Introduction

In a world where safety is paramount, understanding explosion proof materials becomes crucial, especially in industries that deal with hazardous environments. These materials are designed to withstand explosive forces and protect both equipment and personnel from potential disasters. But what exactly defines an explosion-proof material, and how does it differ from other types of protective solutions?

Understanding Explosion Proof Materials

Explosion proof materials are specifically engineered to contain any internal explosions and prevent the ignition of surrounding flammable substances. This involves a careful selection of robust materials that can endure extreme conditions without compromising safety. When asking, What is the most explosion-resistant material? one must consider various options, including metals like steel and aluminum, as well as advanced composites.

Importance in Hazardous Environments

The importance of using explosion proof materials cannot be overstated in hazardous environments such as oil rigs, chemical plants, and mining operations. In these settings, even a minor spark can lead to catastrophic events; thus, employing the right materials is essential for ensuring safety and compliance with industry regulations. Moreover, understanding what makes a light explosion-proof is vital for selecting appropriate lighting solutions that meet specific operational needs.

Overview of Industry Standards

Navigating through the myriad industry standards related to explosion proofing can be overwhelming but is necessary for compliance and safety assurance. Organizations like the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) set stringent guidelines that manufacturers must follow when producing explosion proof equipment and materials. Familiarity with these standards helps businesses determine which products are truly safe for use in explosive atmospheres while answering questions about whether LED bulbs are explosion-proof or if they meet intrinsic safety criteria.

What Materials Are Explosion-Proof?

Metals: A Look into Steel and Aluminum

Steel and aluminum are two of the most commonly used metals when discussing explosion-proof materials. Steel is renowned for its strength and durability, making it an excellent choice for heavy-duty applications in environments prone to explosions. On the other hand, aluminum offers a lighter alternative while still maintaining robust resistance against blasts, making it ideal for portable equipment where weight is a concern.

Both metals have their unique advantages; steel's high tensile strength means it's often used in structural applications, while aluminum's corrosion resistance makes it suitable for outdoor or marine settings. When considering what is the most explosion-resistant material among metals, steel often takes the lead due to its inherent toughness under extreme conditions. However, the choice ultimately depends on specific application needs and environmental factors.

Non-Metallic Options: Plastics and Composites

Exploring non-metallic options reveals a fascinating world of plastics and composites that also qualify as explosion-proof materials. Advanced plastics can withstand significant pressure and impact without shattering or combusting, which makes them appealing for various industrial applications. Composites, often made from a blend of fibers like carbon or glass with resins, provide exceptional strength-to-weight ratios while being resistant to chemical exposure.

These materials are particularly useful in areas where traditional metals may corrode or become damaged over time due to environmental factors. For instance, composite enclosures can be engineered to meet specific safety criteria without sacrificing performance or durability. As industries seek lighter yet robust solutions, these non-metallic options continually gain traction as viable alternatives in explosion-prone settings.

Comparing Traditional vs. Modern Materials

When comparing traditional versus modern materials in terms of blast resistance, it's essential to assess how advances in technology have changed the landscape of explosion-proof solutions. Traditional materials like steel have long been trusted for their reliability; however, modern innovations such as high-performance composites are redefining what's possible regarding safety standards and performance metrics.

What makes a light explosion-proof? It’s not just about using heavy-duty metals anymore; today's designs incorporate lightweight yet durable options that maintain compliance with industry regulations while offering enhanced functionality—think LED fixtures encased in advanced polymers instead of bulky metal housings. As we discuss what makes a light intrinsically safe versus merely explosion-proof, understanding these material advancements becomes crucial for selecting appropriate lighting solutions in hazardous areas.

In summary, whether opting for sturdy metals like steel and aluminum or exploring innovative plastics and composites, knowing what materials are explosion-proof will empower industries to make informed decisions about safety measures tailored to their specific needs.

