Introduction

Are you familiar with explosion-proof cable connectors? These specialized connectors play a crucial role in industrial safety, ensuring that electrical systems remain safe in hazardous environments. In this guide, we'll delve into the world of explosion-proof cable connectors, explore the importance of CGBS and EBY Explosionproof Portable Cord Connectors, and discuss the need for explosion-proof wiring.

Understanding Explosion-Proof Cable Connectors

Explosion-Proof Cable Connectors are designed to prevent the ignition of flammable gases or vapors in hazardous environments. These connectors are essential for maintaining safety in industries such as oil and gas, chemical processing, and mining.

Importance of CGBS and EBY Explosionproof Portable Cord Connectors

CGBS and EBY Explosionproof Portable Cord Connectors are specifically engineered to provide reliable connections in explosive atmospheres. These connectors offer a high level of protection against potential hazards, making them indispensable for industrial applications.

Exploring the Need for Explosion-Proof Wiring

In environments where flammable gases or dust are present, explosion-proof wiring is essential to prevent catastrophic accidents. By using specialized cables and connectors, businesses can ensure the safety of their workers and equipment.

What are Explosion-Proof Cable Connectors?

Explosion-Proof Cable Connectors are essential components in hazardous environments, designed to prevent the ignition of flammable gases, vapors, or dust. These connectors are constructed with robust materials and sealing techniques to contain any potential explosion within the device, ensuring safety in volatile settings.

Explaining the Basics of Explosion-Proof Connectors

Explosion-Proof Cable Connectors are engineered to withstand and contain explosions within hazardous locations, preventing the risk of fire or explosion propagation. These connectors feature robust housings and sealing mechanisms that prevent the entry of flammable substances into electrical enclosures, ensuring reliable performance in high-risk environments.

Features and Benefits of Explosion-Proof Cable Connectors

The key features of Explosion-Proof Cable Connectors include durable construction, corrosion resistance, and high ingress protection ratings to safeguard against hazardous elements. These connectors provide a secure electrical connection while minimizing the risk of sparking or arcing, making them ideal for use in oil refineries, chemical plants, pharmaceutical facilities, and other volatile industries.

Applications and Industries Requiring Explosion-Proof Connectors

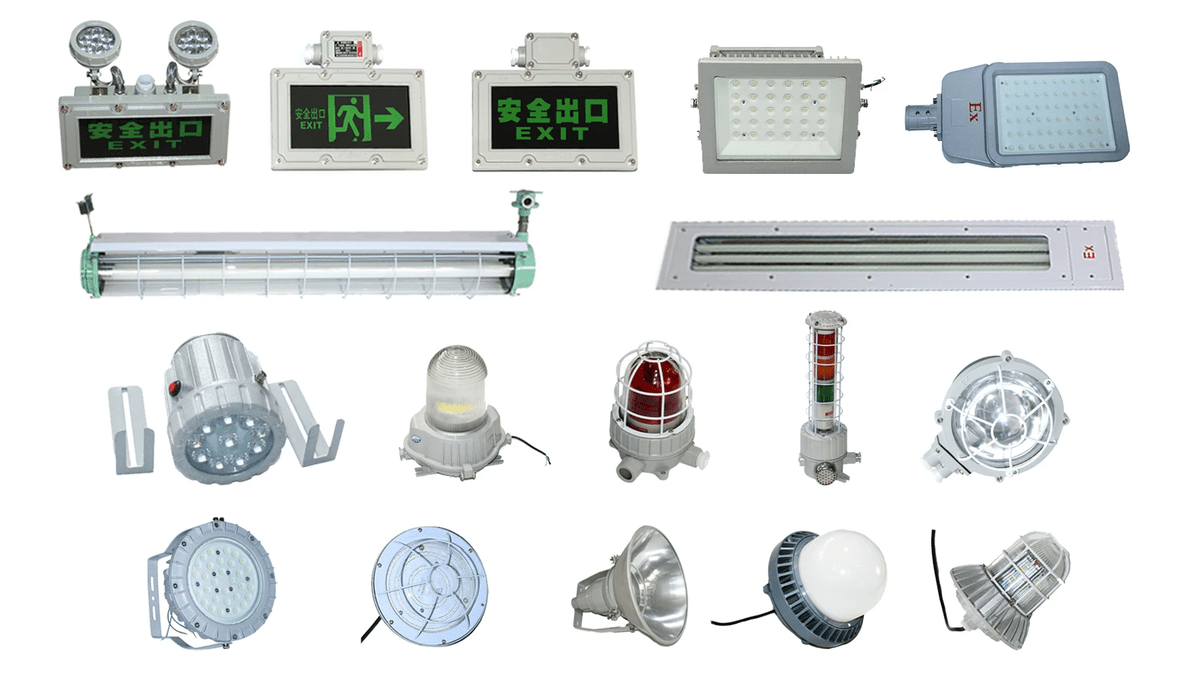

Explosion-Proof Cable Connectors are crucial for a wide range of applications in industries such as oil and gas, petrochemicals, mining, food processing, and wastewater treatment plants. They are used in equipment such as motors, pumps, lighting fixtures, control panels, sensors, and instrumentation that operate in potentially explosive atmospheres.

