Introduction

In an era where safety is paramount, flameproof panels stand out as crucial components in various industrial applications. These robust structures are designed to contain explosions and prevent flames from escaping, making them essential for environments prone to hazardous materials. Understanding the nuances of flameproof technology helps industries safeguard their operations while adhering to strict safety standards.

Understanding Flameproof Panels

Flameproof panels are engineered to withstand and contain explosive forces, ensuring that any internal combustion does not escape into the surrounding environment. The design of a flameproof panel is meticulous, focusing on pressure resistance and airtight sealing to effectively manage potential hazards. By delving into flameproof panel specifications, one can appreciate how these components play a vital role in enhancing workplace safety.

Importance of Flameproof Technology

The significance of flameproof technology cannot be overstated; it serves as the first line of defense against fire-related incidents in high-risk areas. Implementing flameproof solutions not only protects personnel but also minimizes damage to equipment and facilities, thereby preserving business continuity. As industries evolve and regulations tighten, the demand for reliable flame proof panel boxes continues to grow, underscoring the importance of investing in quality solutions.

Applications Across Industries

Flameproof panels find their place across various sectors including oil and gas, chemical manufacturing, pharmaceuticals, and mining—industries where flammable substances are commonplace. In these environments, the use of a flame proof enclosure or junction box is not just recommended; it's often mandated by safety regulations. With leading manufacturers producing innovative designs that meet rigorous standards, organizations can confidently implement these technologies to enhance operational safety while navigating the complexities of compliance.

What Are Flameproof Panels?

Flameproof panels are essential components designed to protect sensitive equipment and personnel in hazardous environments. They are engineered to contain any explosion or fire that may occur within the enclosure, preventing it from spreading to the surrounding area. Understanding their definition and functionality helps clarify their critical role in safety across various industries.

Definition and Functionality

A flameproof panel is an enclosure that provides a safe environment for electrical equipment operating in potentially explosive atmospheres. These panels function by containing any internal explosion, allowing pressure to build up only within the confines of the box before safely venting through specialized outlets. This design minimizes the risk of ignition of external flammable substances, making flameproof panels vital for industries like oil and gas, chemicals, and mining.

Key Characteristics of Flameproof Panels

Flameproof panels boast several key characteristics that set them apart from standard enclosures. They are typically constructed from robust materials such as aluminum or stainless steel, which can withstand extreme temperatures and pressures during an explosion. Additionally, flame proof panel designs often include features like tight seals and specific pressure ratings to ensure maximum safety and compliance with industry regulations.

Flameproof Panel Specifications

These specifications include dimensions, ingress protection (IP) ratings, temperature classifications, and certification standards such as ATEX or IECEx. Each specification ensures that the flame proof panel box meets safety requirements while effectively protecting sensitive equipment in hazardous environments.

The Science Behind Flameproof Technology

Flameproof technology is a fascinating field that merges engineering with safety, particularly in environments where flammable materials are present. At the core of this technology lies the flame proof panel, designed to withstand explosions and prevent flames from escaping. Understanding how these panels function is crucial for anyone involved in industries where safety is paramount.

How Flameproof Panels Work

Flameproof panels operate on a straightforward yet effective principle: containment. When an explosion occurs within a flame proof panel box, the design ensures that any pressure generated stays contained, preventing flames from breaching the enclosure. This is achieved through robust construction and strategic sealing methods that work together to maintain integrity under extreme conditions.

The functionality of flame proof enclosures hinges on their ability to absorb shockwaves and dissipate heat without compromising safety. Each flame proof junction box is meticulously crafted to meet stringent industry standards, ensuring maximum protection against potential hazards. Furthermore, regular testing and adherence to flame proof panel specifications guarantee that these products remain reliable over time.

The Importance of Pressure and Sealing

Pressure management and sealing are critical components of effective flameproof technology. A well-sealed flame proof panel can withstand internal pressures generated during an explosion without allowing flames or gases to escape into the surrounding environment. This aspect not only protects personnel but also minimizes property damage in hazardous areas.

