Introduction

When it comes to working in hazardous environments, safety should always be the top priority. Understanding hazardous location lighting is crucial for ensuring a safe work environment, and exploring the right accessories can make all the difference in keeping workers protected. Whether it's emergency lighting or explosion-proof lights, having the right equipment is essential for maintaining safety standards.

Understanding Hazardous Location Lighting

Hazardous location lighting accessories play a vital role in providing illumination in areas where flammable gases, vapors, or combustible dusts may be present. These accessories are designed to withstand harsh conditions and reduce the risk of accidents in potentially dangerous environments.

Importance of Safety in Hazardous Environments

In hazardous environments, safety is paramount. Using hazardous location lights can significantly minimize the risk of fire or explosions caused by electrical equipment, ensuring that workers can carry out their tasks without compromising their well-being.

Exploring Hazardous Location Lighting Accessories

From explosion-proof fixtures to specialized wiring and control systems, there are various accessories available to enhance safety in hazardous locations. Choosing the right accessories can make a world of difference in preventing accidents and maintaining compliance with safety regulations.

What are Hazardous Location Lights?

Hazardous location lights are specifically designed to be used in areas where flammable gases, vapors, or combustible dusts are present. These lights are classified into different types based on the specific hazardous environment they will be used in, such as Class I, II, or III. They are crucial for ensuring safety and preventing potential explosions or fires in these high-risk areas.

Types of Hazardous Location Lights

There are various types of hazardous location lights available, including LED fixtures, fluorescent lights, high-intensity discharge (HID) lights, and incandescent fixtures. Each type is designed to meet specific lighting requirements for different hazardous locations and provide adequate illumination while minimizing the risk of ignition.

In addition to the different types of hazardous location lights, it's important to consider the specific environmental conditions in which they will be used. For example, LED fixtures are known for their energy efficiency and long lifespan, making them ideal for locations with limited access for maintenance. On the other hand, fluorescent lights may be better suited for areas where color rendering is important, such as in a chemical processing plant where workers need to accurately distinguish between different substances.

Key Features of Hazardous Location Lights

Key features of hazardous location lights include rugged construction to withstand harsh environments, corrosion resistance to protect against chemical exposure, and explosion-proof ratings to prevent the ignition of flammable substances. Additionally, these lights often have sealed enclosures and specialized wiring to ensure safe operation in hazardous areas.

Hazardous location lights are designed to provide reliable illumination in challenging and potentially dangerous environments. With their rugged construction, these lights can withstand the rigors of industrial settings, including exposure to extreme temperatures, moisture, and physical impact. This durability ensures that the lights will continue to function effectively, reducing the need for frequent maintenance and replacement.

Benefits of Using Hazardous Location Lights

Using hazardous location lights offers numerous benefits such as improved safety by reducing the risk of fire or explosion in volatile environments. They also provide energy efficiency through advanced lighting technologies like LED fixtures and contribute to cost savings by minimizing maintenance needs due to their durable design.

In addition, hazardous location lights are designed to withstand harsh environmental conditions, making them suitable for use in areas with extreme temperatures, high humidity, or corrosive substances. This durability ensures that the lights remain operational and reliable even in the most challenging industrial settings, reducing the risk of downtime and productivity loss. Furthermore, these lights are often equipped with features such as motion sensors and remote monitoring capabilities, enhancing overall security and control in hazardous environments.

Which Type of Lighting Could be Hazardous?

Hazardous location lighting accessories play a crucial role in ensuring safety in environments where flammable gases, vapors, liquids, combustible dust, or fibers are present. These accessories include explosion-proof enclosures, conduit seals, and cable glands that protect lighting fixtures from igniting hazardous substances.

Identifying Potential Hazards in Lighting

In hazardous environments, traditional lighting fixtures can pose a risk due to their potential to create sparks or excessive heat. These hazards can lead to explosions or fires in areas with volatile substances. It's important to identify these potential hazards and choose lighting options that are specifically designed for use in such environments. When evaluating potential hazards in lighting, it's crucial to consider the type of materials being handled in the environment. Certain substances may be more susceptible to ignition from traditional lighting sources, making it essential to opt for specialized fixtures that minimize this risk.

Common Risks in Hazardous Environments

Common risks in hazardous environments include the presence of flammable gases and vapors, combustible dust, and other potentially explosive materials. Traditional lighting fixtures may not be suitable for use in these areas as they can ignite these substances, leading to catastrophic consequences.

