Introduction

Understanding the Threshold Temperature for Flammable Liquid Classification is crucial for ensuring workplace safety and compliance with regulations. It is essential to know the temperature at which a substance is classified as a flammable liquid and how to handle these materials safely. From flammable cabinets to proper signage, various measures are in place to mitigate the risks associated with class 3 hazardous materials and dangerous goods classification.

Understanding the Threshold Temperature for Flammable Liquid Classification

The temperature at which a substance is classified as a flammable liquid varies but generally falls below 100 degrees Fahrenheit. This threshold temperature indicates the point at which a substance can produce enough vapor to ignite in the presence of an ignition source, posing significant fire hazards.

Importance of Knowing the Threshold Temperature

Knowing the threshold temperature for flammable liquids is crucial for implementing appropriate safety measures in the workplace. It allows businesses to identify and store these materials in designated flammable cabinets, reducing the risk of fire incidents. Additionally, understanding this temperature helps determine the need for specific flammable signs to alert employees and visitors of potential hazards.

How to Safely Handle Flammable Liquids

Properly handling flammable liquids is essential for preventing accidents and ensuring workplace safety.

To mitigate risks, it is crucial to implement the following safety measures:

- Utilize appropriate equipment: Employ specialized tools for transferring and storing flammable liquids, including grounding and bonding equipment to prevent static electricity buildup.

- Determine ignition threshold: Understand the specific temperature at which flammable liquids ignite to implement effective fire prevention strategies.

- Implement temperature control: Maintain flammable liquids within safe temperature parameters to minimize the risk of ignition and accidents.

By adhering to these guidelines, companies can significantly reduce the potential hazards of flammable liquids and comply with relevant regulations.

Exploring the Threshold Temperature

The threshold temperature is crucial for classifying a substance as a flammable liquid. This temperature is typically set at 100°F (37.8°C), as this is the point at which most flammable liquids can produce enough vapor to ignite. Understanding this threshold temperature is essential for safely handling and storing these materials.

What is the Temperature at which a Substance is Classified as a Flammable Liquid

The temperature at which a substance is classified as a flammable liquid is determined by its flash point, which refers to the lowest temperature at which it can produce enough vapor to ignite. For most liquids, this occurs at or below 100°F (37.8°C), making them highly flammable and hazardous if not handled properly.

The flash point of a substance is crucial in determining its classification as a flammable liquid. This temperature is important not only for safety reasons but also for transportation and storage regulations. Understanding the flash point of a substance allows for proper handling and storage procedures to be put in place, reducing the risk of accidents and ensuring the safety of individuals working with these materials.

