Introduction

In today's world, where electric power distribution is at the heart of countless industries, safety is paramount. Electrical systems can pose significant hazards if not properly managed, making the importance of robust safety measures undeniable. This is where explosion proof electrical panels come into play, designed specifically to mitigate risks in potentially explosive environments.

The Importance of Safety in Electrical Systems

Safety in electrical systems cannot be overstated; it protects both lives and property from catastrophic failures. With increasing reliance on electrical power for industrial operations, the potential for accidents escalates without proper safeguards in place. Incorporating features like circuit breakers and explosion proof electrical enclosures is essential to ensure that any unforeseen events are handled efficiently and safely.

What is an Explosion Proof Electrical Panel?

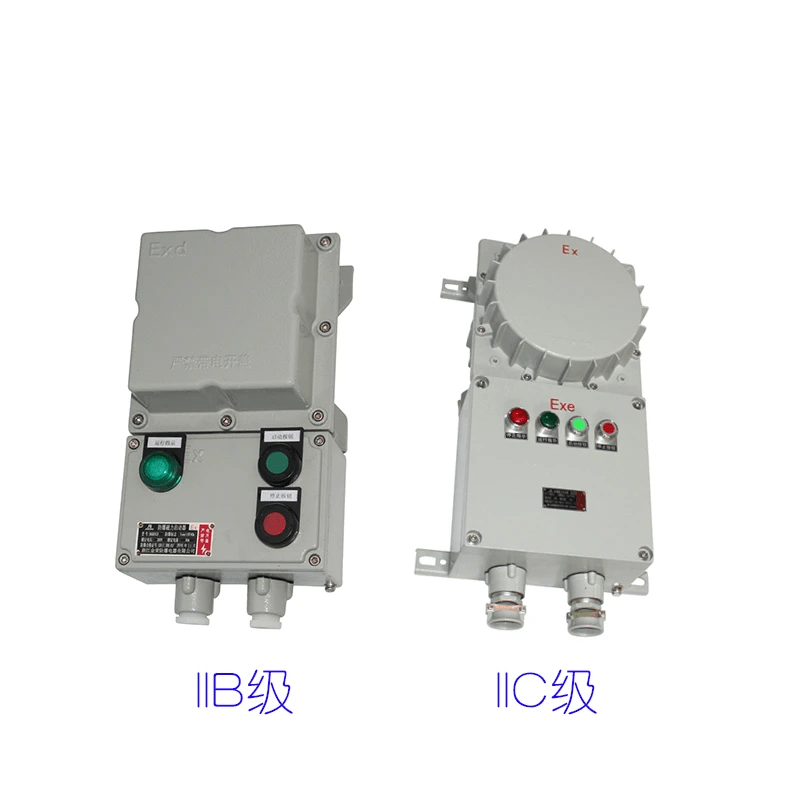

An explosion proof electrical panel is a specially designed enclosure that prevents the ignition of flammable gases or dust within its housing. These panels are built with materials and designs that can withstand extreme conditions while ensuring safe operation of circuit breakers and other components inside. By containing any potential explosions, these panels protect both the equipment and personnel working nearby.

Key Applications of Explosion Proof Panels

Explosion proof panels find their primary applications in industries such as oil and gas, chemical manufacturing, and mining—areas where hazardous materials are commonplace. They serve as critical components in explosion proof control panels that regulate power distribution safely amidst volatile conditions. Additionally, these panels enhance overall operational efficiency by providing reliable protection against environmental risks while ensuring compliance with industry standards.

Understanding Explosion Proof Technology

The Science Behind Explosion Proof Design

The science behind explosion proof design hinges on a combination of pressure containment and ignition prevention. An explosion proof electrical panel is meticulously engineered to withstand internal explosions without allowing flames or hot gases to escape. This is achieved through specialized seals and materials that contain the energy of an explosion, effectively transforming a potentially catastrophic event into a controlled scenario.