Choosing the Right Lighting for Safety

To ensure safety in hazardous environments, it's essential to choose lighting fixtures that are specifically designed and certified for use in such locations. Hazardous location lights are engineered to prevent the ignition of flammable substances and minimize the risk of explosions or fires. By selecting the right lighting options, businesses can effectively mitigate potential hazards and enhance workplace safety.

When selecting lighting for hazardous environments, it's important to consider factors such as the type of hazardous materials present, the temperature of the area, and the potential for dust or moisture. Different types of hazardous location lights are designed to address specific challenges, so it's crucial to assess the unique needs of your environment before making a decision. Additionally, regular maintenance and inspection of these lighting fixtures is essential to ensure they continue to function safely and effectively over time.

What is typically considered a Hazardous Electrical Location?

Hazardous electrical locations are areas where the potential for fire or explosion exists due to the presence of flammable gases, vapors, liquids, combustible dusts, or ignitable fibers. These locations are classified into different zones based on the frequency and likelihood of hazardous conditions.

Definition of Hazardous Electrical Locations

Hazardous electrical locations are defined as areas where the atmosphere contains enough flammable substances to create a risk of explosion or fire. These locations are categorized into different classes and divisions based on the type and characteristics of the hazardous materials present.

Factors Contributing to Hazardous Electrical Locations

Factors contributing to hazardous electrical locations include the presence of volatile substances such as gas, vapor, dust, or fibers that can ignite when exposed to an electrical spark or heat source. Other contributing factors may include poor ventilation, confined spaces, and high temperatures.

Regulations and Standards for Hazardous Electrical Locations

Regulations and standards for hazardous electrical locations are established by organizations such as OSHA (Occupational Safety and Health Administration) and NFPA (National Fire Protection Association). These regulations outline specific requirements for equipment, wiring methods, and safety practices to minimize the risk of ignition in hazardous environments.

What is the Emergency Lighting in Hazardous Areas?

Emergency lighting in hazardous areas is crucial for ensuring the safety of personnel during power outages or emergencies. It provides illumination to guide workers to safety and allows for continued operations in critical situations. Proper emergency lighting is essential for compliance with safety regulations and standards.

Importance of Emergency Lighting in Hazardous Areas

Emergency lighting in hazardous areas plays a vital role in preventing accidents and ensuring the safe evacuation of personnel during emergencies. It helps maintain visibility and enables workers to navigate through potentially dangerous environments, reducing the risk of injury or loss of life. Additionally, emergency lighting supports rescue and response efforts, contributing to overall workplace safety.

Types of Emergency Lighting for Hazardous Environments

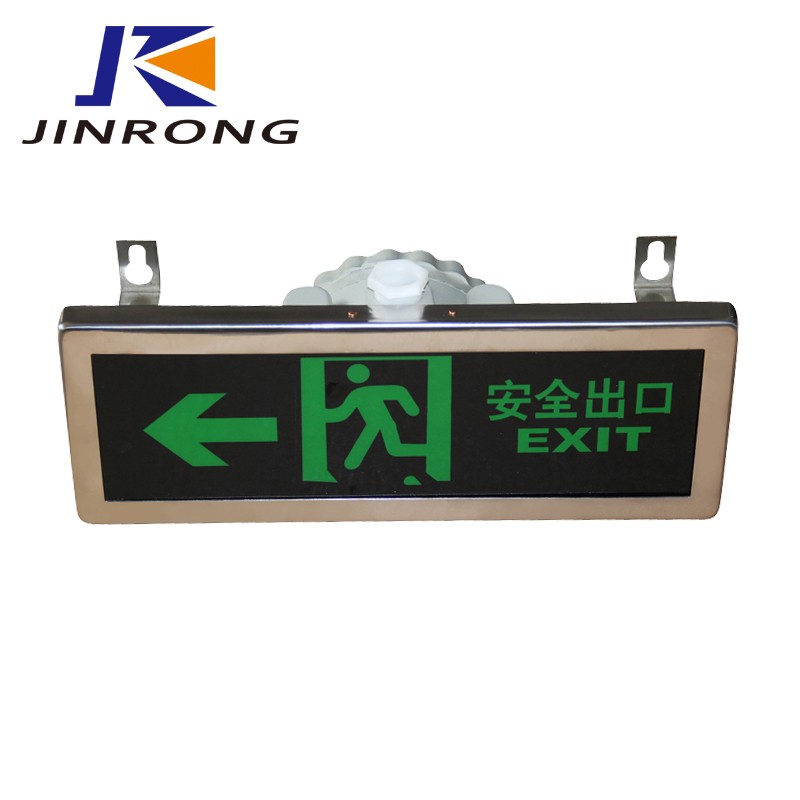

There are various types of emergency lighting designed specifically for hazardous environments, including LED emergency lights, exit signs, and battery-powered portable lights. These lights are built to withstand harsh conditions and provide reliable illumination during power failures or other emergencies. Additionally, some models are equipped with self-testing features for added peace of mind.

