards to ensure they do not become a source of ignition.

Benefits of Explosion-Proof LED Fixtures

LED fixtures that are explosion-proof offer several benefits, including energy efficiency, long lifespan, and low maintenance requirements. Additionally, these fixtures provide bright and reliable illumination in hazardous areas without posing a fire or explosion risk. By choosing LED lighting solutions that are specifically designed for hazardous locations, businesses can enhance safety while reducing operational costs.

Jinrong's Expertise in Ex-Proof Manufacturing

Jinrong has been a trusted manufacturer of explosion-proof lighting for over two decades, specializing in designing and producing high-quality LED fixtures for hazardous environments. With a focus on innovation and compliance with industry standards, Jinrong's expertise in ex-proof manufacturing ensures that their products deliver exceptional performance and reliability in Class 1 Div 2 locations.

General Requirements for Explosion-Proof Light Fixtures

When it comes to explosion-proof LED light fixtures, meeting industry standards for safety is crucial. These standards ensure that the fixtures are designed and manufactured to withstand hazardous environments without posing a risk of ignition or explosion. At Jinrong, we adhere to these stringent safety standards to provide reliable and safe lighting solutions for various industrial applications.

Meeting Industry Standards for Safety

Explosion-proof LED light fixtures must comply with specific regulations set by organizations such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA). These standards outline the construction, testing, and performance requirements that ensure the lights are suitable for use in hazardous locations where flammable gases or vapors may be present. Adhering to these standards is essential for protecting workers and preventing potential accidents in industrial settings.

Importance of Proper Installation and Maintenance

In addition to meeting safety standards, proper installation and regular maintenance are vital for ensuring the effectiveness of explosion-proof LED light fixtures. Correct installation techniques help minimize the risk of damage or malfunction, while routine maintenance can identify any issues early on and prevent potential hazards. At Jinrong, we provide comprehensive installation guidelines and maintenance recommendations to help our customers maximize the lifespan and performance of our ex-proof lighting products.

Insights from Jinrong's 27 Years of Experience

With over 27 years of experience in manufacturing explosion-proof lighting solutions, Jinrong has gained valuable insights into addressing the unique challenges posed by hazardous environments. Our expertise allows us to develop innovative designs that prioritize safety without compromising on illumination quality. We understand the importance of staying ahead of industry advancements to continuously improve our products and provide reliable lighting solutions for diverse industrial applications.

Do LED Lights Carry Fire and Explosion Risks?

Addressing Common Misconceptions

There is a common misconception that LED lights do not carry fire and explosion risks, but this is not entirely true. While LED lights produce less heat than traditional fixtures, they can still pose a risk in hazardous locations if not properly designed and certified as explosion-proof. It's important to understand the specific requirements for explosion-proof lighting in different environments to ensure safety.

It's also important to note that while LED lights may produce less heat, they still require proper ventilation and cooling systems to prevent overheating and potential fire hazards. In addition, the quality of the materials used in LED fixtures can impact their safety in hazardous environments. Ensuring that LED lights are made with durable, explosion-proof materials is crucial for mitigating risks in these settings.

Comparing LED Lights to Traditional Fixtures

When comparing LED lights to traditional fixtures, it's important to consider their differences in terms of heat generation and energy efficiency. LED lights produce significantly less heat, reducing the risk of ignition in hazardous areas. Additionally, they are more energy-efficient and have a longer lifespan, making them a cost-effective choice for industrial and hazardous location lighting.

LED lights also offer a more focused and directional light output, reducing the need for additional fixtures to achieve the desired level of illumination. This not only saves on installation costs but also minimizes light pollution and glare in industrial and hazardous environments. With their ability to provide targeted lighting, LED fixtures contribute to a safer and more efficient work environment.

Relying on Jinrong's Certification and Manufacturing Expertise

To mitigate fire and explosion risks associated with LED lighting, it's crucial to rely on manufacturers with expertise in certification and manufacturing of explosion-proof fixtures. Jinrong has 27 years of experience in producing high-quality explosion-proof LED lights that meet industry standards for safety. Their expertise ensures that their products are suitable for use in hazardous locations while minimizing the risk of fire or explosions.

