Introduction

When it comes to ensuring safety in hazardous environments, understanding class 1 division 2 enclosures, the importance of hazardous area classification, and exploring explosion proof enclosures is crucial. These concepts are essential for protecting against explosions and ensuring compliance with industry regulations.

Understanding Class 1 Division 2 Enclosures

Class 1 Division 2 enclosures are designed to meet specific electrical requirements for hazardous areas where flammable gases or vapors may be present. These enclosures play a vital role in safeguarding electrical equipment and personnel in such environments, preventing potential hazards.

Importance of Hazardous Area Classification

Even a seemingly minor oversight can have catastrophic consequences in industrial environments where flammable materials are present. Hazardous area classification is the cornerstone for safety in these settings, providing a structured approach to identifying and managing explosion and fire risks. Here's why it's crucial:

A Roadmap to Effective Risk Management

- Identifying Flammable Hazards: Classification systematically analyzes an area to determine the likelihood and extent of the presence of flammable gas, vapor, or dust. This creates a clear understanding of the specific hazards workers may encounter.

- Guiding Safety Measures: Based on the classification, appropriate safety measures can be implemented. This includes selecting explosion-proof equipment, establishing safe work procedures, and implementing proper ventilation and control systems to minimize the risk of ignition.

Compliance with Regulations

- Meeting Safety Standards: Many countries and regions have established regulations outlining requirements for hazardous area classification. Complying with these regulations ensures adherence to industry best practices and demonstrates a commitment to worker safety.

- Safeguarding Personnel and Assets: Following established classification processes help prevent accidents and costly incidents that could result in injuries, fatalities, and property damage.

Optimizing Safety Throughout Operations

- Selecting the Right Equipment: Knowing the specific classification of a hazardous area allows for selecting appropriate explosion-proof equipment, such as lighting, electrical components, and tools. This ensures that equipment is designed to withstand the potential hazards present.

- Emergency Preparedness: Proper classification helps establish clear emergency response procedures and evacuation plans. By understanding the potential risks, companies can develop targeted training and ensure personnel know how to respond effectively in case of an incident.

A Collaborative Effort for Safety

Hazardous area classification is a collaborative effort involving engineers, safety professionals, and maintenance personnel. By working together to identify hazards, implement controls, and maintain a safe working environment, organizations can create a culture of safety that prioritizes the well-being of their employees and minimizes the risk of explosions and fires.

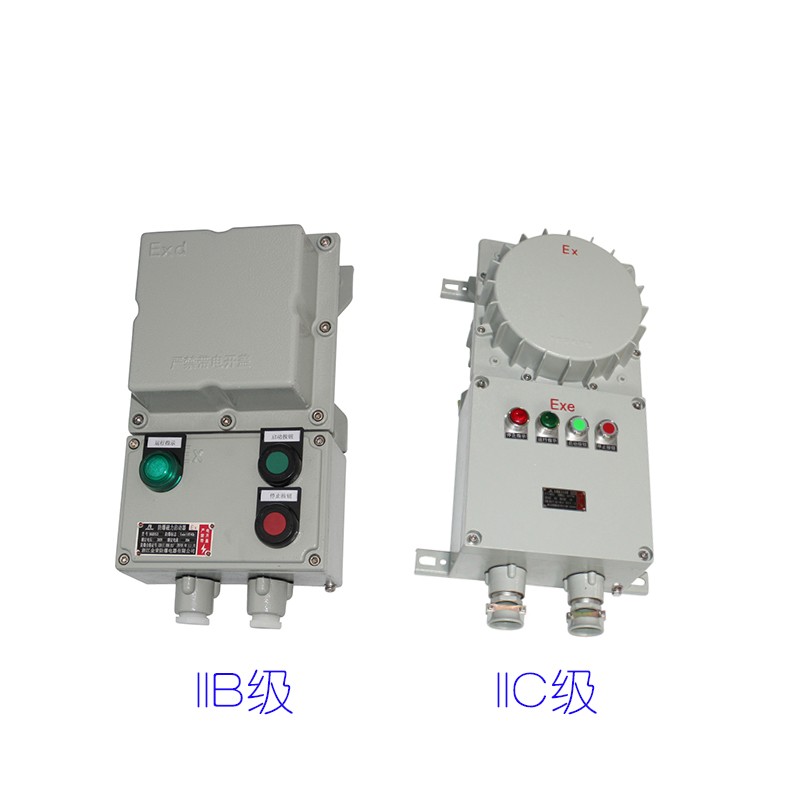

Exploring Explosion Proof Enclosures

Explosion proof enclosures are engineered to contain any internal explosion without igniting the surrounding atmosphere, providing a safe environment for electrical components within hazardous locations. These specialized enclosures are crucial for protecting personnel and equipment from potential explosions.

Class 1 Division 2 enclosures are specifically designed for use in hazardous locations where flammable gases, vapors, or liquids may be present under normal operating conditions. These enclosures are built to withstand and contain any potential explosion, ensuring the surrounding atmosphere remains safe. With their robust construction and strict adherence to safety standards, Class 1 Division 2 enclosures provide peace of mind for personnel working in environments where explosion risks are a concern.

