Introduction

In today's industrial landscape, understanding hazardous area lighting is not just a necessity; it's a responsibility. As industries operate in environments where flammable gases, vapors, or dust may be present, effective lighting becomes crucial to ensure safety and compliance with regulations. This introduction will explore the importance of safety compliance and highlight key features that define effective hazardous lighting solutions.

Understanding Hazardous Area Lighting

What is hazardous area lighting? It refers to specialized lighting designed for environments where explosive atmospheres may exist due to the presence of flammable substances. These areas require unique considerations that differ from standard lighting setups, ensuring that illumination does not pose additional risks to worker safety or equipment integrity.

Importance of Safety Compliance

The importance of safety compliance in hazardous areas cannot be overstated. Adhering to industry standards helps mitigate risks associated with poor lighting and ensures that all workers can perform their tasks safely and efficiently. When facilities prioritize compliance, they not only protect their employees but also enhance overall productivity by reducing accidents related to inadequate visibility.

Key Features of Effective Lighting

When it comes to hazardous area lighting, several key features are essential for optimal performance. Effective lighting must provide adequate brightness while minimizing glare and shadows that could obscure potential hazards. Additionally, it should be durable enough to withstand harsh conditions typical in these environments and meet specific certifications like ATEX for enhanced reliability and safety assurance.

What is Hazardous Area Lighting?

Definition and Standards

Hazardous area lighting is defined by its ability to operate safely in environments classified as hazardous due to the presence of flammable materials. Standards such as ATEX (Atmosphères Explosibles) and IECEx provide guidelines on how products should be designed and tested for use in these areas. Compliance with these standards not only ensures safety but also enhances operational efficiency, making it a critical consideration for industries working with volatile substances.

Common Applications in Industries

You’ll find hazardous area lighting used across multiple industries, including oil and gas, chemical manufacturing, mining, and pharmaceuticals. In these sectors, areas like offshore platforms or chemical processing plants require reliable illumination that won’t spark an explosion—hence the demand for specialized solutions like Zone 1 LED lighting. These applications underscore the importance of understanding what is hazardous area lighting and its role in maintaining safe work environments.

Differences from Standard Lighting

The differences between hazardous area lighting and standard lighting are stark and significant. While standard lights may be suitable for everyday settings like offices or homes, they lack the necessary certifications to operate safely in explosive atmospheres. Hazardous lighting is engineered with robust materials that resist corrosion and impacts while providing adequate brightness without posing ignition risks—making them indispensable for any operation dealing with dangerous substances.

What are the Hazardous Effects of Lighting?

Risks Associated with Poor Lighting

The risks associated with poor lighting in hazardous areas can be severe and multifaceted. Inadequate illumination can lead to accidents, such as slips, trips, and falls, which are particularly prevalent in environments where workers are handling heavy machinery or flammable materials. Furthermore, insufficient visibility may prevent employees from spotting potential hazards promptly, increasing the likelihood of incidents that could escalate into catastrophic failures.

Moreover, poor lighting often results in eye strain and fatigue among workers, which can diminish their focus and responsiveness. This means that not only does hazardous area lighting need to meet certain standards; it must also be implemented effectively to mitigate these risks. In summary, understanding what is hazardous area lighting goes hand-in-hand with recognizing the dangers posed by inadequate illumination.

Impact on Worker Safety and Productivity

The impact of subpar lighting on worker safety cannot be overstated; it directly correlates with productivity levels as well. When employees struggle to see clearly due to inadequate light sources or poorly positioned fixtures, their efficiency plummets. This inefficiency translates into delays and errors that could cost businesses significantly—both financially and reputationally.

Additionally, when workers feel unsafe due to dim or flickering lights in a hazardous environment, their morale takes a hit too. High morale is often linked to higher productivity levels; therefore, ensuring effective hazardous area lighting not only protects workers but boosts overall output as well. So next time you think about what is ATEX lighting or emergency lighting for high-risk areas, remember: it’s not just about compliance—it’s about creating a safe working atmosphere where everyone can thrive.

Importance of Proper Installation

The importance of proper installation cannot be emphasized enough when discussing hazardous LED lighting solutions in risky environments like Zone 1 LED lighting areas. Even the highest-quality fixtures will fail to deliver if they aren’t installed correctly according to industry standards and regulations like ATEX guidelines for explosive atmospheres. Proper installation ensures that lights function optimally while minimizing risks related to electrical faults or exposure to harmful elements.