The Most Blast-Resistant Materials

Exploring Carbon Fiber’s Role

Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a favorite in industries requiring lightweight yet durable solutions. What is the most explosion-resistant material? Many experts point to carbon fiber as a strong contender due to its ability to absorb and dissipate energy effectively during an explosion. Additionally, this material resists corrosion and extreme temperatures, ensuring longevity in hazardous settings where traditional options may fail.

High-Performance Concrete Solutions

High-performance concrete (HPC) has emerged as another formidable option when discussing blast-resistant materials. This specialized concrete is designed with enhanced durability and strength characteristics that allow it to withstand significant explosive forces without crumbling or cracking. By incorporating additives and advanced mixing techniques, HPC can be tailored specifically for environments that demand reliable explosion proof material.

Advances in Composite Materials

Composite materials are at the forefront of innovation when it comes to creating robust solutions for hazardous situations. These advanced composites combine various elements—like fibers and resins—to produce products that are not only lightweight but also incredibly strong against blasts. What makes a light explosion-proof? The strategic layering and bonding of these composite materials provide exceptional resistance to impact and pressure changes associated with explosions.

What Makes a Light Explosion-Proof?

Key Design Features Explained

The design of explosion-proof lights revolves around several critical features that ensure safety and reliability. First and foremost, these lights typically utilize robust materials capable of withstanding high pressures—think steel or specialized composites—making them some of The Most Blast-Resistant Materials available on the market today. Additionally, they often incorporate flame paths, which are engineered to cool any escaping gases before they can ignite an external atmosphere, answering the question: What makes a light explosion-proof?

Role of Sealing and Housing

Sealing and housing play pivotal roles in the effectiveness of explosion-proof lights. High-quality gaskets and seals prevent dust, moisture, and explosive gases from infiltrating the fixture, ensuring longevity while maintaining safety standards. The housing is usually constructed from heavy-duty materials—often classified as explosion proof material—that can endure extreme conditions without compromising performance or safety.

Testing and Certification Standards

To be deemed safe for use in hazardous environments, lights must undergo stringent testing procedures that adhere to industry standards such as ATEX or IECEx certifications. These tests evaluate various factors including pressure resistance, temperature management, and overall durability under explosive conditions—essentially determining What Is The Most Explosion-Resistant Material for each application. Only those that meet these rigorous benchmarks can proudly bear the title of explosion-proof, providing peace of mind for users who rely on them in potentially dangerous settings.

Are LED Bulbs Explosion-Proof?

Advantages of LED Technology in Hazards

LED technology offers several advantages when used in hazardous environments. First, LEDs are energy-efficient, producing less heat compared to traditional incandescent bulbs; this lower heat output reduces the risk of ignition in flammable atmospheres. Furthermore, LEDs have a longer lifespan, which means fewer replacements and less maintenance—an essential factor when working with explosion proof materials that need to meet stringent safety standards.

In addition to energy efficiency and longevity, LED bulbs can be designed with robust materials that enhance their durability against harsh conditions. This aligns well with inquiries about what materials are explosion-proof; manufacturers often use specialized enclosures made from tough metals or reinforced composites to protect the internal components of the light fixture. Thus, while not all LED bulbs are inherently explosion-proof, many can be engineered to meet these essential safety requirements.

Intrinsic Safety vs. Explosion Proofing

Understanding the difference between intrinsic safety and explosion proofing is vital for ensuring proper lighting selection in hazardous areas. Intrinsic safety (IS) refers to a design approach where electrical equipment is incapable of releasing sufficient energy to ignite an explosive atmosphere under normal or fault conditions—essentially making it safe by design. On the other hand, explosion proofing involves creating a protective enclosure that can contain any potential explosions within the fixture itself.

This distinction raises questions like What makes a light intrinsically safe? While both approaches aim for safety in hazardous settings, they do so through different methods: IS relies on low-energy circuits while explosion proof materials focus on robust construction capable of withstanding blasts. Therefore, depending on your specific needs and environment type—whether you prioritize containment or inherent safety—you'll need to choose accordingly between these two methodologies.