Moreover, proper sealing techniques enhance the overall durability of a flame proof enclosure, ensuring it remains operational even under adverse conditions. Regular maintenance checks are essential for confirming that seals remain intact over time, as any compromise could lead to catastrophic failures. Therefore, understanding pressure dynamics plays a vital role in selecting suitable products like the flame proof junction box for specific applications.

Common Materials Used

The materials used in constructing flameproof panels significantly influence their performance and reliability. Typically, high-grade metals such as aluminum or stainless steel are favored due to their strength and resistance to corrosion—attributes essential for longevity in harsh environments. Additionally, specialized coatings may be applied to enhance thermal resistance further.

In conjunction with metal components, insulating materials also play a pivotal role in maintaining safety standards within flame proof light specifications or junction boxes. These materials help manage heat dissipation while providing added protection against electrical hazards associated with flammable atmospheres. Leading manufacturers often invest heavily in research and development to innovate new materials that can elevate the effectiveness of their products.

Choosing the Right Flameproof Panel Box

Factors to Consider

First and foremost, assess the potential hazards in your work environment. Whether it's a chemical plant or an oil rig, different industries have varying requirements for flameproof enclosures. Next, consider the size of the flame proof panel box needed; a well-fitted enclosure not only enhances safety but also maximizes space efficiency.

Another essential factor is the material used in manufacturing these enclosures. Flameproof junction boxes are typically made from robust materials like aluminum or stainless steel that can withstand extreme conditions while preventing ignition sources from escaping. Lastly, don’t forget about certification; ensure that any flameproof light specifications meet industry standards for maximum safety assurance.

Popular Brands and Manufacturers

There are several reputable brands known for their quality flameproof solutions. Companies like Schneider Electric and Rittal have established themselves as leaders in providing reliable flame proof panel boxes that cater to various industrial needs. Additionally, local manufacturers often offer specialized products tailored to regional regulations and environmental conditions.

You should also consider newer players in the market who might offer innovative designs or competitive pricing without compromising on quality. Conduct thorough research on customer reviews and product performance before making a decision—after all, you want a brand that stands behind their products with solid warranties and customer support.

Comparing Flameproof Enclosure Options

When comparing different flameproof enclosure options, start by evaluating their features against your specific requirements. Look at aspects such as ingress protection ratings (IP ratings), which indicate how well an enclosure can resist dust and water penetration—critical factors in hazardous environments. Also pay attention to thermal management features; some enclosures come equipped with cooling systems designed to maintain optimal operating temperatures.

Next, analyze cost versus value—while it may be tempting to go for cheaper options initially, investing in high-quality flame proof panel boxes can save you money down the line through reduced maintenance costs and enhanced durability. Lastly, always check compatibility with other components like flame proof lights or junction boxes within your system to ensure seamless integration.

Essential Flameproof Junction Box Insights

Design and Purpose

Flameproof junction boxes are engineered to contain any explosion that may occur within the box itself, preventing it from propagating outside. The design incorporates robust materials and specialized sealing techniques that adhere to strict flame proof panel specifications. Their primary purpose is not only to safeguard electrical components but also to enhance overall safety in locations where flammable gases or dust may be present.

The functionality of these enclosures extends beyond mere containment; they also provide a secure environment for wiring connections, ensuring durability even in extreme conditions. With various configurations available, flameproof junction boxes can accommodate different types of electrical equipment tailored for specific applications. This versatility makes them a go-to choice across industries such as oil and gas, chemical processing, and mining.

Recommended Flameproof Junction Box Products

When selecting a flameproof junction box, it's essential to consider products from reputable manufacturers known for their commitment to quality and safety standards. Some recommended options include the **Hoffman Flame Proof Junction Box**, which boasts excellent corrosion resistance and robust construction tailored for harsh environments. Another great choice is the **Pepperl+Fuchs Junction Box**, celebrated for its reliability and adherence to rigorous flame proof panel specifications.

