Introduction

In industries where flammable substances are commonplace, the safety and reliability of electrical systems cannot be overstated. This is where explosion proof electrical control comes into play, providing essential protection against potential hazards. Understanding the nuances of flameproof manufacturing is crucial for ensuring compliance with safety standards and protecting both personnel and equipment.

Understanding Explosion Proof Electrical Control

When we talk about explosion proof electrical control, we refer to systems designed to contain any explosions that may occur within their housing. This containment prevents flames or hot gases from escaping into the surrounding environment, which is vital in hazardous locations. But what exactly does it entail? It’s not just about being rugged; it’s about meeting rigorous standards that define how these products operate under extreme conditions.

The Importance of Flameproof Manufacturing

Flameproof manufacturing is critical in safeguarding workplaces from fire hazards associated with flammable gases and dusts. By utilizing flameproof designs, manufacturers can ensure that their products are capable of withstanding explosive atmospheres without compromising safety. This leads us to ask: What is meant by flameproof? It essentially means that a product can endure an internal explosion without allowing flames or pressure waves to escape, thus protecting the external environment.

Jinrong's Role in Safety and Compliance

Jinrong stands out among flameproof manufacturing companies by prioritizing safety and compliance in all its products. With a commitment to quality, Jinrong offers a range of flameproof manufacturing products designed to meet stringent industry regulations while providing reliable performance in hazardous conditions. When considering your options for explosion-proof needs, choosing Jinrong means opting for a partner dedicated to excellence in both safety and innovation.

What is Explosion Proof?

When we talk about explosion-proof equipment, we’re diving into a world where safety meets engineering prowess. Explosion-proof devices are designed to contain any explosion that may occur within them, preventing flames and hot gases from escaping into the surrounding environment. This is crucial in industries where flammable gases or dust are present, ensuring a safer workplace.

Definition and Key Features

At its core, explosion-proof refers to the ability of an enclosure to withstand an internal explosion without allowing flames or pressure to escape. Key features include robust construction materials, sealed joints, and specific design elements that prevent ignition of external hazardous atmospheres. It’s essential for flameproof manufacturing because it allows for reliable operation in environments where risks are high.

Applications in Hazardous Environments

Explosion-proof products find their homes in various hazardous environments such as oil refineries, chemical plants, and grain silos. These locations often have volatile substances that can ignite easily; thus, using explosion-proof equipment is not just beneficial but necessary for safety compliance. The right flameproof manufacturing products help mitigate risks associated with these dangerous settings.

Standards and Regulations

Understanding the standards and regulations surrounding explosion-proof equipment is vital for manufacturers and users alike. Organizations like the National Fire Protection Association (NFPA) and the International Electrotechnical Commission (IEC) set forth guidelines that dictate how these products should be constructed and tested. Compliance with these standards ensures that flameproof manufacturing companies deliver safe and reliable solutions tailored to industry needs.

What is Meant by Flameproof?

When we talk about flameproof design, we are diving into a world where safety meets innovation. Flameproof manufacturing involves creating products that can withstand and contain an explosion within their housing, preventing flames from escaping into the surrounding environment. This is crucial in industries where flammable gases, vapors, or dust are present, as it significantly reduces the risk of catastrophic incidents.

Explaining the Concept of Flameproof Design

Flameproof design refers to a construction method that ensures any internal explosion is contained within the equipment itself. It typically involves robust materials and specific engineering techniques to prevent flames from escaping and igniting surrounding flammable substances. Understanding what is meant by flameproof? helps in recognizing how these products play a pivotal role in maintaining safety standards across various hazardous environments.

Real-World Applications of Flameproof Products

Flameproof manufacturing products find their place in several industries, including oil and gas, chemical processing, and mining. These sectors often face environments with explosive atmospheres; hence, flameproof solutions are not just beneficial but essential for operational safety. From flameproof motors to switchgear and lighting fixtures, these products ensure that operations can continue without compromising safety or compliance with regulations.

