Introduction

In an increasingly hazardous world, the need for flameproof equipment has never been more critical. These specialized devices are designed to prevent explosions and fires in environments where flammable gases, vapors, or dust may be present. Understanding what flameproof electrical equipment entails is essential for industries that prioritize safety and compliance.

Understanding Flameproof Equipments

Flameproof equipments are engineered to withstand internal explosions without allowing flames or hot gases to escape into the surrounding atmosphere. This technology is crucial in settings like oil refineries, chemical plants, and mining operations where volatile substances are commonplace. Knowing how these devices function can help organizations implement effective safety measures and protect both personnel and property.

Importance of Safety Standards

Safety standards play a pivotal role in the manufacturing and application of flameproof equipment. Compliance with established guidelines ensures that these devices operate effectively under extreme conditions while minimizing risks associated with explosive environments. By adhering to rigorous safety standards, companies can enhance their reputation while safeguarding their workforce.

Applications of Flameproof Equipment

Flameproof equipment finds its place across various industries, from petrochemicals to pharmaceuticals. These devices are crucial for protecting sensitive operations against potential hazards that could lead to catastrophic incidents. Whether it’s in a bustling factory or an offshore drilling rig, understanding where flame proof equipment is required can guide businesses in selecting the right solutions for their specific needs.

What is Flameproof Electrical Equipment?

Flameproof electrical equipment is designed to operate safely in environments where flammable gases, vapors, or dust are present. This specialized technology prevents any ignition sources within the equipment from igniting the surrounding atmosphere. Understanding what flameproof electrical equipment entails is crucial for industries that prioritize safety and compliance.

Defining Flameproof Technology

Flameproof technology refers to a set of engineering principles that ensure electrical devices can withstand internal explosions without allowing flames or hot gases to escape into the surrounding environment. Essentially, these devices are built with robust enclosures that can contain any potential explosion, thus preventing ignition of flammable materials outside. When asking What is flameproof electrical equipment? it’s essential to recognize that this technology is not just about durability; it's about creating a safe interface in hazardous locations.

How Flameproof Equipment Works

Flameproof equipment operates on the principle of containment and pressure control. When an internal explosion occurs, the enclosure withstands the pressure while preventing flames from escaping through carefully designed joints and seals. This mechanism ensures that even if an explosion were to happen inside the device, it would not pose a risk to its surroundings—a critical aspect when considering What is the standard for flameproof equipment?

Common Applications of Flameproof Equipment

Flameproof equipments find their place in various industries where explosive atmospheres are a concern, such as oil and gas, chemical manufacturing, and mining operations. In these sectors, you’ll often see flameproof lighting fixtures, motors, and control panels designed specifically for hazardous environments. The importance of selecting appropriate flameproof equipment cannot be overstated; it directly relates to safety standards and compliance across diverse applications.

What is the Standard for Flameproof Equipment?

Flameproof equipment must meet stringent safety standards to ensure they can withstand hazardous environments without igniting flammable gases or dust. Understanding these standards is crucial for manufacturers and users alike, as they define the reliability and safety of flameproof electrical equipment in various industries. In this section, we will explore key certifications, guidelines from recognized bodies, and methods to ensure compliance in manufacturing flameproof equipments.

Key Certifications and Standards

There are several key certifications that flameproof electrical equipment must adhere to, ensuring their performance in potentially explosive atmospheres. Among these certifications are ATEX (from the European Union) and IECEx (International Electrotechnical Commission), which provide a framework for testing and certifying equipment designed for hazardous locations. Compliance with these standards not only enhances safety but also boosts confidence among users regarding the reliability of their flameproof equipments.

In addition to ATEX and IECEx, other important certifications include UL (Underwriters Laboratories) for North America and CSA (Canadian Standards Association). These organizations set rigorous testing criteria that flameproof electrical equipment must pass before it can be deemed safe for use in hazardous environments. Manufacturers should prioritize obtaining these certifications to assure clients that their products meet global safety expectations.

IEC and NFPA Guidelines

The International Electrotechnical Commission (IEC) provides guidelines that outline the requirements for flameproof electrical equipment through its IEC 60079 series standards. These guidelines cover various aspects such as design, construction, testing, and marking of flameproof equipments used in explosive atmospheres. Adhering to IEC standards ensures that manufacturers develop products capable of withstanding ignition sources while maintaining operational efficiency.

