Introduction

When it comes to electrical enclosures, understanding the differences between Class 1 Div 2 enclosures and standard enclosures is crucial for safety and compliance in hazardous environments. From explosion-proof enclosures to NEMA 4X ratings, the right choice can make all the difference in protecting your facility and personnel.

Understanding Class 1 Div 2 Enclosures

Class 1 Div 2 enclosures are specifically designed for use in hazardous locations where flammable gases or vapors may be present. They are built to contain potential explosions and prevent them from igniting the surrounding atmosphere, ensuring a safe working environment for your team.

Class 1 Div 2 enclosures are designed to contain potential explosions and provide protection against external elements such as dust and water. This makes them suitable for various industrial applications where the environment may be harsh and unpredictable. Additionally, these enclosures are constructed with durable materials that can withstand the rigors of daily use, ensuring long-lasting performance and reliability for your equipment.

Exploring Standard Enclosures

Choosing the proper enclosure for your electrical components depends on the environment they'll be placed in. Standard enclosures offer a valuable solution for many situations. Here's what makes them a suitable choice:

- Suitable for Non-Hazardous Environments: Standard enclosures are ideal for areas without explosion risks.

- Versatility and Adaptability: Their design allows for various applications, making them a practical choice for many electrical needs.

- Protection from Everyday Elements: Standard enclosures shield electrical components from dust, moisture, and other common environmental factors, ensuring their functionality.

While they may not be as robust as Class 1 Div 2 enclosures, standard enclosures provide a reliable and versatile solution for protecting electrical components in non-hazardous environments.

Importance of Choosing the Right Electrical Enclosure

You've explained the key differences between Class I Division 2 enclosures and standard enclosures. Here are some additional points to consider:

- Hazard Classification:

You mentioned Class I Division 2, but there are other classifications for hazardous locations (Class II, Division 1, for example). Understanding your specific facility's classification (based on the National Electrical Code or NEC) is crucial for choosing the proper enclosure. - Construction Differences: Class I Division 2 enclosures are typically sturdier and have features like flame arrestors or increased gaps to prevent sparks from igniting external flammable materials. Standard enclosures may be made of lighter materials and lack these specialized features.

- Cost: Class I Division 2 enclosures are generally more expensive due to their specialized design and testing requirements.

