Introduction

In an increasingly hazardous world, the need for safety and protection in various industrial applications is paramount. Explosion Proof Enclosures serve as critical barriers against explosive environments, ensuring that sensitive equipment operates safely without risk of ignition. Understanding these enclosures is essential for industries that handle flammable materials or operate in volatile atmospheres.

Understanding Explosion Proof Enclosures

Explosion Proof Enclosures are specially designed housings that protect electrical and electronic equipment from explosive atmospheres. These enclosures are built to contain any explosion originating within them, preventing flames or hot gases from escaping and igniting surrounding materials. By adhering to strict standards and regulations, a blast rated enclosure ensures reliability and safety in high-risk environments.

Importance of Blast Rated Enclosure

The significance of a blast rated enclosure cannot be overstated; it acts as a vital safeguard against potential disasters in workplaces where flammable gases or dust are present. These enclosures not only protect personnel but also prevent costly damage to equipment and facilities. Investing in high-quality Explosion Proof Enclosures can ultimately save companies from financial losses while enhancing overall workplace safety.

Applications of Explosion-Proof Junction Boxes

Explosion-Proof Junction Boxes play a crucial role in various industries, including oil and gas, chemical manufacturing, pharmaceuticals, and mining. These junction boxes provide secure connections for electrical wiring in hazardous locations where traditional junction boxes would fail to meet safety standards. By utilizing these specialized solutions, companies can ensure compliance with regulations while maintaining operational efficiency in risky environments.

What is an Explosion Proof Enclosure?

When it comes to safety in hazardous environments, the term Explosion Proof Enclosures comes up frequently. These enclosures are designed to contain any explosions that might occur within them, preventing the ignition of surrounding flammable materials. In essence, they act as a protective barrier, ensuring that equipment such as Explosion-Proof Junction Boxes operates safely without posing a risk to personnel or property.

Definition and Standards

An explosion proof enclosure is defined by its ability to withstand internal explosions without allowing flames or hot gases to escape into the surrounding atmosphere. To meet this definition, these enclosures must adhere to various international standards, such as those set by the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC). Compliance with these standards ensures that a blast rated enclosure can effectively protect against potential hazards in explosive atmospheres.

Key Features and Components

The effectiveness of an explosion proof enclosure lies in its robust design and construction materials. Key features typically include heavy-duty metal casings, specially designed seals that prevent gas ingress, and reinforced mounting options for stability in harsh conditions. The components used in these enclosures are crucial; they often incorporate thermal insulation and pressure-relief mechanisms that work together to minimize risks associated with explosive environments.