Now let's move on to understanding CGBS and EBY Explosionproof Portable Cord Connectors.

CGBS and EBY Explosionproof Portable Cord Connectors

Explosion-Proof Cable Connectors are essential in industrial settings, and CGBS and EBY are two leading brands in this space. These connectors are designed to provide a safe and reliable connection for portable cord applications in hazardous environments.

Overview of CGBS and EBY Explosionproof Portable Cord Connectors

CGBS and EBY Explosionproof Portable Cord Connectors are specifically engineered to prevent the ignition of hazardous atmospheres, making them ideal for use in oil refineries, chemical plants, and other high-risk settings. These connectors are built to withstand extreme conditions while ensuring the safety of personnel and equipment.

Advantages and Specifications of CGBS and EBY Connectors

The CGBS and EBY connectors boast a range of advantages, including rugged construction, corrosion resistance, and compatibility with various cable types. With certifications from regulatory bodies such as UL and CSA, these connectors meet stringent safety standards to provide peace of mind in hazardous locations.

Real-Life Examples of Using CGBS and EBY Connectors

In real-world applications, CGBS and EBY Explosionproof Portable Cord Connectors have proven their reliability in protecting against the risks posed by explosive atmospheres. From offshore drilling platforms to pharmaceutical manufacturing facilities, these connectors have played a crucial role in maintaining safety while enabling critical operations.

Remember that when it comes to choosing explosion-proof portable cord connectors for your industrial needs, quality is paramount. With CGBS and EBY products offering top-notch performance backed by industry certifications, you can trust that your operations will remain safe even in the most challenging environments.

What Makes an Explosion-Proof Connector Special?

Understanding the Design and Technology Behind Explosion-Proof Connectors

Explosion-proof cable connectors are designed with robust materials and advanced technology to prevent the ignition of flammable gases or vapors in hazardous environments. These connectors are constructed with specialized seals, gaskets, and enclosures to contain any potential explosions within the connector itself, ensuring safety in volatile settings.

Comparing Explosion-Proof Connectors with Standard Connectors

In contrast to standard connectors, explosion-proof cable connectors are engineered to withstand extreme conditions such as high temperatures, corrosive substances, and mechanical impact. The design of explosion-proof connectors includes features like flameproof enclosures and increased ingress protection, making them suitable for use in hazardous areas where standard connectors would pose a significant risk.

Tips for Selecting the Right Explosion-Proof Connectors

When choosing explosion-proof cable connectors, it's crucial to consider factors such as the specific hazardous classification of the environment, the type of wiring being used, and any additional requirements for temperature or chemical resistance. Consulting with experienced suppliers like Jinrong can provide valuable insights into selecting the most suitable explosion-proof connectors for your industrial applications.

Stay tuned for more information on Is there an explosion proof cable? coming up next!

Is There an Explosion-Proof Cable?

Exploring the Availability of Explosion-Proof Cables

When it comes to explosion-proof cable connectors, the availability of explosion-proof cables is crucial. These specialized cables are designed to withstand hazardous environments and prevent the risk of explosions. With a focus on safety and reliability, explosion-proof cables are readily available from reputable suppliers like Jinrong, ensuring that industrial settings have access to the necessary components for their operations.

In addition to their availability, it's important to consider the durability and flexibility of explosion-proof cables. These cables are not only resistant to explosions but also to corrosion, moisture, and extreme temperatures. This makes them suitable for a wide range of industrial applications, providing a reliable and long-lasting solution for hazardous environments. With their robust construction and high-performance capabilities, explosion-proof cables offer peace of mind for businesses operating in potentially dangerous settings.

Understanding the Role of Cables in Explosion-Proof Systems

In explosion-proof systems, cables play a critical role in ensuring that electrical connections are safe and secure. These cables are specifically engineered to contain any potential sparks or heat that could lead to an explosion in volatile environments. By using explosion-proof cables in conjunction with connectors such as CGBS and EBY Explosionproof Portable Cord Connectors, industrial facilities can maintain a high level of safety while also optimizing their operational efficiency.

When choosing the right cable for explosion-proof wiring, it is essential to consider the specific requirements of the environment in which it will be used. Factors such as temperature, exposure to chemicals, and potential mechanical stress should all be taken into account when selecting the appropriate cable. Additionally, it is important to ensure that the chosen cable meets all relevant industry standards and regulations to guarantee its effectiveness in preventing explosions.