On the other hand, the National Fire Protection Association (NFPA) offers guidelines specific to fire prevention measures associated with flammable liquids or gases. The NFPA 70 National Electrical Code (NEC) includes provisions related to Class I Division 1 areas where flammable gases could be present continuously or intermittently. By following both IEC and NFPA guidelines, manufacturers can create a robust framework ensuring their flameproof electrical equipment is safe across different jurisdictions.

Ensuring Compliance in Manufacturing

To maintain compliance with established standards for flameproof equipments during manufacturing processes requires thorough planning and execution at every stage of production. First off, manufacturers should implement quality management systems aligned with ISO 9001 principles to ensure consistent product quality throughout production cycles. Regular audits can also help identify potential non-compliance issues early on before they escalate into significant problems.

Incorporating advanced technologies such as automated testing systems can streamline compliance checks by providing real-time data on product performance against safety standards like ATEX or IECEx requirements. Additionally, continuous training programs for staff involved in manufacturing processes will keep them informed about emerging regulations surrounding what is the standard for flameproof equipment? This proactive approach not only minimizes risks but also fosters a culture of safety within organizations producing flameproof electrical equipment.

Where is Flameproof Equipment Required?

Flameproof equipment plays a crucial role in various industries where hazardous environments are present. Understanding the sectors that require flameproof solutions helps ensure safety and compliance with regulations. From oil and gas to chemical manufacturing, the need for reliable flameproof electrical equipment cannot be overstated.

Industries Needing Flameproof Solutions

Several industries are heavily reliant on flameproof equipment to mitigate risks associated with explosive atmospheres. The oil and gas sector is perhaps the most notable, where volatile gases and flammable liquids are part of everyday operations. Other industries such as mining, pharmaceuticals, and food processing also require flameproof solutions to protect workers and assets from potential hazards.

In addition to these primary sectors, transportation of hazardous materials often mandates the use of flameproof electrical equipment for safe handling. The construction industry also uses such equipment during projects in potentially explosive environments like refineries or chemical plants. Ultimately, understanding what is flameproof electrical equipment helps stakeholders make informed decisions about safety measures across various applications.

