Introduction

What You Need to Know About Explosion Proof J Boxes

Explosion proof junction boxes, often referred to as explosion proof j boxes, are engineered for use in areas where flammable gases or dust are present. They provide a reliable solution for safeguarding electrical connections and equipment from igniting hazardous materials. Understanding their construction and functionality is essential for anyone involved in industries such as oil and gas, chemical manufacturing, or mining.

The Importance of Choosing a Reliable Supplier

Selecting a reputable explosion proof junction box supplier is paramount for ensuring quality and compliance with safety regulations. A dependable supplier not only provides products that meet rigorous standards but also offers valuable support throughout the purchasing process. Investing time in researching suppliers can save you from future headaches related to product failures or non-compliance issues.

Key Features of Quality Explosion Proof Junction Boxes

Quality explosion proof electrical junction boxes come equipped with several key features designed to enhance safety and performance. Look for robust materials like aluminum or high-grade non-metallic options that withstand harsh conditions while providing excellent sealing against dust and moisture ingress. Additionally, ensure that your chosen ex proof junction box meets relevant industry certifications—this guarantees that you're investing in a product built to last under extreme circumstances.

Top Explosion Proof Junction Box Suppliers

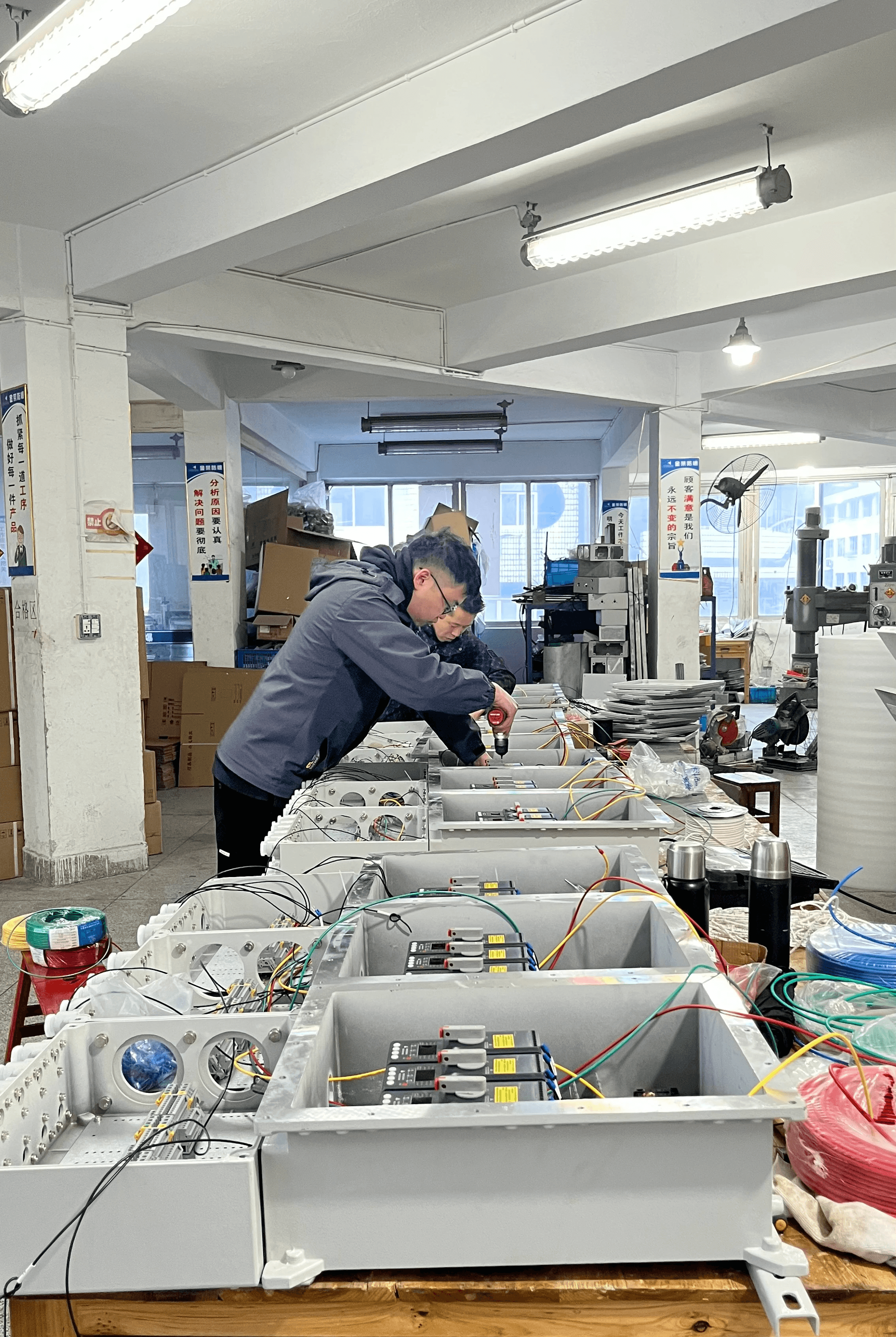

Jinrong: A Legacy of Excellence in Ex Proof Products

Jinrong has carved out a reputation as a leading explosion proof junction box supplier known for its high-quality products and innovative designs. Their explosion proof electrical junction boxes are engineered to withstand harsh environments while ensuring maximum safety and reliability. With years of experience under their belt, Jinrong's dedication to excellence makes them a go-to choice for industries requiring robust ex proof junction boxes.

One of the standout features of Jinrong's offerings is their extensive range of explosion proof j boxes tailored to various applications. Whether you need aluminum or non-metallic options, they have you covered with solutions that meet compliance standards and industry requirements. Customers appreciate not only the durability but also the user-friendly designs that simplify installation and maintenance.

Moreover, Jinrong prioritizes customer satisfaction by offering excellent support services alongside their products. Their knowledgeable team is always ready to assist clients in selecting the right explosion proof electrical boxes for their specific needs. With a focus on quality assurance and rigorous testing protocols, choosing Jinrong means investing in safety without compromise.

Adalet: Pioneers in Explosion Proof Solutions

Adalet stands out as one of the pioneers in providing comprehensive explosion proof solutions across various sectors. As an established explosion proof junction box supplier, they offer an array of specialized products designed specifically for hazardous environments. Their commitment to innovation has led them to develop some of the most advanced explosion proof electrical junction boxes available on the market today.

