Introduction

In industries where safety is paramount, explosion proof j boxes are essential components that protect electrical connections in hazardous environments. These specialized enclosures, also known as explosion-proof junction boxes, are designed to contain any potential explosions from ignitable gases or dust, ensuring the safety of both personnel and equipment. With the increasing focus on workplace safety regulations, understanding the value of these protective solutions has never been more important.

Importance of Explosion Proof J Boxes

The significance of explosion proof j boxes cannot be overstated; they serve as a critical line of defense against catastrophic failures in volatile settings. By effectively containing any explosive forces within their sturdy casings, these junction boxes provide peace of mind for operators working in high-risk areas such as oil rigs, chemical plants, and grain silos. Investing in quality explosion-proof junction box covers and reliable designs can dramatically reduce the risk of accidents and enhance overall operational efficiency.

Common Applications in Harsh Environments

Explosion proof j boxes find their place across various industries that face harsh conditions and potential ignition sources. From petrochemical facilities to wastewater treatment plants, these robust enclosures ensure safe electrical connections while standing up to extreme temperatures and corrosive substances. The versatility offered by options like the explosion proof junction box 3/4 inch or 1/2 inch configurations makes them suitable for a range of applications where safety is non-negotiable.

Overview of Leading Brands

Crouse-Hinds explosion-proof boxes are renowned for their durability and innovative design features tailored to meet industry standards. Additionally, brands like Jinrong offer versatile options that cater to diverse needs while maintaining compliance with safety regulations—ensuring you have a dependable solution no matter your application requirements.

Understanding Explosion Proof J Boxes

What are Explosion-proof Junction Boxes?

Explosion-proof junction boxes are enclosures that house electrical connections while preventing the escape of sparks or heat that could ignite flammable materials outside the box. Essentially, they act as a barrier between potentially explosive atmospheres and electrical equipment, ensuring safe operation in harsh conditions. Notably, brands like Crouse-Hinds offer a variety of explosion-proof junction box covers specifically designed to meet rigorous safety standards.

These robust enclosures come in various sizes and configurations—such as the explosion proof junction box 1/2 inch or 3/4 inch—catering to different installation needs. Their construction materials often include heavy-duty metals or composites that withstand extreme temperatures and pressures. This makes them indispensable for any facility where volatile substances might be present.

Key Features and Benefits

One of the standout features of explosion proof j boxes is their ability to contain explosions should they occur inside the enclosure, thus preventing any external ignition sources from causing harm. Additionally, these junction boxes often feature weatherproof designs that protect against moisture and dust ingress, further enhancing their reliability in harsh environments. The use of high-quality materials ensures durability over time, minimizing maintenance costs associated with frequent replacements.

Another significant benefit is compatibility with various cable types and sizes; whether you're using an explosion proof junction box 1/2 inch or 3/4 inch configuration, there's likely a solution tailored for your specific application needs. Moreover, many brands incorporate easy-installation features into their designs—think pre-drilled holes or quick-connect fittings—which simplify setup without compromising safety standards. This ease-of-use factor can save valuable time during installation while ensuring compliance with necessary regulations.

Standards and Certifications

Safety is paramount when it comes to explosion-proof junction boxes; thus they must adhere to stringent industry standards and certifications such as ATEX (for Europe) or NEC (for North America). These guidelines ensure that each product has been rigorously tested under controlled conditions before being deemed suitable for use in hazardous areas. It's essential to choose products from reputable manufacturers like Crouse-Hinds who consistently meet these standards.

Certification marks on an explosion-proof junction box cover indicate its compliance with safety regulations—look for labels that specify temperature classes and protection levels relevant to your environment's risks. Familiarizing yourself with these certifications not only helps you choose safer equipment but also aids in maintaining compliance during inspections or audits by regulatory bodies. Ultimately, understanding these standards will empower you to make informed decisions when selecting your next set of explosion proof j boxes.

Top Brands for Robust Solutions

Crouse-Hinds Explosion-Proof Boxes

Crouse-Hinds is a name synonymous with quality when it comes to explosion-proof junction boxes. Their products are designed with advanced features that ensure maximum protection against ignitable gases and dust. The Crouse-Hinds explosion-proof boxes come with various configurations, including options for both 1/2 inch and 3/4 inch connections, making them versatile for different installations.