What are Class 1 Division 2 Enclosures?

Definition and Purpose

Class 1 Division 2 enclosures are designed to protect electrical equipment in hazardous locations where flammable gases or vapors may be present. These enclosures are constructed to contain any potential explosions, preventing them from igniting the surrounding atmosphere and causing a catastrophic event. These enclosures provide peace of mind for industries operating in potentially volatile environments by meeting specific regulatory standards for safety and performance. Additionally, they help to minimize the risk of fire and explosion, ensuring the safety of personnel working in these hazardous locations.

Class 1 Division 2 Electrical Requirements

When it comes to electrical requirements, Class 1 Division 2 enclosures must meet strict standards to ensure safety in hazardous environments. They must be designed with features such as explosion-proof seals, corrosion-resistant materials, and effective ventilation systems to prevent the buildup of flammable gases.

In addition to these features, Class 1 Division 2 electrical enclosures must also be designed with robust locking mechanisms to prevent unauthorized access and tampering. This ensures that only qualified personnel can access the electrical components, reducing the risk of accidents or malfunctions. Furthermore, these enclosures should have clear labeling and signage to indicate potential hazards and proper operating procedures, promoting a safe working environment for all personnel.

Ensuring Safety in Hazardous Environments

The primary purpose of Class 1 Division 2 enclosures is to provide a safe environment for electrical equipment in areas where there is a risk of explosive atmospheres. Industries can use these specialized enclosures to ensure that their operations remain secure and compliant with safety regulations.

By utilizing Class 1 Division 2 enclosures, industries can effectively mitigate the risks of explosive atmospheres and prevent potential accidents or disasters. These specialized enclosures are designed to contain any sparks or heat generated by electrical equipment, ensuring no ignition source is present in the hazardous area. This proactive approach not only safeguards the well-being of workers but also minimizes the likelihood of costly downtime and damage to equipment.

Hazardous Area Classification Explained

Class 1 Div 2 Definition

In hazardous areas where flammable gases, vapors, or liquids may be present in quantities sufficient to cause an explosion, Class 1 Division 2 enclosures are essential for protecting electrical equipment. These enclosures are designed to prevent the ignition of flammable substances and ensure the safety of personnel working in these environments.

In addition to protecting electrical equipment, Class 1 Division 2 enclosures also play a crucial role in maintaining the integrity of the surrounding environment. By containing any potential ignition sources, these enclosures help minimize the risk of fire and explosion, thereby safeguarding personnel and the facilities and assets within the hazardous area. This proactive approach to safety underscores the importance of using Class 1 Division 2 enclosures in environments where flammable substances pose a significant threat.

Hazardous Area Classification Chart

The hazardous area classification chart clearly explains the different classes and divisions used to categorize hazardous locations. It outlines the specific requirements for electrical equipment in each classification, helping industries determine the appropriate protection methods for their facilities.

The hazardous area classification chart is an essential tool for industries to ensure compliance with safety standards. By clearly outlining the specific requirements for electrical equipment in each classification, the chart helps companies determine the appropriate protection methods for their facilities. This not only ensures the safety of workers and the surrounding environment but also helps avoid costly fines and penalties for non-compliance with regulations.

Ensuring Compliance with Safety Standards

Compliance with safety standards is crucial in hazardous environments to prevent potential explosions and protect workers from harm. By adhering to Class 1 Division 2 electrical requirements and utilizing explosion-proof enclosures, industries can ensure that their operations meet the necessary safety standards and regulations.

By utilizing explosion proof enclosures, industries can effectively contain any potential explosions in hazardous environments. These enclosures are designed to withstand and mitigate an explosion's impact, thereby protecting workers and equipment from harm. This proactive approach to safety ensures compliance with regulations and demonstrates a commitment to prioritizing the well-being of all personnel.

The Significance of Explosion Proof Enclosures

When it comes to hazardous environments, the significance of explosion proof enclosures cannot be overstated. These specialized enclosures are designed to protect against explosions, ensuring the safety of both personnel and equipment. Controlling potential hazards within the enclosure is crucial in minimizing the risk of catastrophic events.

1. Protecting Against Explosions

Explosion proof enclosures are engineered to withstand and contain explosions that may occur within hazardous areas. By preventing the ignition of flammable gases, vapors, or dusts from escaping into the surrounding environment, these enclosures provide a critical layer of protection for personnel and equipment operating in Class 1 Division 2 environments.

Explosion-proof enclosures are designed to meet rigorous industry standards and undergo thorough testing to ensure their reliability in hazardous environments. They are constructed with robust materials and feature specialized sealing mechanisms to prevent the escape of flammable substances. As a result, they offer peace of mind for businesses operating in volatile settings, as they can trust that their equipment is shielded from potential explosions.

2. Ensuring Equipment Safety

In addition to safeguarding personnel, explosion proof enclosures also ensure the safety and integrity of electrical and electronic equipment installed within them. By preventing external elements from entering the enclosure and causing ignition sources, these specialized enclosures help maintain the reliability and functionality of critical equipment in hazardous locations.

