Introduction

When it comes to understanding Class 1 Div 2 requirements, it's crucial to grasp the specific regulations and standards that apply to hazardous locations. Ensuring compliance with these requirements is essential for the safety of personnel and equipment in these environments. Jinrong brings its expertise in ex-proof manufacturing to provide reliable solutions that meet Class 1 Div 2 standards.

Understanding Class 1 Div 2 Requirements

Class 1 Div 2 refers to hazardous locations where flammable gases or vapors may be present, but only under abnormal conditions. It's important to understand the specific criteria for electrical equipment in these areas, including temperature ratings, enclosure types, and other safety measures to prevent ignition.

Importance of Ensuring Compliance

Compliance with Class 1 Div 2 requirements is crucial for preventing potential hazards and ensuring the safety of workers and facilities in hazardous environments. Failure to meet these standards can lead to serious consequences, including accidents, injuries, and damage to equipment.

Jinrong's Expertise in Ex-Proof Manufacturing

Jinrong has a proven track record of expertise in manufacturing ex-proof equipment that meets the stringent requirements of Class 1 Div 2 environments. With a focus on quality and safety, Jinrong provides innovative solutions that help clients achieve compliance with confidence.

Exploring Class 1 Div 2 Requirements

When it comes to understanding class 1 div 2 requirements, it's essential to grasp the definition and scope of these regulations. Class 1 Div 2 refers to a hazardous location where flammable gases or vapors may be present in the air in quantities sufficient to produce explosive or ignitable mixtures. The scope of these requirements encompasses various industries such as oil and gas, chemical, pharmaceutical, and more.

Definition and Scope of Class 1 Div 2

Class 1 Div 2 locations are classified as areas where flammable gases or vapors are not likely to be present in an explosive concentration under normal operating conditions. However, they may exist due to abnormal conditions such as equipment failure or accidental release. It's crucial for businesses operating in these environments to comply with class I div II regulations to ensure the safety of their personnel and facilities.

Key Factors to Consider for Compliance

Compliance with class I div II requirements involves several key factors, including selecting suitable ex equipment that meets the specified safety standards for use in hazardous locations. It also requires implementing proper installation, maintenance, and inspection practices for all ex-proof products used within the classified area. Additionally, training employees on the importance of adhering to safety protocols is vital for compliance.

Benefits of Meeting Class 1 Div 2 Requirements

Meeting class I div II requirements offers numerous benefits, such as reducing the risk of workplace accidents and ensuring uninterrupted operations in hazardous environments. Compliance also enhances overall safety measures within the facility and demonstrates a commitment to prioritizing employee well-being. Moreover, adhering to these regulations can lead to cost savings by avoiding potential fines and liabilities associated with non-compliance.

Ex Equipment in Class I Div 2

When it comes to Class 1 Div 2 requirements, having reliable ex-proof lighting solutions is crucial for ensuring safety in hazardous environments. These lighting solutions are designed to prevent the ignition of flammable gases, vapors, or liquids, making them essential for compliance with Class I Div 2 standards. With Jinrong's expertise in ex-proof manufacturing, you can trust that our lighting solutions are not only compliant but also durable and efficient.

Reliable Ex-Proof Lighting Solutions

Jinrong offers a wide range of reliable ex-proof lighting solutions that meet the stringent requirements of Class I Div 2. From LED fixtures to emergency lighting systems, our products are designed to provide superior illumination while minimizing the risk of ignition in hazardous locations. With features such as robust enclosures and advanced thermal management, our ex-proof lighting solutions are built to withstand the most demanding industrial environments.