The durability of Crouse-Hinds explosion-proof junction box covers is particularly noteworthy; they are built to withstand harsh conditions while maintaining effective sealing against environmental elements. This brand not only focuses on functionality but also adheres to strict industry regulations, ensuring that all products meet necessary certification standards. With a wide range of sizes and configurations available, Crouse-Hinds remains a top choice for professionals seeking reliable explosion proof j boxes.

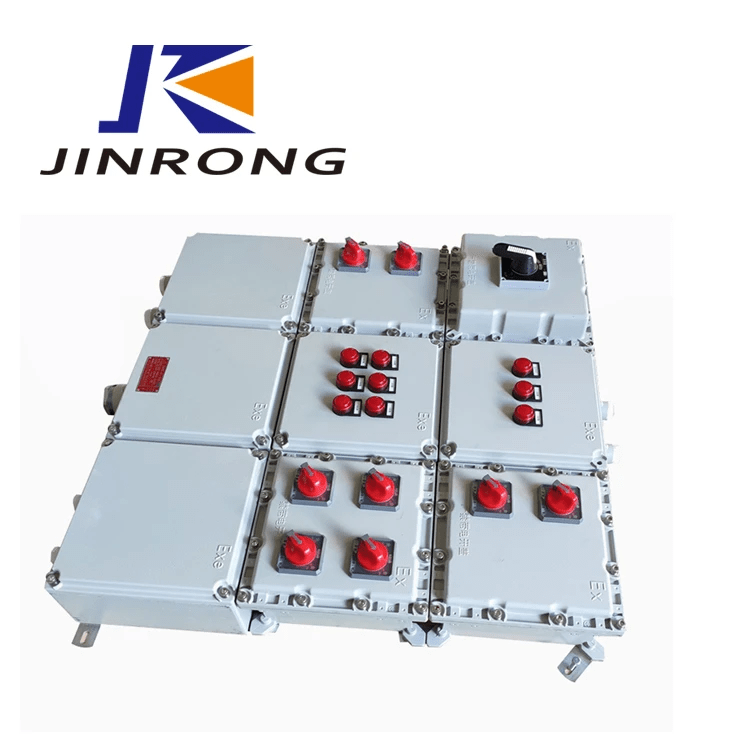

Jinrong’s Versatile Options

Jinrong has carved out a niche for itself by offering versatile options in the realm of explosion-proof junction boxes. Their products cater to various industrial applications and are recognized for their adaptability in challenging environments. The Jinrong explosion proof junction box lineup includes choices that accommodate both 1/2 inch and 3/4 inch conduit fittings, providing flexibility based on specific project needs.

One standout feature of Jinrong's offerings is their focus on user-friendly designs that simplify installation without compromising safety or compliance with regulations. These explosion-proof junction boxes not only provide essential protection but also boast an aesthetic appeal that can seamlessly blend into industrial settings. With an emphasis on innovation and quality control, Jinrong continues to be a strong contender among notable manufacturers in this sector.

Other Notable Manufacturers

In addition to Crouse-Hinds and Jinrong, several other manufacturers have made significant contributions to the market for explosion proof j boxes. Brands like Appleton Electric and Hubbell Wiring Device-Kellems offer robust solutions designed specifically for hazardous locations where safety is paramount. Their products include various types of explosion-proof junction box covers tailored to withstand extreme conditions while ensuring secure electrical connections.

These manufacturers prioritize compliance with industry standards such as NEC (National Electrical Code) and IECEx (International Electrotechnical Commission Explosive Atmospheres), which further solidifies their reputation within the sector. Additionally, many companies now incorporate advanced materials into their designs to enhance durability without sacrificing weight or ease of installation—an important consideration when working in confined spaces or challenging environments.

In summary, whether you're leaning towards Crouse-Hinds' trusted designs or exploring Jinrong's flexible options, it's clear there's no shortage of high-quality choices when selecting your next explosion-proof junction box.

Choosing the Right Explosion Proof Junction Box

Selecting the right explosion proof junction box is essential for ensuring safety and functionality in hazardous environments. With various options available, understanding what to look for can make all the difference in your project's success. Whether you’re dealing with Crouse-Hinds explosion-proof boxes or other brands, making an informed choice will help you avoid costly mistakes down the line.