For those seeking variety, the **Adalet Flame Proof Junction Box** offers multiple sizes and configurations suitable for diverse applications while maintaining high safety standards. Each of these products not only meets industry requirements but also provides peace of mind when installed in potentially hazardous areas. Remember that investing in high-quality flameproof enclosures is crucial for minimizing risks associated with explosive atmospheres.

Installation Best Practices

Installing a flame proof junction box requires careful attention to detail to ensure optimal performance and compliance with safety regulations. First off, always consult the manufacturer's guidelines regarding installation procedures specific to your chosen flame proof enclosure model; this ensures compatibility with existing systems while adhering strictly to local codes. Proper sealing techniques are vital—gaskets must be intact, ensuring no gaps exist that could allow flammable gases or dust ingress.

Next up is cable entry; using appropriate conduit fittings helps maintain the integrity of your installation by preventing exposure of wires that could lead to short circuits or explosions—no one wants that! Finally, regular inspections post-installation are key; they help detect any wear or damage over time so you can address issues before they escalate into serious hazards.

In conclusion, understanding essential insights about flameproof junction boxes will empower you as you navigate through hazardous environments confidently while enhancing workplace safety.

Essentials of Flameproof Light Specifications

Key Features of Flameproof Lighting

Flameproof lighting is characterized by its robust construction and ability to prevent ignition sources from escaping the enclosure. One essential aspect is the flame proof panel design, which effectively contains any potential explosions within the light fixture itself. Additionally, these lights typically feature high-quality materials that resist corrosion and can endure harsh environmental conditions, making them ideal for industrial applications.

Another important feature is energy efficiency; many modern flameproof lights utilize LED technology, which not only reduces power consumption but also offers longer lifespans compared to traditional bulbs. Furthermore, flame proof light specifications often include specific ratings for temperature and humidity resistance, ensuring they perform well in various settings—from oil rigs to chemical plants. Ultimately, investing in reliable flameproof lighting means enhanced safety and reduced maintenance costs in hazardous areas.

Leading Flameproof Light Manufacturers

The market for flameproof lighting has seen numerous manufacturers emerge as leaders in safety and innovation. Companies like Schneider Electric and ABB have established themselves with a wide range of products that meet stringent industry standards while offering exceptional durability and performance. When searching for a reputable flame proof light manufacturer, it’s essential to consider their experience and commitment to quality assurance.

Another notable player is R.STAHL, known for its extensive portfolio of explosion-proof fixtures designed specifically for challenging environments such as petrochemical facilities or mining operations. These manufacturers continuously invest in research and development to keep up with evolving safety regulations while enhancing their product lines with cutting-edge technology. Choosing a trusted brand ensures you receive reliable solutions that adhere to strict flame proof panel specifications.

Safety Standards and Certifications

Safety standards are paramount when it comes to selecting any type of electrical equipment intended for hazardous locations—flameproof lighting included! The most recognized certifications include ATEX (from Europe) and IECEx (international), which guarantee that products meet rigorous guidelines regarding explosion protection measures associated with specific environments. Compliance with these standards assures end-users that their chosen products are tested against real-world scenarios involving flammable gases or dust.

Additionally, manufacturers often provide detailed documentation regarding their products' performance under various conditions—this includes information on temperature ratings, ingress protection levels (IP ratings), and other critical factors relevant to flame proof junction box applications or similar enclosures. By understanding these certifications, you can confidently select appropriate solutions tailored specifically for your operational needs while adhering strictly to safety protocols.

Jinrong: A Leader in Flameproof Solutions

Company History and Experience

Founded with a vision to revolutionize industrial safety, Jinrong has been at the forefront of flameproof solutions for over two decades. Their extensive experience in producing high-quality flame proof panels and enclosures has equipped them with invaluable insights into market needs and technological advancements. Throughout their journey, they have consistently adapted to industry changes, ensuring that their flame proof panel specifications meet the evolving demands of various sectors.