Moreover, regular maintenance checks following installation play a critical role in sustaining effective performance over time; neglected systems may deteriorate quickly under harsh conditions typical of industrial settings. Therefore, investing time and resources into proper installation practices pays off immensely by enhancing both safety compliance and operational efficiency within hazardous areas.

In conclusion, understanding what are the hazardous effects of lighting emphasizes the need for robust solutions tailored specifically for dangerous work environments—because when safety shines bright through effective illumination strategies, everyone wins!

What is ATEX Lighting?

Overview of ATEX Standards

ATEX standards are divided into two main directives: one for manufacturers of equipment (ATEX 2014/34/EU) and another for employers (ATEX 1999/92/EC). These regulations lay out the requirements for designing, testing, and certifying hazardous area lighting to ensure it can operate safely in environments where flammable gases or dust may be present. Compliance with these standards not only protects workers but also minimizes the risk of catastrophic incidents that could arise from inadequate lighting solutions.

Compliance and Certification Process

The journey to compliant hazardous area lighting begins with thorough risk assessments to identify potential hazards in specific environments. Manufacturers must then design their products according to ATEX guidelines, followed by rigorous testing and certification processes conducted by accredited bodies. Once certified, these products can be labeled with the appropriate markings indicating their suitability for various zones, such as Zone 1 LED lighting for areas with a high likelihood of explosive atmospheres.

Benefits of ATEX Certified Lighting

Investing in ATEX certified hazardous lighting brings numerous benefits beyond mere compliance; it enhances overall workplace safety and boosts employee confidence. These lights are designed specifically for challenging environments, ensuring reliability even under extreme conditions while reducing maintenance costs over time. Furthermore, using certified equipment can lead to increased productivity as employees feel safer knowing they are protected by robust solutions designed explicitly for hazardous areas.

Emergency Lighting for High-Risk Areas

In hazardous environments, the importance of reliable emergency lighting cannot be overstated. When unexpected power outages occur or emergencies arise, having a dependable lighting system can make all the difference in ensuring safety and guiding personnel to exits. This is especially critical in industries where hazardous area lighting is utilized, as poor visibility can exacerbate risks associated with dangerous substances or equipment.

Importance of Reliable Emergency Lighting

Reliable emergency lighting serves as a crucial safety net in high-risk areas, illuminating escape routes and providing guidance during emergencies. Without proper emergency lighting, workers may struggle to navigate through hazardous conditions, increasing the likelihood of accidents or injuries. Additionally, effective emergency lighting can significantly improve response times and minimize panic among employees during critical situations.

Types of Emergency Hazardous Lighting

There are several types of emergency hazardous lighting systems designed specifically for high-risk areas. These include self-contained battery-operated lights that activate automatically during power failures and centralized systems that draw power from a backup generator or battery bank. Each type has its own advantages; for instance, self-contained units are easier to install while centralized systems often offer more extensive coverage across larger spaces.

Best Practices for Installation and Maintenance

To ensure optimal performance of emergency lighting in hazardous areas, following best practices for installation and maintenance is essential. First and foremost, it’s important to assess the specific needs of the environment—this includes understanding what is hazardous area lighting and how it interacts with existing systems. Regular inspections should be conducted to check functionality and compliance with standards like ATEX; this ensures that all components are operational when they are needed most.

Choosing Hazardous LED Lighting

Advantages of LED Technology

LED technology has revolutionized hazardous area lighting by offering several key advantages over traditional lighting solutions. First and foremost, LEDs are energy-efficient, consuming significantly less power while providing brighter illumination, which is essential in high-risk areas. Additionally, they have a longer lifespan, reducing maintenance costs and downtime—two critical factors in industries where every minute counts.

Moreover, LEDs produce minimal heat compared to incandescent or halogen bulbs, which is vital in preventing ignition of flammable materials present in hazardous locations. This feature makes them ideal for environments that require strict adherence to safety standards like ATEX regulations. With lower energy consumption and reduced heat output, hazardous LED lighting not only enhances workplace safety but also contributes to sustainability efforts.

Key Features to Look For

When selecting hazardous LED lighting for your facility, there are several key features you should prioritize to ensure compliance and effectiveness. Firstly, look for lights that meet ATEX certification standards; this guarantees that they are safe for use in explosive atmospheres. Additionally, consider luminance levels; adequate brightness is crucial since poor visibility can lead to accidents—what are the hazardous effects of lighting?

Another important feature is durability; choose lights constructed from robust materials that can withstand harsh conditions typical of industrial environments. Finally, ensure that the fixtures have proper ingress protection (IP) ratings to safeguard against dust and moisture infiltration—this adds another layer of safety for workers operating under hazardous conditions.