Class 3 Hazardous Materials and their Threshold Temperatures

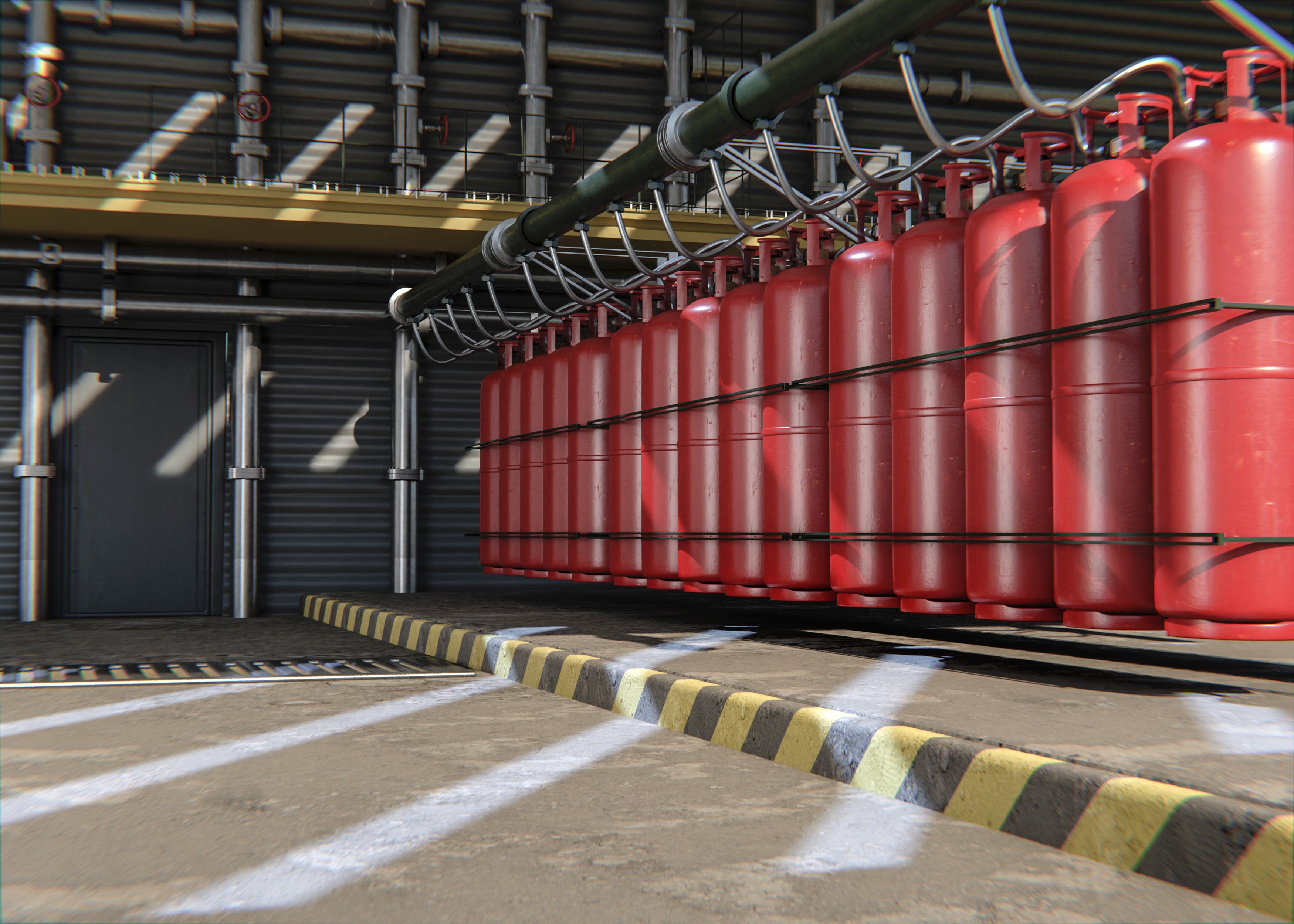

Class 3 hazardous materials are highly flammable liquids with flash points below 100°F (37.8°C). These include gasoline, ethanol, and acetone, all of which pose significant fire hazards if not stored and handled correctly due to their low threshold temperatures.

Additionally, the improper storage and handling of flammable liquids can lead to environmental hazards, as spills and leaks can contaminate soil and water sources. Releasing these substances into the environment can have long-lasting effects on ecosystems and wildlife, making it crucial to follow proper safety protocols when dealing with Class 3 hazardous materials. Furthermore, the transportation of flammable liquids also presents a significant risk, as accidents during transit can result in fires and explosions, posing a threat to public safety and infrastructure.

Examples of Fire Hazards due to Flammable Liquids

Due to their low ignition temperature, flammable liquids pose a significant fire risk. Mishandling these substances can cause catastrophic consequences, from industrial accidents to household mishaps.

To mitigate these risks, it is essential to:

- Understand the threshold temperatures of different flammable liquids.

- Implement proper storage practices to prevent container damage and leaks.

- Develop and follow strict spill response protocols for immediate containment.

- Provide comprehensive fire safety training to all personnel.

By prioritizing safety measures and fostering a culture of vigilance, we can significantly reduce the risk of fire hazards associated with flammable liquids.

Safety Measures for Flammable Liquids

Flammable liquids are classified based on their flash point, the temperature at which they can ignite. Understanding the temperature at which a substance is classified as a flammable liquid is crucial for safe handling and storage. Flammable cabinets play a vital role in providing secure storage for these hazardous materials, preventing accidental fires, and protecting workers.

Flammable Cabinets and their Role in Storage

Flammable cabinets are specifically designed to store flammable liquids, offering fire-resistant protection and containment in case of spills or leaks. They are constructed with double-walled steel and have built-in vents to prevent the buildup of flammable vapors. Proper labeling and segregation within these cabinets are essential to ensure compliance with safety regulations.

Flammable cabinets are crucial in maintaining a safe and organized workplace environment. By providing a designated storage area for flammable liquids, they help prevent accidents and minimize the risk of fire or explosion. Additionally, proper labeling and segregation within the cabinets ensure that each substance is stored in its designated place, making it easier for employees to locate and access the materials they need while maintaining compliance with safety regulations.

Importance of Flammable Signs in Workplaces

Flammable signs are crucial safety measures that communicate the presence of hazardous materials. These signs serve multiple important functions:

- Warning: Flammable signs alert workers and visitors to potential fire hazards, encouraging caution and preventing accidents.

- Guidance: Clear signage helps individuals understand how to handle flammable substances safely and take necessary precautions.

- Emergency Response: In case of an incident, these signs assist emergency responders in quickly identifying dangerous goods, enabling efficient response.

- Compliance: By clearly marking areas containing flammable materials, businesses demonstrate adherence to safety regulations and reduce the risk of legal issues.

Flammable signs are essential for creating a safe working environment and protecting personnel and property.

Ensuring Compliance with Dangerous Goods Classification

Businesses must adhere to dangerous goods classification guidelines when handling, storing, or transporting flammable liquids. Compliance involves proper packaging, labeling, documentation, and employee training to mitigate risks associated with these hazardous materials. Regular audits and inspections help ensure that safety measures are being followed consistently.

By implementing safety measures such as using flammable cabinets, displaying appropriate signage, and complying with dangerous goods classification standards, businesses can effectively minimize the potential risks of flammable 3 materials while ensuring a safe work environment for everyone involved.