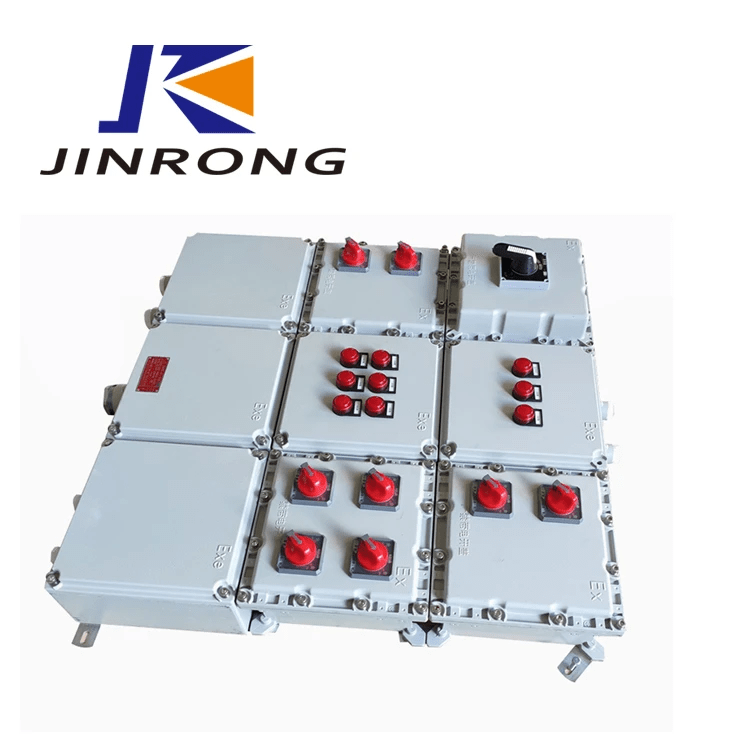

Range of Products Offered

Jinrong boasts an impressive lineup of products designed specifically for hazardous areas where fire risks are prevalent. Their offerings include robust flame proof junction boxes, durable flame proof panel boxes, and versatile flame proof enclosures that cater to diverse applications across industries such as oil and gas, chemical processing, and mining. Each product is crafted with meticulous attention to detail, ensuring compliance with stringent safety standards while providing reliable performance.

Commitment to Quality and Safety

Quality assurance is at the heart of Jinrong's operations; every product undergoes rigorous testing before reaching the market. The company adheres strictly to international safety certifications for all its offerings, including their renowned flame proof light specifications which ensure safe illumination in perilous settings. By prioritizing quality control and safety protocols, Jinrong not only protects lives but also enhances operational efficiency across various industries.

Conclusion

In the ever-evolving landscape of industrial safety, flameproof technology stands as a beacon of reliability and innovation. As industries continue to recognize the importance of safeguarding against fire hazards, flameproof panels, junction boxes, and lighting solutions will undoubtedly play a pivotal role in ensuring operational safety. The future promises advancements that will further enhance the effectiveness and efficiency of these critical components.

The Future of Flameproof Technology

The future of flameproof technology is bright, with ongoing research and development aimed at improving flame proof panel specifications and overall performance. Innovations in materials science are likely to yield even more resilient flame proof enclosure options that can withstand extreme conditions while offering enhanced functionality. As industries grow increasingly aware of the risks associated with hazardous environments, we can expect to see an uptick in demand for advanced flame proof products tailored to specific applications.

Enhancing Safety in Hazardous Areas

Enhancing safety in hazardous areas is not just about compliance; it's about creating a culture of prevention and awareness. Flame Proof Junction Boxes and other protective solutions are essential for mitigating risks associated with flammable substances found in various sectors such as oil and gas, chemicals, and mining. By investing in high-quality flameproof light specifications and enclosures, businesses can significantly reduce the likelihood of accidents while promoting a safer working environment for their employees.

Choosing Jinrong for Your Flameproof Needs

When it comes to selecting reliable flameproof solutions, Jinrong stands out as a preferred choice among industry professionals. With an extensive range of products including flame proof panel boxes and junction boxes designed for rigorous environments, Jinrong's commitment to quality ensures that you receive only the best. By choosing Jinrong for your flameproof needs, you're not just purchasing products; you're investing in peace of mind knowing you have made a safe choice backed by expertise.