What sets Adalet apart is their deep understanding of industry challenges and regulations governing safety equipment like ex proof junction boxes. They ensure that all their products adhere strictly to compliance standards while also being user-friendly for quick installations and maintenance tasks. This dedication not only enhances workplace safety but also contributes positively to operational efficiency.

Additionally, Adalet’s extensive portfolio includes custom solutions tailored to unique project requirements—an invaluable asset for industries with specific needs or constraints. Whether you’re looking for durable materials or specialized configurations in your explosion proof j boxes, Adalet's expertise ensures you receive exactly what you need without any hassle.

Appleton: Trusted Name in Electrical Safety

Appleton has long been synonymous with electrical safety and reliability in hazardous locations worldwide; they are indeed a trusted name among explosion proof junction box suppliers. Their range of explosion proof electrical boxes combines rugged construction with innovative technology designed specifically for challenging conditions found in industrial settings. Appleton’s commitment to quality ensures that every product meets stringent safety standards.

The company’s expertise extends across diverse applications—from oil refineries to chemical plants—making them an ideal partner when selecting your next ex proof junction box solution. They offer various options that cater not just to functionality but also aesthetics without compromising on performance or safety features essential for explosive atmospheres.

Furthermore, Appleton places great emphasis on customer education regarding compliance standards associated with using their products effectively within different industries’ contexts—ensuring users make informed decisions about which models best suit their operational needs while adhering strictly to regulatory guidelines surrounding installation practices related specifically towards explosion-proof systems like theirs!

Understanding Explosion Proof Electrical Junction Boxes

What Makes an Electrical Box Explosion Proof?

An explosion proof j box is engineered with specific features that set it apart from standard electrical boxes. The key elements include a strong housing that can withstand internal explosions and a sealing mechanism that prevents gas or dust ingress. Additionally, these explosion proof electrical boxes undergo rigorous testing to ensure they meet industry standards and can effectively contain any explosive event without compromising safety.

Applications in Hazardous Environments

Explosion proof junction boxes find their place in various industries where flammable gases or dust are present, such as oil and gas, chemical manufacturing, and mining operations. Their ability to safely house electrical connections makes them essential for protecting equipment and personnel in these hazardous settings. For instance, an explosion proof j box might be utilized on offshore drilling platforms where the risk of explosive atmospheres is ever-present.