Furthermore, explosion proof enclosures are designed to meet industry regulations and standards for hazardous locations. This ensures that the equipment housed within these enclosures complies with safety requirements, reducing the risk of accidents and ensuring adherence to legal guidelines. By providing a secure environment for electrical and electronic equipment, these enclosures contribute to overall workplace safety and regulatory compliance.

3. Meeting Industry Regulations

The use of explosion proof enclosures is not only a matter of safety but also a regulatory requirement in many industries. Compliance with industry standards such as Class 1 Division 2 electrical requirements necessitates using these enclosures to mitigate potential hazards of flammable substances in various industrial settings.

In addition to ensuring safety and regulatory compliance, using explosion-proof enclosures also helps protect valuable equipment and machinery from potential damage caused by explosions or other hazardous events. By investing in these protective measures, industries can avoid costly repairs or replacements and prevent downtime that could impact productivity and profitability. Furthermore, demonstrating a commitment to safety and risk management through the use of explosion proof enclosures can enhance a company's reputation and credibility within its industry.

The Role of Class I Div 2 in Manufacturing

Class 1 Division 2 enclosures are vital in manufacturing, especially in hazardous environments. These enclosures ensure the safety of electrical equipment and personnel, making them essential for industries such as oil and gas, chemical processing, and pharmaceuticals.

Jinrong: a Leader in Ex-Proof Manufacturing

Jinrong has established itself as a leader in manufacturing Class 1 Division 2 enclosures, specializing in explosion-proof solutions for hazardous locations. Their commitment to quality and safety has made them a trusted partner for businesses seeking reliable ex-proof products.

Jinrong's 27 years of expertise in the ex-proof industry have positioned them as a go-to resource for businesses needing reliable solutions for hazardous locations. Their extensive experience and deep understanding of the unique challenges posed by such environments enable them to provide tailored, high-quality products that meet the strictest safety standards. This track record of excellence has solidified Jinrong's reputation as a leader in ex-proof manufacturing, earning the trust and loyalty of clients across various industries.

27 Years of Expertise in Ex-Proof Industry

With over 27 years of experience in the ex-proof industry, Jinrong has honed its expertise in designing and producing Class 1 Division 2 enclosures that meet the highest safety and performance standards. Their extensive knowledge allows them to provide tailored solutions for various industrial applications.

With a commitment to innovation and excellence, Jinrong invests in research and development to stay ahead of industry trends and technological advancements. This dedication allows them to consistently deliver cutting-edge ex-proof products and solutions that meet the evolving needs of their clients. By staying at the forefront of industry developments, Jinrong ensures its customers receive the most advanced and reliable enclosures for hazardous environments.

Providing Quality Ex-Proof Products and Solutions

Jinrong's commitment to providing high-quality ex-proof products and solutions extends beyond just meeting electrical requirements. Their team of experts ensures that every product is compliant and designed for maximum efficiency and durability in harsh environments. Jinrong equips businesses with the tools they need to maintain safety without sacrificing operational effectiveness by offering a comprehensive range of enclosures, lighting fixtures, and other essential equipment.

Partnering with Jinrong for Professional Solutions

As a leader in the industry, Jinrong specializes in meeting diverse industrial needs with its range of class 1 division 2 enclosures. Whether for oil and gas, chemical processing, or pharmaceutical industries, Jinrong provides reliable solutions that adhere to class 1 division 2 electrical requirements.

Meeting Diverse Industrial Needs

Jinrong's class 1 division 2 enclosures are designed for various industrial environments, ensuring safety and compliance with hazardous area classification standards. With a wide range of options available, they can meet the specific needs of different industries, from rugged outdoor settings to sensitive indoor spaces.

Supporting Distributors’ Business Growth

Partnering with Jinrong means supporting distributors' business growth by providing high-quality class 1 div 2 enclosures that meet industry regulations and customer demands. With Jinrong's expertise and commitment to excellence, distributors can confidently expand their product offerings and serve their clients effectively.

Building Profession with Reliable Products

Jinrong's focus on delivering reliable products extends beyond meeting class I div 2 standards. Their enclosures are built to withstand harsh conditions, protect against explosions, and ensure equipment safety within hazardous areas. By choosing Jinrong, professionals can build trust in their operations and enhance their reputation for quality and safety.

Secure Workplace Safety with Ex-Proof Solutions

In today's industrial landscape, workplace safety is paramount. By utilizing class 1 division 2 enclosures, companies can effectively protect against hazardous environments and explosions. These explosion-proof enclosures provide the necessary safeguards to secure workplace safety and protect both personnel and equipment.

Partnering with Industry Leader Jinrong

Partnering with an industry leader like Jinrong ensures access to top-notch class 1 division 2 enclosures that meet all class 1 division 2 electrical requirements. With over 27 years of expertise in the ex-proof industry, Jinrong offers reliable products and solutions prioritizing safety and compliance with industry regulations.

Embracing Class 1 Division 2 Standards

Embracing class 1 division 2 standards is crucial for any company operating in hazardous environments. By incorporating explosion proof enclosures and adhering to hazardous area classification chart guidelines, businesses can ensure compliance with safety standards while protecting their personnel and equipment from potential dangers.