Recommendations for Zone 1 LED Lighting

Zone 1 locations are classified as areas where explosive gas atmospheres may occur during normal operations; thus choosing suitable Zone 1 LED lighting is paramount for ensuring worker safety and compliance with regulations like ATEX standards. For these zones, look for fixtures specifically designed with explosion-proof enclosures that prevent ignition sources from escaping into the surrounding atmosphere.

Additionally, consider lights with adjustable beam angles; this flexibility allows you to direct light precisely where it's needed most without creating dark spots that could pose risks—what is emergency lighting for high-risk areas? Furthermore, investing in smart technology can enhance monitoring capabilities; some modern fixtures come equipped with sensors that provide real-time feedback on performance metrics.

In summary, when choosing hazardous area lighting solutions such as Zone 1 LED lights, focus on energy efficiency and compliance while ensuring durability against environmental challenges.

Conclusion

In the world of hazardous area lighting, the future looks promising as technology advances and safety standards evolve. With an increasing focus on worker safety and productivity, industries are recognizing the critical role that effective lighting plays in hazardous environments. As we move forward, innovations in lighting technology will continue to enhance compliance and operational efficiency.

Future of Hazardous Area Lighting

The future of hazardous area lighting is set to be shaped by ongoing advancements in LED technology and smart lighting solutions. Emerging technologies are not only improving energy efficiency but also enhancing the safety features inherent in these specialized lights. As industries increasingly adopt rigorous safety measures, understanding what is hazardous area lighting will become essential for compliance and risk management.

Enhancing Safety with Innovative Solutions

Innovative solutions are key to enhancing safety within high-risk environments where poor visibility can lead to serious accidents. By integrating smart systems into hazardous LED lighting, companies can monitor conditions in real-time and adjust illumination levels accordingly. This adaptability not only addresses what are the hazardous effects of lighting but also ensures that workers remain safe and productive.

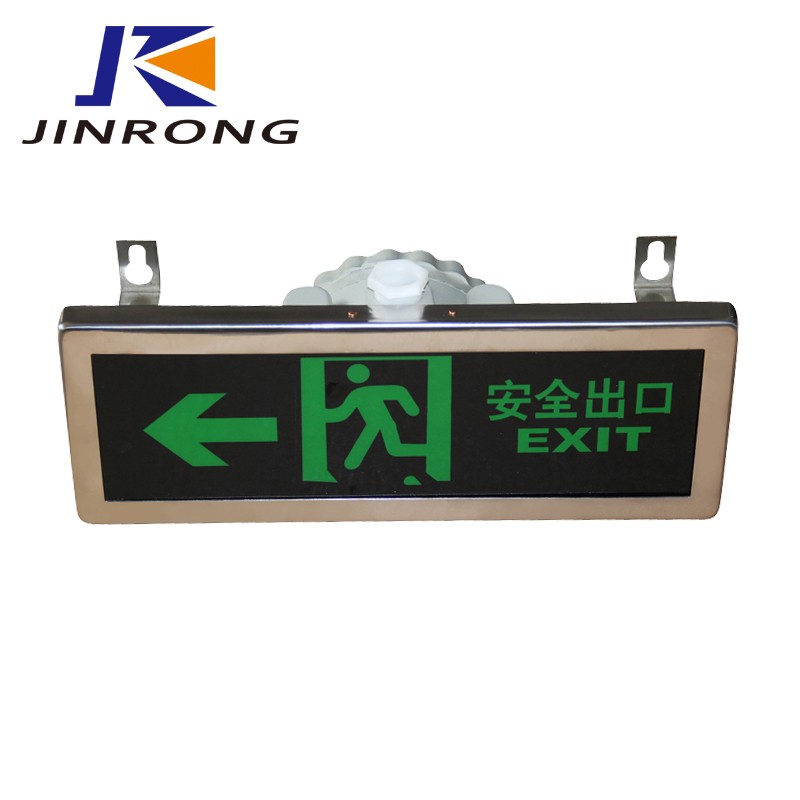

Working with Experts like Jinrong

When it comes to implementing effective hazardous area lighting solutions, partnering with experts like Jinrong can make all the difference. Their knowledge about what is ATEX lighting and how it complies with international standards ensures that your facility meets all necessary regulations while maximizing safety. With their guidance on emergency lighting for high-risk areas, you can trust that your operations will run smoothly even under challenging conditions.