Factors to Consider for Selection

When choosing an explosion-proof junction box, several factors come into play. First and foremost, consider the specific environment where the box will be installed; this includes temperature extremes, moisture levels, and potential chemical exposure. Additionally, evaluate any electrical requirements such as voltage ratings and compatibility with existing systems to ensure that your selected explosion-proof junction boxes meet all necessary specifications.

Another critical factor is the type of materials used in construction. High-quality materials not only enhance durability but also contribute to compliance with safety standards. Look for features like corrosion resistance and impact ratings that align with your project’s needs—after all, a robust explosion-proof junction box can save you from future headaches.

Importance of Size and Compatibility

Size matters when it comes to explosion-proof junction boxes; selecting one that fits well within your installation space is vital for both functionality and safety. An improperly sized box could lead to overheating or insufficient protection against environmental hazards, which defeats its purpose entirely. Therefore, it's crucial to measure your installation area carefully before making a selection.

Compatibility with existing equipment is another aspect not to overlook. Make sure that any connectors or fittings are suitable for use with your chosen explosion-proof junction box cover—this ensures a secure fit that maintains integrity under pressure or during adverse conditions. Remember: compatibility isn’t just about size; it also involves electrical ratings and material types.

Common Configurations: 1/2 Inch and 3/4 Inch

When exploring configurations for explosion proof junction boxes, two common sizes often come up: 1/2 inch and 3/4 inch options are widely used across various applications. The choice between these sizes typically depends on the wiring requirements of your specific project; larger cables may necessitate a 3/4 inch configuration while smaller setups might do just fine with a 1/2 inch option.

It's worth noting that many manufacturers produce both configurations within their product lines—including reputable brands like Crouse-Hinds—which means you have plenty of choices at your fingertips! Additionally, ensure that whichever configuration you choose aligns with local codes and regulations governing installations in hazardous locations.

In summary, selecting the right explosion proof junction box requires careful consideration of factors such as environmental conditions, size compatibility, and standard configurations like 1/2 inch or 3/4 inch options. By being diligent in this process, you're setting yourself up for long-term success in maintaining safety standards while optimizing functionality.

Installation Best Practices

Preparing for Installation

Before you even think about cracking open that box, preparation is key. Start by reviewing the specifications of your explosion-proof junction boxes, such as the Crouse-Hinds explosion-proof boxes, to ensure they meet your project's requirements. Gather all necessary tools and materials, including an appropriate explosion-proof junction box cover, and conduct a thorough site assessment to identify any potential hazards or obstacles.

Next, make sure you have a clear understanding of local regulations regarding electrical installations in hazardous locations. This knowledge will guide you in selecting the right size and type of explosion proof junction box—whether it's a 1/2 inch or 3/4 inch configuration—ensuring compliance with safety standards. Lastly, create a step-by-step plan for installation; this will help streamline the process and minimize errors.

Ensuring Proper Sealing and Protection

Once you're ready to install your explosion-proof junction box, proper sealing is crucial for preventing hazardous substances from entering the enclosure. Make sure to use high-quality gaskets specifically designed for explosion proof applications; these gaskets are essential for maintaining the integrity of your installation over time. When applying any sealing compounds or adhesives, follow manufacturer guidelines closely to avoid compromising protection.

Additionally, pay attention to how you mount your explosion proof junction box; it should be securely fastened while allowing for thermal expansion and contraction without risking damage or degradation over time. Regularly inspect seals and connections after installation—this proactive approach can save you from costly repairs down the line due to wear or environmental factors affecting performance.

Tips for Long-Term Maintenance

Maintaining your explosion proof j boxes is just as important as proper installation; regular upkeep ensures their reliability in demanding conditions. Schedule routine inspections every few months to check for signs of wear or damage on both the exterior and interior components of your explosion-proof junction boxes. Look out for corrosion on metal parts or deterioration on seals that could compromise safety.

Moreover, keep an eye on environmental factors that may impact performance—such as excessive moisture or dust accumulation—which can lead to malfunction if left unchecked. Don't forget about documentation: maintain records of inspections and maintenance activities so you can track any recurring issues effectively over time.