Compliance and Maintenance of Emergency Lighting

Compliance with regulations regarding emergency lighting in hazardous areas is essential for maintaining a safe work environment. Regular maintenance and testing are necessary to ensure that emergency lights function properly when needed most. This includes inspecting batteries, checking bulbs and fixtures, as well as conducting periodic functional tests to verify proper operation.

Industrial & Hazardous Location Lighting

Applications of Industrial & Hazardous Location Lighting

Industrial and hazardous location lighting is essential for a wide range of industries, including oil and gas, chemical plants, mining, and manufacturing facilities. These lights are specifically designed to withstand harsh conditions and provide reliable illumination in potentially dangerous environments.

Industrial and hazardous location lighting is crucial for ensuring the safety of workers and the efficient operation of these industries. These specialized lights are designed to meet specific requirements, such as resistance to corrosion, extreme temperatures, and potential exposure to flammable gases or dust. In addition, they are often required to comply with industry regulations and standards to ensure the highest level of safety and performance.

Specifications and Requirements for Industrial Lighting

Industrial lighting must meet stringent specifications and requirements to ensure safety and compliance with regulations. This includes features such as explosion-proof construction, corrosion resistance, and adherence to specific industry standards for hazardous location lighting.

In addition to meeting safety and regulatory requirements, industrial lighting must also prioritize energy efficiency and sustainability. This includes the use of LED technology, which not only provides bright and reliable illumination but also reduces energy consumption and maintenance costs. By incorporating advanced lighting controls and sensors, industrial facilities can further optimize their lighting systems to minimize waste and maximize operational efficiency.

Innovations in Hazardous Location Lighting Technology

Advancements in hazardous location lighting technology have led to the development of more efficient, durable, and cost-effective lighting solutions. LED technology, in particular, has revolutionized industrial lighting by offering longer lifespan, lower energy consumption, and improved visibility in hazardous areas.

The use of advanced materials and design techniques has also contributed to the development of more rugged and durable hazardous location lighting accessories. These accessories are now able to withstand harsh environmental conditions, such as extreme temperatures, corrosive chemicals, and heavy vibrations, without compromising performance. This increased durability not only reduces maintenance and replacement costs but also improves safety by ensuring that lighting remains operational in hazardous areas.

Conclusion

When it comes to hazardous location lighting, safety should always be the top priority. Choosing the right hazardous location lighting accessories is crucial in ensuring a safe work environment, and Jinrong is here to provide reliable and high-quality solutions for all your lighting needs.

Safety First: Choosing the Right Hazardous Location Lighting

It's essential to prioritize safety when selecting hazardous location lights for your workplace. By understanding the different types of hazardous location lights and their key features, you can make informed decisions that prioritize safety and compliance with regulations.

When choosing hazardous location lighting, it's important to consider the specific requirements of your workplace. Different industries and environments may have unique needs when it comes to lighting in hazardous areas. For example, a chemical processing plant may require explosion-proof fixtures, while an offshore drilling rig may need corrosion-resistant lights. Understanding these specific requirements will help you select the right lighting solutions for your workplace.

Enhancing Workplace Safety with Hazardous Location Lighting

Implementing the right type of lighting in hazardous areas can significantly enhance workplace safety by reducing the risks associated with potential hazards in lighting. Whether it's emergency lighting or industrial & hazardous location lighting, investing in the right solutions can make a significant difference in ensuring a safe work environment.

Jinrong: A Trusted Partner in Hazardous Location Lighting

Jinrong is a trusted partner when it comes to hazardous location lighting, offering a wide range of high-quality products designed to meet the specific requirements of hazardous environments. With our expertise and commitment to safety, we are dedicated to providing reliable solutions that enhance workplace safety and compliance.

Jinrong's range of hazardous location lighting products includes explosion-proof fixtures, emergency lighting, and portable lighting solutions, all designed to withstand the rigors of hazardous environments. Our commitment to safety means that our products undergo rigorous testing and certification to ensure they meet the highest industry standards. By choosing Jinrong as your partner in hazardous location lighting, you can have peace of mind knowing that you are investing in reliable and durable solutions for your workplace.