Key Differences Between Class 1 Div 2 Enclosures and Standard Enclosures

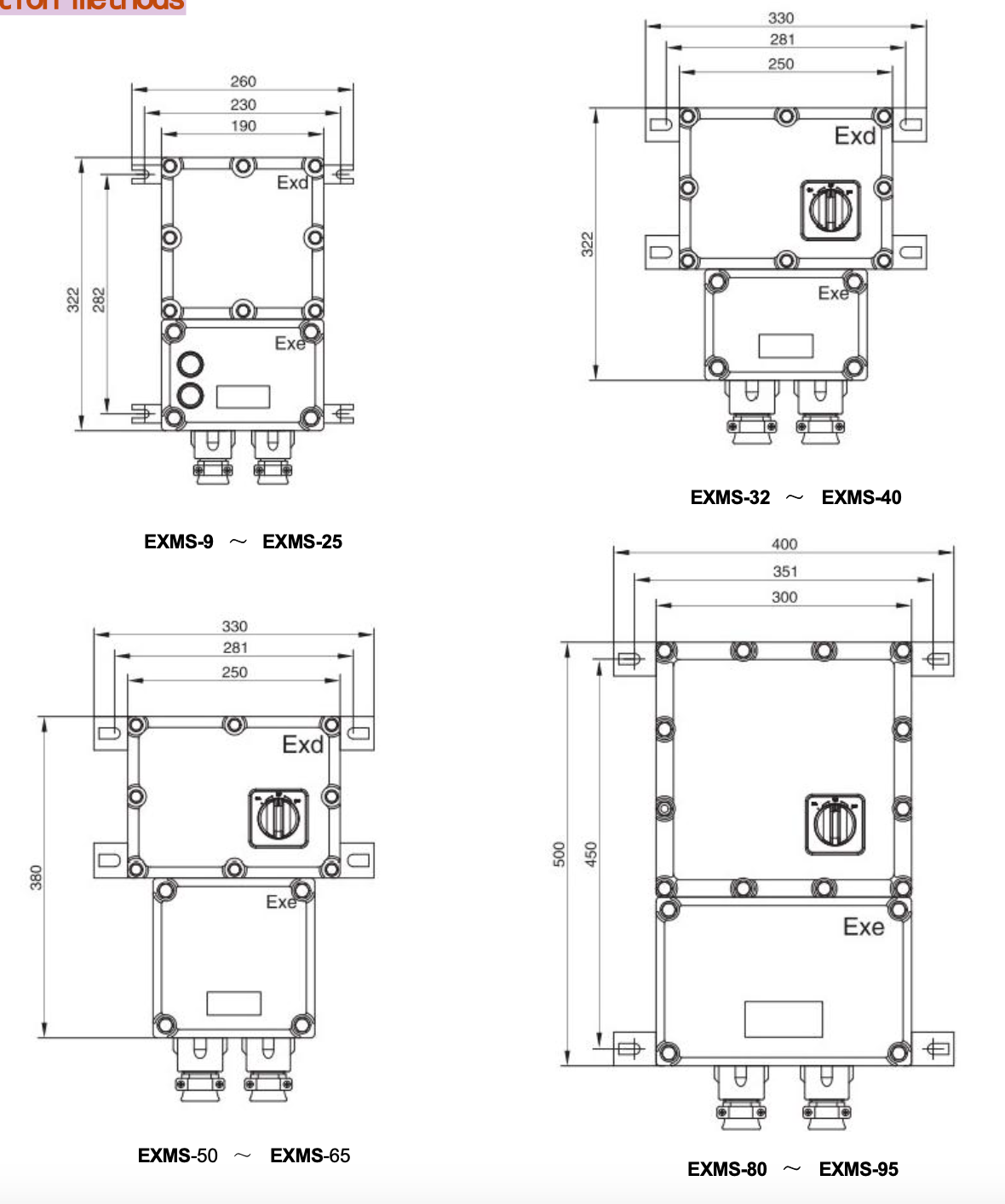

Regarding construction and materials used, class 1 div 2 enclosures are specifically designed to withstand hazardous environments. They utilize rugged materials such as stainless steel or aluminum to prevent the ignition of flammable gases, vapors, or dust. In contrast, standard enclosures may not be equipped with the same level of protection and durability, making them unsuitable for use in potentially explosive atmospheres.

Environmental considerations play a crucial role in determining the suitability of electrical enclosures for specific applications. Class 1 div 2 enclosures are engineered to protect against harsh environmental conditions, including extreme temperatures, corrosive substances, and heavy moisture. This ensures sensitive electrical components remain safe and functional even in challenging surroundings. On the other hand, standard enclosures may not offer the same resistance level and could be susceptible to damage in hazardous locations.

Certification and compliance standards are paramount when selecting electrical enclosures for hazardous areas. Class 1 div 2 enclosures undergo rigorous testing and certification processes to ensure compliance with industry safety standards such as NEMA 4X and UL ratings. These certifications validate the enclosure's ability to contain potential explosions and prevent external elements from compromising its integrity. In contrast, standard enclosures may lack these critical certifications, making them unsuitable for class I div 2 environments.

Now that we've explored the key differences between class 1 div 2 enclosures and standard enclosures regarding construction materials used, environmental considerations, and certification standards, let's explore the advantages of class i division ii electrical enclosures compared to their standard counterparts.

Class 1 Div 2 enclosures offer enhanced safety features, such as explosion-proof and dust-tight designs. These safety measures are crucial in hazardous environments where flammable gases, vapors, and dust may be present. Class 1 div 2 enclosures are specifically engineered to prevent ignition sources from coming into contact with potentially explosive atmospheres, providing an extra layer of protection for personnel and equipment.

Advantages of Class 1 Div 2 Enclosures

Safety and Hazardous Area Protection

Safety is paramount in hazardous environments. Class 1 Div 2 enclosures are designed to protect against flammable gases, vapors, and liquids, ensuring the safety of both personnel and equipment. With robust construction and strict compliance with industry standards, these enclosures offer peace of mind in potentially dangerous settings.

Class 1 Div 2 enclosures are designed to protect hazardous environments and offer durability and longevity. Their robust construction ensures that they can withstand the rigors of harsh conditions, providing reliable protection over the long term. This means businesses can confidently invest in these enclosures, knowing they will continue providing safety and security for years.

Durability and Longevity

Durability is key in harsh industrial environments. Class 1 Div 2 enclosures are built to withstand the rigors of hazardous locations, featuring rugged materials and corrosion-resistant properties that ensure longevity even in the most challenging conditions. This durability translates to reduced maintenance requirements and prolonged service life, making them a reliable investment for any facility.

In addition to their durability, Class 1 Div 2 enclosures also offer cost-efficiency and a high return on investment. By requiring reduced maintenance and boasting prolonged service life, these enclosures help facilities save money in the long run. This cost-effectiveness makes them a smart choice for any industrial environment looking to maximize their budget without sacrificing quality or safety.

Cost-Efficiency and Return on Investment

While the upfront cost might seem higher, Class 1 Div 2 enclosures offer significant long-term advantages, making them a cost-effective choice. Here's how:

- Superior Protection, Reduced Downtime: These enclosures shield your equipment from hazardous environments, minimizing the risk of damage and costly downtime.