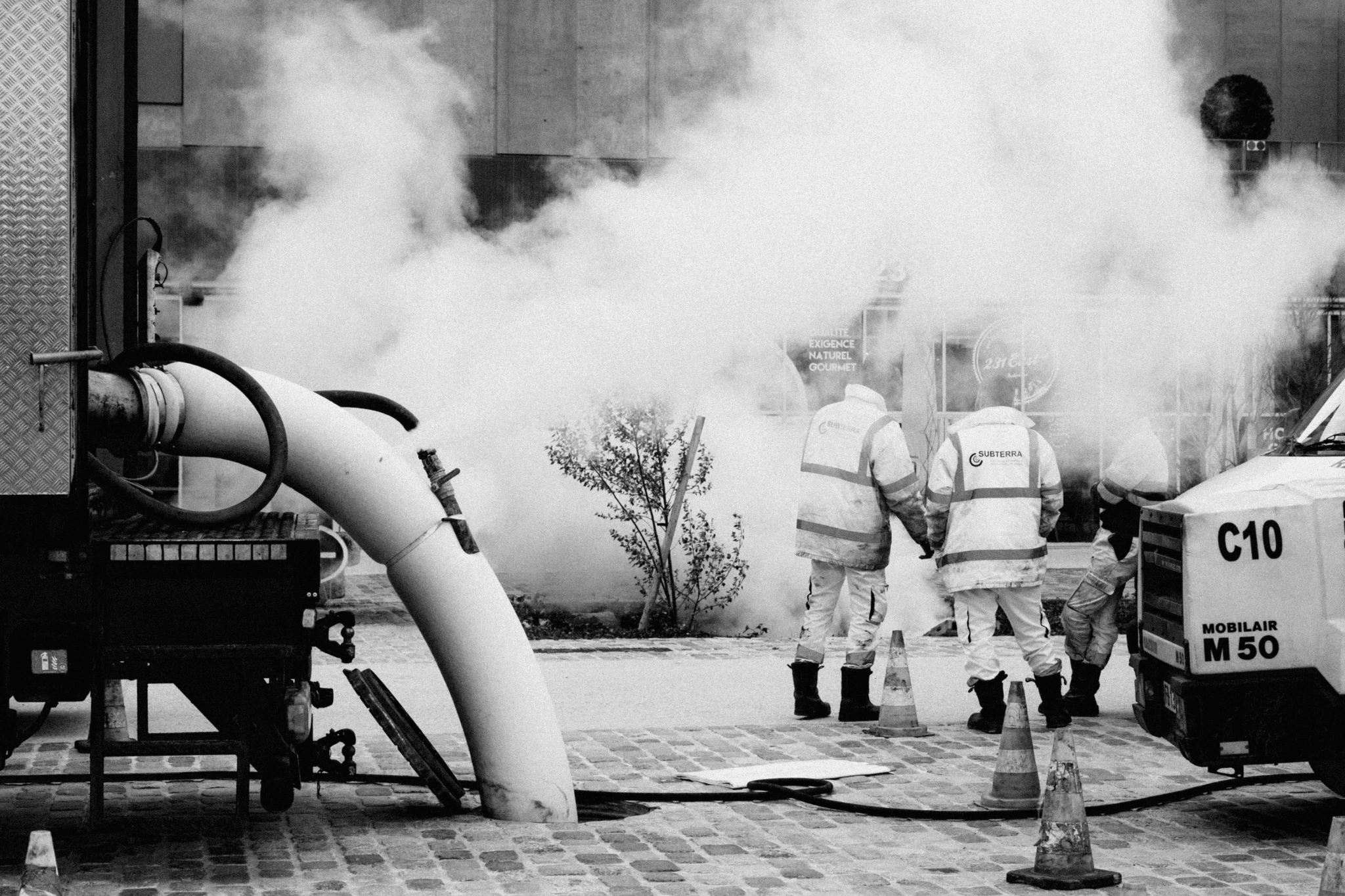

Common Hazards and Environments

Flameproof solutions are essential in environments where flammable gases, vapors, or dust can accumulate. Common hazards include areas with high concentrations of hydrocarbons or chemicals that can ignite easily under certain conditions. These environments often exist in petrochemical facilities, grain silos, or wastewater treatment plants.

Additionally, confined spaces pose significant risks due to limited ventilation; therefore, implementing what is the standard for flameproof equipment becomes critical in these scenarios. Ensuring compliance with safety standards not only protects workers but also minimizes costly downtime caused by accidents or explosions. Identifying these common hazards allows companies to select appropriate flameproof equipments tailored for their unique needs.

Case Studies: Real-World Applications

Real-world applications highlight the importance of utilizing flameproof equipment effectively within hazardous environments. For instance, a major oil refinery implemented advanced flameproof electrical systems after experiencing several near-misses due to gas leaks; this resulted in a significant drop in incidents over time. By investing in high-quality solutions that meet industry standards, they enhanced operational safety while maintaining efficiency.

Another compelling case involves a pharmaceutical company that faced challenges related to dust explosions during production processes involving active pharmaceutical ingredients (APIs). By integrating intrinsically safe systems alongside traditional flameproof equipments into their operations, they successfully mitigated risk while adhering to regulatory guidelines on safety compliance.

These case studies illustrate how organizations can benefit from understanding where is flame proof equipment required and how it applies within their specific contexts—ultimately leading them toward safer work practices while ensuring compliance with industry standards.

What is the Difference Between Flameproof and Intrinsically Safe Equipment?

Key Characteristics of Each Type

Flameproof equipment is designed to contain any explosion that occurs within its housing, preventing flames or hot gases from escaping into the surrounding environment. This is achieved through robust construction and materials that can withstand high pressure and temperature. On the other hand, intrinsically safe equipment operates under a different principle: it limits energy levels—both electrical and thermal—to prevent ignition even in potentially explosive atmospheres.

While flameproof electrical equipment focuses on containing explosions, intrinsically safe devices are engineered to eliminate ignition sources altogether. The key characteristic of flameproof designs lies in their ability to endure extreme conditions without compromising safety standards. In contrast, intrinsically safe technology relies heavily on circuit design and component selection to ensure that any sparks or heat generated during operation remain below ignition thresholds.

Practical Differences in Usage

The practical differences between flameproof and intrinsically safe equipment often dictate their applications across various industries. Flameproof equipments are typically used in environments where explosive gases or vapors are present, such as oil refineries or chemical plants, where containment of potential explosions is paramount. Conversely, intrinsically safe devices find their niche in areas like mining or pharmaceutical manufacturing, where maintaining low energy levels is critical for preventing ignition.