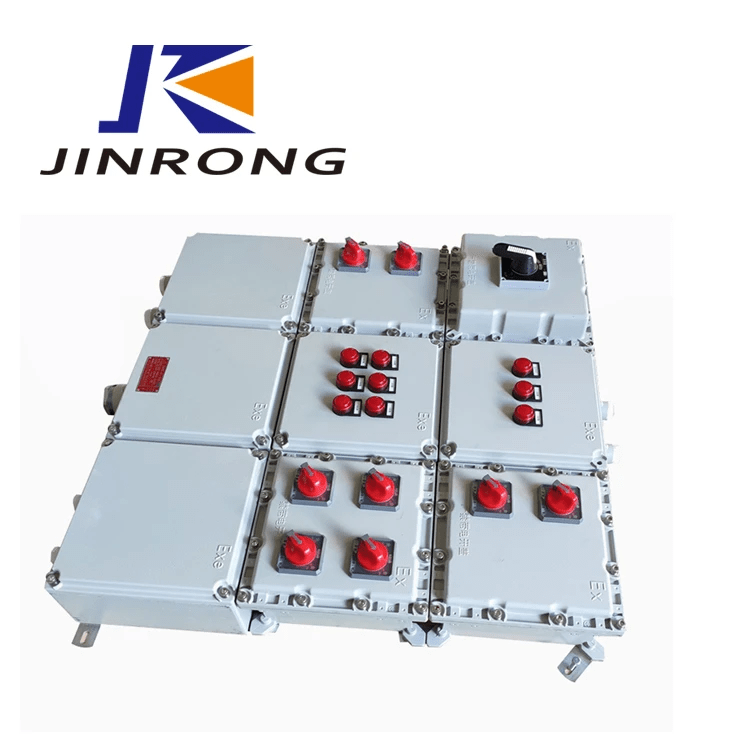

Innovative Ex-Proof Electrical Equipment

In addition to lighting solutions, Jinrong also provides innovative ex-proof electrical equipment that complies with Class I Div 2 requirements. Our electrical products include motor starters, control panels, and junction boxes that are specifically designed for use in hazardous locations where flammable substances may be present. With advanced engineering and rigorous testing, our electrical equipment ensures safe and reliable operation in potentially explosive atmospheres.

Essential Ex-Proof Accessories for Safety

To further enhance safety in hazardous environments, Jinrong offers essential ex-proof accessories such as cable glands, conduit fittings, and sealing compounds. These accessories play a critical role in maintaining the integrity of electrical installations and preventing the ingress of flammable substances. By incorporating these accessories into your Class I Div 2 compliant systems, you can minimize the risk of ignition and ensure a high level of protection for personnel and equipment.

Intrinsically Safe Meaning

In the realm of hazardous locations, understanding the concept of intrinsic safety is crucial. It refers to designing electrical equipment and wiring systems in a way that prevents the generation of sparks or thermal effects that could ignite flammable gases or vapors. Implementing intrinsic safety in ex-proof products ensures that they are safe to use in Class 1 Div 2 environments, where explosive gases, vapors, or liquids may be present.

Understanding the Concept of Intrinsic Safety

Intrinsic safety involves limiting electrical and thermal energy to a level below what is required to ignite a hazardous atmospheric mixture. This is achieved through various techniques such as using current-limiting resistors and encapsulating components to prevent sparks or heat from causing ignition. Understanding this concept is vital for manufacturers producing ex-proof equipment for use in Class I Div 2 locations, as it ensures the safety of workers and facilities.

Implementing Intrinsic Safety in Ex-Proof Products

Implementing intrinsic safety in ex-proof products involves rigorous testing and adherence to stringent standards to ensure that the equipment does not pose a risk of ignition in hazardous environments. This includes designing circuits and components with low energy levels, as well as incorporating protective measures such as explosion-proof enclosures and flameproof barriers. By integrating intrinsic safety measures into their products, manufacturers can provide reliable solutions for Class I Div 2 requirements.

Ensuring Compliance with Intrinsically Safe Standards

Ensuring compliance with intrinsically safe standards requires thorough knowledge of regulatory requirements and industry best practices. Manufacturers must conduct extensive testing and certification processes to validate that their ex-proof products meet the necessary criteria for intrinsic safety. This involves working closely with accredited testing laboratories and certification bodies to guarantee that their equipment complies with established standards for use in Class 1 Div 2 environments.

Importance of Ex E Certification

Significance of Ex E Certification in Ex-Proof Manufacturing

Ex E certification is crucial in ensuring the safety and reliability of electrical equipment used in hazardous environments, such as those classified under class 1 div 2 requirements. This certification signifies that the equipment has been designed and tested to meet specific safety standards for use in potentially explosive atmospheres, providing peace of mind for operators and regulatory compliance. Additionally, obtaining Ex E certification can enhance the reputation of manufacturers within the industry, as it demonstrates a commitment to producing high-quality, safe products. Furthermore, having Ex E certified equipment can also open up new business opportunities, as many industries require this level of certification when selecting suppliers for their hazardous area electrical equipment needs.

Meeting Class I Div 2 Requirements with Ex E Equipment

Ex E certified equipment plays a vital role in meeting the stringent requirements of class I div 2, where the presence of flammable gases or vapors necessitates the use of explosion-proof solutions. By utilizing Ex E certified products, companies can ensure that their operations remain safe and compliant with industry regulations, minimizing the risk of potential hazards and downtime.