Compliance Standards to Look For

When selecting an explosion proof electrical junction box supplier, it's essential to look for compliance with recognized safety standards such as ATEX (in Europe) or NEC (in the United States). These certifications indicate that the products have been rigorously tested for reliability under hazardous conditions. Always verify if your chosen supplier adheres to these standards; this ensures you’re investing in quality explosion proof j boxes that will perform as required under challenging circumstances.

Comparing Different Types of Ex Proof Junction Boxes

Selecting Between Aluminum and Non-Metallic Options

Aluminum explosion proof j boxes are renowned for their strength and resistance to corrosion, making them a popular choice in demanding industrial environments. They excel in areas where durability is paramount, such as oil refineries or chemical plants. On the other hand, non-metallic explosion proof electrical junction boxes provide excellent resistance to harsh chemicals and moisture, making them ideal for industries like pharmaceuticals or food processing.

When considering which option suits your needs best, think about the environment in which your ex proof junction box will be installed. If you anticipate exposure to corrosive substances or extreme weather conditions, non-metallic options may be more suitable. However, if structural integrity under impact is a priority, aluminum should be your go-to choice.

Ultimately, both types of explosion proof electrical boxes have their merits; it’s all about matching their features with your specific requirements. Consulting with a reputable explosion proof junction box supplier can help clarify which material will serve you best based on your operational needs.

The Benefits of Using Explosion Proof J Boxes

Investing in quality explosion proof j boxes offers numerous advantages that go beyond mere compliance with safety regulations. These robust solutions are designed to contain any potential explosions within their confines while preventing any ignition sources from escaping into surrounding areas—an essential feature for maintaining workplace safety. Moreover, they often come equipped with advanced sealing mechanisms that protect against dust and moisture ingress.

Another significant benefit lies in their longevity; high-quality explosion proof electrical junction boxes are built to withstand extreme conditions without compromising functionality over time. This means fewer replacements and reduced maintenance costs—definitely a win-win situation for any industrial operation! Additionally, these products enhance overall system reliability by ensuring uninterrupted power supply even in hazardous environments.

Choosing an experienced explosion proof junction box supplier ensures that you receive products that meet stringent industry standards while also providing expert guidance on installation and maintenance practices tailored to your specific application needs.

Key Considerations for Your Industrial Needs

When selecting an explosion proof j box for your facility, several key factors must be taken into account to ensure optimal performance and safety compliance. First off is understanding the specific environmental hazards present—this includes identifying potential sources of flammable gases or vapors that could lead to dangerous situations if not properly contained by quality ex proof junction boxes.

Next up is assessing the size requirements based on cable entries needed; larger installations may require more expansive models capable of accommodating multiple connections without compromising safety standards or accessibility during maintenance tasks later down the line! Lastly—but certainly not least—is ensuring compatibility with existing equipment; communicating effectively with your chosen explosion proof junction box supplier can help streamline this process immensely.

In summary, taking these considerations seriously will empower you to make informed decisions regarding which type of explosion proof electrical boxes will best suit your unique operational demands while enhancing overall workplace safety at every turn.

Certification and Quality Assurance

Importance of Certifications in Explosion Proof Products

Certifications serve as a guarantee that explosion proof j boxes have been rigorously tested to meet safety standards. These standards ensure that the products can contain any potential explosions within the unit, preventing them from spreading into the surrounding environment. Without proper certifications, users may be at risk, making it essential for businesses to invest in certified explosion proof electrical boxes from reputable suppliers.

Top Certifications for Explosion Proof Electrical Boxes

Several key certifications indicate the reliability of explosion proof junction boxes. Among these are the ATEX (Atmosphères Explosibles) certification, which is vital for equipment used in Europe, and UL (Underwriters Laboratories) certification, widely recognized in North America. Additionally, IECEx certification ensures compliance with international safety standards—crucial for businesses operating globally seeking reliable explosion proof j boxes.

How to Verify Supplier Credentials

To ensure you're dealing with a reputable explosion proof junction box supplier, it's essential to verify their credentials thoroughly. Start by checking if they display relevant certifications prominently on their website or product literature; this transparency indicates reliability and confidence in their offerings. Furthermore, consider reaching out directly for documentation or references regarding their compliance with industry standards—after all, when it comes to safety in hazardous environments, due diligence pays off.