- Lower Insurance Premiums: Their ability to mitigate potential hazards often leads to lower insurance premiums, further enhancing their cost-efficiency.

- Improved Safety and Compliance: Meeting strict industry standards translates to compliant operations, reducing the risk of fines and penalties. This peace of mind adds significant value to your investment.

By prioritizing long-term benefits like reduced downtime and lower insurance costs, Class 1 Div 2 enclosures provide a strong return on investment, making them a smart choice for any operation.

Benefits of Standard Enclosures

Versatility and Adaptability

Standard enclosures like NEMA 4X offer various sizes and configurations to accommodate multiple equipment and applications. They can be easily customized to fit specific needs, making them versatile for different industries and environments. Standard enclosures provide the flexibility to adapt to changing requirements for indoor or outdoor use.

Standard enclosures like NEMA 4X also offer easy installation and maintenance. Their modular design and standardized components make them simple to assemble, saving time and effort during setup. Their accessibility features, such as hinged doors and removable panels, make maintenance and equipment adjustments hassle-free, reducing business downtime.

Ease of Installation and Maintenance

One of the key advantages of standard enclosures is their user-friendly design, which allows for easy installation and maintenance. With simple mounting options and accessible components, these enclosures streamline the process of setting up electrical equipment and conducting routine upkeep. This not only saves time but also reduces downtime for critical operations.

Furthermore, the user-friendly design of standard enclosures also contributes to cost savings by minimizing the need for specialized installation and maintenance expertise. Businesses can rely on their existing staff to handle these tasks without investing in additional training or hiring outside contractors. By making the process more accessible and straightforward, standard enclosures empower organizations to take control of their equipment management, leading to greater efficiency and reduced operational costs.

Application in Non-Hazardous Environments

Standard enclosures are cost-effective for protecting electrical components in non-hazardous settings where explosive gases or vapors are absent. They can be utilized in various industries, including manufacturing facilities, commercial buildings, and telecommunications infrastructure. Their suitability for non-hazardous environments makes them a practical choice for many applications.

In addition to their cost-effectiveness and suitability for non-hazardous environments, standard enclosures also offer easy installation and maintenance. Their simple design and construction make them a practical choice for industries looking for efficient solutions to protect electrical components. This ease of use can save time and cost for businesses, making standard enclosures an attractive option for non-hazardous applications.

Make the Right Choice for Your Facility

When choosing the proper electrical enclosures for your facility, it's crucial to consider the specific needs of your environment. Whether you require class 1 div 2 enclosures for hazardous areas or NEMA 4X enclosures for non-hazardous environments, making the right choice is essential for safety and compliance.

Selecting the appropriate electrical enclosure is a critical decision that can impact the safety and efficiency of your operations. Class 1 div 2 enclosures are designed to protect hazardous locations, while NEMA 4X enclosures offer versatility for various applications. Understanding your facility's specific requirements will help you make an informed decision.

When considering the safety and efficiency of your operations, it's essential to consider your facility's specific requirements. Class 1 div 2 enclosures are designed to protect hazardous locations, making them a crucial choice for facilities with potential risks. On the other hand, NEMA 4X enclosures offer versatility for various applications, allowing for flexibility in meeting different operational needs. By understanding these distinctions and evaluating your facility's unique needs, you can make an informed decision that ensures safety and compliance.

Ensuring Safety and Compliance with Electrical Enclosures

Safety and compliance are paramount in electrical enclosures, especially in hazardous environments. Class 1 div 2 enclosures are specifically engineered to prevent the ignition of flammable gases or vapors, providing a secure solution for potentially dangerous areas. Ensuring your chosen enclosure meets certification and compliance standards is essential for maintaining a safe work environment.

When selecting the right electrical enclosure for hazardous environments, it's crucial to consider factors such as material construction, temperature ratings, and ingress protection. Class 1 div 2 enclosures offer a range of options to suit different environmental conditions, ensuring that your equipment is protected from dust, moisture, and other potential hazards. By partnering with Jinrong for expert guidance, you can navigate these considerations and make an informed decision prioritizing safety and compliance.

Partnering with Jinrong for Expert Guidance

At Jinrong, we understand the importance of selecting the right electrical enclosures for your facility. Our team of experts can provide valuable guidance and support in choosing class 1 div 2 enclosures or other suitable solutions based on your unique requirements. With our extensive knowledge and experience, we can help you navigate through the options available and make an informed decision.

Furthermore, our team at Jinrong is committed to staying up-to-date with the latest industry standards and regulations. This ensures we can provide the most compliant and reliable solutions for your electrical enclosure needs. Whether you require explosion-proof or NEMA-rated enclosures, we can offer expert advice on the best options to meet your safety and operational requirements.