When choosing between these two types of safety solutions, consider the specific hazards present in your environment. For instance, if you're working with highly volatile substances that could ignite easily from sparks or heat, you may lean towards using intrinsically safe solutions instead of relying solely on flameproof technologies. Ultimately, understanding what is flameproof electrical equipment versus its intrinsically safe counterpart enables better risk management tailored to your operational needs.

Choosing the Right Equipment for Your Needs

Selecting the appropriate type of safety equipment involves evaluating both your operational risks and compliance requirements outlined by standards such as those discussed earlier regarding what is the standard for flameproof equipment? Assessing where flame proof equipment is required also plays a significant role; industries like petrochemicals may necessitate a more robust solution than others focused on lower-risk operations.

Additionally, consider factors like maintenance costs and ease of installation when deciding which type suits your application best. Flameproof equipments may require more rigorous inspections due to their complex construction but can offer greater durability under harsh conditions when properly maintained. Alternatively, intrinsically safe systems may provide easier integration into existing setups due to their simpler design but could involve higher upfront costs depending on technology used.

In summary, understanding what is the difference between flameproof and intrinsically safe equipment can guide you towards making smarter choices that align with both safety compliance and operational efficiency.

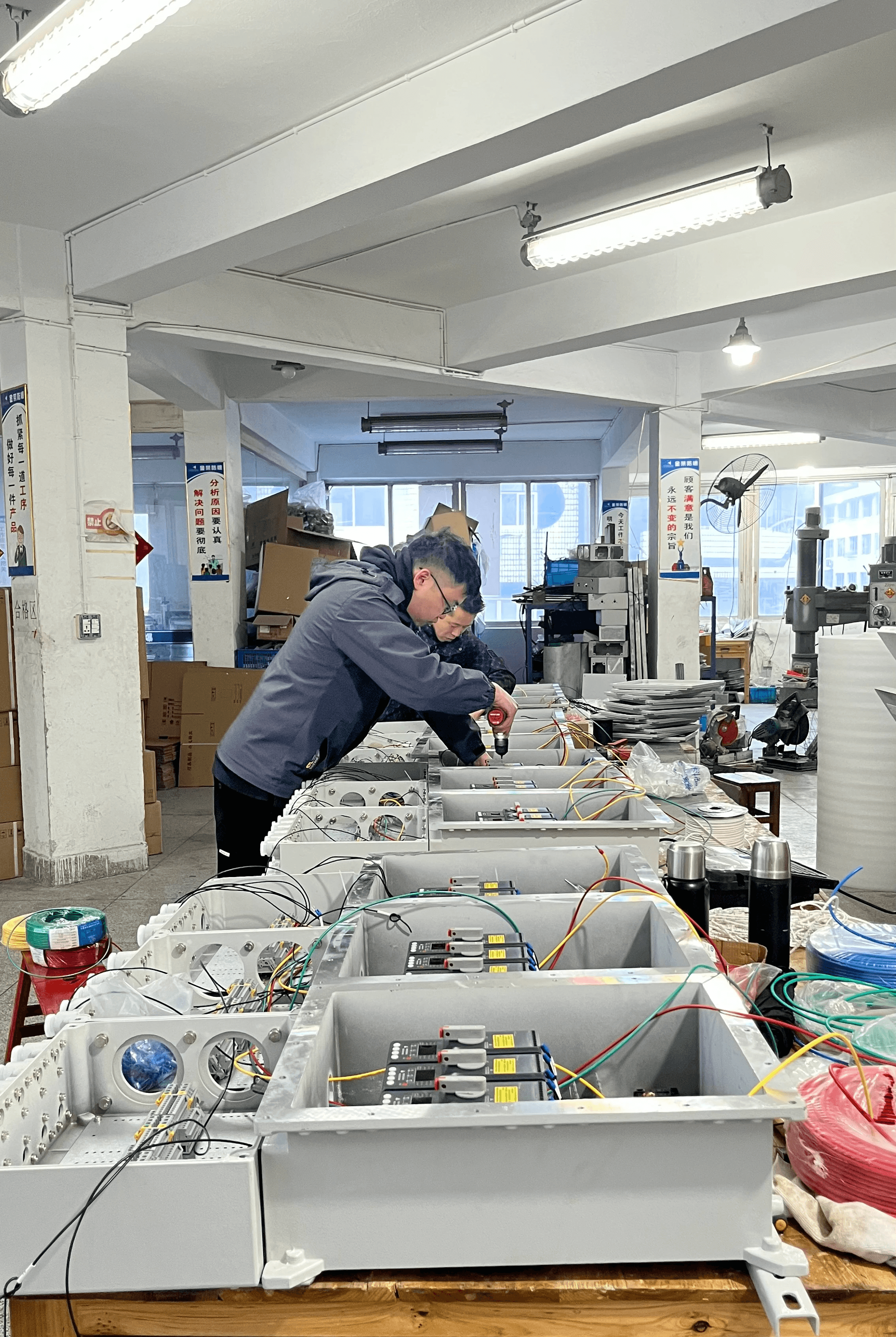

Manufacturer Spotlight: Jinrong

When discussing flameproof equipment, it's essential to highlight manufacturers that have made significant contributions to the industry. One such manufacturer is Jinrong, which has established itself as a key player in producing high-quality flameproof electrical equipment. Their commitment to innovation and safety standards makes them a noteworthy example of excellence in this field.

History and Evolution of Jinrong

Jinrong began its journey several decades ago, focusing on developing cutting-edge flameproof electrical equipment tailored for hazardous environments. Over the years, they have evolved from a small enterprise into a globally recognized brand known for quality and reliability in flameproof solutions. This evolution reflects their dedication to understanding industry needs and adapting their products to meet stringent safety standards.

Product Range and Innovations

The product range offered by Jinrong encompasses various types of flameproof equipment designed for multiple applications across industries. From lighting fixtures to control panels, their offerings are engineered with advanced technology that ensures safety in explosive atmospheres. Continuous innovation drives their development process, allowing them to stay ahead of the curve in meeting what is the standard for flameproof equipment.

Commitment to Quality and Safety

Jinrong's commitment to quality is evident through rigorous testing and adherence to international certifications that guarantee their flameproof equipments meet or exceed industry standards. They prioritize not only compliance but also the practical application of safety measures within real-world environments where flameproof equipment is required. By fostering a culture of safety awareness among employees and clients alike, Jinrong exemplifies what it means to be responsible stewards in the realm of hazardous materials handling.