Moreover, the careful placement of circuit breakers within these panels plays a crucial role in maintaining safety. Industrial breakers are strategically positioned to interrupt power flow during an overload or short circuit, ensuring that any spark or heat generated remains contained within the enclosure. Thus, the synergy between robust design and intelligent circuitry forms the backbone of reliable explosion proof electrical enclosures.

Common Materials Used in Manufacturing

Manufacturers of explosion proof panels utilize materials that can endure extreme conditions while providing maximum protection. Commonly employed materials include aluminum, stainless steel, and cast iron due to their durability and resistance to corrosion. These materials not only enhance the structural integrity of an explosion proof control panel but also contribute to its ability to withstand harsh environmental factors.

In addition to metals, advanced composites may also be used for insulation and sealing purposes within these panels. Such innovations ensure that all components remain functional even under duress from explosive atmospheres or chemical exposure. Therefore, selecting appropriate materials is essential for creating effective electric power distribution systems that prioritize safety.

How Explosion Proof Panels Prevent Hazards

Explosion proof panels prevent hazards through several critical mechanisms designed for risk mitigation. First and foremost, they are built with tight seals that inhibit gas leaks which could ignite under certain conditions; this is vital in industries like oil and gas where flammable vapors are prevalent. The design also incorporates thermal management features that dissipate heat generated by circuit breakers during operation without compromising safety.

Furthermore, regular maintenance checks on these panels can identify any wear or damage before they become serious issues; this proactive approach significantly reduces risks associated with explosive environments. By ensuring proper installation practices and using high-quality components throughout your electric power distribution system, you create a safer workspace for everyone involved. Investing in reliable explosion proof electrical enclosures not only protects assets but also enhances overall operational efficiency.

Circuit Breakers and Their Role

In the realm of explosion proof electrical panels, circuit breakers play a pivotal role in ensuring safety and functionality. These devices are designed to interrupt the flow of electricity in case of an overload or short circuit, thus preventing potential hazards in explosive environments. Selecting the right circuit breakers is crucial for maintaining the integrity of electric power distribution systems within these specialized enclosures.

Types of Circuit Breakers in Explosion Proof Panels

Among them are thermal-magnetic breakers, which provide protection against overloads and short circuits by using heat-sensitive mechanisms alongside magnetic trip features. Additionally, there are residual current devices (RCDs) that detect earth faults and prevent electric shock, making them essential for explosion proof control panels where safety is paramount.

Advantages of Using Industrial Breakers

Industrial breakers offer numerous advantages when integrated into explosion proof electrical enclosures. They are specifically designed to handle higher loads and provide robust protection against extreme conditions often encountered in hazardous environments. Moreover, these industrial-grade circuit breakers ensure a longer lifespan and lower maintenance costs compared to standard options, making them a smart choice for any facility relying on an explosion proof panel for safe electric power distribution.

Choosing the Right Circuit Breakers for Your Needs

Selecting the appropriate circuit breakers for your explosion proof electrical panel involves several considerations tailored to your specific requirements. First, assess the voltage ratings and load capacities necessary for your application; this ensures compatibility with your existing systems while maximizing safety features. Additionally, consider environmental factors such as temperature ranges and exposure to chemicals when choosing industrial breakers; this will help you find a solution that not only safeguards against hazards but also optimizes performance over time.

Key Features of Explosion Proof Electrical Panels

Explosion proof electrical panels are designed to withstand some of the harshest environments while ensuring the safety and reliability of electric power distribution. Their robust construction and specialized designs make them essential for industries where explosive gases or dust may be present. Understanding the key features of these panels can help businesses make informed decisions about their electrical systems.

Robustness and Durability

These enclosures are typically made from heavy-duty materials like stainless steel or aluminum, which not only resist corrosion but also endure high-impact conditions without compromising safety. This durability ensures that circuit breakers within these panels function effectively, even in extreme environments, thereby safeguarding electric power distribution systems.