Selecting the Right LED for Hazardous Areas

Selecting the right LED bulb for hazardous areas requires careful consideration of various factors including compliance with industry standards and environmental conditions present at your site. Look for products that are explicitly labeled as explosion-proof or intrinsically safe, ensuring they meet necessary regulations like ATEX or IECEx certifications tailored for hazardous locations. Knowing what is the most explosion-resistant material used in these fixtures can also guide your decision-making process.

When assessing options, consider aspects such as temperature ratings and compatibility with existing fixtures; understanding what makes a light explosion-proof will help identify suitable choices that minimize risks effectively. Additionally, consulting product specifications will clarify whether an LED bulb meets both intrinsic safety standards and explosive atmosphere requirements—important factors when navigating compliance within various industries.

In conclusion, while not all LEDs are created equal regarding their suitability for explosive environments—many can be adapted through thoughtful engineering practices involving robust construction materials designed specifically for hazard mitigation purposes.

What Makes a Light Intrinsically Safe?

Understanding Intrinsic Safety Standards

Intrinsic safety standards are formulated by various regulatory bodies to ensure that electrical equipment operates safely in explosive atmospheres. These standards dictate how devices should be designed and tested to minimize the risk of ignition from sparks or heat generated during normal operation. The most recognized standards include those set by organizations such as ATEX (Europe) and NEC (North America), which help define what materials are explosion-proof and what makes a light intrinsically safe.

Components that Ensure Safety

The components used in intrinsically safe lights play a critical role in ensuring safety in hazardous environments. These lights typically feature low-energy circuits that limit voltage and current, reducing the likelihood of ignition even under fault conditions. Additionally, using specialized explosion proof material that can withstand extreme conditions further enhances their reliability, ensuring they perform optimally where safety is non-negotiable.

Applications in Various Industries

Intrinsically safe lighting finds applications across numerous industries including oil and gas, mining, pharmaceuticals, and chemical processing. In these sectors where volatile substances may be present, using lights that comply with intrinsic safety standards helps mitigate risks associated with explosions or fires. With advancements in LED technology prompting questions like Are LED bulbs explosion-proof?, it's essential for businesses to carefully assess their lighting options based on both performance and compliance with industry regulations.

Conclusion

In the realm of hazardous environments, selecting the right explosion proof material is crucial for ensuring safety and compliance. With various options available, understanding what materials are explosion-proof and their specific applications can make a significant difference. As industries continue to evolve, so do the standards and technologies surrounding these essential materials.

Choosing the Right Explosion Proof Material

Understanding what makes a light explosion-proof is just as vital when selecting lighting solutions for hazardous areas. Not only should you look at traditional metals like steel and aluminum but also consider modern alternatives that meet stringent safety standards. Ultimately, making an educated choice about your explosion proof material can save lives and protect assets.

Navigating Industry Compliance and Standards

Navigating industry compliance and standards can be daunting but is necessary to ensure that your operations meet legal requirements while maintaining safety protocols. Familiarizing yourself with regulations around what makes a light intrinsically safe or how LED bulbs fit into these categories will empower you to make better decisions. Each industry may have its own guidelines regarding what materials are explosion-proof; thus, staying informed about updates in regulations is key.

Moreover, understanding testing procedures for different materials helps clarify how they withstand extreme conditions—after all, not all materials labeled as “explosion-proof” are created equal! Ensuring that your selected products comply with recognized standards will provide peace of mind when working in potentially dangerous situations.