Conclusion

In the realm of industrial safety, selecting the right flameproof equipment is not merely a matter of compliance; it's a commitment to ensuring the well-being of personnel and the integrity of operations. Understanding what is flameproof electrical equipment is crucial, as it helps in making informed decisions that align with specific industry needs. The right choice can significantly mitigate risks associated with hazardous environments, reinforcing the importance of adhering to established standards.

Selecting the Right Flameproof Equipment

When it comes to selecting flameproof equipment, one must consider various factors such as environmental conditions, potential hazards, and compliance with relevant standards. What is the standard for flameproof equipment? This question often leads to an exploration of certifications like ATEX or IECEx that ensure products are suitable for explosive atmospheres. Additionally, consulting with manufacturers who specialize in flameproof technologies can provide valuable insights into which products best suit your operational requirements.

It's also essential to differentiate between various types of safety solutions available in the market. Many professionals wonder about what is the difference between flameproof and intrinsically safe equipment? Understanding these distinctions can guide you toward making choices that enhance safety while optimizing performance in your specific application context. Ultimately, investing time in research will pay off when it comes to protecting both assets and lives.

Future Trends in Flameproof Technologies

The future of flameproof technologies looks promising as innovations continue to emerge within this critical sector. With advancements in materials science and engineering practices, manufacturers are developing more efficient and reliable flameproof equipments designed for even harsher environments. Emerging trends such as smart sensors integrated into these systems will likely enhance real-time monitoring capabilities, providing an additional layer of protection against potential hazards.

Moreover, there’s a growing emphasis on sustainability within industrial practices that influences how flameproof electrical equipment is designed and deployed. As industries strive for greener operations, manufacturers are exploring eco-friendly materials while maintaining stringent safety standards—what a win-win! This shift not only addresses environmental concerns but also aligns with regulatory demands across various sectors.

Final Thoughts on Safety Compliance

Safety compliance should never be an afterthought; instead, it must be woven into the fabric of any operation dealing with hazardous materials or environments. Understanding where is flame proof equipment required ensures you're not just meeting legal obligations but actively safeguarding your workforce against potential dangers associated with flammable substances or explosive atmospheres. Regular training sessions on recognizing hazards and using appropriate flameproof equipments can further bolster a culture of safety within organizations.

As we look ahead, it's clear that staying updated on industry standards and emerging technologies will be vital for anyone involved in managing hazardous environments. Remembering what is flameproof electrical equipment entails understanding its applications can help streamline processes while prioritizing safety above all else—because at the end of the day, protecting people should always come first!