Moreover, explosion proof control panels are engineered to withstand temperature fluctuations and humidity levels that could jeopardize standard electrical equipment. The reinforced design minimizes wear and tear over time, allowing for reliable long-term operation in hazardous locations. Investing in a durable explosion proof panel means fewer replacements and repairs, translating to significant cost savings down the line.

Certification Standards to Look For

When selecting an explosion proof electrical panel, it's crucial to consider certification standards that ensure compliance with safety regulations. Look for panels certified by organizations such as Underwriters Laboratories (UL) or the International Electrotechnical Commission (IEC), which indicate a product has undergone rigorous testing for safety in explosive environments. These certifications provide peace of mind that the panel can effectively contain any potential explosions.

Additionally, understanding the classification system—such as Class I Division 1 or Class II Division 2—will help you choose an explosion proof panel suitable for your specific application needs. Each classification defines environmental hazards where these panels can safely operate without risk of ignition from sparks or heat generated by circuit breakers inside them. Adhering to these standards is not just a legal requirement; it’s a commitment to workplace safety.

Innovative Designs for Enhanced Safety

The evolution of technology has led to innovative designs in explosion proof electrical enclosures that prioritize user-friendliness alongside safety features. Modern explosion proof control panels often incorporate advanced ventilation systems that allow heat dissipation without compromising their sealed integrity against explosive atmospheres. This innovation helps maintain optimal operating temperatures for circuit breakers while minimizing risks associated with overheating.

Moreover, many manufacturers now offer customizable options tailored to specific industrial needs, such as integrated monitoring systems that provide real-time data on performance metrics and potential hazards within the enclosure itself. These smart features enhance overall operational efficiency while keeping personnel informed about any anomalies in electric power distribution systems before they escalate into serious issues. With such advancements in design and technology, choosing an explosion proof electrical panel becomes less daunting—and much more beneficial—for ensuring workplace safety.

The Benefits of Using Explosion Proof Enclosures

Protecting Against Explosive Environments

Explosion proof electrical panels are engineered to withstand extreme conditions, effectively protecting against explosive environments. Whether it's a chemical plant or an oil rig, these enclosures safeguard sensitive electrical components from ignition sources that could lead to disastrous outcomes. Utilizing circuit breakers within these explosion proof control panels further enhances safety by providing reliable protection against overloads and short circuits.

The design of an explosion proof panel ensures that any internal explosion is contained, preventing flames or gases from escaping into the surrounding atmosphere. This not only protects personnel but also minimizes damage to equipment and infrastructure in high-risk settings. By investing in explosion proof electrical enclosures, companies can significantly reduce the risk associated with working in hazardous locations.

Improving Power Distribution Efficiency

Efficiency is key when it comes to electric power distribution, and explosion proof enclosures play a vital role in achieving this goal. These specialized electrical panels facilitate optimal power flow while ensuring that all components remain protected from environmental hazards. By integrating industrial breakers into these systems, businesses can enhance their overall operational efficiency while maintaining stringent safety standards.

Moreover, the robust construction of explosion proof control panels helps minimize downtime due to maintenance or repairs caused by environmental factors. With improved durability and reliability, companies can expect better performance from their electrical systems over time. This efficiency translates into smoother operations and increased productivity across various industrial applications.

Long-Term Cost Savings and Maintenance

Investing in explosion proof electrical enclosures may seem costly upfront; however, the long-term savings they provide often outweigh initial expenses significantly. By reducing incidents of equipment failure due to explosions or other hazards, businesses can save on repair costs and minimize production interruptions caused by accidents or malfunctions. Furthermore, the durability of these panels means they require less frequent replacement compared to standard alternatives.

Regular maintenance practices for explosion proof panels ensure that they continue functioning optimally without incurring excessive costs over time. Identifying signs of wear early on allows for timely interventions that prevent larger issues down the line while maintaining operational integrity within hazardous environments. Ultimately, utilizing quality explosion proof electrical enclosures leads not only to enhanced safety but also substantial cost savings for businesses operating under risky conditions.