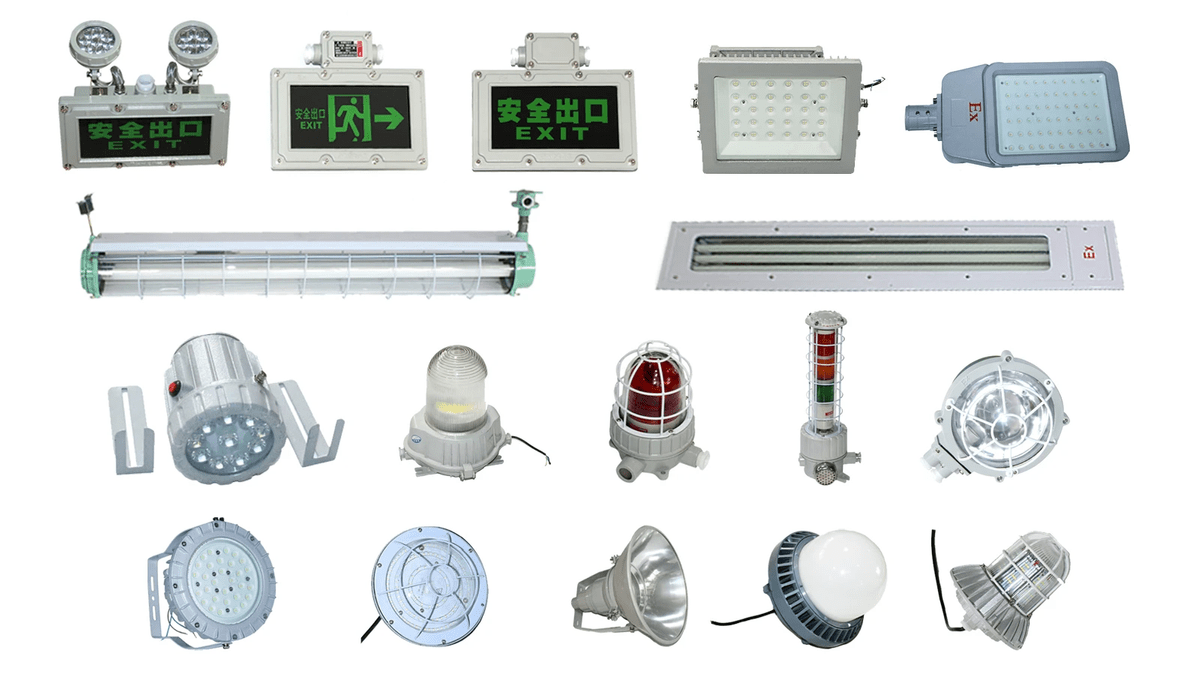

Types of Explosion-Proof Enclosures

There are several types of explosion-proof enclosures tailored for specific applications and environments. Among them are junction boxes specifically designed for electrical connections in hazardous areas, control panels built for safe operation under explosive conditions, and lighting fixtures engineered to prevent ignition sources from escaping their confines. Each type serves a distinct purpose while maintaining compliance with safety regulations associated with blast rated enclosures.

How Do Explosion Proof Enclosures Work?

Explosion-proof enclosures are designed to contain and prevent the ignition of explosive atmospheres, ensuring safety in hazardous environments. These enclosures utilize innovative engineering and materials to withstand internal explosions while protecting sensitive electrical components, such as those found in explosion-proof junction boxes. Understanding how these mechanisms work is crucial for industries that operate in potentially explosive atmospheres.

Mechanisms of Protection

The primary mechanism behind a blast rated enclosure is its ability to contain an explosion within its walls, preventing it from escaping into the surrounding environment. This containment is achieved through robust construction materials and designs that can absorb shock and pressure generated during an explosion. Additionally, many explosion-proof enclosures feature pressure relief vents that allow gases to escape safely without compromising the integrity of the enclosure itself.

Another critical aspect is the use of flame paths—carefully designed gaps or openings that ensure any flames generated internally are cooled before they can ignite external gases or vapors. The combination of these protective features ensures that explosion-proof junction boxes can operate safely even in volatile conditions, making them essential for industries like oil and gas, chemical manufacturing, and mining.

Testing and Certification Processes

Before an explosion-proof enclosure can be deemed safe for use, it must undergo rigorous testing and certification processes established by international standards like ATEX (European Union) or NEC (National Electrical Code in the U.S.). These tests assess various factors including temperature rise, pressure resistance, and overall durability under simulated explosive conditions. Only after passing these stringent evaluations can a product earn its certification mark, assuring users that it meets all necessary safety requirements.

Manufacturers often conduct additional testing beyond regulatory requirements to enhance their products' reliability further. This commitment to quality helps ensure that products such as blast rated enclosures maintain their integrity over time while providing peace of mind to operators working in hazardous environments.

Importance of Proper Installation

Even the best-designed explosion proof enclosures will fail if not installed correctly; therefore, proper installation is paramount for achieving maximum protection against explosions. It’s essential to follow manufacturer guidelines meticulously when positioning these enclosures within a facility since improper placement could expose them to risks they were designed to mitigate. Additionally, regular inspections should be conducted post-installation to ensure that no damage has occurred during setup or due to environmental factors over time.

Training personnel involved in installation is also crucial; they must understand both the technical specifications and safety protocols associated with using blast rated enclosures effectively. By prioritizing proper installation practices alongside routine maintenance checks, companies can significantly reduce risks associated with explosive atmospheres while maximizing operational efficiency.

Choosing the Right Explosion Proof Enclosure

Selecting the right explosion proof enclosure is crucial for ensuring safety and compliance in hazardous environments. With various options available, it’s essential to understand the specific needs of your application. A blast rated enclosure must meet stringent standards to protect against potential explosions, making informed choices vital.