Why Flameproof Matters in Manufacturing

The importance of flameproof manufacturing cannot be overstated; it directly impacts worker safety and operational efficiency. When companies invest in flameproof solutions, they not only comply with industry standards but also foster a culture of safety that enhances employee morale and productivity. Moreover, understanding what is the difference between flameproof and intrinsically safe systems allows manufacturers to make informed decisions tailored to their needs.

Flameproof vs. Intrinsically Safe

When navigating the world of hazardous environments, understanding the nuances between flameproof and intrinsically safe designs is crucial for ensuring safety and compliance. Both terms are often thrown around in discussions about explosion-proof technologies, but they serve different purposes and applications. This section will clarify what intrinsic safety entails, highlight key differences between these two approaches, and guide you in choosing the right solution for your needs.

Defining Intrinsic Safety

Intrinsic safety is a design philosophy aimed at preventing ignition in hazardous areas by limiting electrical energy to safe levels. Essentially, it means that even if a fault occurs, the device will not produce enough energy to ignite an explosive atmosphere. This approach is particularly useful in industries where flammable gases or dust may be present, allowing for safer operation without compromising functionality.

Key Differences Between the Two Approaches

The primary difference between flameproof manufacturing and intrinsic safety lies in how each method manages potential ignition sources. Flameproof designs contain any explosion within an enclosure, preventing flames from escaping into the surrounding environment—think of it as a sturdy fortress protecting against fire hazards. On the other hand, intrinsically safe devices mitigate risk by ensuring that their internal components never reach levels capable of igniting flammable materials; it’s more about prevention than containment.

Another distinction worth noting is their respective certifications; flameproof products require a flameproof certificate to demonstrate compliance with relevant standards, while intrinsically safe devices adhere to different criteria focused on energy limitations. In practical terms, this means that while both solutions enhance safety in hazardous environments, they do so through fundamentally different mechanisms.

Choosing the Right Solution for Your Needs

Selecting between flameproof manufacturing products and intrinsically safe devices depends largely on your specific application requirements and environmental conditions. If your operations involve high-energy processes or large volumes of potentially explosive substances, investing in flameproof equipment might be more suitable due to its robust containment capabilities. Conversely, if you're working with delicate electronic systems or need flexibility without compromising safety standards, then opting for intrinsically safe solutions could be your best bet.

Ultimately, understanding what is meant by flameproof versus intrinsic safety allows manufacturers to make informed decisions tailored to their unique operational challenges. Whether you’re exploring flameproof manufacturing companies or diving deep into product specifications like “What is the difference between flameproof and explosion-proof motors?”, knowing these distinctions can significantly enhance workplace safety.

Types of Flameproof Manufacturing Products

Flameproof manufacturing encompasses a range of products designed to operate safely in hazardous environments where flammable gases or dust may be present. These products are engineered to prevent the ignition of explosive atmospheres, ensuring safety and compliance across various industries. Understanding the types of flameproof manufacturing products available is crucial for businesses looking to enhance their safety measures.

Overview of Available Products

When exploring flameproof manufacturing, you'll encounter a variety of products tailored for different applications. Common offerings include flameproof motors, enclosures, lighting fixtures, and control systems that meet stringent safety standards. Each product is designed with specific features that prevent the escape of flames or sparks, thereby minimizing risks in potentially explosive atmospheres.

In addition to traditional flameproof items, advancements have led to innovative solutions such as smart electrical control systems that integrate seamlessly into existing setups. These products not only provide safety but also enhance operational efficiency through improved monitoring and control capabilities. With an array of options on the market, understanding what is meant by flameproof becomes essential for selecting the right equipment.