Installation and Maintenance Best Practices

When it comes to explosion proof electrical panels, proper installation and maintenance are paramount to ensure safety and efficiency in hazardous environments. These panels, designed to withstand explosive conditions, require a meticulous approach during setup and upkeep. By adhering to best practices, you can enhance the longevity of your explosion proof electrical enclosures and ensure optimal performance of the circuit breakers within.

Professional Installation Guidelines

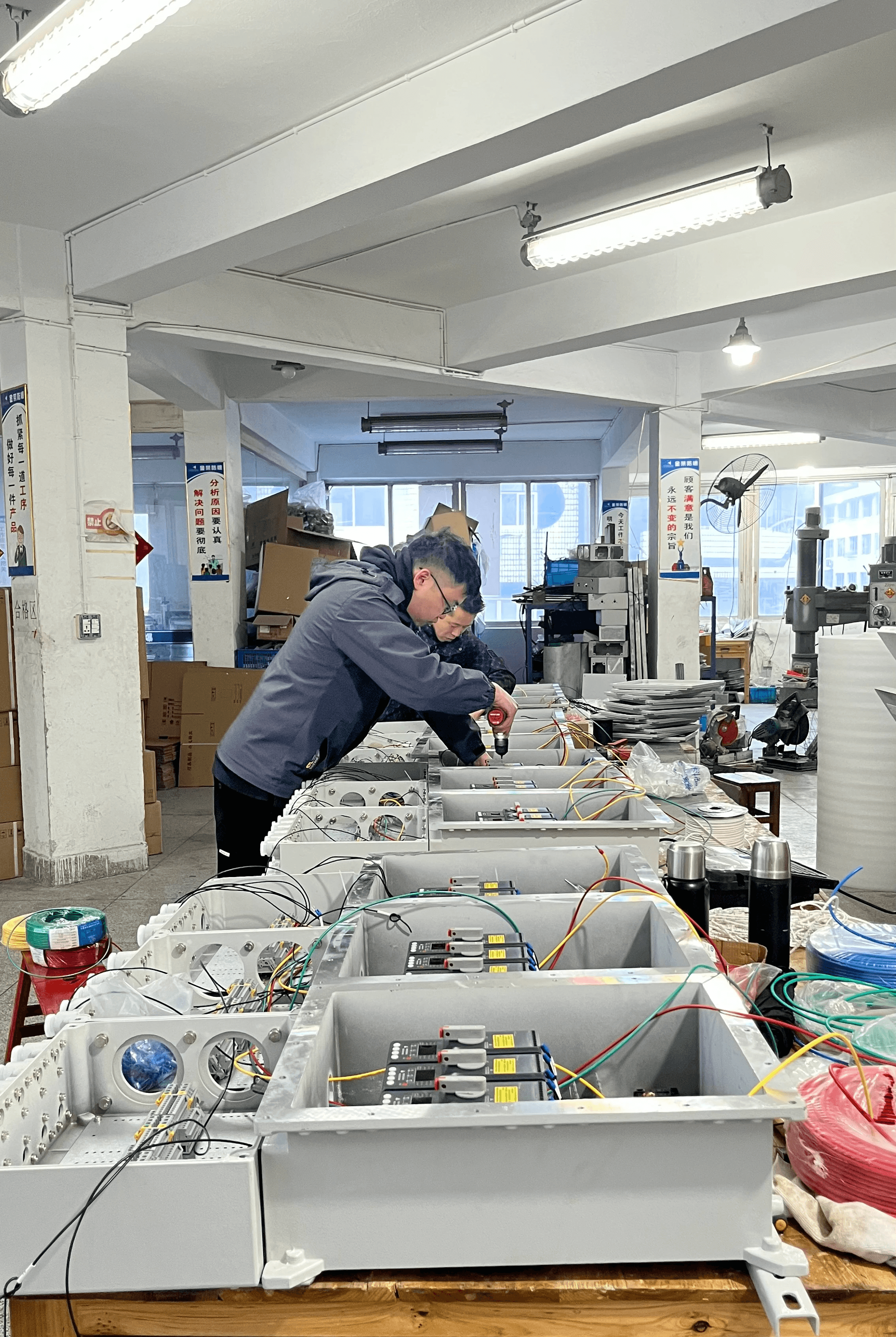

Professional installation of an explosion proof electrical panel is crucial for maintaining safety standards. Always engage qualified electricians who are familiar with the specific requirements of explosion proof technology; they will ensure that all connections meet regulatory guidelines for electric power distribution. Additionally, it’s essential to consider the environment where the panel will be installed—factors such as temperature, humidity, and potential exposure to corrosive substances can significantly influence installation methods.

Proper grounding is another critical aspect; ensuring that your explosion proof control panel is adequately grounded minimizes risks associated with static discharge or electrical faults. Furthermore, all circuit breakers should be tested post-installation to verify their functionality under expected operational conditions. Investing in professional installation not only enhances safety but also helps avoid costly repairs or replacements down the line.

Regular Maintenance Tips for Safety

Regular maintenance ensures that your explosion proof electrical panels function effectively over time while minimizing hazards associated with wear and tear. Schedule routine inspections at least once a year; during these checks, assess the integrity of seals on your explosion proof enclosures as well as any visible signs of corrosion or damage. Keeping circuit breakers clean and free from dust or debris is essential for maintaining their reliability in critical situations.

Another vital maintenance tip involves testing all components regularly; this includes checking that industrial breakers trip correctly under overload conditions. Documenting these tests can help track performance trends over time and identify potential issues before they escalate into major problems. Remember that proactive maintenance not only safeguards personnel but also extends the lifespan of your equipment.

Identifying Signs of Wear and Tear