Factors to Consider

When choosing an explosion proof enclosure, several factors come into play. First, consider the environment where the enclosure will be installed; factors like temperature, humidity, and exposure to chemicals can significantly influence material selection. Additionally, understanding the classification of hazardous locations is essential since it dictates which types of explosion-proof junction boxes are suitable for your needs.

Another critical factor is the size and configuration of your equipment—ensuring that there’s adequate space for installation and maintenance can save you headaches down the line. Pay attention to ingress protection (IP) ratings as well; a higher rating indicates better resistance against dust and moisture ingress, which is paramount in explosive atmospheres. Finally, don’t forget about ease of access for routine inspections and maintenance—after all, a well-maintained blast rated enclosure is far more effective.

Common Materials and Designs

Explosion proof enclosures come in various materials designed to withstand harsh conditions while providing reliable protection from explosions. Common materials include aluminum and stainless steel due to their durability and resistance to corrosion; these materials also help ensure that your explosion-proof junction boxes maintain their integrity over time. Furthermore, some manufacturers offer fiberglass-reinforced plastic options that are lightweight yet robust enough for many applications.

Design-wise, enclosures can vary from compact models ideal for tight spaces to larger units suited for more extensive equipment setups. The choice between a sealed design or one featuring cooling fins should align with your specific thermal management requirements as well; overheating can lead to failures even in blast rated enclosures if not properly addressed. Ultimately, striking a balance between functionality and safety features will yield optimal results.

Understanding Hazardous Locations

Understanding hazardous locations is fundamental when selecting an explosion proof enclosure tailored to your needs. These locations are classified based on the likelihood of explosive atmospheres occurring due to flammable gases or dusts present in the environment; this classification helps determine which type of explosion proof enclosures will be most effective in mitigating risks associated with those environments.

For instance, Class I areas involve flammable gases or vapors while Class II pertains to combustible dusts—each class has its own set of requirements regarding design and construction standards for enclosures like explosion-proof junction boxes. Moreover, within each class are divisions that further specify conditions under which these hazards may exist; knowing these details ensures compliance with necessary regulations while enhancing workplace safety.

In summary, selecting an appropriate blast rated enclosure hinges on understanding both environmental factors and regulatory classifications surrounding hazardous locations. By carefully considering these elements along with material choices and designs available on the market today, you’ll be better equipped to make informed decisions that prioritize safety without sacrificing functionality.

Maintenance and Inspection of Ex-Proof Equipment

Maintaining and inspecting explosion-proof equipment is vital to ensure safety and reliability in hazardous environments. Regular checks on the integrity of blast rated enclosures, such as Explosion-Proof Junction Boxes, can prevent potential failures that could lead to catastrophic incidents. A proactive approach to maintenance not only extends the lifespan of these enclosures but also ensures compliance with industry safety standards.

Routine Maintenance Practices

Routine maintenance practices for explosion-proof enclosures include regular inspections, cleaning, and testing of components. Inspectors should check for any signs of corrosion or damage to the enclosure's surface, as even minor wear can compromise its protective capabilities. Additionally, ensuring that seals and gaskets are intact is crucial; a compromised seal can allow hazardous materials to infiltrate the enclosure, defeating its purpose.

Another key practice is the verification of electrical connections within the Explosion-Proof Junction Boxes. Loose or corroded connections can lead to arcing or short circuits, which pose serious risks in explosive atmospheres. Keeping a detailed maintenance log helps track inspections and repairs over time, allowing for better planning and resource allocation.

Signs of Wear and Tear

Identifying signs of wear and tear on blast rated enclosures requires vigilance and experience. Common indicators include visible rust or corrosion on metal surfaces, which may suggest exposure to moisture or corrosive substances that threaten structural integrity. Cracks or dents in the enclosure can also signal potential failure points; even small imperfections may allow explosive gases access into what should be a secure environment.

Another sign is unusual noise emanating from junction boxes during operation; this could indicate internal component failure or overheating issues needing immediate attention. It's essential to regularly review operational performance metrics—any deviations from established norms could hint at underlying problems with your explosion-proof equipment.