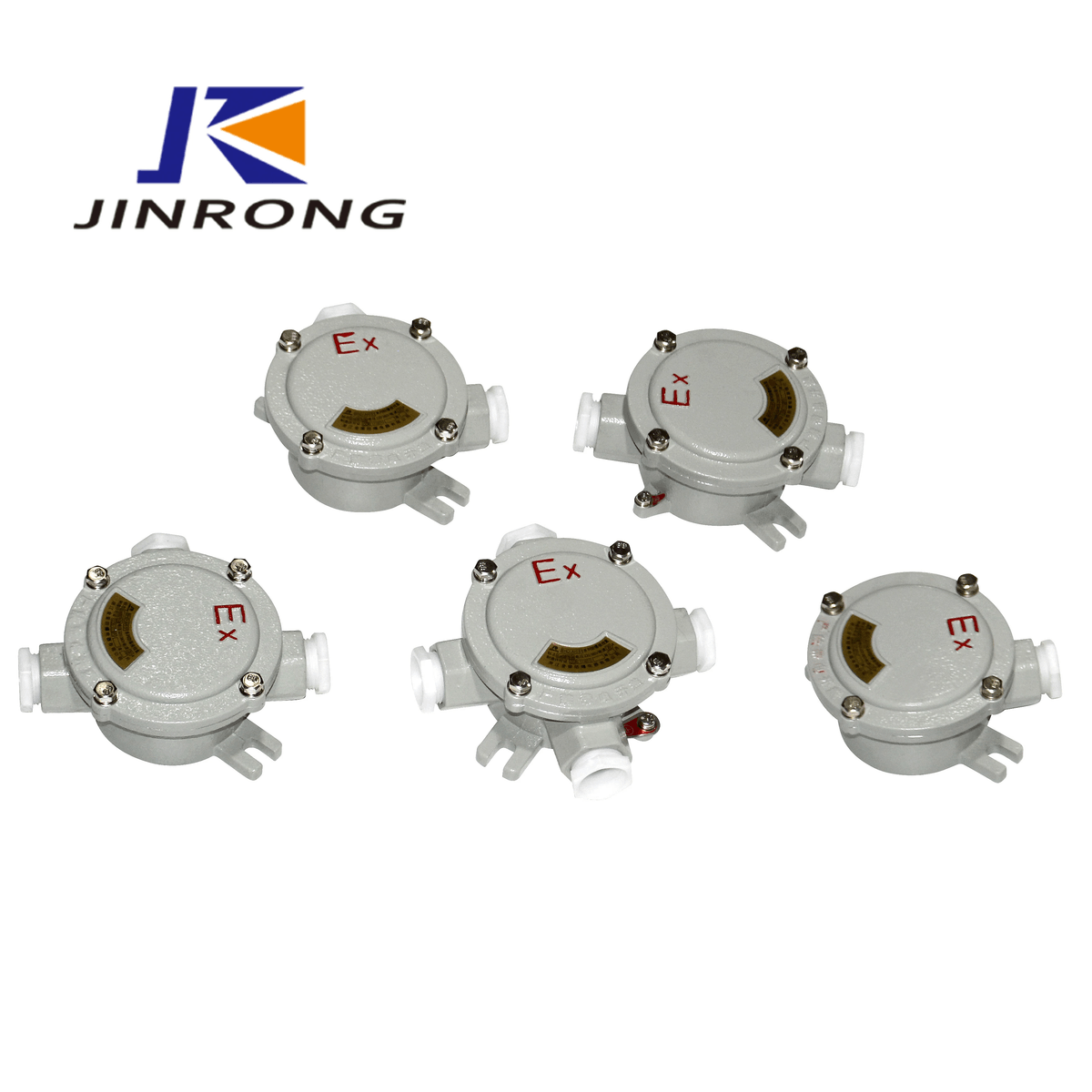

Highlights of Jinrong’s Electrical Control Solutions

Jinrong stands out among flameproof manufacturing companies by offering cutting-edge electrical control solutions that prioritize both safety and performance. Their range includes advanced control panels and motor starters specifically designed for use in hazardous locations, ensuring compliance with industry regulations while delivering reliability under pressure. Jinrong's commitment to quality means that their products are rigorously tested to withstand extreme conditions without compromising on functionality.

One key feature of Jinrong’s offerings is their adaptability; these electrical control solutions can be customized to meet specific client needs while adhering to strict flameproof standards. This flexibility allows businesses from various sectors—such as oil and gas, chemical processing, and mining—to find suitable solutions tailored for their unique environments. By focusing on innovation and customer satisfaction, Jinrong exemplifies what it means to lead in flameproof manufacturing.