Flammable Liquid Handling Practices

When handling flammable liquids, following safe practices guidelines is crucial. Understanding the temperature at which a substance is classified as a flammable liquid is the first step in ensuring safety. It's also important to always use appropriate personal protective equipment, such as gloves and goggles, to minimize the risk of accidents.

Guidelines for Safe Handling of Flammable Liquids

Proper ventilation is key when working with flammable liquids, as it helps to reduce the buildup of vapors that can lead to fire or explosion. Additionally, it's essential to use spark-proof tools and equipment in areas with flammable liquids. Regular training and education for employees on safe handling procedures should also be implemented to maintain a culture of safety within the workplace.

Furthermore, it's important to have a designated flammable liquid storage area equipped with proper containment measures in case of spills or leaks. This can help prevent the spread of flammable liquids and minimize the risk of fire or explosion. In addition, storage containers and equipment should be regularly inspected to ensure they are in good working condition and free from any potential hazards.

Using the Correct Equipment for Flammable Liquid Transfer

Using the correct equipment for transferring flammable liquids is crucial in preventing accidents. This includes using approved pumps and containers that are designed specifically for these types of substances. It's also important to inspect all equipment regularly to ensure that it is in good working condition and free from any defects that could lead to leaks or spills. Additionally, it's essential to provide proper training to employees handling these materials, ensuring they understand the risks and how to use the equipment safely.

Best Practices for Storage and Containment

Proper storage and containment play a significant role in minimizing the risks associated with flammable liquids. This involves utilizing designated flammable cabinets designed to safely store these substances and implementing secondary containment measures such as spill trays or berms. It's also essential to clearly label all containers with appropriate flammable signs to ensure easy identification.

By adhering to these best practices for handling flammable liquids, businesses can significantly reduce the likelihood of accidents or incidents occurring in their work environments.

Understanding Ex-Proof Manufacturing

Jinrong's 27 Years of Experience in Ex-Proof Manufacturing

Jinrong has been a leader in ex-proof manufacturing for 27 years, providing top-notch expertise and innovative solutions for hazardous environments. Their extensive experience ensures that their products meet the highest safety standards and comply with all relevant regulations.

Jinrong's commitment to excellence extends beyond its products to its customer service. Its team of experts is dedicated to providing personalized solutions and support for each client's specific needs, ensuring a smooth and successful implementation of ex-proof equipment. With a focus on building long-term partnerships, Jinrong goes above and beyond to deliver exceptional value and reliability to its customers.

Range of Ex-Proof Products, from Lighting to Electrical Equipment

Jinrong offers many ex-proof products, including lighting fixtures, electrical equipment, and control systems. Each product is meticulously designed and tested to prevent the ignition of flammable gases or vapors, making them essential for industries dealing with volatile substances.

Impact of Ex-Proof Certification on Safety

The ex-proof certification guarantees that the equipment is safe to use in hazardous areas where flammable liquids are present. This certification provides peace of mind to workers and employers, minimizing the risk of fire or explosion. Companies can prioritize safety without compromising efficiency by choosing ex-proof certified products from Jinrong.

Ensure Safety and Compliance with Flammable 3 Regulations

Understanding the threshold temperature for flammable liquid classification is crucial for workplace safety. It determines the proper handling and storage of these hazardous materials, reducing the risk of fire incidents. Partnering with a trusted ex-proof manufacturing company like Jinrong ensures access to reliable equipment that complies with flammable 3 regulations.

Importance of Proper Classification and Handling of Flammable Liquids

Accurate classification of flammable liquids based on their threshold temperature is crucial for maintaining a safe workplace.

Proper classification offers several key benefits:

- Risk assessment and mitigation: Identifying the flash point of a liquid helps determine appropriate storage methods, such as using flammable cabinets.

- Employee safety: Understanding the flammability of different liquids allows for proper handling procedures and protective measures.

- Compliance: Adhering to classification standards ensures compliance with safety regulations.

By diligently classifying flammable liquids, businesses can significantly reduce the risk of fire hazards and create a safer working environment.

Partnering with a Trusted Ex-Proof Manufacturing Company like Jinrong

Jinrong's 27 years of experience in ex-proof manufacturing makes them a reliable partner for businesses dealing with flammable liquids. Their range of ex-proof products, from lighting to electrical equipment, ensures companies can access high-quality solutions that meet dangerous goods classification standards. By partnering with Jinrong, businesses can prioritize safety and compliance.

Compliance with Flammable 3 regulations is non-negotiable when handling hazardous materials. Using flammable signs in workplaces helps raise awareness about potential risks and reinforces employee safety measures. By ensuring adherence to dangerous goods classification guidelines, businesses can maintain a safe environment while minimizing the likelihood of accidents.

Furthermore, businesses should regularly conduct training sessions to educate employees about properly handling and storing flammable materials. These sessions can also include emergency response protocols in case of accidents or spills. By empowering employees with the knowledge and skills to deal with hazardous materials, companies can further enhance safety measures and reduce the potential for harm in the workplace.