Ensuring Compliance with Safety Standards

Ensuring compliance with safety standards involves adhering strictly to guidelines set forth by organizations such as OSHA (Occupational Safety and Health Administration) and NFPA (National Fire Protection Association). Regular audits are necessary not only for confirming adherence to regulations but also for validating that all explosion-proof equipment meets current industry standards like IECEx or ATEX certifications for international operations.

Documentation plays an essential role in compliance; maintaining records of inspections, repairs, and modifications ensures accountability while providing evidence during safety audits. Furthermore, partnering with reputable manufacturers like Jinrong guarantees that you receive high-quality products designed specifically for hazardous environments—this commitment enhances overall safety in your operations involving blast rated enclosures.

Case Studies: Successful Applications of Ex-Proof Solutions

In today's hazardous environments, the significance of explosion-proof solutions cannot be overstated. Various industries have recognized the need for robust safety measures, leading to a surge in the demand for blast rated enclosures and explosion-proof junction boxes. These solutions not only enhance workplace safety but also ensure compliance with stringent regulations.

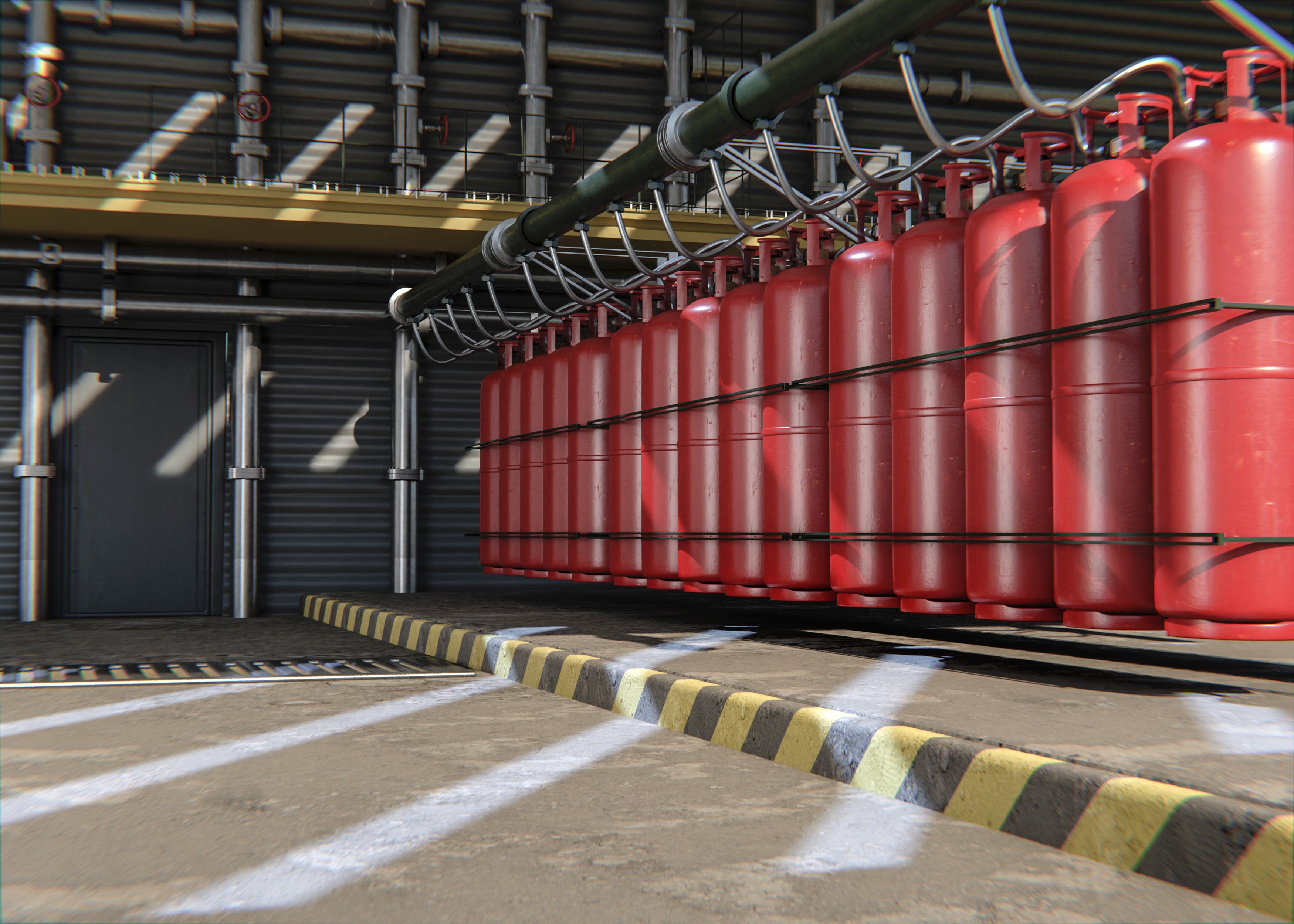

Industries Benefiting from Blasting Solutions

Several sectors stand to gain immensely from the implementation of explosion-proof enclosures. The oil and gas industry, known for its volatile environments, relies heavily on these protective measures to prevent catastrophic failures. Similarly, chemical manufacturing facilities utilize explosion-proof junction boxes to safeguard against flammable materials and gases that could lead to dangerous explosions.

Additionally, food processing plants are increasingly adopting blast rated enclosures to protect electrical equipment from dust and moisture that can create hazardous conditions. Pharmaceutical companies also benefit by ensuring that their sensitive processes remain safe from explosive risks. Ultimately, any industry operating in potentially explosive atmospheres must prioritize the integration of ex-proof solutions into their operational frameworks.

Real-World Examples of Jinrong Products

Jinrong has carved a niche in providing high-quality explosion-proof solutions across various sectors. One notable example is their line of blast rated enclosures designed specifically for offshore oil rigs, where they withstand extreme conditions while protecting vital electrical components from potential explosions caused by flammable gases. Another successful application includes their explosion-proof junction boxes used in chemical plants where the risk of ignition is ever-present due to volatile substances.