Importance of Certifications in Flameproof Manufacturing

In the realm of flameproof manufacturing, certifications play a pivotal role in ensuring product safety and compliance with established standards. A flameproof certificate serves as proof that a product has undergone rigorous testing and meets specific safety criteria necessary for operation in hazardous areas. This certification process involves thorough evaluations by accredited organizations which assess aspects such as construction integrity and performance under extreme conditions.

The importance of certifications cannot be overstated; they provide peace of mind for manufacturers and end-users alike by guaranteeing that equipment will perform safely when exposed to potential ignition sources. Moreover, understanding what is the difference between flameproof and intrinsically safe designs helps stakeholders make informed decisions about which type best suits their operational needs—ensuring both safety and efficiency remain top priorities within any organization.

Investing in certified flameproof manufacturing products not only safeguards personnel but also protects assets against costly downtime due to accidents or regulatory penalties—making it an essential consideration for any business operating in high-risk environments.

Understanding Flameproof Certification

In the world of flameproof manufacturing, certification is a crucial component that ensures safety and compliance in hazardous environments. A flameproof certificate verifies that a product has met stringent safety standards, allowing it to operate safely in areas where flammable gases or vapors may be present. This certification is not just a piece of paper; it’s a testament to the reliability and integrity of flameproof manufacturing products.

What is a Flameproof Certificate?

A flameproof certificate serves as an official acknowledgment that a product can withstand internal explosions without igniting external explosive atmospheres. Essentially, it guarantees that the design and construction of the product adhere to specific safety standards set forth by regulatory bodies. Without this certificate, manufacturers risk not only their reputation but also the safety of workers in potentially explosive environments.

The Process of Obtaining Certification

Obtaining a flameproof certificate involves rigorous testing and evaluation by accredited testing agencies specializing in hazardous equipment. Manufacturers must submit their products for thorough examination, which includes assessments on materials used, design integrity, and performance under extreme conditions. Once all criteria are met, the agency issues the certification, paving the way for safe deployment in industries like oil and gas or chemical processing.

How Certification Impacts Product Safety

The impact of flameproof certification on product safety cannot be overstated; it acts as both a shield and a guarantee for users in hazardous workplaces. Certified products are engineered to prevent ignition sources from escaping into potentially explosive atmospheres—this is particularly significant when considering what is meant by flameproof? Moreover, understanding what is the difference between flameproof and intrinsically safe can lead to informed decisions about which type of protection suits specific applications best. Ultimately, certification ensures that manufacturers uphold high standards while contributing positively to workplace safety.

Conclusion

In wrapping up our exploration of flameproof manufacturing, it’s clear that the future holds exciting developments in safety and compliance for hazardous environments. As industries continue to evolve, so too will the technology and standards surrounding flameproof products, ensuring they meet the highest safety requirements. The demand for reliable solutions will propel innovation, making flameproof manufacturing a cornerstone of industrial safety.

The Future of Flameproof Manufacturing

Looking ahead, flameproof manufacturing is poised for significant advancements driven by technological innovations and stricter regulations. With an increasing focus on sustainability, manufacturers will likely explore eco-friendly materials that still meet rigorous safety standards. Moreover, as industries expand into more complex environments, understanding what is meant by flameproof design will become essential for ensuring worker safety and operational efficiency.

Jinrong’s Commitment to Quality

At Jinrong, quality isn't just a buzzword; it's a core value that permeates every aspect of our operations in the realm of explosion-proof solutions. Our dedication to producing only the highest-quality flameproof manufacturing products ensures that our clients receive reliable and compliant equipment tailored to their needs. By consistently adhering to industry standards and obtaining necessary certifications, we reinforce our commitment to quality in all aspects of flameproof manufacturing.

Why Choose Jinrong for Your Explosion Proof Needs

Choosing Jinrong means opting for excellence in explosion-proof solutions backed by years of experience in the field. Our comprehensive understanding of what is the difference between flameproof and intrinsically safe designs allows us to offer tailored advice based on your specific requirements. Additionally, with our robust range of offerings—coupled with a strong reputation among leading flameproof manufacturing companies—Jinrong stands out as your go-to partner for all things related to explosion-proof motors and equipment.