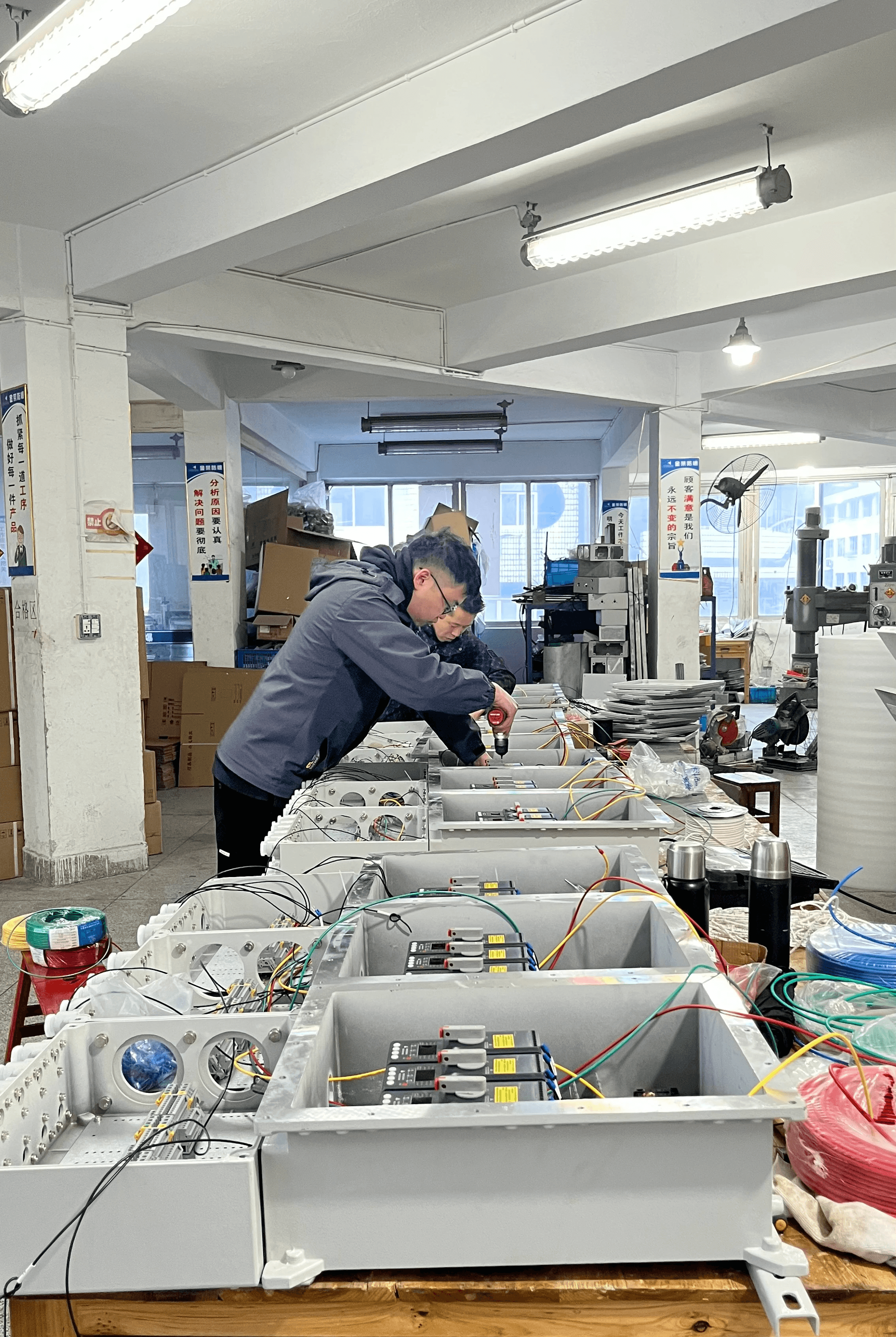

Jinrong: Trusted Partner in Ex-Proof Solutions

When it comes to finding reliable solutions for hazardous environments, Jinrong stands out as a trusted partner in ex-proof solutions. With extensive experience in providing high-quality explosion proof material options tailored to various industries, they ensure compliance with all relevant safety standards while offering innovative products like LED bulbs designed specifically for such settings.

From understanding what makes a light intrinsically safe to identifying The Most Blast-Resistant Materials available today—Jinrong has you covered at every step of the process! Their commitment to excellence means you can focus on your operations while knowing you're backed by top-tier expertise in explosion-proof technology.