Moreover, Jinrong's products have been instrumental in upgrading safety protocols within food processing facilities by offering durable enclosures that comply with hygiene standards while preventing ignition sources. Each case demonstrates how investing in top-notch ex-proof equipment can lead to safer work environments and improved operational efficiency.

Lessons Learned from Implementation

The journey toward implementing effective explosion-proof solutions reveals critical lessons for industries aiming to enhance safety protocols. First and foremost, understanding the specific hazards associated with each environment is essential when selecting appropriate blast rated enclosures or explosion-proof junction boxes; one size does not fit all! Additionally, it’s crucial for organizations to prioritize regular maintenance checks—wear and tear can compromise even the best-designed systems.

Furthermore, successful implementation often hinges on collaboration with experienced manufacturers like Jinrong who understand industry-specific needs and compliance requirements intimately. By learning from real-world applications and continuously adapting strategies based on feedback and performance data, businesses can significantly reduce risks associated with explosive atmospheres while fostering a culture of safety.

Conclusion

In summary, understanding the significance of explosion proof enclosures is crucial for ensuring safety in hazardous environments. These specialized enclosures, including explosion-proof junction boxes, are designed to contain and prevent explosions from spreading, thereby protecting both personnel and equipment. The importance of selecting the right blast rated enclosure cannot be overstated; it can mean the difference between a safe workspace and a potential disaster.

Key Takeaways on Explosion Proof Enclosures

Explosion proof enclosures serve as vital safeguards in industries where flammable gases or dust are present. They are built to withstand internal explosions without allowing flames or pressure to escape, thus minimizing risks significantly. When choosing an explosion-proof junction box, it's essential to consider factors such as location classification and environmental conditions to ensure optimal protection.

Future Trends in Ex-Proof Manufacturing

The future of explosion proof enclosures is bright with advancements in technology paving the way for more innovative solutions. Manufacturers are increasingly focusing on materials that enhance durability while reducing weight, making installations easier without compromising safety standards. Additionally, smart technologies may soon be integrated into these systems for real-time monitoring of environmental conditions within blast rated enclosures.

Partnering with Experts like Jinrong for Success

Their extensive knowledge ensures you choose the right type of blast rated enclosure tailored to your specific needs while adhering to safety regulations. With their support, you can confidently navigate compliance challenges and focus on what matters most—keeping your operations safe and efficient.