Recommendations for Choosing the Right Cable for Explosion-Proof Wiring

Selecting the right cable for explosion-proof wiring requires careful consideration of factors such as environmental conditions, voltage ratings, and insulation materials. It's essential to work with experienced suppliers who can provide guidance on choosing the most suitable cable for specific applications. Whether it's a flexible portable cord or a rigid conduit cable, having access to expert advice can make all the difference in creating a secure and compliant explosion-proof wiring system.

When it comes to selecting the right cable for explosion-proof wiring, it's crucial to also consider the potential for mechanical damage in the installation area. Factors such as exposure to heavy machinery, sharp objects, or high foot traffic can impact the durability and safety of the cable. Working with suppliers who understand these risks and can recommend cables with reinforced jackets or armor can help ensure a longer lifespan and reduced risk of accidents.

Building a Safe and Reliable Industrial Environment

In industrial settings, the use of explosion-proof cable connectors is crucial for ensuring safety and preventing potential hazards. These connectors are designed to contain any sparks or flames that may occur due to electrical malfunctions, making them essential for hazardous environments where flammable gases or vapors are present. By using explosion-proof cable connectors, industrial facilities can significantly reduce the risk of explosions and protect both personnel and equipment.

Importance of Using Explosion-Proof Connectors in Industrial Settings

The importance of using explosion-proof cable connectors in industrial settings cannot be overstated. These connectors play a vital role in preventing ignition sources from causing catastrophic accidents in areas where volatile substances are present. By utilizing these specialized connectors, industries can maintain a safe working environment and comply with stringent safety regulations.

Compliance and Regulations for Explosion-Proof Wiring

When it comes to explosion-proof wiring, compliance with regulations is paramount. Industries must adhere to strict guidelines set forth by organizations such as OSHA, NEC, and ATEX to ensure that their electrical systems are properly safeguarded against potential explosions. Failure to comply with these regulations can result in severe consequences, including fines and work stoppages.

Best Practices for Ensuring Safety with Explosion-Proof Connectors

To ensure the utmost safety when using explosion-proof cable connectors, it's essential to follow best practices such as regular inspections, proper installation techniques, and ongoing maintenance. Additionally, training employees on the correct usage of these connectors is crucial for preventing accidents and maintaining a secure working environment.

By implementing the right combination of CGBS and EBY Explosionproof Portable Cord Connectors along with compliant cables designed specifically for hazardous environments, industries can effectively mitigate the risks associated with electrical systems in volatile settings.

Is there an explosion proof cable?

Yes! Specialized cables designed for use in hazardous locations are available to meet the unique requirements of explosion-proof wiring systems. These cables are constructed with durable materials that can withstand extreme conditions while minimizing the risk of sparking or igniting flammable substances.

What are explosion proof connectors?

Explosion-proof connectors are specially designed electrical fittings that prevent sparks or flames from escaping into hazardous areas where flammable gases or vapors may be present. They provide a secure connection while containing any potential sources of ignition within the connector housing.

What is an explosion proof plug?

An explosion-proof plug is a type of connector that is certified for use in hazardous locations where explosive atmospheres may exist. These plugs are engineered to prevent any internal arcing or sparking from igniting flammable substances outside the connector housing.

What are the special cables required for explosion proof wiring?

Special cables required for explosion-proof wiring must meet stringent standards for durability and safety in hazardous environments. These cables feature robust construction and insulation materials that minimize the risk of sparking or ignition while providing reliable electrical connectivity.

Conclusion

Advancing Industrial Safety with Explosion-Proof Cable Connectors

In conclusion, explosion-proof cable connectors play a crucial role in ensuring safety in industrial environments. These connectors, including CGBS and EBY Explosionproof Portable Cord Connectors, provide the necessary protection against potential explosions and hazardous situations. By choosing the right connector for your industrial needs, you can effectively mitigate risks and create a secure working environment.

Choosing the Right Connector for Your Industrial Needs

When it comes to selecting the right connector for your industrial needs, it's essential to consider the specific requirements of your application. Whether you need explosion-proof cable connectors for hazardous locations or high-risk environments, understanding the features and benefits of different connectors is key to making an informed decision. With the right connector in place, you can ensure reliable performance and compliance with safety regulations.

Partnering with Jinrong for Reliable and High-Quality Explosion-Proof Solutions

For reliable and high-quality explosion-proof solutions, partnering with Jinrong is a smart choice. With a wide range of explosion-proof cable connectors and accessories, Jinrong offers innovative solutions designed to meet the demands of various industries. By collaborating with Jinrong, you can access expert guidance and support to address your specific needs for explosion-proof wiring and ensure a safe working environment.

Remember that safety is paramount in any industrial setting, and investing in top-notch explosion-proof cable connectors is a proactive step towards creating a secure workplace environment while complying with industry regulations.