Utilizing Ex E certified equipment not only ensures safety and compliance but also demonstrates a company's commitment to prioritizing the well-being of its employees and the surrounding environment. By investing in explosion-proof solutions, organizations can showcase their dedication to upholding high standards of safety and reliability, ultimately enhancing their reputation within the industry. Additionally, the use of Ex E certified products can contribute to cost savings in the long run by minimizing the potential for accidents, damage, and downtime.

Jinrong's Commitment to Ex E Certified Products

At Jinrong, we are dedicated to providing high-quality ex-proof solutions that adhere to strict safety standards, including Ex E certification. Our commitment to offering a wide range of certified products ensures that our clients can easily access reliable equipment that meets class I div 2 requirements without compromising on performance or safety.

Our team at Jinrong understands the importance of ensuring compliance with Class I Div 2 standards, which is why we continuously invest in research and development to stay ahead of industry regulations. By staying abreast of the latest safety requirements, we can guarantee that our Ex E certified products are always in line with the most current standards, giving our clients peace of mind when it comes to safety and regulatory compliance. Additionally, our commitment to ongoing testing and quality control means that our products consistently meet or exceed industry benchmarks for reliability and performance.

Ensuring Compliance with Class I Div 2

When it comes to ensuring compliance with Class 1 Div 2 requirements, it's crucial to take proactive steps to meet the necessary standards. This includes thoroughly understanding the specific requirements for hazardous locations and implementing appropriate measures to address potential risks.

Steps to Ensure Compliance with Class I Div 2 Requirements

To ensure compliance with Class 1 Div 2 requirements, businesses should start by conducting a comprehensive assessment of their facilities and operations. This involves identifying all potential sources of ignition and evaluating the suitability of equipment for use in hazardous environments. Additionally, regular inspections and maintenance are essential to ensure ongoing compliance.

After conducting the initial assessment, businesses should develop and implement a detailed plan for mitigating potential ignition sources and ensuring the proper use of equipment in hazardous areas. This may involve investing in specialized equipment or making modifications to existing systems to minimize the risk of sparks or overheating. Furthermore, employees should receive thorough training on safety protocols and procedures for working in Class 1 Div 2 environments to ensure that compliance is maintained at all times.

Best Practices for Meeting Regulatory Standards

Meeting regulatory standards for Class I Div 2 requires adherence to best practices such as using certified ex equipment, implementing proper installation and maintenance procedures, and providing adequate training for employees working in hazardous locations. It's also important to stay updated on any changes or updates to regulations and standards that may impact compliance.

In addition to these best practices, it is essential to conduct regular inspections and audits to ensure ongoing compliance with regulatory standards. This includes documenting all equipment installations, maintenance activities, and employee training sessions to provide evidence of adherence to regulations. Furthermore, establishing clear communication channels for reporting any potential hazards or non-compliance issues is crucial for maintaining a safe working environment in hazardous locations.

Jinrong's Support for Compliance Assurance

Jinrong understands the complexities of ensuring compliance with Class I Div 2 requirements and offers comprehensive support to help businesses navigate these challenges. With a focus on providing high-quality ex equipment and expert guidance, Jinrong is committed to assisting clients in meeting regulatory standards with confidence.

Jinrong's support for compliance assurance extends beyond just providing equipment and guidance. We also offer training programs to educate businesses on best practices for maintaining compliance in Class I Div 2 environments. Our team of experts is dedicated to staying up-to-date on regulatory changes and industry standards, ensuring that our clients have access to the most current information and resources available. By partnering with Jinrong, businesses can feel confident in their ability to meet and exceed compliance requirements.

Conclusion

Achieving Compliance with Class 1 Div 2

At Jinrong, we understand the importance of meeting class 1 div 2 requirements to ensure safety in hazardous environments. Our expertise in ex-proof manufacturing allows us to provide reliable solutions that comply with these stringent standards, giving our clients peace of mind.

Partnering with Jinrong for Ex-Proof Solutions

When it comes to ex-proof solutions, partnering with Jinrong means gaining access to top-notch equipment that meets class i div 2 requirements. Our commitment to excellence and compliance ensures that you receive the highest quality products for your industrial needs.

Meeting Regulatory Requirements with Confidence

With Jinrong as your partner, you can confidently navigate the complex landscape of regulatory requirements. Our ex-proof solutions are designed to meet and exceed class i div 2 standards, allowing you to focus on your operations without worrying about compliance issues.