Recognizing signs of wear and tear on an explosion proof electrical panel can save you from catastrophic failures in hazardous environments. Look out for discoloration or charring around circuit breakers—these may indicate overheating or arcing issues that need immediate attention. Additionally, inspect gaskets on your explosion proof enclosures; if they appear cracked or brittle, it's time for replacements to maintain a secure seal against explosive elements.

Pay close attention to unusual noises coming from within the panel; humming or buzzing sounds could signal malfunctioning components needing inspection or replacement by professionals experienced with electric power distribution systems. Finally, be vigilant about monitoring any fluctuations in voltage levels—these irregularities could signal deeper issues within your system requiring prompt intervention before leading to dangerous situations.

Conclusion

In the realm of industrial safety, ensuring that electrical systems are equipped with the right protective measures is paramount. The use of explosion proof electrical panels is a critical step in safeguarding environments where flammable materials may be present. By integrating robust circuit breakers and innovative designs, these panels provide a reliable means of electric power distribution while minimizing risks.

Ensuring Safety with Proper Equipment

Safety in industrial settings hinges on the quality and reliability of equipment used, particularly when dealing with volatile environments. Explosion proof electrical enclosures are designed to contain any potential sparks or explosions, preventing them from igniting surrounding gases or dust. By investing in high-quality explosion proof control panels, businesses can significantly reduce the risk of catastrophic failures and ensure compliance with safety regulations.

How Jinrong Enhances Electrical Safety

Jinrong stands out as a leader in manufacturing explosion proof electrical panels that prioritize both safety and performance. Their products are engineered using advanced materials and technology to withstand harsh conditions while providing superior protection against explosive hazards. With a focus on innovation, Jinrong's explosion proof panel solutions incorporate state-of-the-art circuit breakers that enhance operational efficiency and reliability for electric power distribution systems.

Future Trends in Explosion Proof Technology

The future of explosion proof technology is promising, driven by advancements in materials science and engineering practices. Emerging trends indicate a shift towards smarter explosion proof electrical panels that integrate IoT capabilities for real-time monitoring and diagnostics. As industries continue to evolve, the demand for more sophisticated explosion proof electrical enclosures will likely increase, paving the way for enhanced safety measures across various sectors.