By adhering to these best practices during preparation, sealing, and maintenance phases, you'll enhance not only the longevity but also the safety of your installation involving various configurations like 1/2 inch or 3/4 inch options in explosion proof j boxes.

Complying with Safety Standards

In industries where hazardous materials are present, complying with safety standards is non-negotiable. Explosion proof j boxes play a crucial role in ensuring safety and preventing catastrophic incidents. Understanding the relevant regulations helps organizations select the right explosion-proof junction boxes that meet legal and safety requirements.

Understanding Relevant Regulations

To navigate the complex landscape of safety regulations, it’s essential to familiarize yourself with standards such as the National Electrical Code (NEC) and various international guidelines like ATEX or IECEx. These regulations dictate how explosion-proof junction boxes must be designed, tested, and installed to mitigate risks in hazardous environments. Compliance not only protects workers but also ensures that your operations remain legally sound and efficient.

Importance of Certification and Testing

Certification from recognized bodies is vital for any explosion-proof junction box—whether it’s a Crouse-Hinds explosion-proof box or another brand. These certifications indicate that the product has undergone rigorous testing to ensure it can withstand explosive atmospheres without compromising safety. By investing in certified products, you gain peace of mind knowing that your equipment meets industry standards for performance and reliability.

How Compliance Affects Choice of Equipment

When selecting an explosion-proof junction box, compliance should be at the forefront of your decision-making process. The choice between an explosion proof junction box 3/4 inch or a 1/2 inch variant may hinge on specific regulatory requirements for your industry or location. Ultimately, prioritizing compliance ensures you choose equipment that not only fits your operational needs but also enhances overall workplace safety.

Conclusion

In the realm of industrial safety, the choice of explosion proof j boxes is paramount. These robust solutions are designed to withstand harsh environments and prevent catastrophic incidents, making them essential for various applications. By selecting the right explosion-proof junction boxes, industries can significantly enhance their safety protocols and protect personnel and equipment alike.

Maximizing Safety with the Right J Boxes

Explosion proof j boxes are specifically engineered to contain any potential explosions within their confines, ensuring that hazardous environments remain secure. Utilizing products like Crouse-Hinds explosion-proof boxes provides an added layer of reliability, as these brands adhere strictly to industry standards and regulations.

Moreover, understanding the specific requirements of your environment will guide you in selecting between options like an explosion proof junction box 1/2 inch or a more substantial explosion proof junction box 3/4 inch configuration. Proper installation and maintenance further enhance safety; therefore, investing time in these areas pays dividends in risk reduction. Ultimately, a proactive approach towards selecting and maintaining your explosion-proof junction boxes can dramatically reduce hazards in critical settings.

Investing in Quality for Harsh Conditions

Investing in quality is vital when dealing with harsh conditions where failure is not an option. High-quality products like Crouse-Hinds explosion-proof boxes not only meet rigorous safety standards but also offer durability that cheaper alternatives simply cannot match. When you invest in reliable explosion-proof junction boxes, you're safeguarding your operation against downtime caused by equipment failure or accidents.

Moreover, opting for premium materials ensures that your equipment can endure extreme temperatures and corrosive elements often found in industrial settings. While upfront costs may be higher for quality products such as these, the long-term benefits—reduced maintenance costs and enhanced operational efficiency—far outweigh initial expenditures. Remember that when it comes to protecting lives and assets, skimping on quality is a gamble no business should take.

Future Trends in Explosion Proof Technology

As technology advances at breakneck speed, so too does innovation within the realm of explosion proof j boxes. The future promises smarter solutions equipped with sensors that monitor environmental conditions and alert operators before issues arise—taking preventive measures to new heights! Additionally, advancements in materials science could lead to even lighter yet stronger designs for explosion-proof junction box covers.

Furthermore, increased automation will likely influence how we approach installation and maintenance procedures for these critical components. With trends leaning toward sustainability and energy efficiency across industries globally, manufacturers may focus on creating eco-friendly options without compromising safety standards—a win-win scenario! As we move forward into this evolving landscape of explosion proof technology, staying informed about emerging trends will be crucial for ensuring continued compliance with safety regulations while maximizing operational effectiveness.