Common Applications for Explosion Proof J Boxes

Explosion proof junction boxes are critical components in various industries where safety and reliability are paramount. These robust electrical enclosures are designed to prevent the ignition of flammable gases, vapors, or dust that may be present in hazardous environments. Choosing a reputable explosion proof junction box supplier ensures that you receive high-quality products that meet industry standards and regulations.

Industries Utilizing Explosion Proof Junction Boxes

Several industries rely heavily on explosion proof electrical junction boxes due to the inherent risks associated with their operational environments. The oil and gas sector is one of the most prominent users, where volatile substances necessitate stringent safety measures. Other industries include chemical manufacturing, pharmaceuticals, mining, and food processing—each requiring specialized ex proof junction boxes to protect against potential explosions.

In addition to these sectors, utility companies managing power generation and distribution also utilize explosion proof j boxes to safeguard equipment in potentially hazardous locations. The marine industry is another key player, as vessels often encounter explosive atmospheres due to fuel vapors and other flammable materials onboard. By investing in quality explosion proof electrical boxes from trusted suppliers, businesses can ensure compliance with safety regulations while protecting their employees and assets.

Real-World Examples of Successful Installations

One notable example of successful installation involves a major oil refinery that incorporated explosion proof j boxes throughout its processing facilities. These enclosures were strategically placed near pumps and valves handling flammable liquids, significantly enhancing safety protocols while allowing for efficient operation. Another case study highlights a chemical plant that upgraded its existing infrastructure by replacing standard electrical boxes with certified explosion proof solutions—resulting in reduced risk of accidents and improved overall productivity.

In the food processing industry, a large manufacturer opted for explosion proof electrical junction boxes in its packaging department where dust from dry ingredients could pose an ignition risk. This proactive measure not only safeguarded employees but also ensured uninterrupted operations during peak production times. Such real-world applications demonstrate the effectiveness of using high-quality ex proof junction boxes across various sectors.

Benefits of Investing in Quality Electrical Boxes

Investing in quality explosion proof j boxes offers numerous advantages beyond mere compliance with safety standards. First and foremost, these products provide peace of mind by minimizing the risk of explosions or fires caused by faulty electrical connections or equipment failures—an invaluable asset for any business operating in hazardous conditions. Additionally, reliable explosion proof electrical boxes often come equipped with features such as corrosion resistance and enhanced durability, leading to lower maintenance costs over time.

Moreover, partnering with a reputable explosion proof junction box supplier ensures access to cutting-edge technology designed specifically for challenging environments—resulting in better performance and longevity than standard options can provide. Finally, utilizing high-quality products not only enhances workplace safety but can also improve operational efficiency by reducing downtime associated with equipment failure or regulatory penalties related to non-compliance.

Conclusion

In wrapping up our discussion on explosion proof junction boxes, it’s clear that choosing the right supplier is paramount to ensuring safety and reliability in hazardous environments. With numerous options available, selecting a reputable explosion proof electrical junction box supplier can make all the difference in your operational efficiency and safety standards. Jinrong stands out as a leader in this field, providing high-quality products tailored to meet diverse industrial needs.

Why Choose Jinrong for Your Electrical Needs

Choosing Jinrong as your explosion proof junction box supplier is a decision rooted in trust and performance. With a legacy of excellence, their explosion proof j boxes are engineered to withstand the toughest conditions while ensuring optimal safety. Their commitment to quality means that each explosion proof electrical junction box undergoes rigorous testing and adheres strictly to compliance standards.

The Future of Explosion Proof Solutions

The future of explosion proof solutions looks promising as technology continues to evolve, offering enhanced features and improved materials for ex proof junction boxes. Innovations such as smart monitoring systems will soon be integrated into these products, allowing for real-time data collection and analysis in hazardous environments. As industries grow more complex, investing in advanced explosion proof electrical boxes will be essential for maintaining safety and efficiency.

Making an Informed Decision in Supplier Selection

When it comes to selecting an explosion proof j box supplier, informed decision-making is crucial. Look for suppliers who not only provide quality products but also demonstrate expertise through certifications and industry experience. By prioritizing suppliers like Jinrong who offer reliable support along with their explosion proof j boxes, you can ensure that your projects meet all necessary safety requirements while remaining cost-effective.