Everything You Need to Know About Explosion-Proof LED Lighting

Highlighting Unique Features of LED Ex-Proof Fixtures

When it comes to explosion-proof LED lighting, unique features like robust construction, sealed wiring, and corrosion-resistant materials ensure safe operation in hazardous locations. These fixtures are designed to withstand extreme conditions while providing reliable illumination, making them a top choice for industries with explosive atmospheres.

In addition to their durable construction and resistance to corrosion, explosion-proof LED fixtures also offer energy efficiency and long lifespan. These fixtures are designed to minimize energy consumption while providing bright and reliable illumination, making them a cost-effective choice for hazardous environments. With their low maintenance requirements and long-lasting performance, LED ex-proof fixtures offer a practical solution for industries looking to enhance safety without compromising on quality.

Exploring Different Hazardous Locations

From chemical plants to oil refineries, hazardous locations present unique challenges for lighting. Explosion-proof LED fixtures are suitable for Class 1 Div 2 areas where flammable gases or vapors may be present under normal operating conditions. They also work well in Class 2 Div 2 environments with combustible dust.

Explosion-proof LED fixtures are designed to withstand the harsh conditions of hazardous locations, making them a reliable choice for industries where safety is paramount. These fixtures provide bright, energy-efficient lighting that can enhance visibility and reduce the risk of accidents in potentially dangerous environments. With their durable construction and long lifespan, explosion-proof LED fixtures offer a cost-effective solution for illuminating hazardous areas while minimizing maintenance needs.

Jinrong's Wide Range of Ex-Proof Lighting Series

Jinrong offers a wide range of explosion-proof lighting series tailored to meet the specific needs of different industries and applications. Whether it's high bay lights for manufacturing facilities or wall-mounted fixtures for offshore platforms, Jinrong's extensive product line ensures there's a suitable solution for every hazardous location.

In addition to providing a diverse range of explosion-proof lighting options, Jinrong also prioritizes energy efficiency and durability in their products. LED technology is integrated into many of their fixtures, offering long-lasting illumination while consuming minimal power. This not only reduces operational costs but also contributes to a more sustainable and environmentally friendly work environment. Furthermore, Jinrong's commitment to quality ensures that their ex-proof lighting series is built to withstand harsh conditions, giving businesses peace of mind when it comes to safety and reliability.

Conclusion

When it comes to explosion-proof LED lighting, it's essential to understand the requirements and benefits. LED shop lights can be explosion-proof, especially when they meet Class 1 Div 2 classification and industry standards for safety. Understanding hazardous location lighting is crucial for proper installation and maintenance, and Jinrong's expertise can help distributors grow their business in this specialized market.

Are LED Shop Lights Explosion-Proof?

LED shop lights can indeed be explosion-proof when they are designed and certified to meet the necessary safety standards for hazardous locations. With the right classification and proper installation, these fixtures can provide a safe and reliable lighting solution for industrial environments.

LED shop lights that are explosion-proof are specifically designed to prevent the ignition of flammable gases and dust in hazardous environments. These lights are constructed with durable materials and sealed to prevent any sparks or heat from escaping. Additionally, they undergo rigorous testing and certification to ensure they meet the necessary safety standards for use in potentially explosive atmospheres.

A Quick Guide to Hazardous Location Lighting

Hazardous location lighting requires careful consideration of the potential risks associated with flammable substances or combustible dust. It's essential to choose explosion-proof light fixtures that are specifically designed for these environments, ensuring safety and compliance with regulations.

After selecting the appropriate explosion-proof light fixtures, it's important to consider the installation and maintenance of these lighting systems. Proper installation by qualified professionals is crucial to ensure that the fixtures are securely mounted and connected to prevent any potential hazards. Additionally, regular maintenance and inspection of hazardous location lighting are necessary to identify and address any issues that may arise over time, ensuring continued safety and compliance with regulations.

How Jinrong Helps Distributors Grow Their Business

Jinrong's extensive experience in manufacturing explosion-proof LED lighting can provide distributors with high-quality products that meet industry standards. By partnering with Jinrong, distributors can offer reliable solutions for hazardous locations, expanding their product offerings and growing their business in this specialized market.

By understanding the unique features of explosion-proof LED lighting, meeting general requirements for safety, addressing misconceptions about fire and explosion risks, and exploring different hazardous locations, you can make informed decisions about choosing the right fixtures for your specific needs. With Jinrong's expertise in ex-proof manufacturing, you can trust that you're getting reliable products that meet industry standards while also growing your business as a distributor in this specialized market.